Microbial grouting anchoring method for grouting in cavity and microbial grouting anchoring structure

An anchoring method and microbial technology, applied in the direction of building structure, building components, heat preservation, etc., can solve the problems affecting the compactness of the product, the air is not easy to discharge, and the anchoring effect is poor, so as to improve the uniformity of the product, good filling, The effect of preventing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

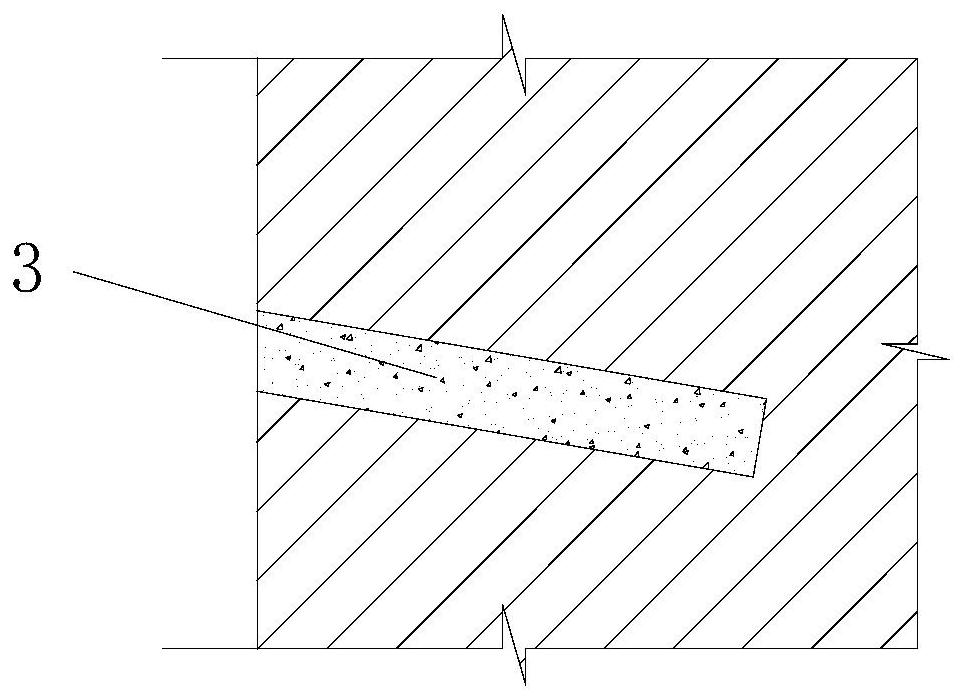

[0045] In a typical embodiment of the present invention, such as Figure 1-Figure 7 As shown, a microbial grouting anchoring method for cavity grouting is proposed.

