Absorbing core for treating excrement and manufacturing method for absorbing core

A technology for absorbing cores and manufacturing methods, which is applied in the field of personal hygiene products, can solve the problems of weakening the function of SAP, insufficient bonding strength, and insufficient space, and achieves increased liquid absorption, stable overall structure, and increased utilization rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

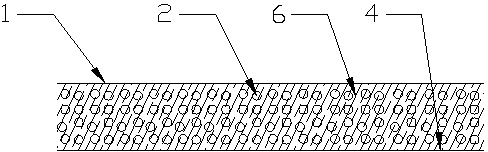

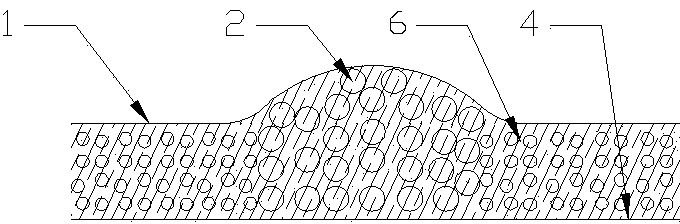

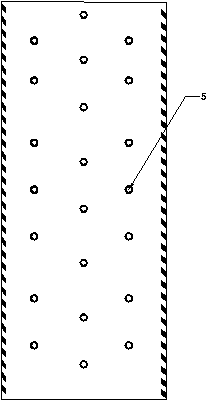

[0041] Such as Figure 3 ~ Figure 6 , an absorbent core for treating excrement, comprising a non-woven surface layer 1, a non-woven bottom layer 4, and a SAP layer formed by covering the surface layer 1 and the bottom layer 4 with SAP2, wherein a supporting structure layer 3 is arranged in the middle of the SAP layer, The absorbent core is divided into small pieces of absorbent core structure by the heat-melt adhesive part 5, each small piece of absorbent core protrudes relative to the heat-melt adhesive part 5 in the thickness direction, and the adjacent small piece of absorbent core The hot-melt bonding portion 5 between them forms a depression, and the hot-melt bonding portion 5 generated during hot rolling during the production process is rolled through to form a through hole.

[0042] The manufacturing method of the absorbent core for treating excrement in this embodiment includes the following steps:

[0043] (I) Spread the SAP2 evenly on the bottom layer 4 with a sprea...

Embodiment 2

[0049] Such as Figure 7 ~ Figure 9 As shown, repeat Example 1, the difference is that the absorbent core for treating excrement removes the middle support structure layer 3, and becomes only the non-woven fabric surface layer 1, the non-woven fabric bottom layer 4 and the surface layer 1 and A three-layer structure formed by the bottom layer 4 coated SAP layer.

[0050] Correspondingly, the steps of the manufacturing method in this embodiment omit the steps (II) and (III) in the above-mentioned embodiment 1.

Embodiment 3

[0052] Repeat Example 1, except that, as Figure 10 As shown, in the steps of the manufacturing method of this embodiment, the process of applying the hot roll to the laid material in step (II) of the above-mentioned embodiment 1 for preliminary thermal bonding and setting is omitted, but until the covering of the surface material is completed Afterwards, proceed directly to the final thermobonding setting.

[0053]The above are only illustrations and descriptions of the preferred embodiments of the present invention, and the structure of the absorbent core of the present invention can also be changed or replaced, such as: after the step (Ⅲ) of Embodiment 1, a layer of supporting structure layer 3 is covered , and spread another layer of SAP2 on the covered support structure layer 3, and then cover the surface layer material, so that another layer of SAP layer is superimposed, so that the absorbent core has better liquid absorption capacity. Of course, more support structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com