Method for preparing doped ZnO-based film through magnetron sputtering

A magnetron sputtering and thin film technology, applied in sputtering coating, metal material coating process, vacuum evaporation coating, etc., can solve the problems of increasing research cost, lack of doping means, and limiting flexible adjustment of thin film components , to achieve the effect of low cost, controlled doping amount and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1—A high-purity Al target is used as a dopant source to grow an AZO film on a quartz substrate.

[0047] Firstly, Al-doped ZnO thin film (AZO) is prepared by alternately magnetron sputtering ZnO and Al targets using sub-molecular layered doping technology, and is annealed at 400-800°C for 30-60 minutes in an air atmosphere. The growth conditions are:

[0048]

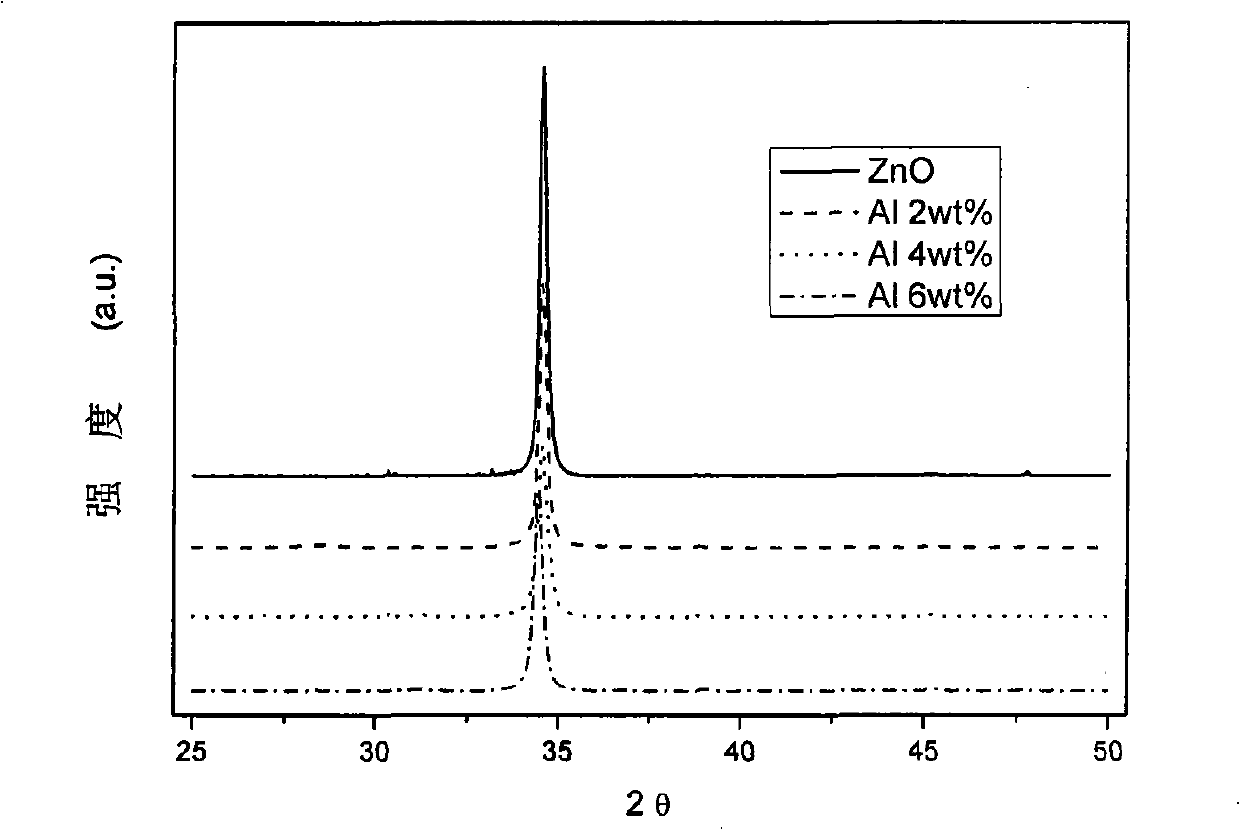

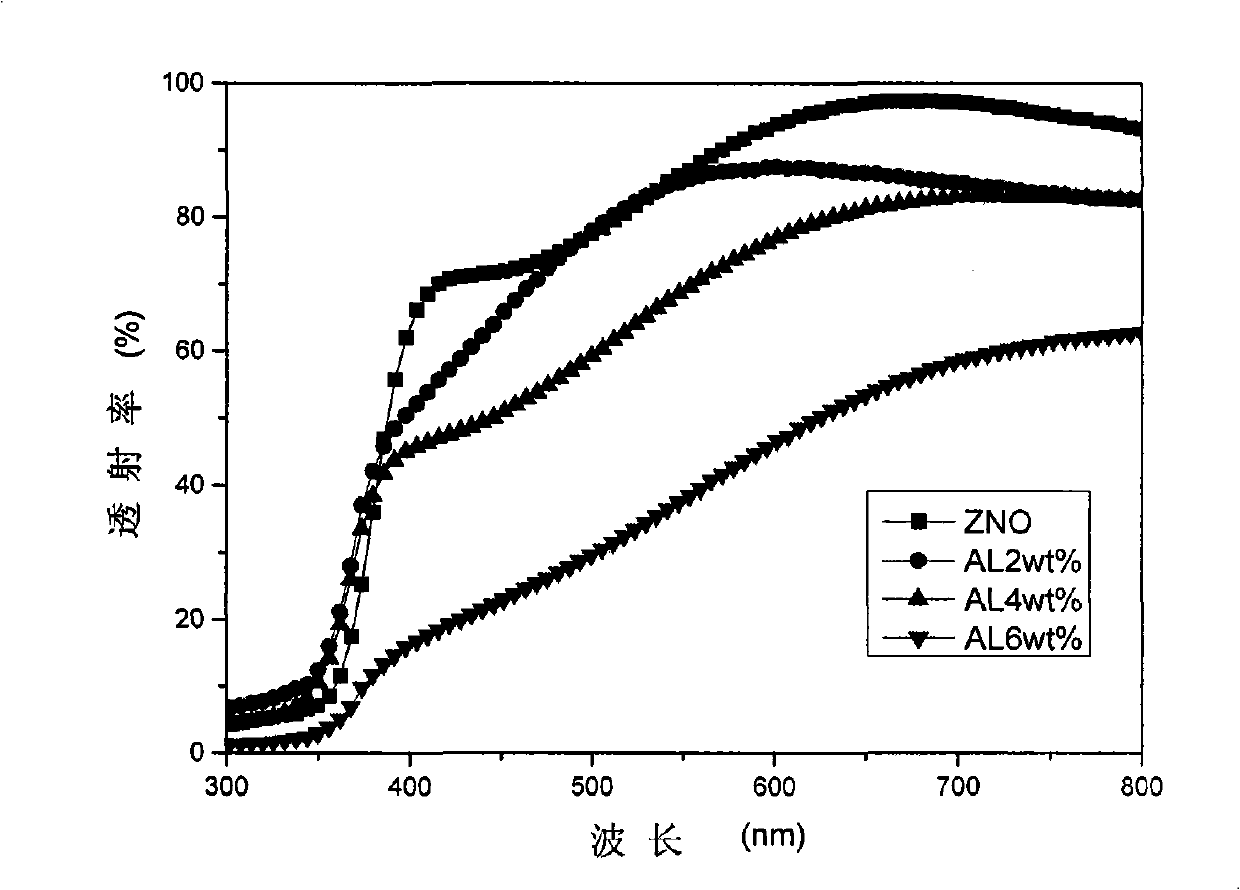

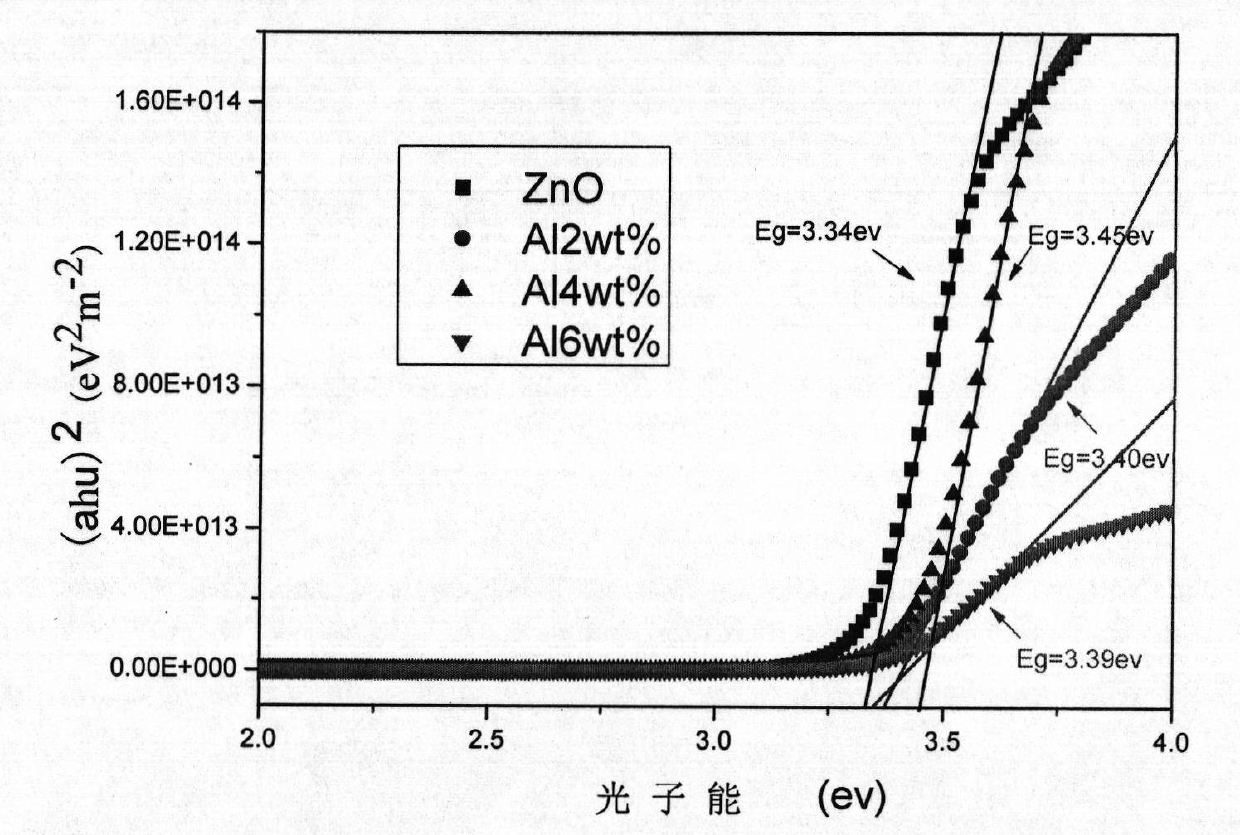

[0049] By changing the sputtering time of the Al target and controlling the content of doped Al (0-6wt%), a good transparent conductive film (TCO) is prepared. After annealing at 400°C, the crystalline quality of the film was improved, and the