A small hole inner wall strengthening device and method

A technology for strengthening devices and inner walls of holes, which is applied in vacuum evaporation plating, coating, melt spraying, etc., can solve the problems of low strengthening efficiency, complicated strengthening system, and difficulty in large-scale industrial application, and achieve uniform distribution, Increased reinforcement efficiency and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

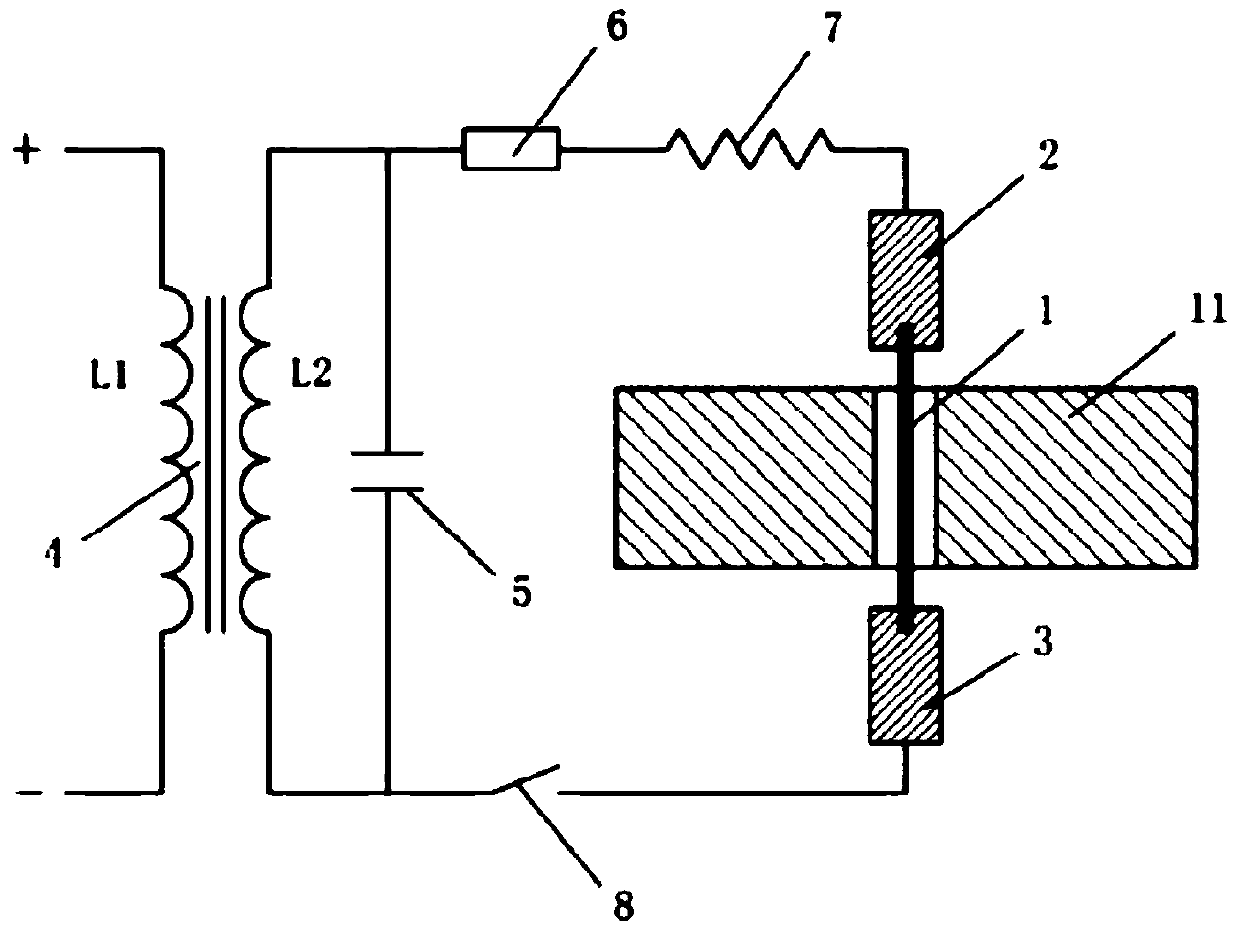

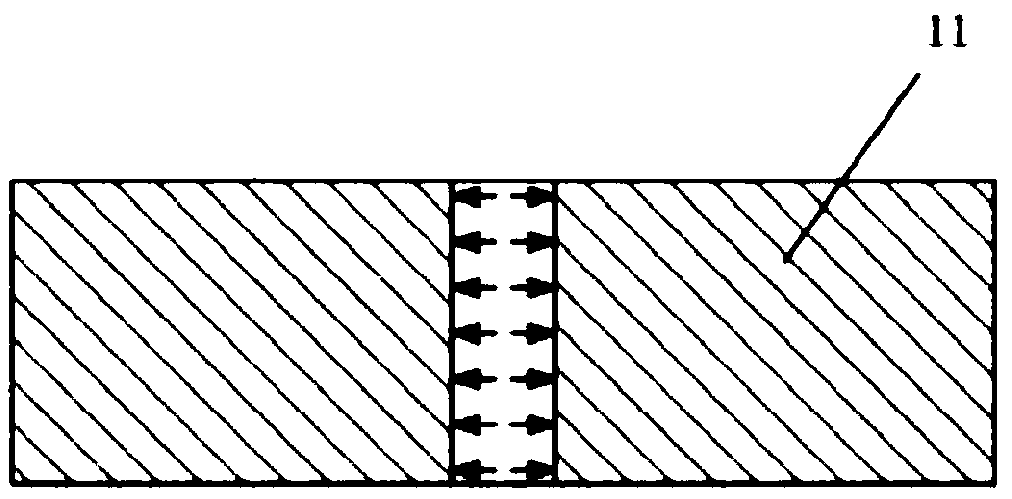

[0042] Such as Figure 1 to Figure 8 As shown, a small hole inner wall strengthening device of the present invention mainly includes a metal load 1, a first electrode 2, a second electrode 3 and a metal vaporization circuit. Among them, the metal load 1 is penetrated in the hole of the part with holes 11, the first electrode 2 and the second electrode 3 are respectively clamped and connected to the two ends of the metal load 1, and the metal vaporization circuit is connected with the first electrode 2 and the second electrode. 3-phase connection. The metal vaporization circuit, the first electrode 2, the second electrode 3 and the metal load 1 together form a circuit loop. The metal vaporization circuit specifically includes a transformer 4 , a pulse capacitor 