Multipurpose soft tube

A multi-purpose, hose technology, applied in the direction of hoses, suction hoses, pipes, etc., can solve the problems of inability to disassemble, complicated process, high manufacturing cost, etc., and achieve scientific setting, expanded use range, and wide use range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

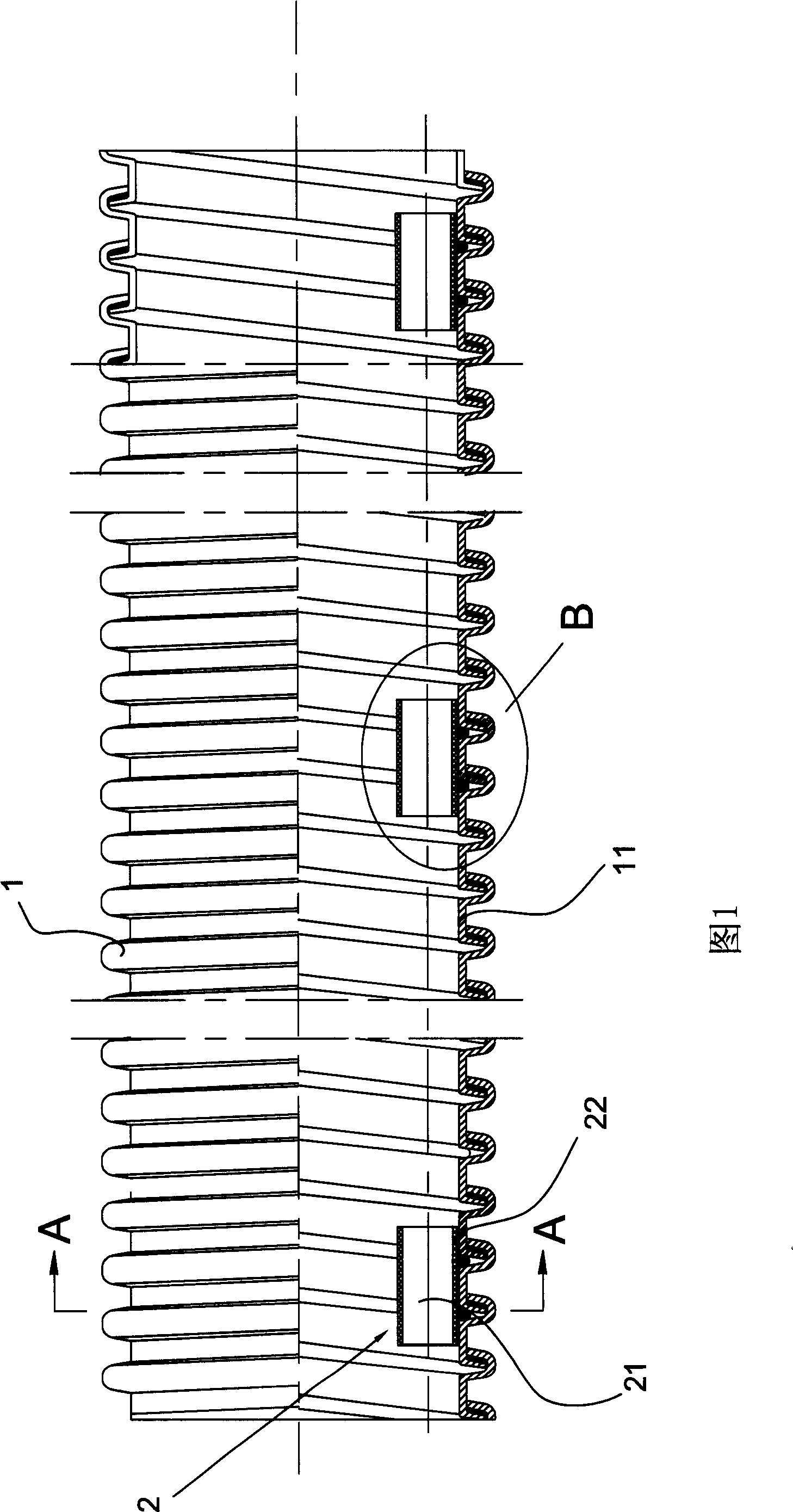

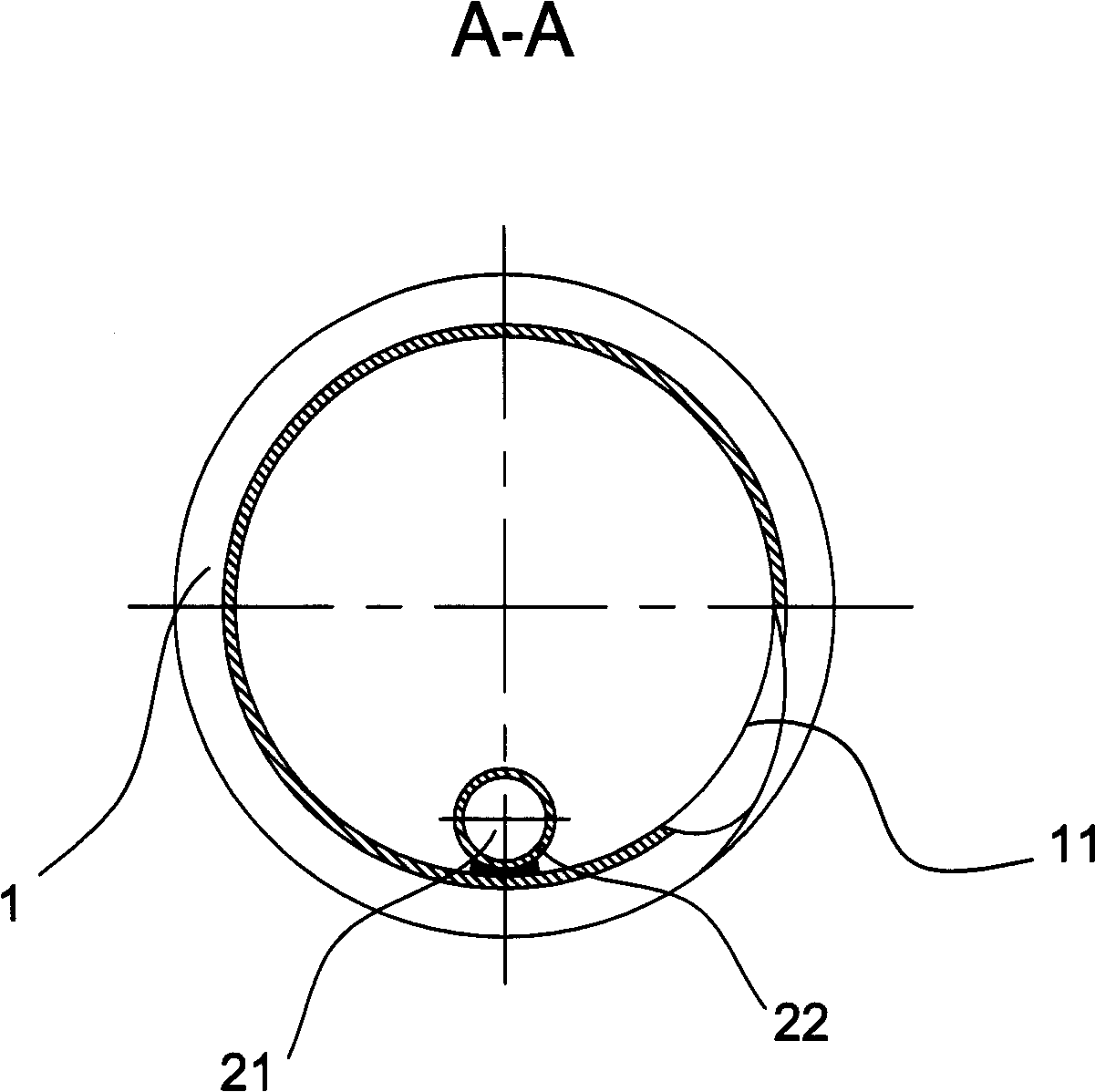

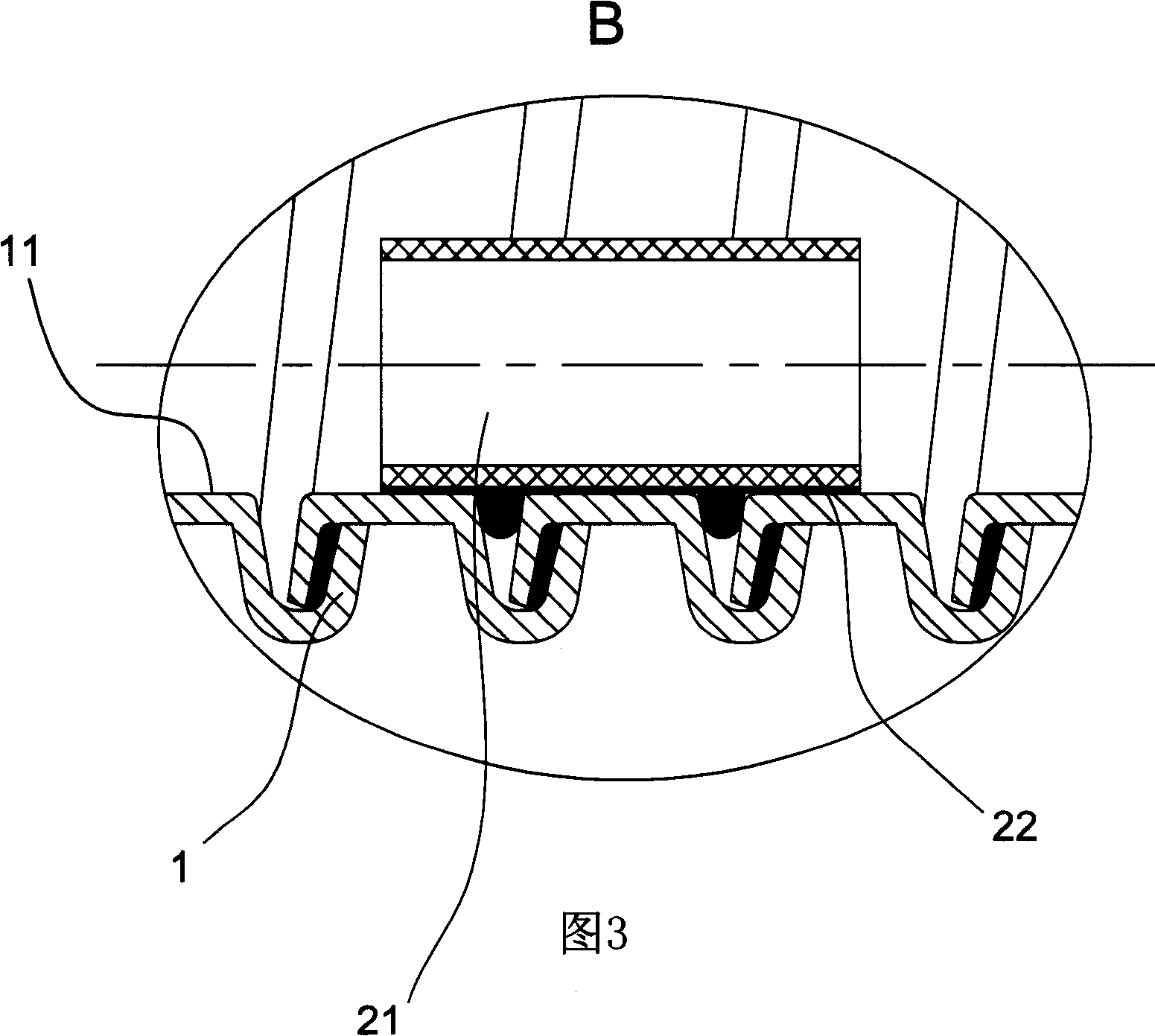

[0053] like Figure 1~6 A multi-purpose hose is shown, which includes a hose 1, and a plurality of positioning pieces 2 arranged at intervals along the length direction of the hose are fixedly arranged on the inner wall surface 11 of the hose. An accommodating channel 21 extending in the length direction.

[0054] In the embodiment shown in the figure, a group of multiple positioning members 2 distributed along the same straight line are fixedly arranged on the inner wall surface 11 of the hose, and the straight line is parallel to the axis of the hose 1 .

