A kind of preparation method of doped graphene foam

A graphene foam and graphene technology, applied in the field of preparation of modified graphene foam, can solve the problems of difficult reduction of graphene foam, restriction of large-scale practical application, uncontrollable size of final product, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Mix sodium metaaluminate and graphene oxide dispersion evenly according to the mass ratio of dopant and graphene oxide at 1:4, then put it in a high-pressure reactor and react at 140°C for 6h, then place the reactant at -20°C After freezing for 12 hours, it was freeze-dried at -55°C and 2 Pa for 24 hours to obtain graphene oxide airgel doped with aluminum oxide nanoparticles; the hydrazine hydrate and graphene oxide airgel doped with nanoparticles According to the mass ratio of 1:10, they were respectively placed in a reaction vessel with a vacuum degree of 0.02MPa, and reacted at 90°C for 6h, then washed with water and ethanol in sequence, and then dried at 70°C and a vacuum degree of 0.01MPa for 12h.

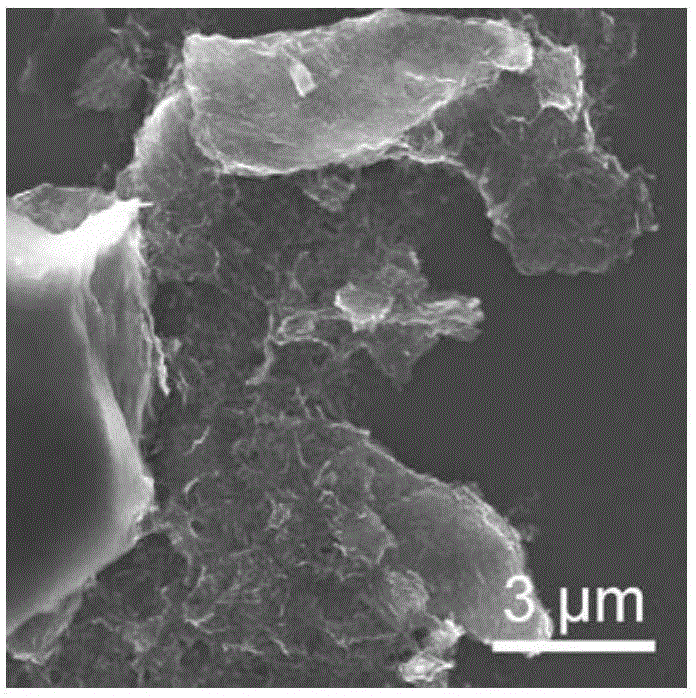

[0032] The doping amount of the foam is 18wt%, and the specific surface area is 116m 2 / g, the pore volume is greater than 0.136cm 3 / g, see Figure 5 It is 75% that X-ray photoelectron spectrum test, fitting calculation obtain reduction degree, see Figure 8 ; Scann...

Embodiment 2

[0034] Mix tetrabutyl titanate and graphene oxide dispersion evenly according to the mass ratio of dopant and graphene oxide at 1:5, then put them into a high-pressure reactor and react at 160°C for 12h, then place the reactants at -40°C After freezing for 6 h at -55 °C and 5 Pa, freeze-drying for 48 h, the graphene oxide airgel doped with titanium dioxide nanoparticles was obtained; the hydrazine hydrate and the graphene oxide airgel doped with nanoparticles Ratio 1:12 respectively placed in a reaction vessel with a vacuum of 0.01MPa, reacted at 80°C for 12h, then washed with water and ethanol in turn, and then dried at 60°C and a vacuum of 0.015MPa for 18h.

[0035] The doping amount of the foam is 15wt%, and the specific surface area is 127m 2 / g, the pore volume is greater than 0.122cm 3 / g, the degree of reduction is 70%, scanning electron microscopy shows that titanium dioxide grows uniformly on the graphene sheet in the form of nanoparticles, see Figure 9 , 10 , the...

Embodiment 3

[0037] Mix tetraethyl titanate and graphene oxide dispersion evenly according to the mass ratio of dopant and graphene oxide at 1:20, then put it into a high-pressure reactor and react at 120°C for 6h, and then place the reactant at -20 After being frozen at ℃ for 12 hours, it was freeze-dried at -40 ℃ and 1 Pa for 36 hours to obtain graphene oxide airgel doped with titanium dioxide nanoparticles; pure hydrazine and graphene oxide airgel doped with nanoparticles The ratio of 1:15 was placed in a reaction vessel with a vacuum of 0.005MPa, reacted at 60°C for 24h, then washed with water and ethanol in turn, and then dried at 70°C and a vacuum of 0.012MPa for 20h.

[0038] The doping amount of the foam is 3.5wt%, and the specific surface area is 94m 2 / g, the pore volume is greater than 0.101cm 3 / g, the degree of reduction is 50%, scanning electron microscopy shows that titanium dioxide grows uniformly on the graphene sheet in the form of nanoparticles, and the difference betwe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com