5 , a resistor 6 , an inductor 7 and a high voltage discharge switch 8 . The power supply input together with the transformer 4 and the pulse capacitor 5 form a charging circuit. The primary coil L1 of the transformer...

Embodiment 2

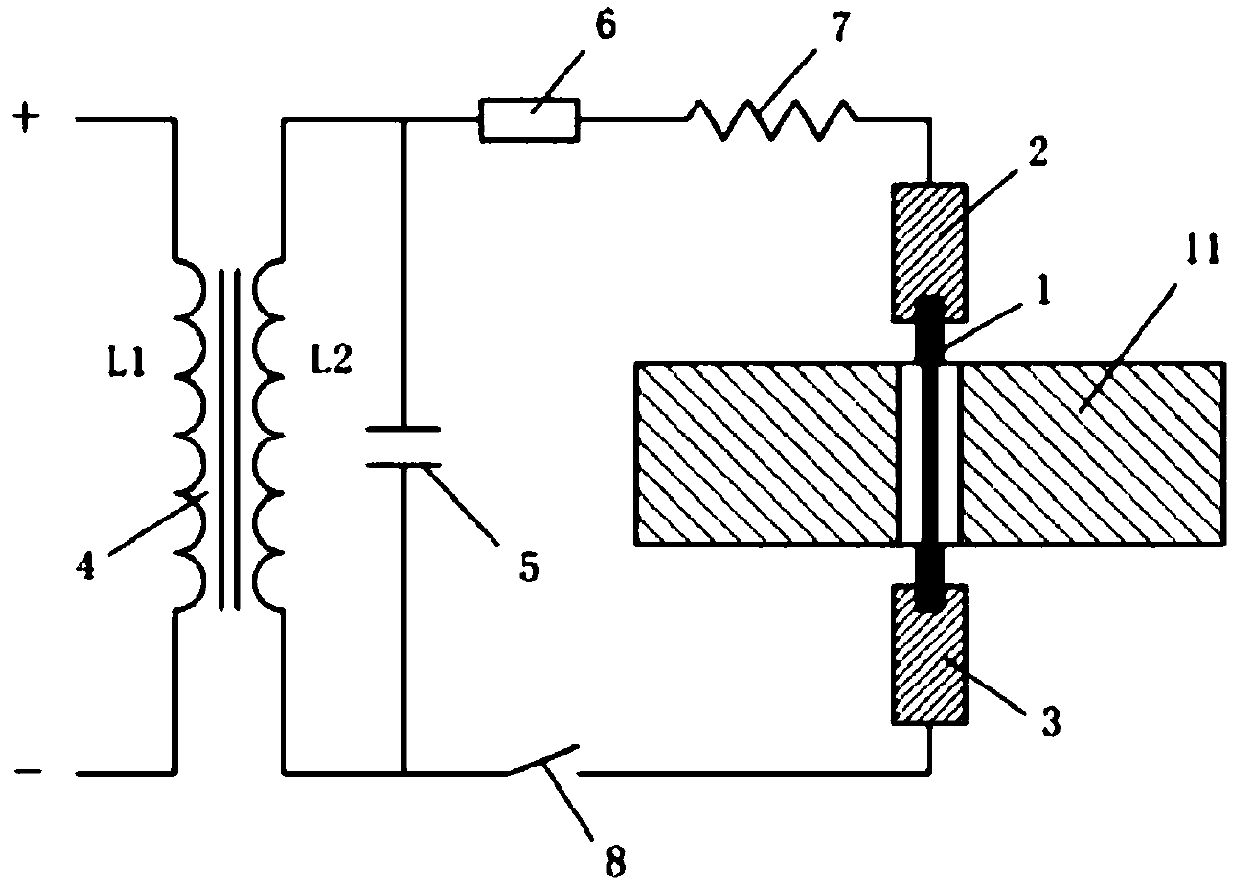

[0049] Such as Figure 9 As shown, a small hole inner wall strengthening device of the present invention, the main structure of the device is the same as that of embodiment 1, except that an elastic sleeve 10 is sleeved on the metal load 1 corresponding to the inner wall of the hole, and the metal load 1 The exterior is not coated.

[0050] When the small hole inner wall strengthening device is used, the high-voltage discharge switch 8 is disconnected first, and the voltage is boosted through the transformer 4 to charge the pulse capacitor 5. When the charging voltage of the pulse capacitor 5 reaches the set value, the charging circuit stops working; The discharge switch 8 is closed, and the pulse capacitor 5 is discharged to vaporize the metal load 1. The gas pressure generated after the gasification of the metal load 1 drives the elastic sleeve 10 to elastically expand, and the gas pressure is evenly applied to the inner wall of the hole, forming a A uniform residual compre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com