[0055] For a non-standard cylindrical hose, if the hose is truncated conical, a plurality of positioning pieces 2 are arranged along the inner wall surface 11 of the hose, and the straight line where the multiple positioning pieces 2 are located is in line with the hose 1. Axis lines intersect.

[0056] Each locator is a single-hole collar 22, such as Figure 1~3 As shown in , a receiving channel 21 extending along the ...

Embodiment 2

[0059] like Figure 4~6 As shown, this multi-purpose hose is roughly the same as the multi-purpose hose in Embodiment 1, except that each positioning part in this embodiment is a porous collar 23, and multiple holes along the length direction of the hose 1 are formed in the porous collar 23. The extended receiving channel 21, shown as a two-hole collar, forms two receiving channels inside it.

Embodiment 3

[0061] like Figure 7-9 The shown multi-purpose hose includes a hose 1, and a plurality of positioning parts 2 arranged at intervals along the length direction of the hose 1 are fixedly arranged on the inner wall surface 11 of the hose. The accommodating channels 21 extending in the length direction of the hose 1 are provided with small tubes 3 inserted in the accommodating channels 21 of the plurality of positioning members 2 , and the small tubes 3 extend along the length direction of the hose 1 .

[0062] Since the small tube 3 is inserted in the positioning part 2, a gap 5 is formed between the small tube outer wall surface 31 and the hose inner wall surface 11 between two adjacent positioning parts 2, and the small tube outer wall surface 31 is formed by the gap 5. It is not in contact with the inner wall surface 11 of the hose. In this way, when working, there will be no direct heat transfer between the small tube 3 and the hose 1, so that the two will not affect each o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com