Method for preparing rare earth-doped yag nano-powder by partial liquid phase precipitation method

A yttrium aluminum garnet and rare earth doping technology is applied in chemical instruments and methods, rare earth metal compounds, alumina/aluminum hydroxide, etc., and can solve the problems of high cost, poor powder dispersion, and unfavorable large-scale production, etc. Achieve the effect of facilitating washing, high light-to-light conversion efficiency, and avoiding aluminum loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

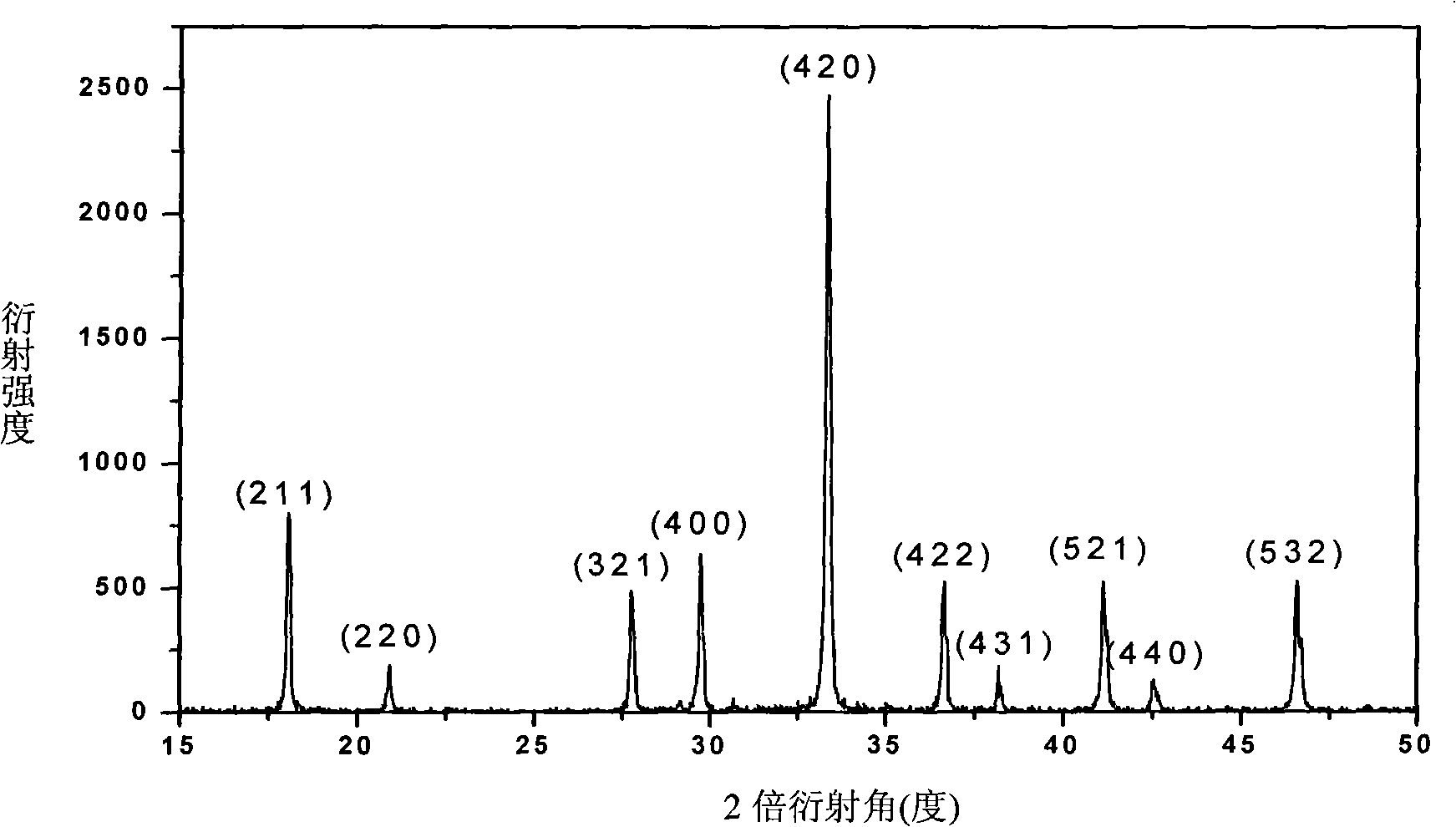

[0034] Embodiment 1: 2%Nd: the ammonium oxalate reverse drip method synthesis of YAG nanopowder

