Anion-cation co-doped modified lithium-rich manganese composite positive electrode material and preparation method thereof

A composite cathode material, anion and cation technology, applied in the direction of positive electrode, active material electrode, battery electrode, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The invention provides a method for preparing an anion-cation co-doped modified lithium-rich manganese composite positive electrode material, comprising the following steps:

[0038] The nickel-cobalt-manganese oxide precursor, dopant and lithium source are magnetically stirred and mixed in a solvent, dried and calcined to obtain a lithium-rich manganese composite positive electrode material modified by anion and cation co-doping modification;

[0039] The dopant is a cationic salt and an anionic salt; the cationic salt is selected from one or more of sodium salt, potassium salt, rubidium salt and cesium salt; the anionic salt is selected from fluorine salt, chlorine salt, sulfur One or more of salt and phosphorus salt.

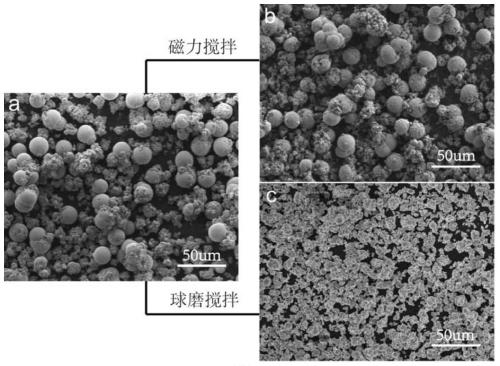

[0040] The present invention mixes nickel-cobalt-manganese oxide precursors, dopants and lithium sources by means of magnetic stirring. This mixing method can not only maintain the morphology of the precursors to the greatest extent, but also obtain th...

