Preparation method of ZnS/Si nuclear-shell nanowires or nanobelts and polycrystal Si tubes

A nanobelt and nanowire technology, which is applied in the field of ZnS/Si core-shell nanowire or nanobelt and polycrystalline Si tube preparation, can solve the problem that it is difficult to control the shape and diameter of silicon-based semiconductor nanomaterials, and achieve low cost. , Simple operation, good controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

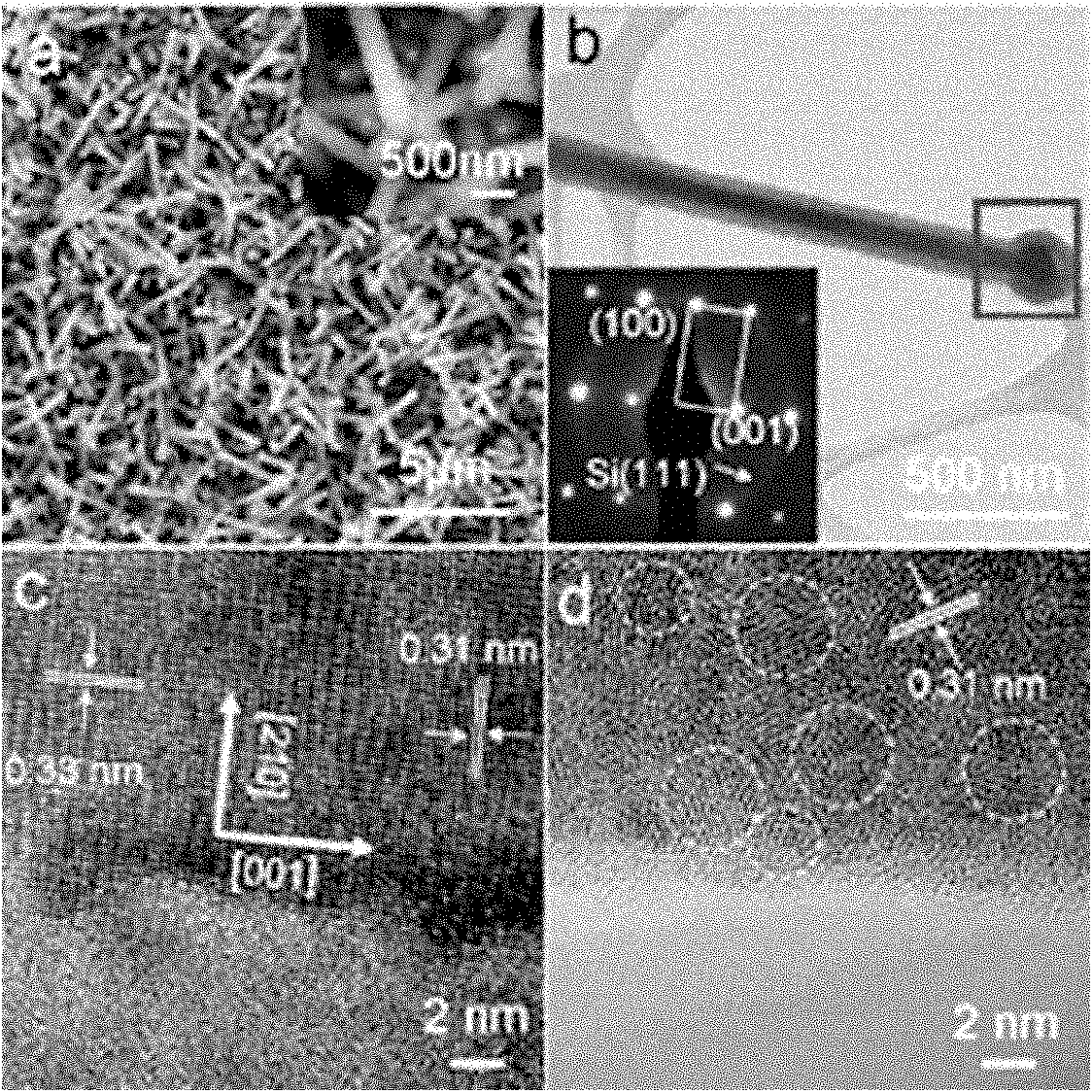

Embodiment 1

[0027] (1) Preparation of ZnS template

[0028] First, the alumina tube was installed in a vacuum tube furnace as a heating chamber, 2g of ZnS powder (Alfa Aldrich, 99.99%) was placed in the middle of the alumina tube as an evaporation source, and a silicon wafer with a 5nm gold film evaporated was placed in the Downstream in the direction of airflow in the pipe.