XRD results showed that all the films had only (002) diffraction peaks, with obvious C-axis preferred orientation, see Picture 1-1 . The average transmittance of the film exceeds 80% in the visible range, see Figure 1-2 . Through the fitting of the ellipsometric spectrum, the optical constant spectrum and film thickness of the AZO thin film sample are giv...

Embodiment 2

[0050] Example 2—Using high-purity Co as a dopant source target, a ZnO:Co(ZCO) film was grown on a Si substrate.

[0051] Firstly, the Co-doped ZnO thin film (ZCO) is prepared by alternately sputtering ZnO and Co targets using submolecular layered doping technology, and is annealed at 400-800°C for 30-60 minutes in a vacuum atmosphere. The growth conditions are:

[0052]

[0053]

[0054] The XRD test results show that the (002) crystal planes of ZCO films with different Co doping amounts have a strong diffraction peak, and their 2θ are very close to the diffraction peaks of pure ZnO crystals, indicating that all ZCO films have c-axis preference orientation, see diagram 2-1 . The depth spectrum of each atom in the ZCO film measured by XPS shows that the layered doping technology is an effective film doping method. The content of Co element on the surface of the film is slightly higher than that in the interior, but the overall content of Co in the film is The distrib...

Embodiment 3

[0055] Example 3—Using a high-purity Mg target as a dopant source to grow Mg on a quartz substrate x Zn 1-x O alloy film.

[0056] Mg-doped ZnO films (Mg x Zn 1-x O), the samples were all annealed at a high temperature of 800° C. for 30 minutes in a nitrogen atmosphere. The growth conditions are:

[0057]

[0058]

[0059] Studies have shown that when the Mg component is low, all Mg x Zn 1-x The O thin film has a ZnO-like (0002) diffraction peak, with an obvious C-axis preferred orientation, and the film has a hexagonal single-phase structure; Similar to MgO(200) diffraction peaks, the sample is a mixed phase of hexagonal phase and cubic phase Figure 3-1 ; In the visible region, the average transmittance of the film exceeds 85%, see Figure 3-2 . With the increase of Mg composition, the transmittance decreases slightly; when the Mg composition is low, the absorption edge will blue shift with the increase of oxygen content, annealing temperature and Mg compositi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com