Embodiment 1

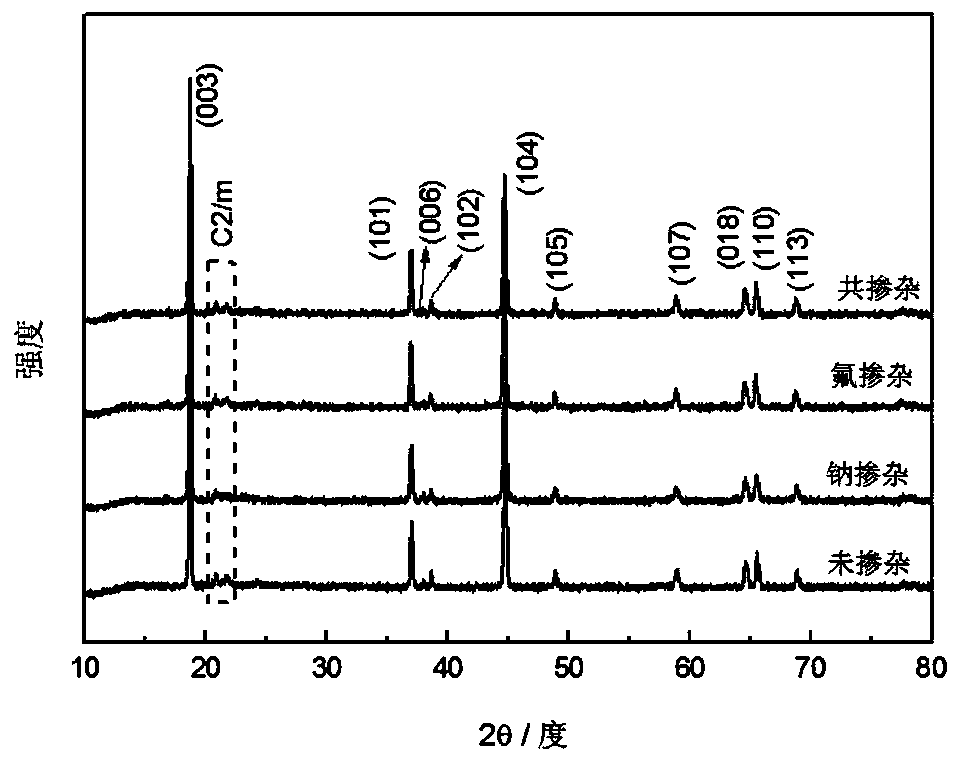

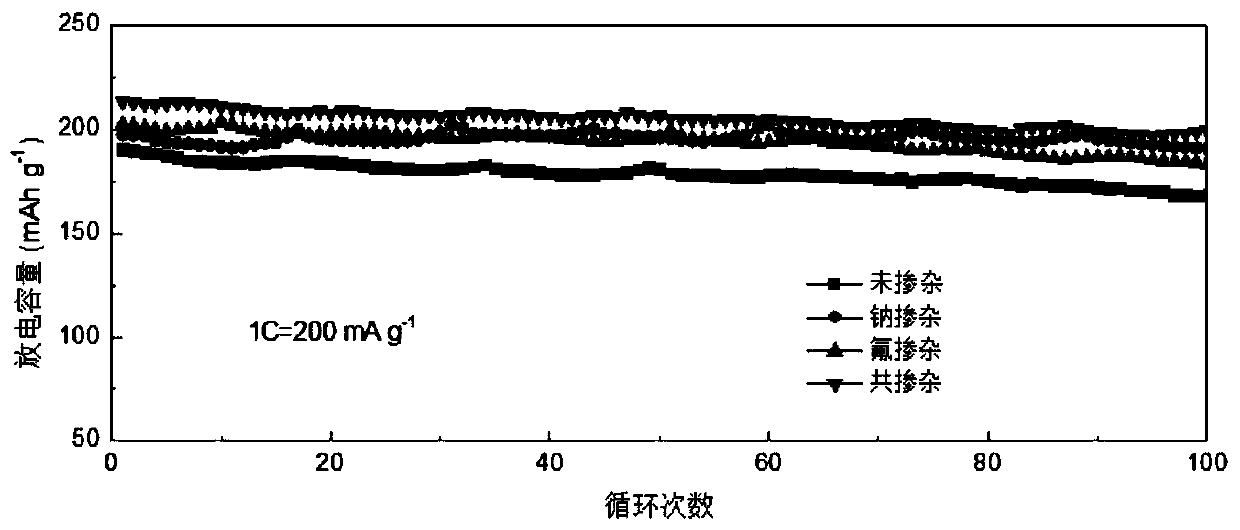

[0078] The positive electrode material is an initial spherical lithium-rich manganese positive electrode Li 1.2 Ni 0.13 co 0.13 mn 0.54 o 2 , Na and F monodoped cathode Li 1.15 Na 0.05 Ni 0.13 co 0.13 mn 0.54 o 2 , Li 1.2 Ni 0.13 co 0.13 mn 0.54 o 1.95 f 0.05 , Na and F co-doped positive Li 1.15 Na 0.05 Ni 0.13 co 0.13 mn 0.54 o 1.95 f 0.05 , the specific operation is as follows:

[0079] The molar concentration is the mixed metal ion solution (200ml) of the nickel sulfate of 2M, cobalt sulfate, manganese sulfate (Ni:Co:Mn molar ratio is 0.13:0.13:0.54) and the excessive 5% sodium carbonate of 2M and 0.15M Ammonia solution (200ml) was slowly added dropwise into the reaction kettle with a peristaltic pump respectively, the reaction temperature was controlled at 50°C, pH=7.9, the stirring speed was 800r / min, and the reaction was aged for 20h after the dropwise addition. Then the obtained precipitate was filtered, washed, and dried at 80° C. for 24 hours to...

Embodiment 2

[0086] The modified lithium-rich manganese-based oxide cathode material is a co-doped spherical lithium-rich manganese cathode material obtained by co-doping sodium carbonate and lithium fluoride: Li 1.15 Na 0.05 Ni 0.13 co 0.13 mn 0.54 o 1.95 f 0.05 , the specific operation is as follows:

[0087] The mixed metal ion solution (200ml) that molar concentration is the nickel sulfate of 2M, cobalt sulfate, manganese sulfate (Ni:Co:Mn molar ratio is 0.13:0.13:0.54), the excessive 5% sodium carbonate solution of 2M and 0.15M Aqueous ammonia solution (200ml) was slowly added dropwise into the reaction kettle with a peristaltic pump respectively, the reaction temperature was controlled to be 50°C, pH=7.95, and the stirring speed was 800r / min. The material was filtered, washed, and dried at 80°C for 24 hours to obtain a spherical nickel-cobalt-manganese carbonate precursor.

[0088] Accurately weigh 4.875g of the quasi-spherical nickel-cobalt-manganese carbonate precursor, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coulombic efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com