Preparation method of nitrogen-doped graphene

A nitrogen-doped graphene and nitrogen source technology, applied in the field of nitrogen-doped graphene preparation, can solve the problems of complex operation, high equipment requirements, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

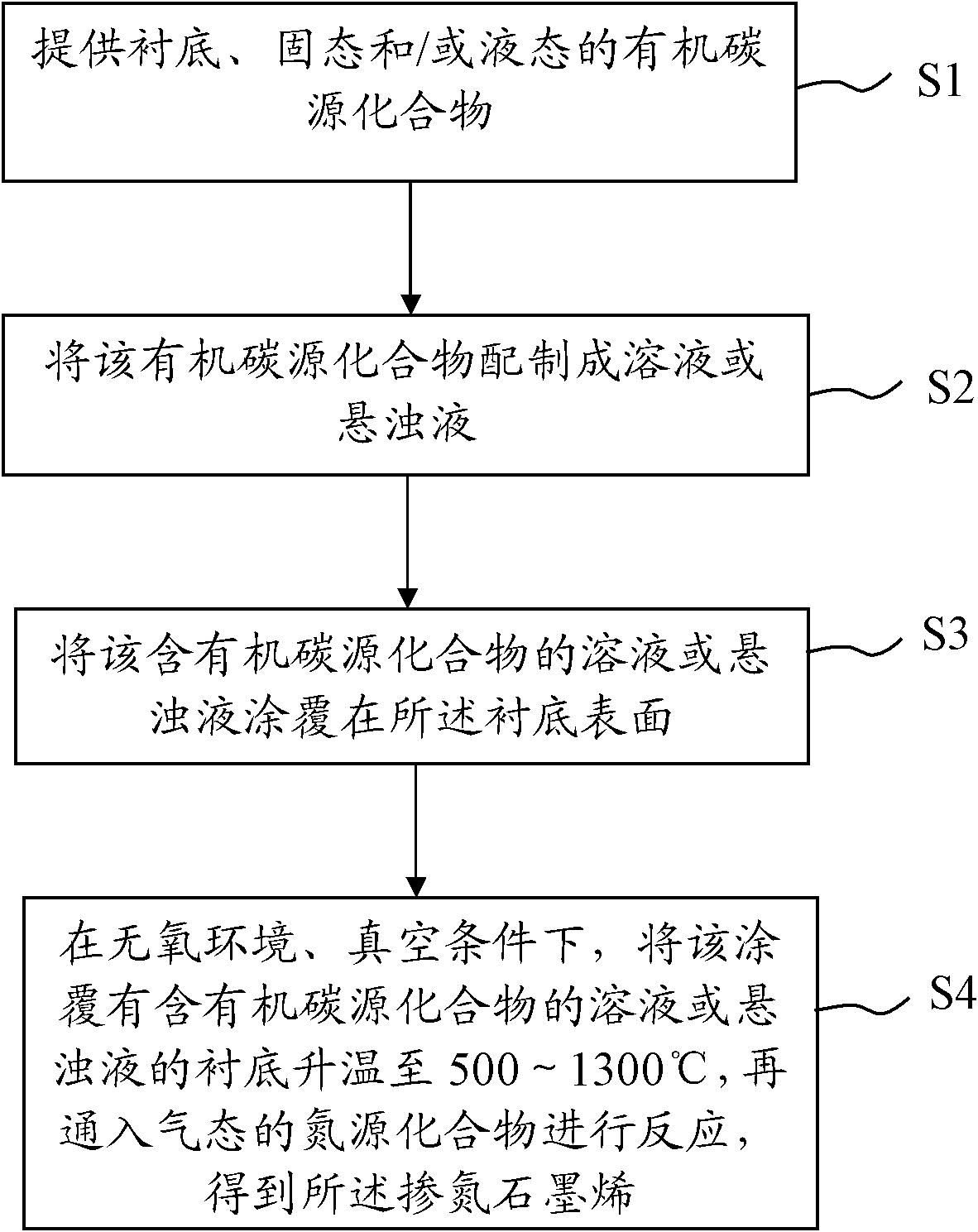

[0016] The embodiment of the present invention provides a method for preparing nitrogen-doped graphene with simple process, high yield, low production cost, and easy operation and control. The technological process of the preparation method of this nitrogen-doped graphene is as figure 1 Shown, adopt chemical vapor deposition method to prepare nitrogen-doped graphene, it comprises the following steps:

[0017] S1: Provide substrate, solid and / or liquid organic carbon source compound;

[0018] S2: preparing the organic carbon source compound into a solution or suspension;

[0019] S3: coating the solution or suspension containing the organic carbon source compound on the surface of the substrate;

[0020] S4: In an oxygen-free environment and under vacuum conditions, the substrate coated with the solution or suspension containing an organic carbon source compound is heated up to 500-1300 ° C, and then a gaseous nitrogen source compound is introduced to react to obtain the obta...

Embodiment 1

[0034]The preparation method of nitrogen-doped graphene, comprises the steps:

[0035] S11. Ultrasonic cleaning the nickel foil substrate with deionized water, ethanol, and acetone and then drying, preparing ferrocene into a solution with a mass percentage concentration of 20 wt%, and then spin-coating it on the surface of the substrate;

[0036] S12. Put the substrate coated with ferrocene into the reaction chamber, and seal the reaction chamber, and use mechanical pumps, Roots pumps and molecular pumps to pump the reaction chamber to 10 -3 Below Pa, and keep it for 10 minutes, turn off the molecular pump and start heating;

[0037] S13. When the substrate temperature reaches 500°C, keep the temperature constant, and then feed in nitrogen-containing substance ammonia gas with a flow rate of 10 sccm, and start to generate nitrogen-doped graphene; wherein, the amount of nitrogen gas fed in is related to the amount of ferrocene Relationship: The molar ratio of carbon to nitroge...

Embodiment 2

[0043] The preparation method of nitrogen-doped graphene, comprises the steps:

[0044] S21. Ultrasonic cleaning the copper foil substrate with deionized water, ethanol, and acetone and then drying it, and preparing a solution with a mass percent concentration of 5 wt% of nickelocene, and then spin-coating it on the surface of the substrate;

[0045] S22. put the substrate coated with nickelocene into the reaction chamber, and seal the reaction chamber, and use a mechanical pump, Roots pump and molecular pump to pump the reaction chamber to 10 step by step. -3 Below Pa, and keep it for 30 minutes, turn off the molecular pump and start heating;

[0046] S23. When the substrate temperature reaches 1300°C, keep the temperature constant, and then feed the nitrogen-containing substance methylamine with a flow rate of 200 sccm, and start to generate nitrogen-doped graphene; wherein, the amount of methylamine fed is the same as the amount of nickelocene Relationship: The molar ratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com