Manufacturing method of composite tungsten oxide nanoparticle, infrared absorbing material and infrared shielding body

A manufacturing method and nanoparticle technology, applied in radiation-absorbing coatings, tungsten oxide/tungsten hydroxide, nanotechnology, etc., can solve the problems of high cost and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

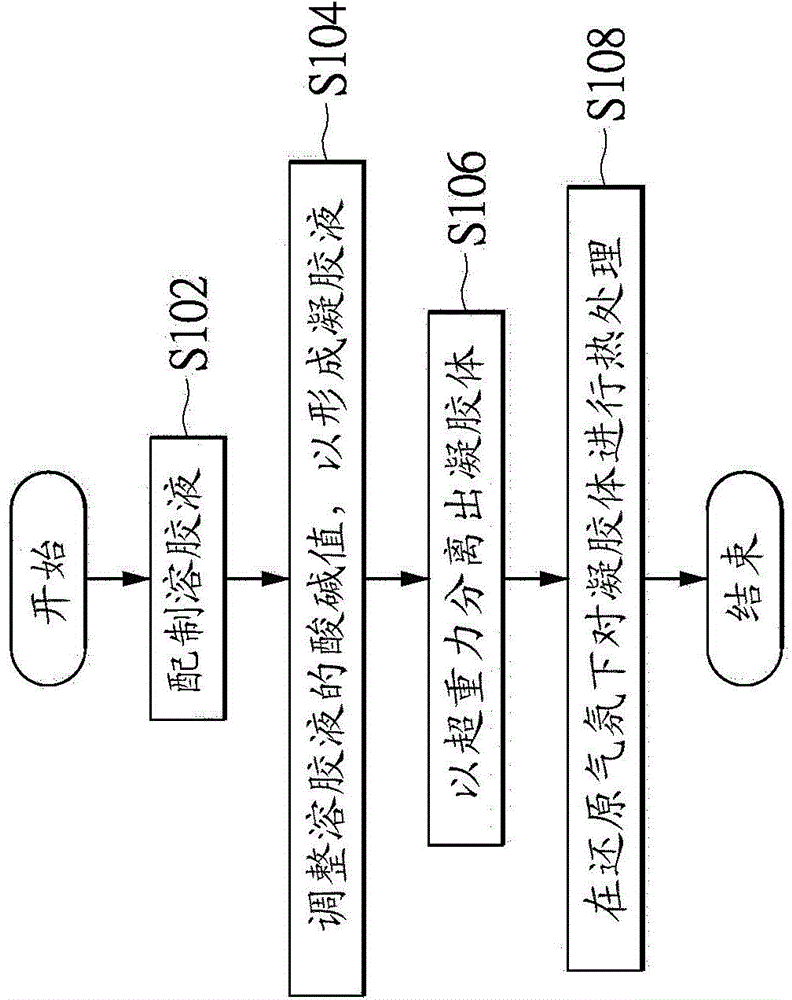

Method used

Image

Examples

preparation example Construction

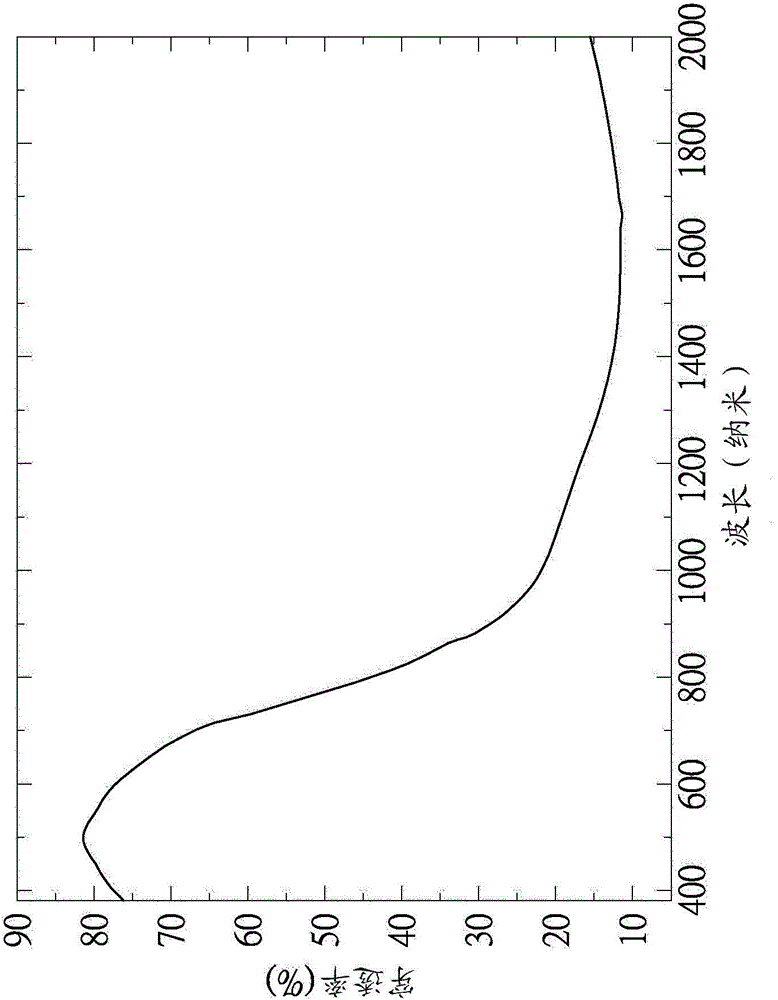

[0035] Further, the present invention also proposes an infrared shielding body, which is made by mixing a nano-slurry formed by mixing the above-mentioned infrared absorbing material and a dispersant with a resin. In this embodiment, the preparation method of the infrared shielding body may include the following steps: First, mix the above-mentioned external ray absorbing material and a dispersant in an appropriate solvent, wherein the dispersant can be polymeric acidic, polymeric basic or A polymer neutral dispersant; then, apply wet pulverization to the mixture obtained in the previous step to form a nano-slurry; afterward, mix the nano-slurry with a media resin, and apply it to a substrate For the surface, the medium resin can be used alone or in combination with thermosetting resins, ultraviolet curing resins, electron beam curing resins, room temperature curing resins, thermoplastic resins, etc.

[0036] In order to enable those skilled in the art to easily understand the...

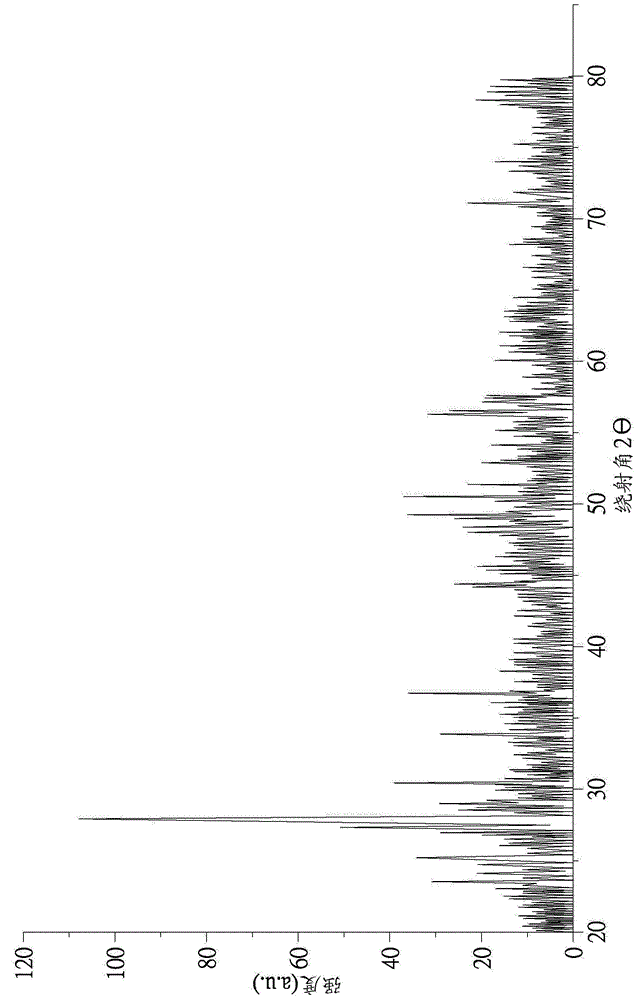

experiment example 1

[0037] Experimental Example 1: Directly dissolve tungsten hexachloride, cesium hydroxide, and potassium hydroxide in aqueous ethanol solution, and add an appropriate amount of water dropwise until precipitation occurs. Its chemical reaction formula is as follows:

