Method for preparing fluorinated graphene through microwave hydrothermal method

A technology of fluorinated graphene and microwave hydrothermal method, applied in graphene, nano-carbon and other directions, can solve the problems of complex equipment required for the reaction, harsh reaction conditions, and high cost of raw materials, so that it is easy to popularize and use, and has few influencing factors. , the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

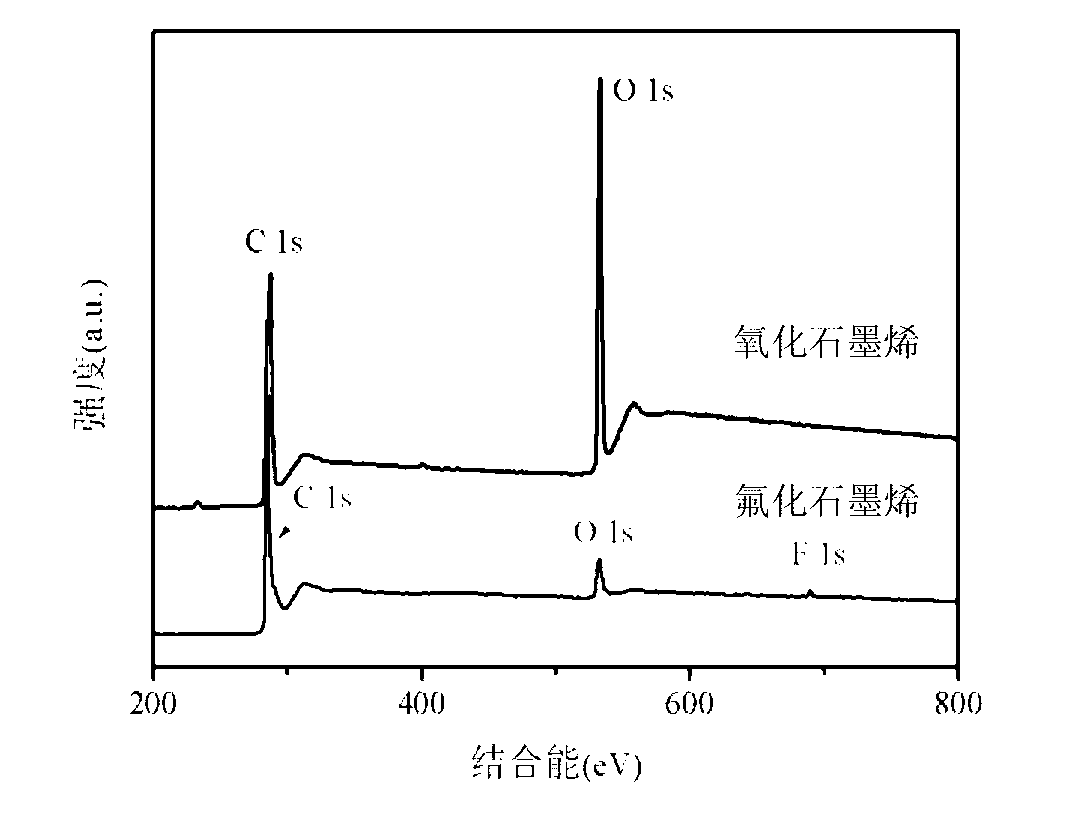

[0025] (1) Preparation of aqueous dispersion of graphene oxide: place the flask in an ice-water bath, pour an appropriate amount of concentrated sulfuric acid; mix 3g flake graphite powder, 1.5g NaNO 3 Pour into the flask, stir evenly, and then cool for 3h, so that the temperature of the system is 0°C; add 9g KMnO to the mixed solution 4 , stir evenly, and keep the system temperature below 20°C during this period; move the flask into an oil bath, keep the temperature at 35°C for 2 hours, add deionized water, and after 10 minutes, add diluted hydrogen peroxide to obtain a bright yellow solution; filter the reactants, and use Repeated washing with 10% hydrochloric acid and distilled water, suction filtration, dialyzing the obtained viscous solid until the pH value is close to neutral; drying and grinding the obtained solid to obtain graphite oxide; weigh 100mg of graphite oxide, measure 50mL of distilled water, and pour it into a beaker , using an ultrasonic cleaner (40KHz, 100W...

Embodiment 2

[0031] (1) Preparation of aqueous dispersion of graphene oxide: place the flask in an ice-water bath, pour an appropriate amount of concentrated sulfuric acid; mix 3g flake graphite powder, 1.5g NaNO 3 Pour into the flask, stir evenly, and then cool for 3h, so that the temperature of the system is 0°C; add 9g KMnO to the mixed solution 4 , stir evenly, and keep the system temperature below 20°C during this period; move the flask into an oil bath, keep the temperature at 35°C for 2 hours, add deionized water, and after 10 minutes, add diluted hydrogen peroxide to obtain a bright yellow solution; filter the reactants, and use Repeated washing with 10% hydrochloric acid and distilled water, suction filtration, dialyzing the obtained viscous solid until the pH value is close to neutral; drying and grinding the obtained solid to obtain graphite oxide; weigh 60mg of graphite oxide, measure 60mL of distilled water, and pour it into a beaker , using an ultrasonic cleaner (40KHz, 100W)...

Embodiment 3

[0037] (1) Preparation of aqueous dispersion of graphene oxide: place the flask in an ice-water bath, pour an appropriate amount of concentrated sulfuric acid; mix 3g flake graphite powder, 1.5g NaNO 3 Pour into the flask, stir evenly, and then cool for 3h, so that the temperature of the system is 0°C; add 9g KMnO to the mixed solution 4 , stir evenly, and keep the system temperature below 20°C during this period; move the flask into an oil bath, keep the temperature at 35°C for 2 hours, add deionized water, and after 10 minutes, add diluted hydrogen peroxide to obtain a bright yellow solution; filter the reactants, and use Repeated washing with 10% hydrochloric acid and distilled water, suction filtration, dialyzing the obtained viscous solid until the pH value is close to neutral; drying and grinding the obtained solid to obtain graphite oxide; weigh 80mg of graphite oxide, measure 60mL of distilled water, and pour it into a beaker , using an ultrasonic cleaner (40KHz, 100W)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com