Spray drying preparation of spherical lithium manganate doped slurry

A technology of heteromanganese oxide and spherical shape, which is applied in the field of spray drying preparation of spherical doped lithium manganate slurry, which can solve the problems of fast product capacity decay, uncontrollable shape and size of lithium manganate particles, etc., and achieve cycle performance Improvement, environmental friendliness, uniform particle size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

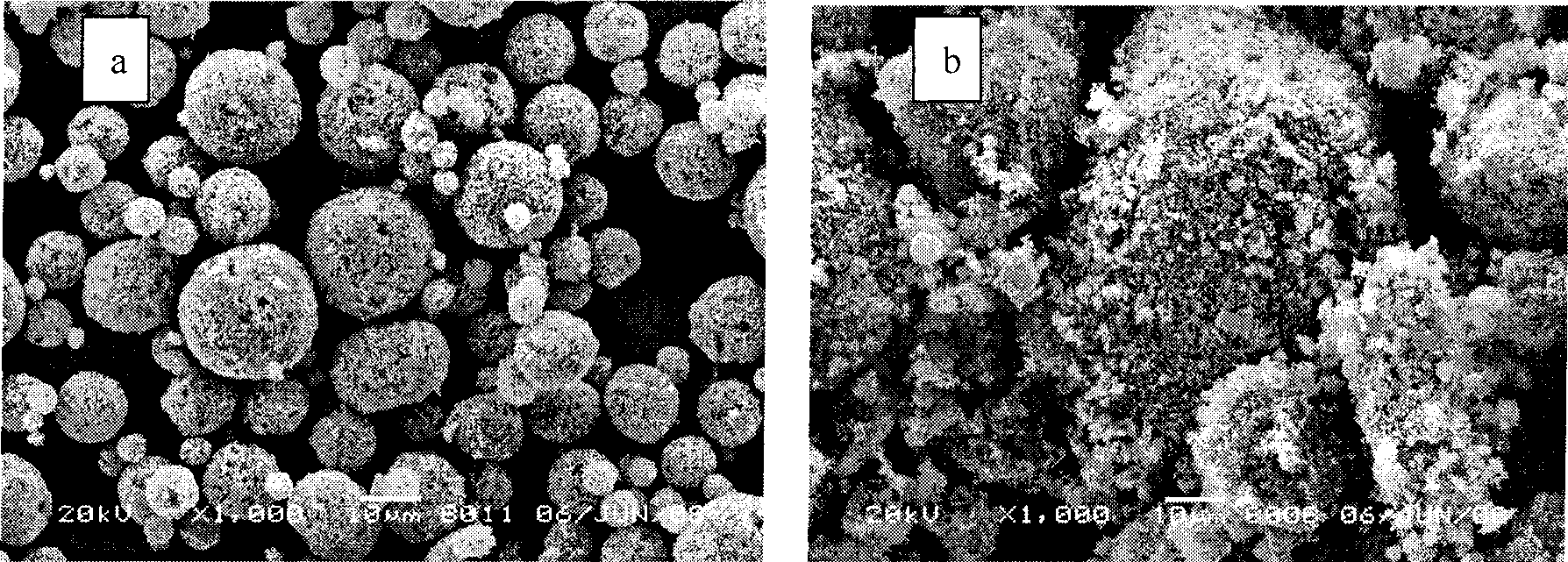

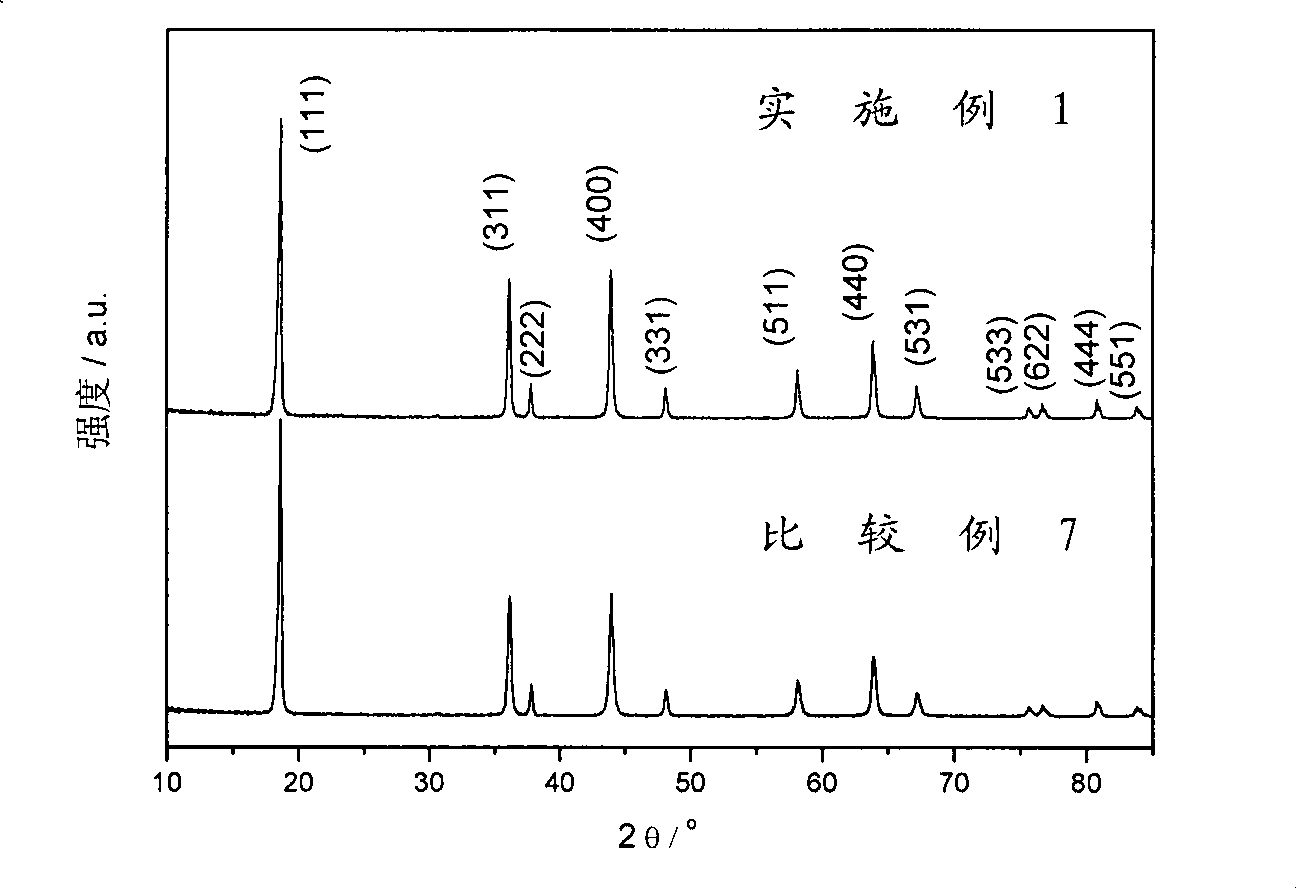

Embodiment 1

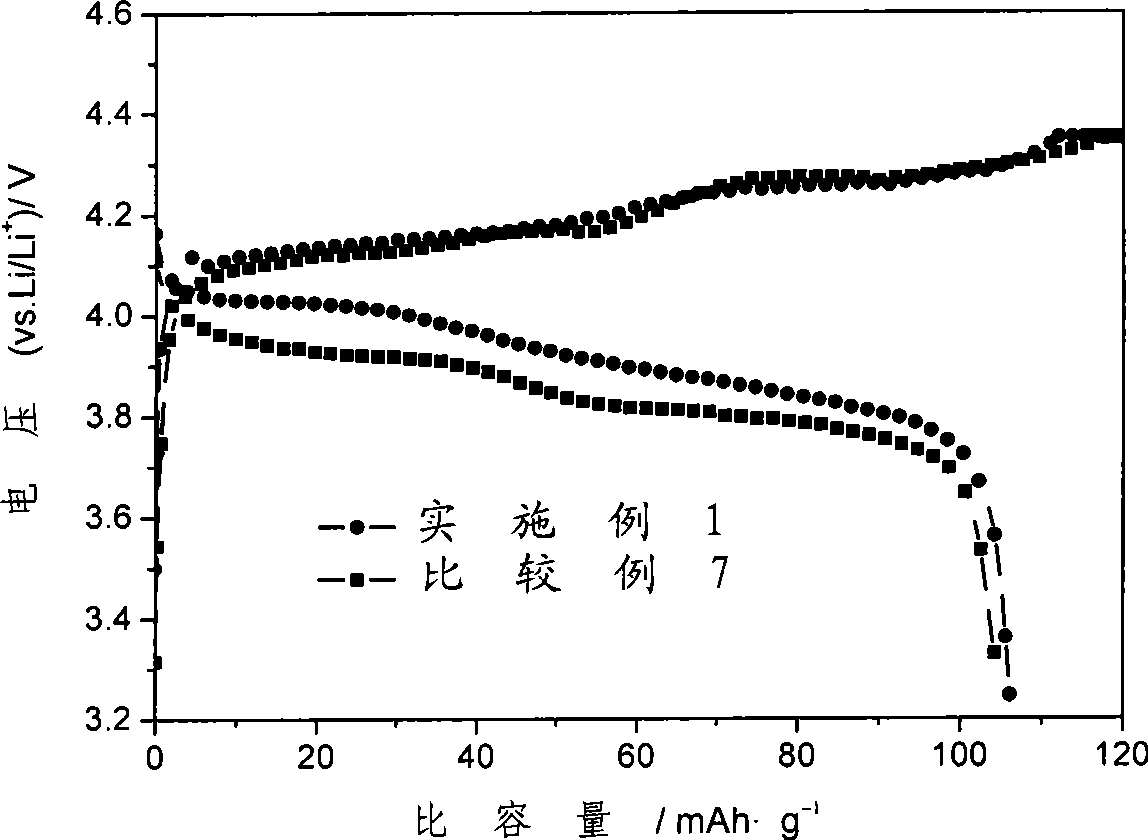

[0026] Example 1: Mix 1000g of manganese dioxide (EMD), 215g of lithium carbonate, 100g of chromium acetate solution (50wt.%), and 60g of soluble starch, add 2L of deionized water, and perform mechanical ball milling for 0.5-5h to obtain a uniformly mixed slurry The uniformly mixed slurry is spray-dried, the inlet temperature is 350 °C, and the outlet temperature is 100 °C to obtain spherical precursors; the spherical precursors are calcined at 500-700 °C for 3-6 hours, and then calcined at 700-800 °C 12-16h to obtain spherical chromium-doped lithium manganate Li 1.05 Cr 0.04 Mn 1.96 O 4 .

