Digital manufacturing method for light permeable concrete

A light-transmitting concrete and digital manufacturing technology, which is applied in the direction of manufacturing tools, building structures, grinding/polishing equipment, etc., can solve the problems of stress concentration inside the light-transmitting concrete, heavy workload, and difficulty in controlling the distance between optical fibers, etc. Fast layout, increased mechanical strength, and the effect of protecting the surface of optical fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

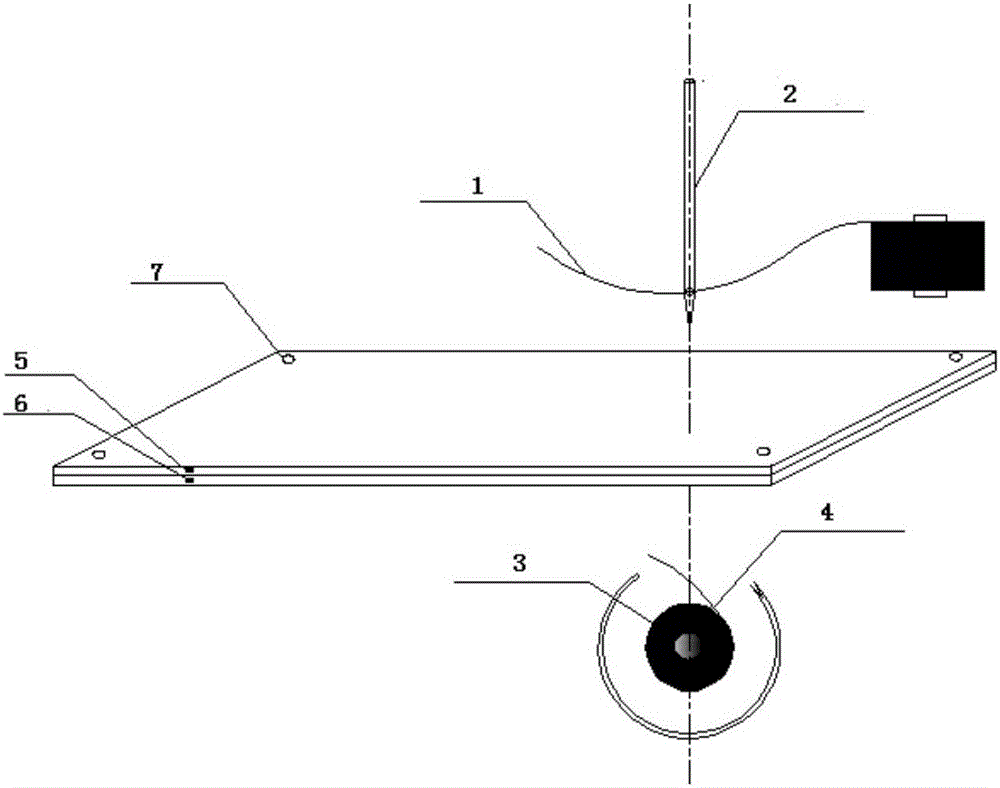

[0033] Such as Figure 5 Shown, the light-transmitting concrete digital manufacturing method that the present invention adopts is as follows:

[0034] 1) The mass ratio of the prepared concrete is: cement: water: water reducer: fine aggregate = 1:0.3:0.012:1.2, fluidity 180mm;

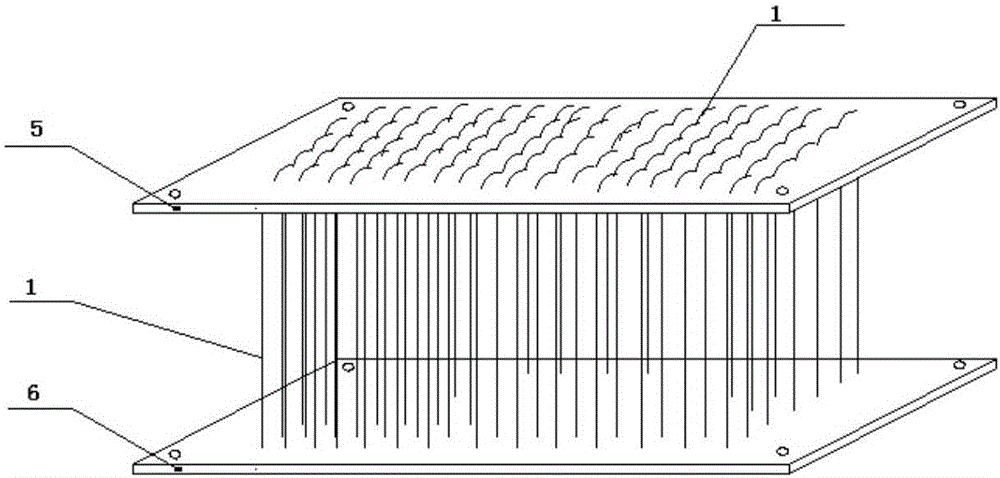

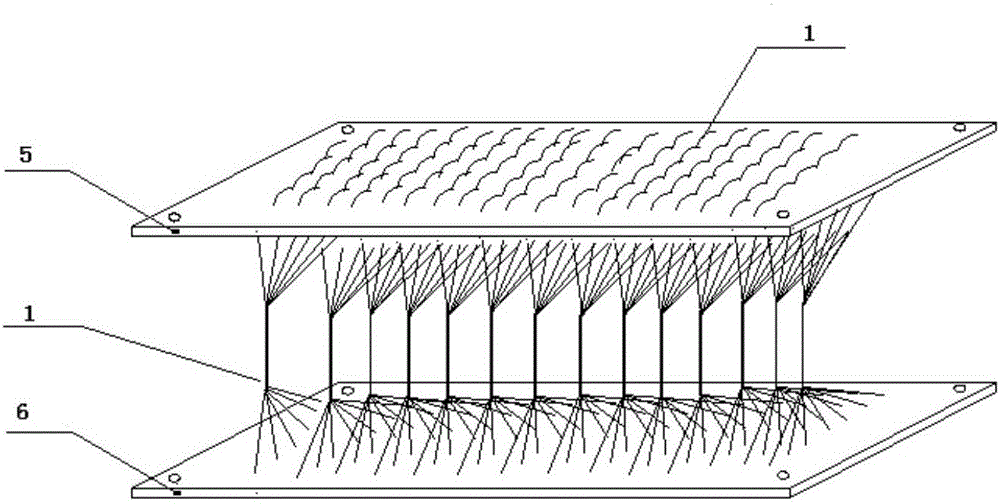

[0035] 2) Set the optical fiber arrangement in the computer as a rectangular arrangement of 30×36, the optical fiber spacing is 3mm×3mm, and the optical fiber substrate size is 5mm×100mm×100mm;

[0036] 3) According to figure 1 and figure 2 As shown, intersperse and fix the optical fiber; according to the set optical fiber arrangement spacing a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com