Monitoring method and device for parameters in industrial manufacturing

A technology of industrial manufacturing and process parameters, which is applied in the field of data processing, can solve problems affecting the operation accuracy of machines, and achieve the effect of improving monitoring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

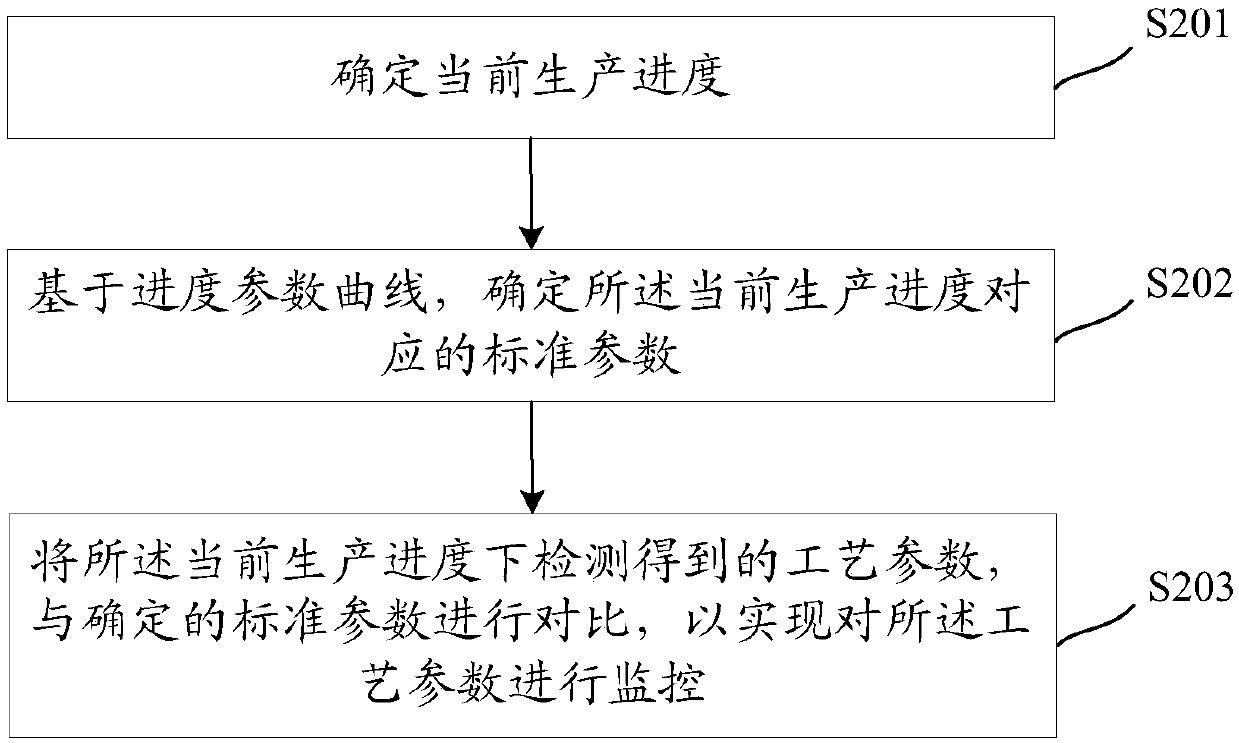

[0065] Embodiments of the present application are described below in conjunction with the accompanying drawings.

