Method for preparing zinc oxide-based sputtering target material

A sputtering target material, zinc oxide-based technology, applied in the direction of sputtering coating, metal material coating process, ion implantation plating, etc. Advanced problems, to achieve the effect of high purity, easy large-scale industrial production, and low sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

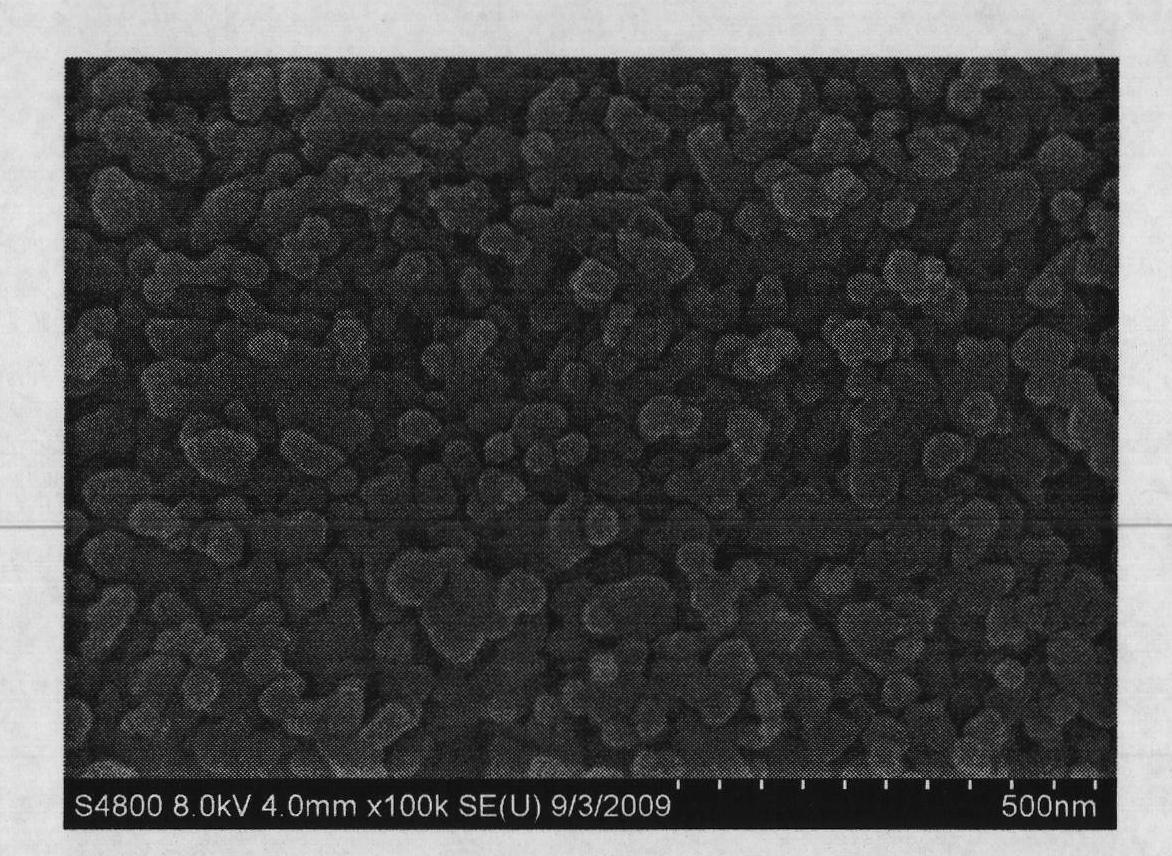

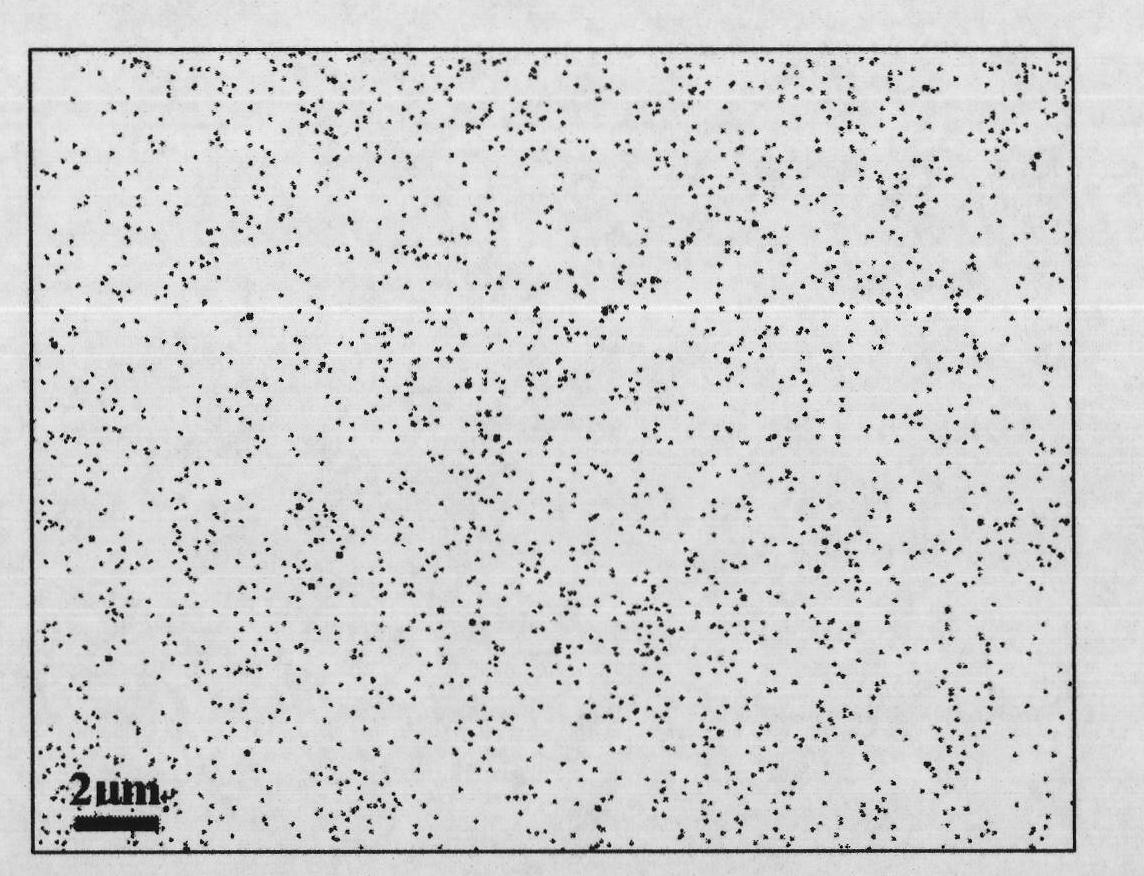

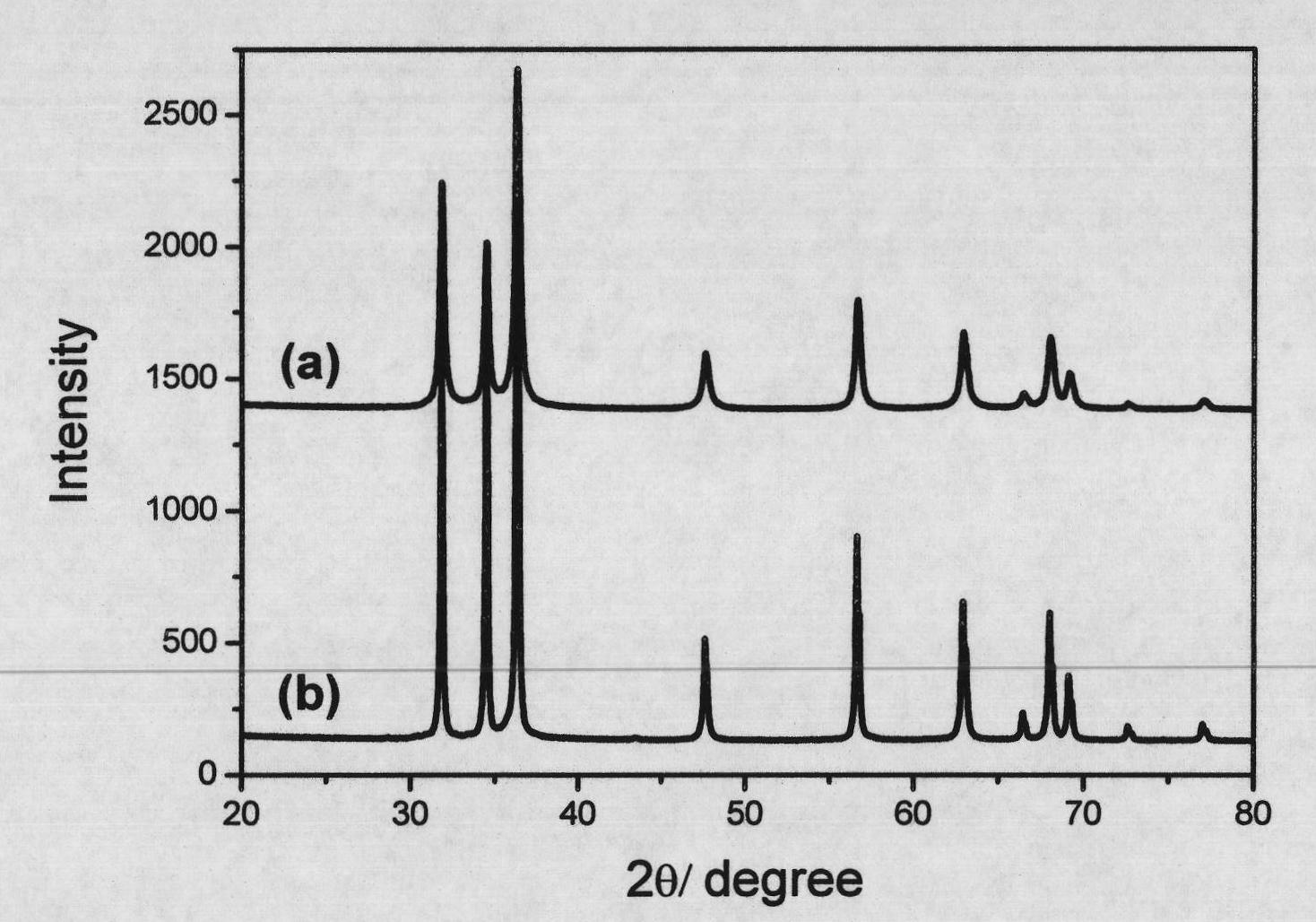

[0053] Example 1 Preparation of doped zinc oxide nanopowder

[0054] Dissolve aluminum nitrate and zinc nitrate together in deionized water to form a salt solution with a total salt concentration of 1 mol / L, wherein the molar ratio between aluminum ions and zinc ions is 0.032:1, under strong stirring at a speed of 600 rpm Evenly add dropwise to 3mol / L ammonia solution (solvent is deionized water) at a rate of 20mL / min, keep the pH value of the system at 7.5±0.5 and the temperature at 30°C during the dropwise addition process, and obtain the co-precipitated product; After aging the co-precipitated product for 24 hours, the precipitate was washed three times with