Single ticket different pattern identification sorting work flow

A work flow and ticket technology, which is applied to record carriers, instruments, computer parts, etc. used by machines, can solve the problems of inconsistent sorting and ticket collection directions of a single ticket, meet the needs of fast and accurate automatic production, improve The effect of reaction speed and difficulty reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The workflow of identifying and sorting different patterns of a single ticket includes the following steps:

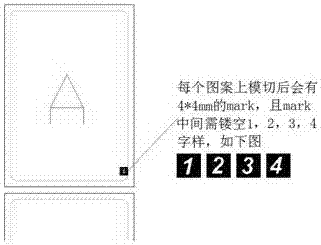

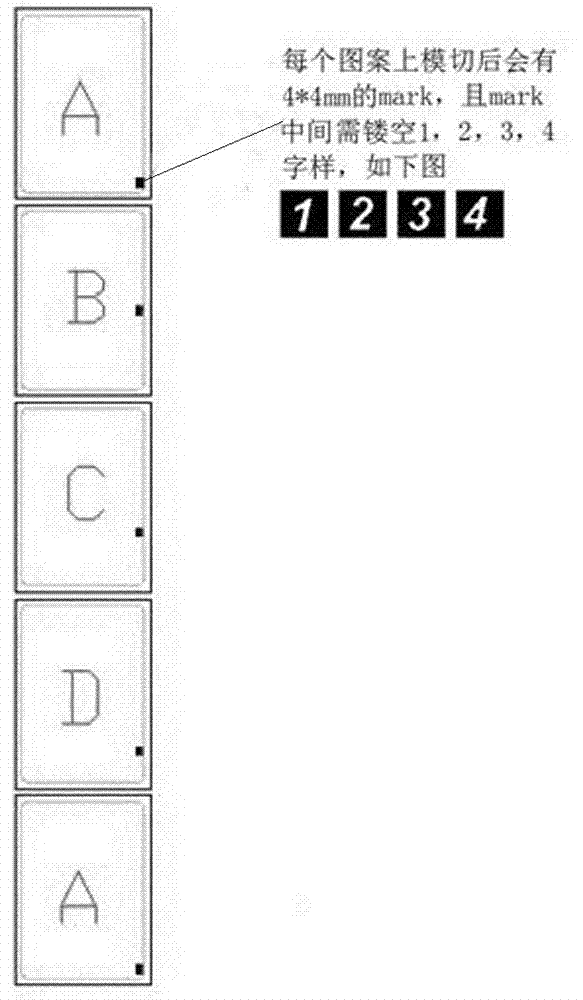

[0033] 1) Print the pattern on the ticket material, and at the same time print the identification Mark (that is, the identification feature point) on each ticket card, and the middle of the Mark logo is hollowed out with Arabic numerals (such as figure 2 , image 3 As shown, there will be a 4*4mm Mark after die-cutting on each printed pattern, and the middle of the Mark needs to be hollowed out with words such as 1, 2, 3, 4);

[0034] For tickets with the same printed pattern, the Mark position is the same, and the number marked by the Mark is also the same; for tickets with different printed patterns, the Mark position is different, even if the direction of the ticket is reversed, the Mark position is also different, and the Mark The numbers identified are also different;

[0035] 2) Laminating and die-cutting, and then using the sensor to identify the mark,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com