Three-dimensional digitized manufacturing system for whole life cycle of industrial manufacturing and realization method thereof

A full life cycle, industrial manufacturing technology, applied in manufacturing computing systems, electrical digital data processing, office automation, etc., can solve problems such as non-compliance, cumbersome process, lack of technology, etc., and achieve the effect of lightweight design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

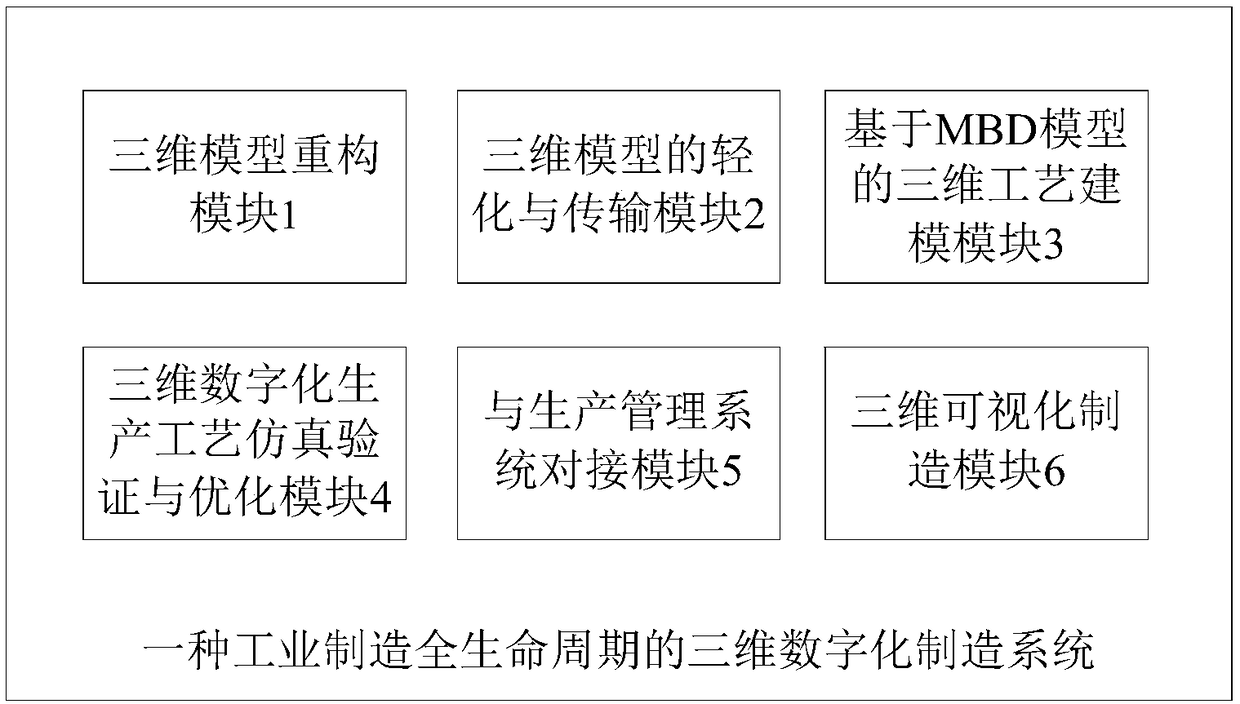

[0046] Such as figure 1 , Figure 8 As shown, a 3D digital manufacturing system for the entire life cycle of industrial manufacturing, respectively interacts with several 3D design software and production management systems for information interaction. The 3D digital manufacturing system includes the 3D model reconstruction module 1, the 3D model Lightweight and transmission module 2, 3D process modeling module based on MBD model 3, 3D digital production process simulation verification and optimization module 4, docking module with production management system 5 and 3D visualization manufacturing module 6;