deionized water and once with absolute ethanol, and then dried in an oven at 100°C for 10 hours to obtain a dry white product; the white product was dried at 600°C Calcining at lower temperature for 2 hours, the aluminum-doped zinc oxide nanopowder was obtained, wherein the molar ratio between aluminum ions and zinc ion...

Embodiment 2

[0057] Example 2 Preparation of doped zinc oxide nanopowder

[0058] Dissolve aluminum nitrate and zinc nitrate together in deionized water to form a salt solution with a total salt concentration of 0.5 mol / L, wherein the molar ratio between aluminum ions and zinc ions is 0.032:1, and the At a speed of 5mL / min, it was evenly added dropwise to 2mol / L ammonia solution (the solvent was deionized water), and the pH value of the system was kept at 8.3±0.3 during the dropwise addition process, and the temperature was 20°C to obtain the coprecipitated product ; After the co-precipitated product was aged for 24h, the precipitate was washed 4 times with deionized water, then washed 2 times with absolute ethanol, and then dried in an oven at 100°C for 10h to obtain a dry white product; the white product was dried at 500°C Calcining at high temperature for 2 hours to obtain aluminum-doped zinc oxide nanopowder, wherein the molar ratio between aluminum ions and zinc ions is 0.032:1.

[0...

Embodiment 3

[0060] Example 3 Preparation of doped zinc oxide nanopowder

[0061] Dissolve aluminum nitrate and zinc nitrate together in deionized water to form a salt solution with a total salt concentration of 3 mol / L, wherein the molar ratio between aluminum ions and zinc ions is 0.02:1, under strong stirring at a speed of 400 rpm Add it dropwise evenly at a rate of 50mL / min to a 5mol / L ammonia solution (the solvent is deionized water), keep the pH of the system at 9.6±0.4 during the dropwise addition, and keep the temperature at 50°C to obtain a co-precipitated product; After aging the co-precipitated product for 30 hours, the precipitate was washed 5 times with deionized water, then washed 2 times with absolute ethanol, and then dried in an oven at 100°C for 15 hours to obtain a dry white product; the white product was dried at 700°C Calcining at lower temperature for 3 hours to obtain aluminum-doped zinc oxide nanopowder, wherein the molar ratio between aluminum ions and zinc ions is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com