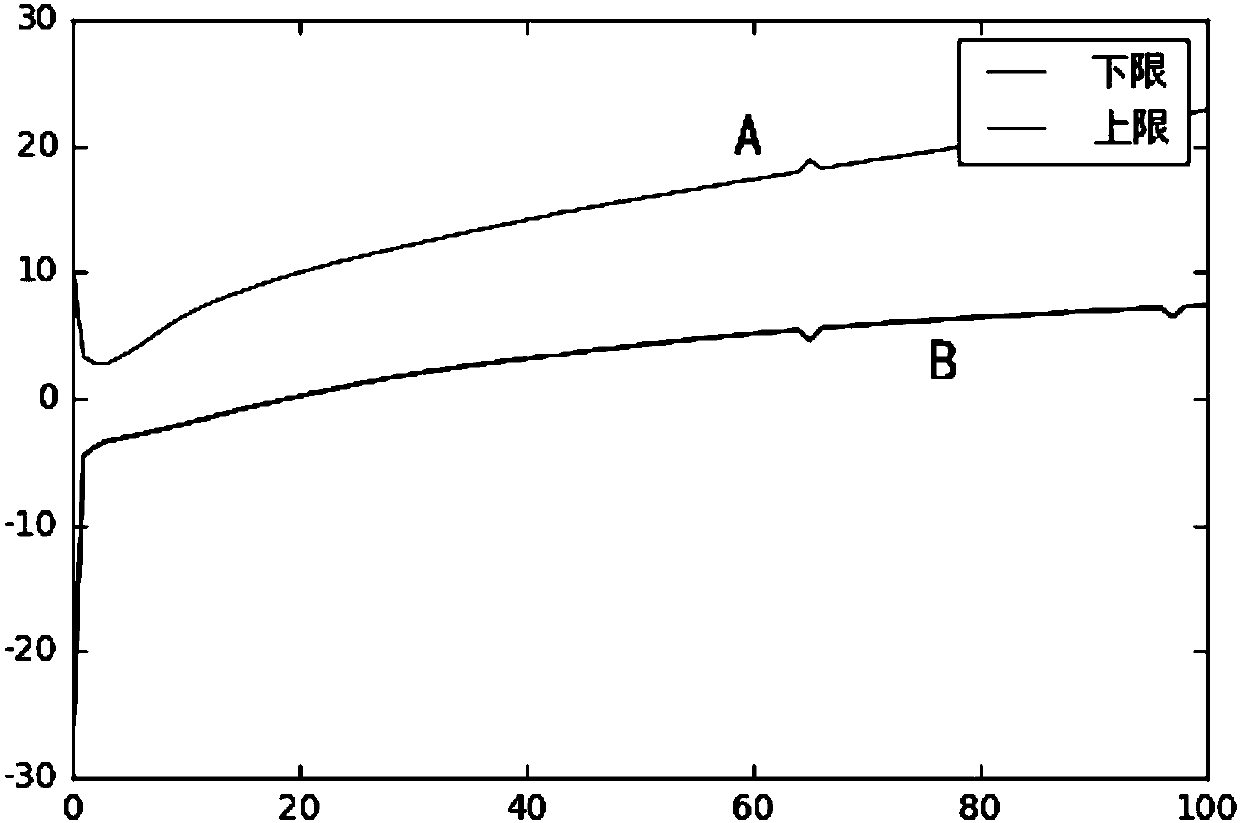

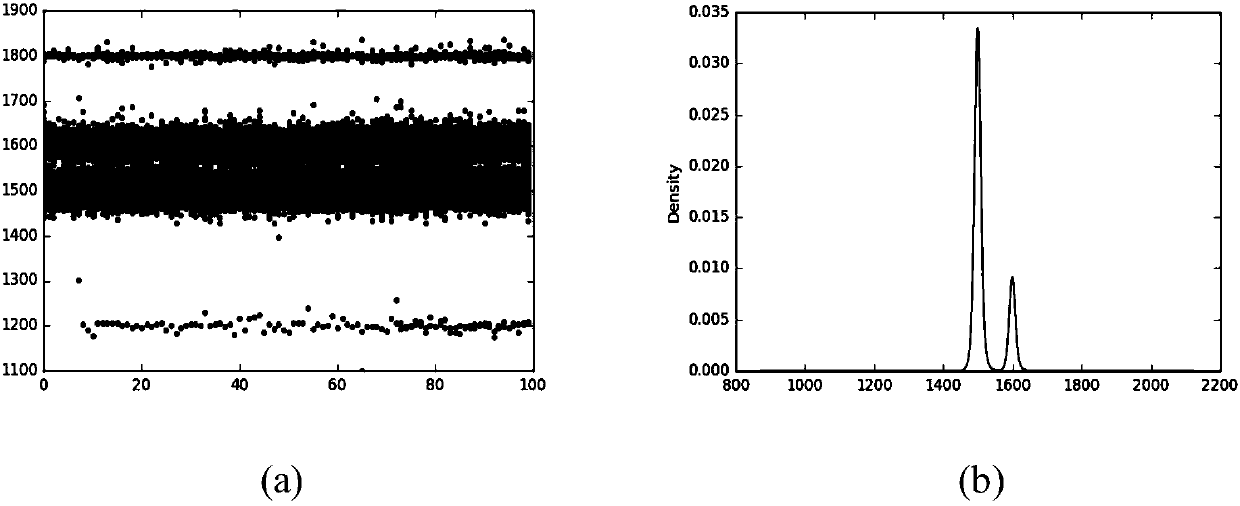

[0066] In the production process of industrial manufacturing, the equipment will collect real-time physical quantities such as temperature, flow rate, line speed, humidity, etc. These physical quantities can be called process parameters. In order to be able to detect abnormalities of process parameter values in time during the production process, it is necessary to monitor the process parameters in real time throughout the production process, and monitor whether the parameter values exceed the reasonable range of parameter values. In the traditional parameter monitoring method, the process parameters collected in a batch are generally monitored. In the process of monitoring, a process parameter collected in the batch is usually selected as a separate monitoring object, and a fixed parameter value standard is set for this parameter, and then it is monitored whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com