MBD-based aviation complex structural member inspection method

A technology of complex structures and inspection methods, applied in the direction of geometric CAD, etc., can solve problems such as time-consuming and laborious, long manual inspection cycle, and inspection accuracy cannot be guaranteed, so as to improve inspection efficiency, eliminate missed inspections, and ensure accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

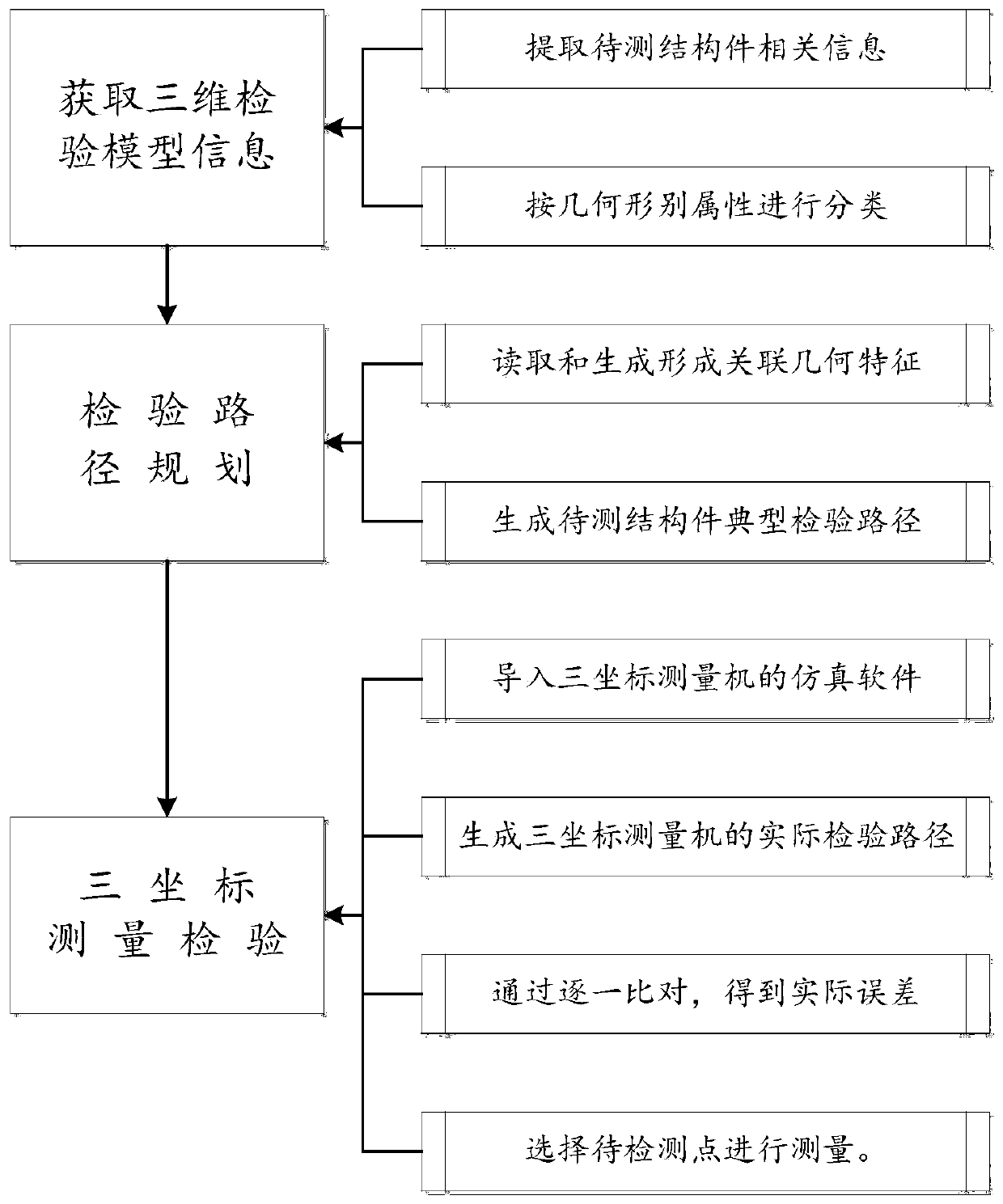

[0025] The specific implementation process includes:

[0026] 1. According to the MBD-based labeling specifications and inspection requirements, the relevant inspection information including the 3D model is automatically obtained through software identification technology.

[0027] 2. By acquiring and integrating the inspection information and associating the geometric features of the 3D model, the definition of the 3D inspection model based on MBD is completed.

[0028] 3. According to different testing requirements, select the appropriate testing methods and testing tools, and complete the formulation of a testing process.

[0029] Repeat the above process, plan the detection sequence according to the sequence of the detection process, and realize the definition of the measurement process. According to the defined measurement process, the measurement plan is generated, and according to the measurement plan, the corresponding three-coordinate measurement equipment is selecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com