[0035] This batch of Al was measured by thermogravimetric experiment 2 o 3 The aluminum element in the powder is converted into pure Al 2 o 3 95.305%, 5N purity Y 2 o 3 Coarse powder is dissolved in high-purity concentrated nitric acid in a 90°C water bath to prepare 1mol / L Y(NO 3 ) 3 solution, 5N purity Nd 2 o 3 Dissolve in dilute nitric acid to make 0.5mol / L Nd(NO 3 ) 3 .

[0036] 1. Add 0.002g PVP to 40ml of 1mol / L ammonium oxalate (pH=4), mix well, weigh 1.337gAl 2 o 3 Powder. Add it into the mixture, ultrasonically disperse for 30 minutes, and stir in a water bath at 40°C with strong magnetic force to form a uniform suspension.

[0037] 2. Measure 14.7ml of 1mol / L Y(NO 3 ) 3 and 0.6ml of 0.5mol / L Nd(NO 3 ) 3 , diluted to 50ml with deionized water, mixed evenly and added dropwise to the above suspension at a rate of 4ml / min, and then continued to stir and age...

Embodiment 2

[0040] Embodiment 2: 2%Nd: the ammonium oxalate positive drop method synthesis of YAG nanopowder

[0041] 1. Measure 14.7ml of 1mol / L Y(NO 3 ) 3 and 0.6ml of 0.5mol / L Nd(NO 3 ) 3 , diluted to 50ml with deionized water, added 0.01mL oleic acid, mixed well, weighed 1.337gAl 2 o 3 Powder (this batch of Al was measured by thermogravimetric experiment 2 o 3 The aluminum element in the powder is converted into pure Al 2 o 3 is 95.305%). Add it into the mixture, ultrasonically disperse for 30min, and then stir strongly with magnetic force to form a uniform suspension.

[0042] 2. Measure 25ml of 1mol / L ammonium oxalate (PH=4), add it dropwise at a rate of 2ml / min into the above high-intensity stirred suspension, and continue to stir and age for 12 hours.

[0043] 3. After aging, filter and wash with a vacuum filtration device, wash with deionized water for 3 times, and wash with absolute ethanol for 2 times.

[0044] 4. Under normal pressure, dry the precipitate filter cak...

Embodiment 3

[0045] Embodiment 3: 2%Nd: the ammonium bicarbonate back-drop method synthesis of YAG nanopowder

[0046] This batch of Al was measured by thermogravimetric experiment 2 o 3 The aluminum element in the powder is converted into pure Al 2 o 3 95.305%, 5N purity Y 2 o 3 Coarse powder is dissolved in high-purity concentrated nitric acid in a 90°C water bath to prepare 1mol / L Y(NO 3 ) 3 solution, 5N purity Nd 2 o 3 Dissolve in dilute nitric acid to make 0.5mol / L Nd(NO 3 ) 3

[0047] 1. To 60ml of 2mol / L NH 4 HCO 3 Add 0.001g of PVP, mix well, weigh 1.337g of light Al 2 o 3 . Add it into the mixture, ultrasonically disperse for 30 minutes, and stir strongly at room temperature to form a uniform suspension.

[0048] 2. Measure 14.7ml of 1mol / L Y(NO 3 ) 3 and 0.6ml of 0.5mol / L Nd(NO 3 ) 3 , diluted to 50ml with deionized water, mixed evenly and added dropwise to the above suspension at a rate of 4ml / min, and then continued to stir and age for 12 hours.

[0049] 3....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com