Preparation method for doped graphene foams

A graphene foam and graphene technology are applied in the field of preparation of modified graphene foam, and can solve the problems of high equipment requirements and production costs, uncontrollable size of final products, and difficulty in reducing graphene foams.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Mix sodium metaaluminate and graphene oxide dispersion evenly according to the mass ratio of dopant and graphene oxide at 1:4, then put it in a high-pressure reactor and react at 140°C for 6h, then place the reactant at -20°C After freezing for 12 hours, it was freeze-dried at -55°C and 2 Pa for 24 hours to obtain graphene oxide airgel doped with aluminum oxide nanoparticles; the hydrazine hydrate and graphene oxide airgel doped with nanoparticles According to the mass ratio of 1:10, they were respectively placed in a reaction vessel with a vacuum degree of 0.02MPa, and reacted at 90°C for 6h, then washed with water and ethanol in sequence, and then dried at 70°C and a vacuum degree of 0.01MPa for 12h.

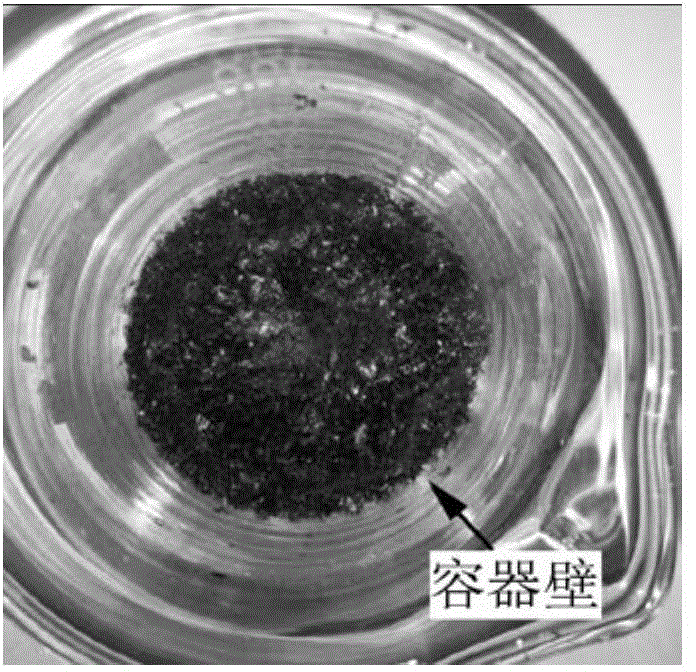

[0032] The doping amount of the foam is 18wt%, and the specific surface area is 116m 2 / g, the pore volume is greater than 0.136cm 3 / g, see Figure 5 It is 75% that X-ray photoelectron spectrum test, fitting calculation obtain reduction degree, see Figure 8 ; Scann...

Embodiment 2

[0034] Mix tetrabutyl titanate and graphene oxide dispersion evenly according to the mass ratio of dopant and graphene oxide at 1:5, then put them into a high-pressure reactor and react at 160°C for 12h, then place the reactants at -40°C After freezing for 6 h at -55 °C and 5 Pa, freeze-drying for 48 h, the graphene oxide airgel doped with titanium dioxide nanoparticles was obtained; the hydrazine hydrate and the graphene oxide airgel doped with nanoparticles Ratio 1:12 respectively placed in a reaction vessel with a vacuum of 0.01MPa, reacted at 80°C for 12h, then washed with water and ethanol in turn, and then dried at 60°C and a vacuum of 0.015MPa for 18h.

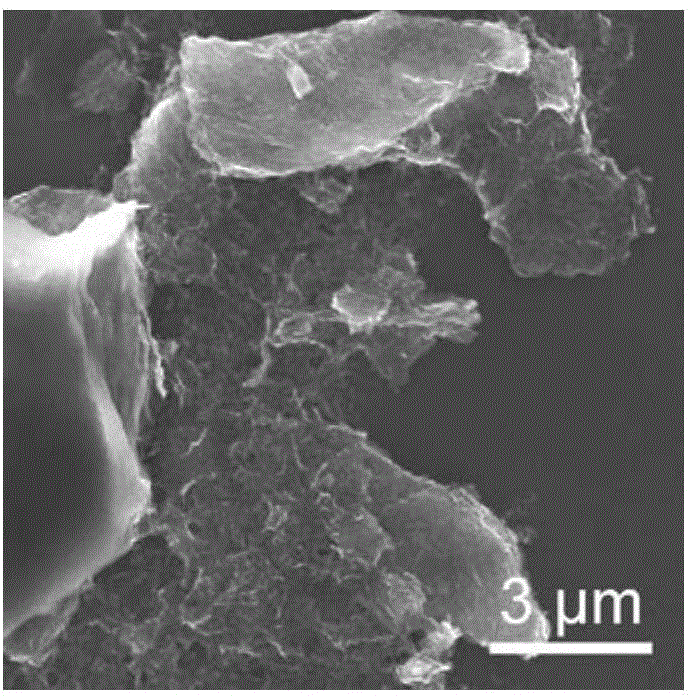

[0035] The doping amount of the foam is 15wt%, and the specific surface area is 127m 2 / g, the pore volume is greater than 0.122cm 3 / g, the degree of reduction is 70%, scanning electron microscopy shows that titanium dioxide grows uniformly on the graphene sheet in the form of nanoparticles, see Figure 9 , 10 , the...

Embodiment 3

[0037] Mix tetraethyl titanate and graphene oxide dispersion evenly according to the mass ratio of dopant and graphene oxide at 1:20, then put it into a high-pressure reactor and react at 120°C for 6h, and then place the reactant at -20 After being frozen at ℃ for 12 hours, it was freeze-dried at -40 ℃ and 1 Pa for 36 hours to obtain graphene oxide airgel doped with titanium dioxide nanoparticles; pure hydrazine and graphene oxide airgel doped with nanoparticles The ratio of 1:15 was placed in a reaction vessel with a vacuum of 0.005MPa, reacted at 60°C for 24h, then washed with water and ethanol in turn, and then dried at 70°C and a vacuum of 0.012MPa for 20h.

[0038] The doping amount of the foam is 3.5wt%, and the specific surface area is 94m 2 / g, the pore volume is greater than 0.101cm 3 / g, the degree of reduction is 50%, scanning electron microscopy shows that titanium dioxide grows uniformly on the graphene sheet in the form of nanoparticles, and the difference betwe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com