[0038] wCl 6 +H 2 O+CsOH+KOH→WOCl 4 +K + +Cs + +HCl+H 2 o

[0039] WOCl 4 +Cs + +K + +HCl→WO 3 (↓)+Cs + +K + +6HCl

[0040] Then use supergravity to separate most of the solution from the precipitate to obtain a muddy precipitate (gel) and then use a vacuum oven to extract the solvent into a dry powder, place the dried cesium tungsten oxychloride powder in a high-temperature furnace, and A certain proportion of inert gas and hydrogen gas can reduce the composite potassium cesium tungsten oxychloride to potassium cesium tungsten oxide. The process conditions are as follows: in a high-temperature furnace, the temperature is raised from room temperature to 580° C. at a rate of 3-5° C. per minute, and sinter...

Embodiment 2

[0043] Example 2: directly dissolve tungsten hexachloride, cesium hydroxide, and rubidium hydroxide in an aqueous ethanol solution, and add an appropriate amount of water in a dropwise manner until precipitation occurs. Its chemical reaction formula is as follows:

[0044] wCl 6 +H 2 O+CsOH+RbOH→WOCl 4 +Rb + +Cs + +HCl

[0045] WOCl 4 +Cs + +Rb + +HCl→WO 3 (↓)+Cs + +Rb + +6HCl

[0046] Then, use supergravity to separate most of the solution from the precipitate, obtain the muddy precipitate, and then use a vacuum oven to extract the solvent into a dry powder, place the dry cesium tungsten oxychloride powder in a high-temperature furnace, and gas and hydrogen to reduce the complex potassium cesium tungsten oxychloride to potassium cesium tungsten oxide. The process conditions are as follows: in a high-temperature furnace, the temperature is raised from room temperature to 580° C. at a rate of 3-5° C. per minute, and sintered at a constant temperature of 580° C. for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com