Preparation method for nano hydroxylapatite doped with metal ions

A nano-hydroxyapatite and metal ion technology is applied in the fields of biomedicine and nano-material preparation, which can solve the problems of complicated operation, long preparation period, complicated sol-gel process, etc., and achieves easy control of dosage and uniform doping. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

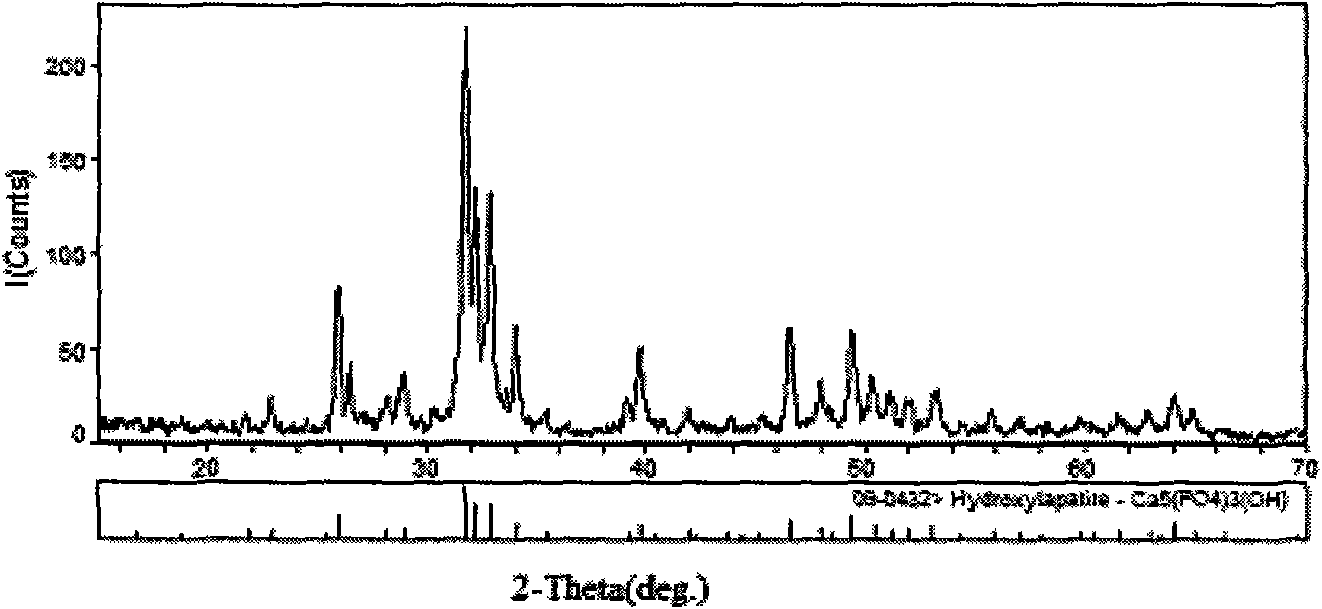

[0014] Embodiment 1, at first, prepare respectively the Ca(NO 3 ) 2 and (NH 4 ) 2 HPO 4 solution, and by Ca(NO 3 ) 2 and (NH 4 ) 2 HPO 4 The volume ratio is 1.67 mixed with HNO 3 Adjust the pH of the mixed solution to 3 , where AgNO 3 Mass: The volume of solution A is 1×10 -4 (g): 1 (ml), then use HNO 3 Adjust the pH of the mixed solution 2 ) 2 Obtain solution C, wherein, CO(NH 2 ) 2 Quality: The volume of solution B is 0.06 (g): 1 (ml); Finally, under magnetic stirring, solution C was heated and refluxed at 100°C for 4 hours. After the reaction, it was naturally cooled to room temperature, then vacuum filtered and water After washing, it was dried at 100° C. for 24 hours to finally obtain Ag ion-doped nano-hydroxyapatite crystals. see figure 1 , the results show that the obtained sample is a pure nano-hydroxyapatite crystal, and the grain size calculated by the Sherri formula based on the (002) crystal plane is 28.7nm. There is no crystal line of silver and it...

Embodiment 2

[0015] Embodiment 2, at first, prepare respectively the Ca(NO 3 ) 2 and (NH 4 ) 2 HPO 4 solution, and by Ca(NO 3 ) 2 and (NH 4 ) 2 HPO 4 The volume ratio is 1.67 mixed with HNO 3 Adjust the pH of the mixed solution 3 ) 3 , where La(NO 3 ) 3 Mass: The volume of solution A is 3×10 -4 (g): 1 (ml), then use HNO 3 Adjust the pH of the mixed solution 2 ) 2 Obtain solution C, wherein, CO(NH 2 ) 2 Quality: the volume of solution B is 0.03 (g): 1 (ml); finally, under magnetic stirring, solution C was heated to reflux at 100°C for 3 hours, after the reaction was completed, it was naturally cooled to room temperature, then vacuum filtered and washed with water After washing, it was dried at 100° C. for 24 hours, and finally La ion-doped nano-hydroxyapatite crystals were obtained.

Embodiment 3

[0016] Embodiment 3, at first, prepare respectively the Ca(NO of 0.2mol / L 3 ) 2 and (NH 4 ) 2 HPO 4 solution, and by Ca(NO 3 ) 2 and (NH 4 ) 2 HPO 4 The volume ratio is 1.67 mixed with HNO 3 Adjust the pH of the mixed solution 3 ) 2 , where Cu(NO 3 ) 2 Mass: The volume of solution A is 5×10 -4 (g): 1 (ml), then use HNO 3 Adjust the pH of the mixed solution 2 ) 2 Obtain solution C, wherein, CO(NH 2 ) 2 Quality: The volume of solution B is 0.05 (g): 1 (ml); Finally, under magnetic stirring, solution C was heated and refluxed at 100°C for 5 hours. After the reaction, it was naturally cooled to room temperature, then vacuum filtered and water After washing, it was dried at 100° C. for 24 hours to finally obtain Cu ion-doped nano-hydroxyapatite crystals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com