[0029] Secondly, seal the whole system and pump the pressure inside the pipe to 6×10 -2 Pa, filled with 5% H 2 high-purity Ar gas at a rate of 25 cubic centimeters per minute, and keep the pressure in the tube at 4×10 4 Pa. The middle part of the tube, where the ZnS powder is located, is heated to 1050°C at a rate of 20°C per minute. At this time, the substrate region has a temperature gradient of 900°C to 400°C along the gas flow direction, and the temperature gradient is maintained for about 4 hours.

[0030] Finally, the heating is stopped, the tube is cooled to room temperature, ZnS nanowires are formed in t...

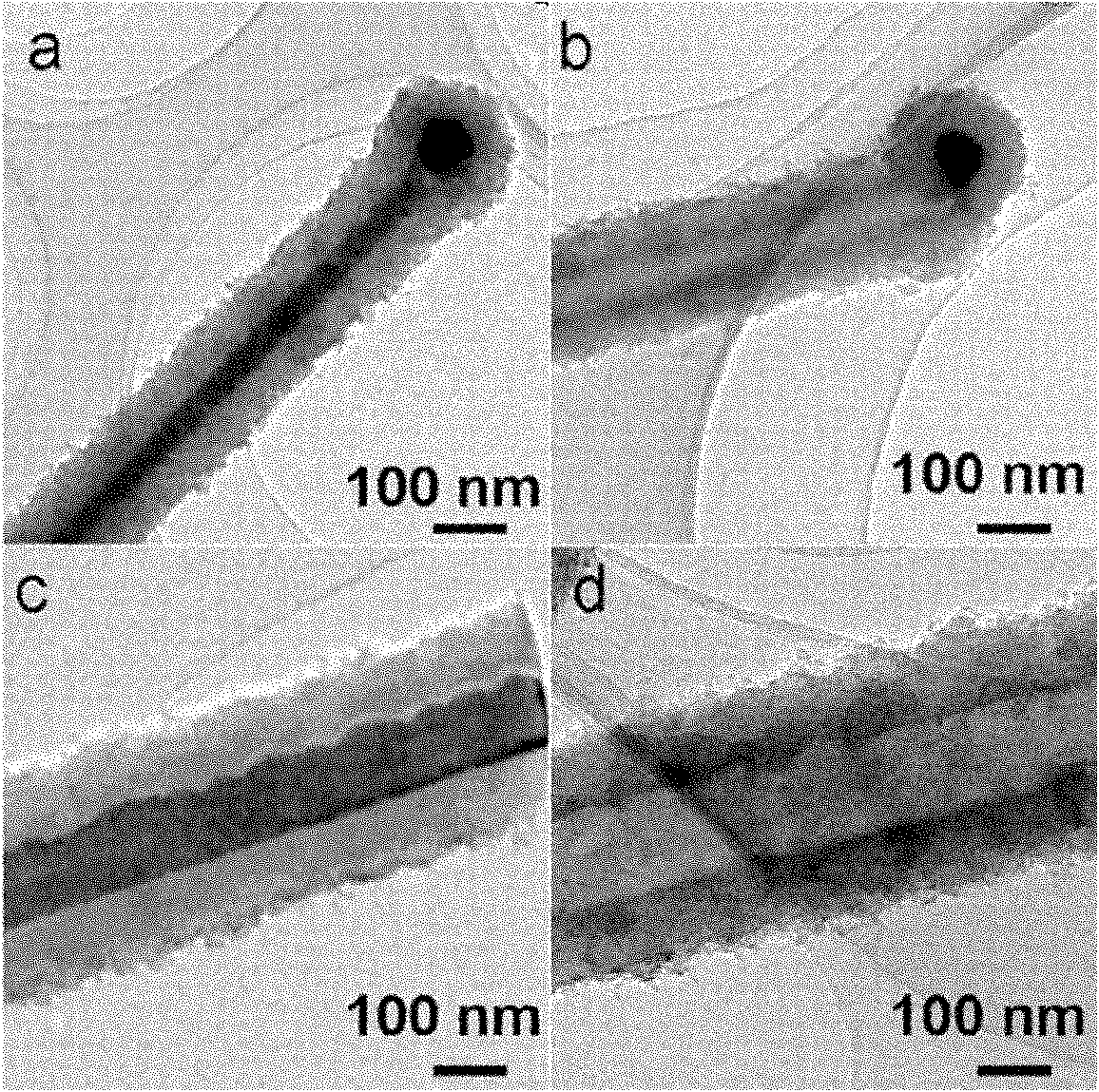

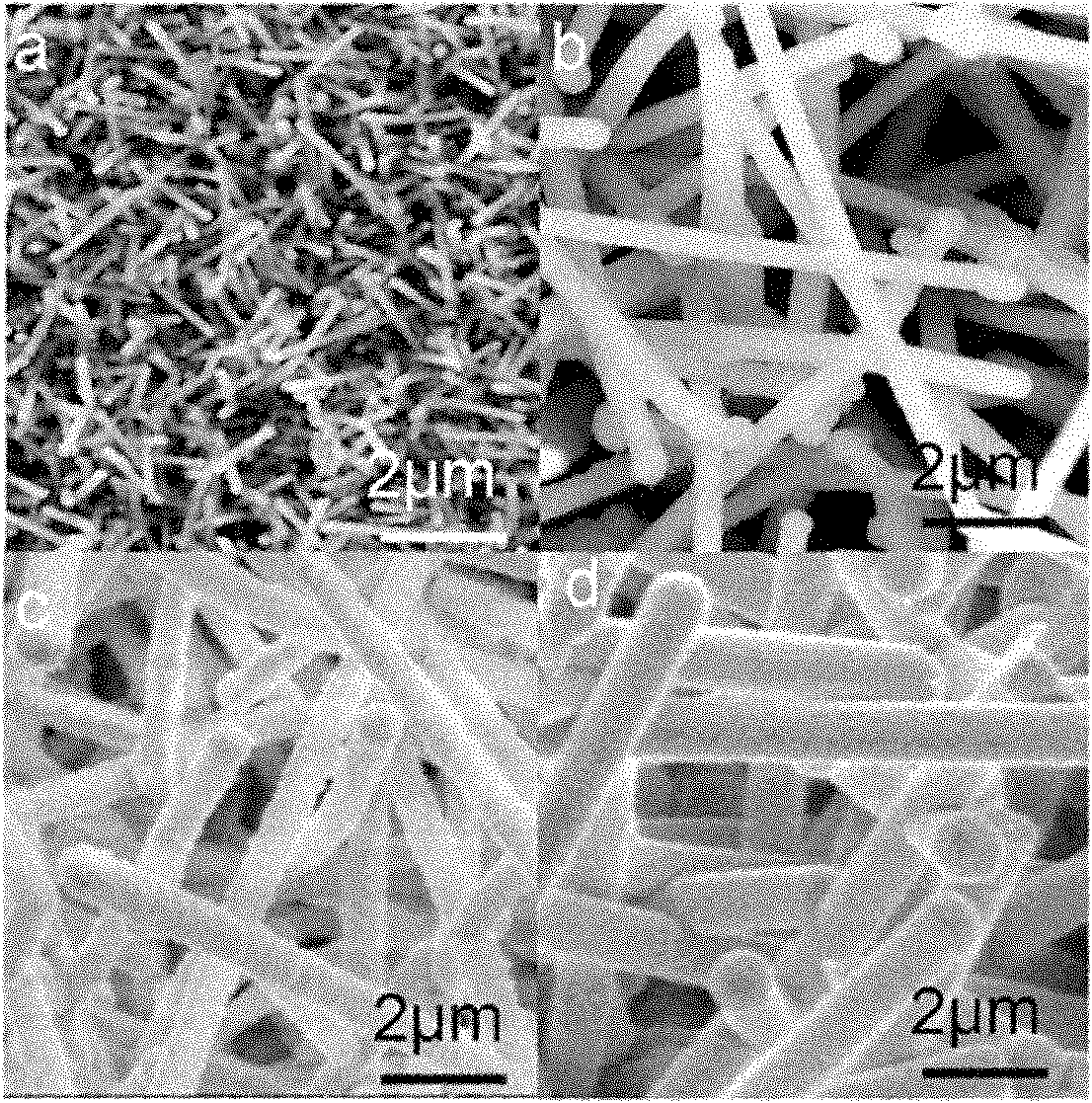

Embodiment 2

[0038] (1) Preparation of ZnS template

[0039] First, the alumina tube was installed in a vacuum tube furnace as a heating chamber, 2g of ZnS powder (Alfa Aldrich, 99.99%) was placed in the middle of the alumina tube as an evaporation source, and a silicon wafer with a 5nm gold film evaporated was placed in the Downstream in the direction of airflow in the pipe.

[0040] Secondly, seal the whole system and pump the pressure inside the pipe to 6×10 -2 Pa, filled with 5% H 2 high-purity Ar gas at a rate of 50 cubic centimeters per minute, and keep the pressure in the tube at 1×10 4 Pa. The middle part of the tube, where the ZnS powder is located, is heated to 1100°C at a rate of 50°C per minute. At this time, the substrate region has a temperature gradient of 900°C to 400°C along the gas flow direction, and the temperature gradient is maintained for about 2 hours.

[0041] Finally, the heating is stopped, the tube is cooled to room temperature, ZnS nanowires are formed in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com