Bend pipe measuring and allowance locating method facing digital manufacture

A positioning method and pipe bending technology, applied in the field of computer vision, can solve the problems of segmentation method analysis, failure to calculate the end point of the straight line segment and the center point of the arc segment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

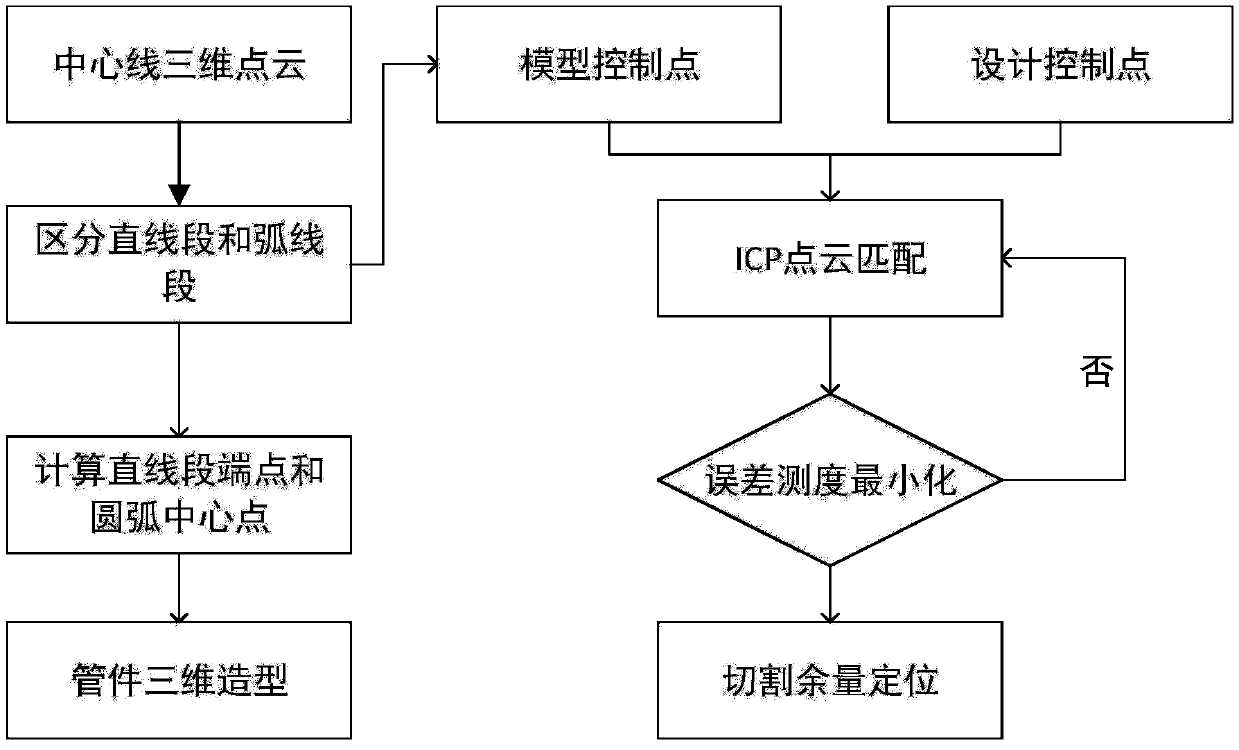

[0053] Such as figure 1 As shown, the specific steps of a digital manufacturing-oriented elbow measurement and margin positioning method of the present invention are as follows:

[0054] Step 1: Use a single laser tracker and a plane target to globally calibrate multiple visual sensors, and unify the coordinate systems of the visual sensors at different positions into the global coordinate system of the laser tracker;

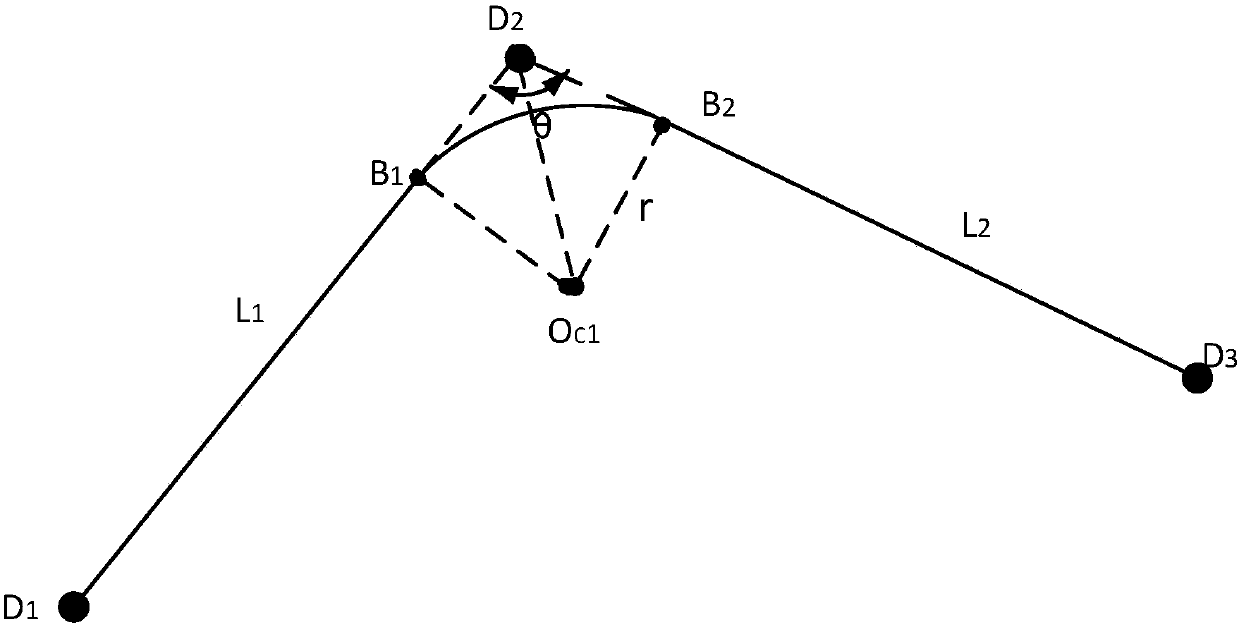

[0055] Step 2: Synchronously trigger multiple visual sensors to collect the bend image, use the edge detection algorithm to detect the edge of the bend image, use the morphological thinning method to obtain the center line of the bend image, remove the branches on the center line, and use the bidirectional pole The line matching algorithm performs three-dimensional reconstruction of the center line to obtain the center line of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com