[0027] The battery performance tests of the obtained materials all used 2025 type button cells, which were assembled in a glove box filled with high-purity argon gas. The negative electrode adopts metal lithium sheet, the diaphragm adopts Celgard 2300 PP / PE / PP three-layer microporous composite membrane, and the electrolyte adopts 1mol·L -1 LiPF 6 / EC:DMC (1:1), where EC is ethylene c...

Embodiment 2

[0028] Example 2: Mix 500g of manganese dioxide (EMD), 123g of lithium carbonate, 62g of aluminum acetate, and 30g of PEG, add 1L of deionized water, and perform mechanical ball milling for 0.5-5h to obtain a uniformly mixed slurry; The material is spray-dried with an inlet temperature of 350 °C and an outlet temperature of 120 °C to obtain spherical precursors; the spherical precursors are calcined at 500-700 °C for 3-6 h, and then calcined at 700-800 °C for 12-16 h to obtain spherical aluminum-doped Lithium manganate Li 1.1 Al 0.1 Mn 1.9 O 4 . The battery was prepared according to the method of Example 1 and tested. Under the condition of charge and discharge rate of 0.2C, the initial discharge capacity of the material reaches 104.3mAh·g -1 , the capacity remains at 96.5mAh g after 50 cycles -1 , the capacity retention rate is only 93%.

Embodiment 3

[0029] Example 3: Mix 500g of manganese dioxide (CMD), 118g of lithium carbonate, 137g of magnesium acetate (tetrahydrate), and 30g of PVA, add 1L of deionized water, and perform mechanical ball milling for 0.5-5h to obtain a uniformly mixed slurry; The uniformly mixed slurry is spray-dried with an inlet temperature of 350°C and an outlet temperature of 120°C to obtain spherical precursors; the spherical precursors are calcined at 500-700°C for 3-6h, and then calcined at 700-800°C for 12-16h Obtain spherical magnesium-doped lithium manganate LiMg 0.2 Mn1.8 O 4 . The battery was prepared according to the method of Example 1 and tested. Under the condition of charge and discharge rate of 0.2C, the initial discharge capacity of the material reaches 111mAh·g -1 , the capacity remains at 101.7mAh g after 50 cycles -1 , the capacity retention rate is 92%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com