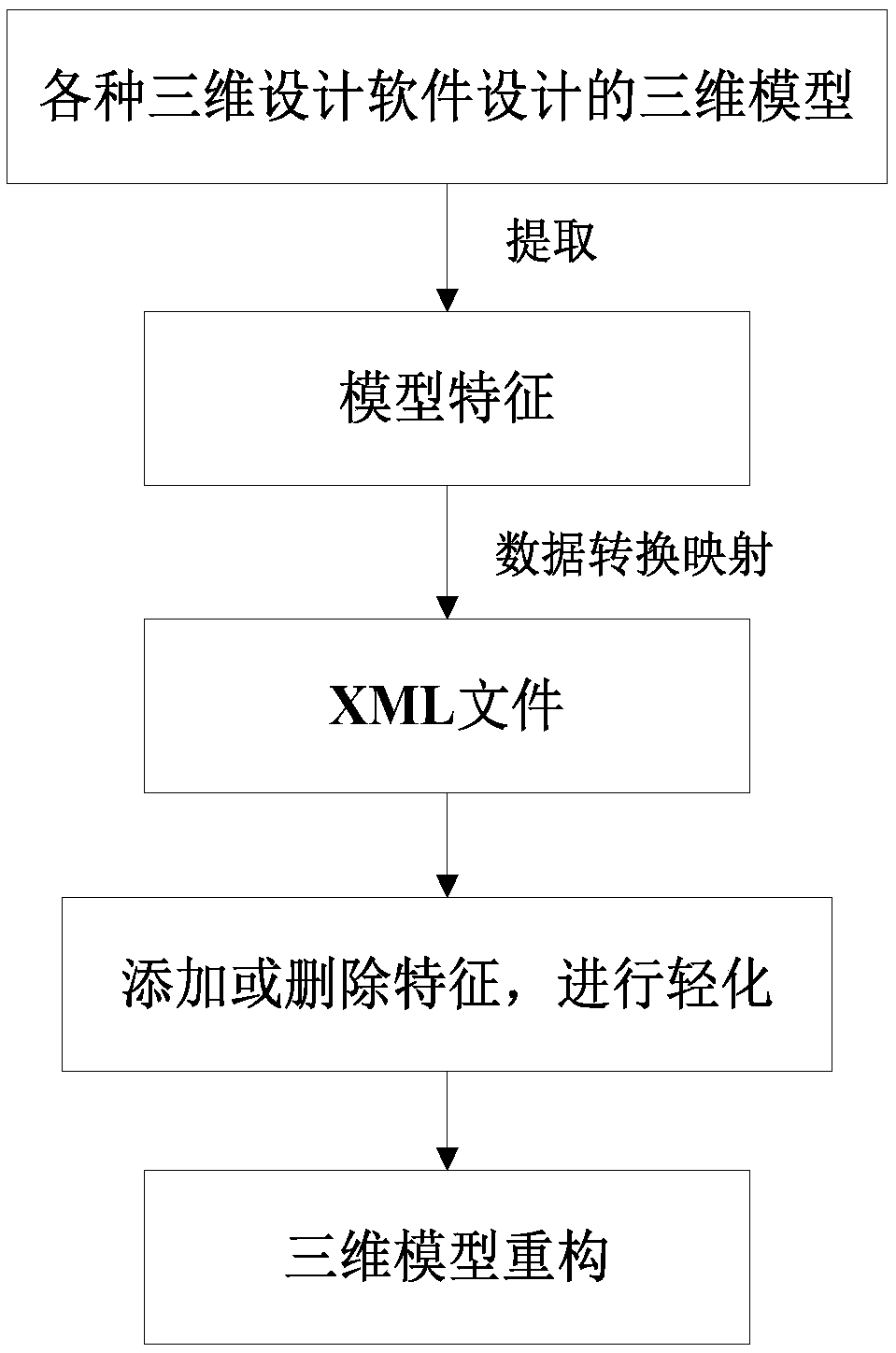

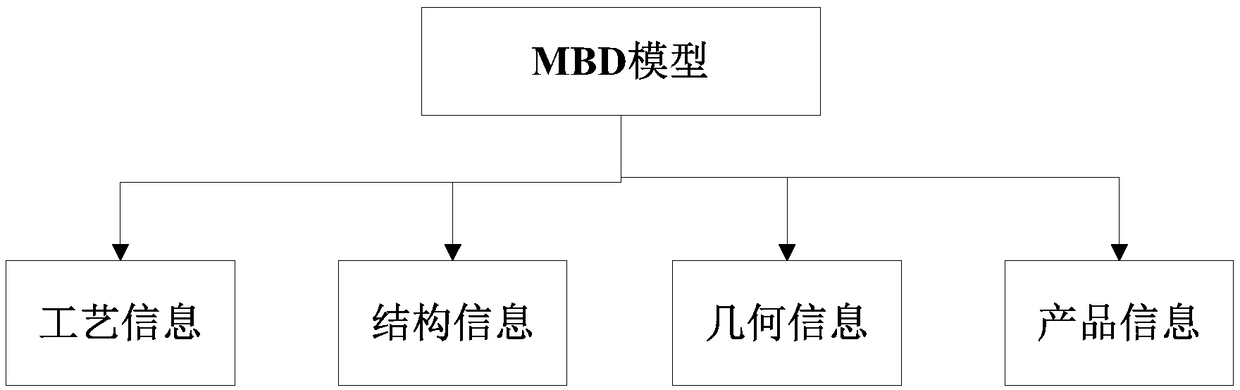

[0047] The 3D model reconstruction module 1 is used to perform format conversion on 3D models from various 3D design software so as to obtain a 3D format reconstruction model, extract and classify feature information of the 3D models, and process the 3D models according to the MBD model integration standard. The 3D model is reconstructed so as to obtain the MBD model; spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com