Pipeline welding line information extraction method based on three-dimensional design model

A three-dimensional design and model technology, applied in the direction of calculation, special data processing applications, instruments, etc., can solve the problem that the three-dimensional design model cannot directly obtain the welding seam information, so as to improve the compilation efficiency, ensure the accuracy, and achieve the effect of welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

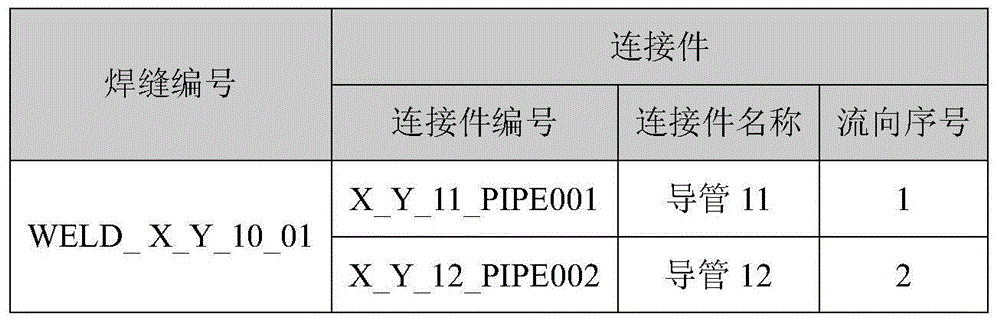

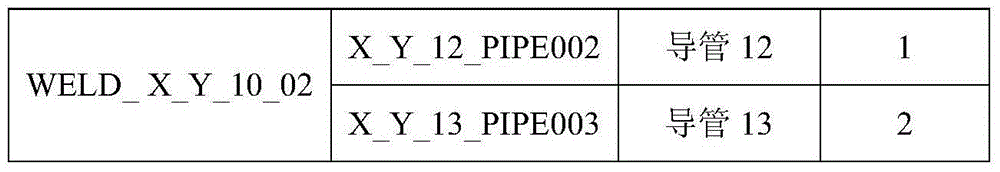

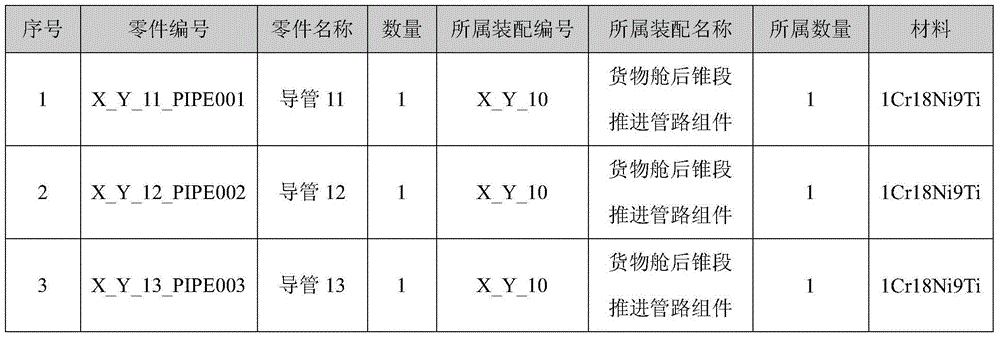

[0018] A method for extracting pipeline weld seam information based on a three-dimensional design model, the steps of which are as follows:

[0019] (1) Follow the naming rules of the following model files when establishing a PROE-based pipeline component assembly model: the pipeline component assembly model naming rule is: model code_cabin / subsystem_component code.ASM; pipeline model The naming rule is: model code_cabin / subsystem_component code_PIPE three-digit natural number serial number.PRT; the naming rule of the weld model is: WELD_model code_cabin / subsystem_component code_two-digit natural number serial number .PRT. Other assembly components (e.g. valve bodies, filters) are coded and must be differentiated from piping components, piping and welds.

[0020] The described specifications are stored in the parameter property table of the piping component assembly model. 3D callouts are drawn on the solid model of each part and are represented by arrows with text that is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com