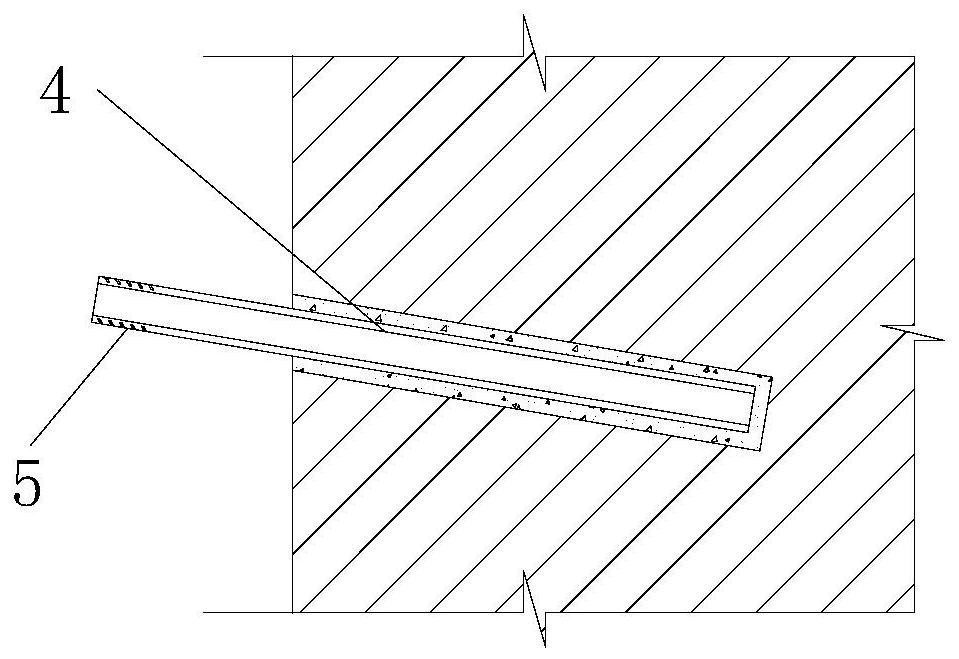

[0046] First, the anchor member used in this method is composed of a hollow anchor rod (in this embodiment, a hollow screw 4) and a nut 17. The anchor section of the hollow screw 4 extends into the borehole of the anchor matrix 1, and the hollow screw 4 The free section is provided with a threaded button 5 and is tightly connected with a nut 17 .

[0047] The steps of its anchoring method are:

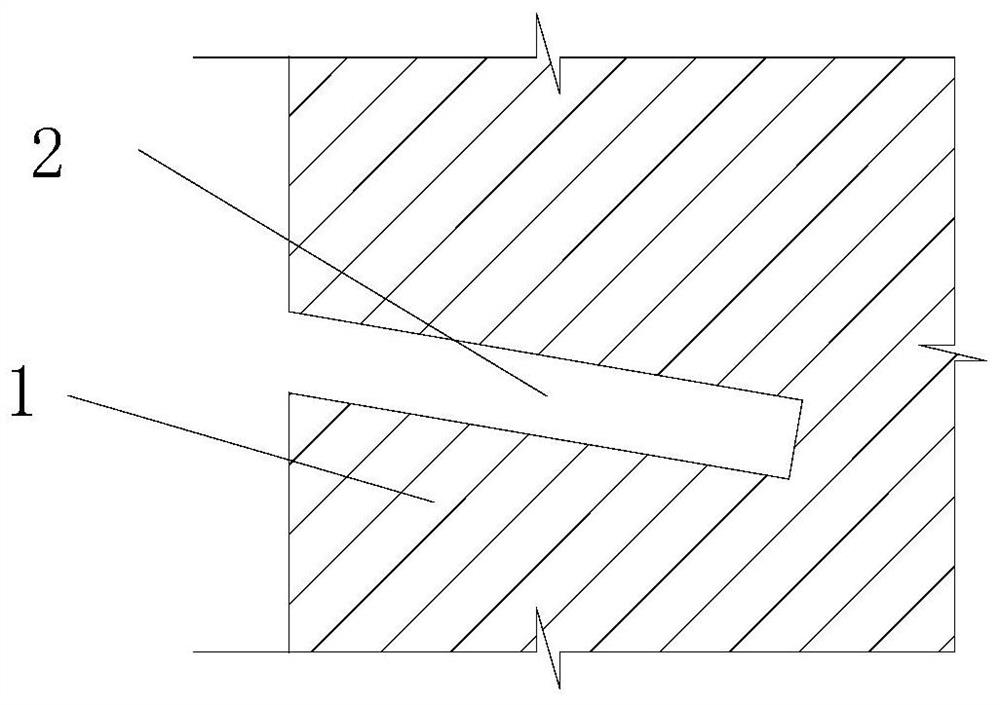

[0048] Step 1, first drill holes on the anchorage substrate 1 such as the wall, such as figure 1 Shown; the diameter of the borehole 2 is 2 to 3mm larger than the hollow screw of the anchoring member, so as to fill the screw.

[0049] The borehole is inclined downward, and the angle with the horizontal direction is about 15-20 degrees. The height of the borehole opening is higher than the height of the borehole bottom ...

Embodiment 2

[0078] This embodiment provides a microbial grouting anchorage structure, such as Figure 6 As shown, it includes a hollow anchor rod (here it is a hollow screw 4), the hollow anchor rod is a hollow structure, the middle part of the hollow anchor rod is provided with a side hole communicating with the internal cavity, and the hollow screw rod 4 extends to the drill hole 2 of the anchor matrix 1 A calcium carbonate cement body 18 induced by microorganisms is arranged between the borehole and the hollow screw 4, and a fixed object 16 is arranged on the side wall of the anchoring matrix. 19 and nut 17, the first surface of the wedge-shaped backing plate is attached to the fixed object, the second surface of the wedge-shaped backing plate is adjacent to the nut, the second surface of the wedge-shaped backing plate is perpendicular to the axial direction of the hollow screw rod 4, and the The end face is pressed tightly against the second face of the wedge-shaped backing plate.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com