Method for preparing three-dimensional electrostatic-spinning nonwoven support material and device thereof

A scaffold material and electrospinning technology, applied in the preparation method and device field of three-dimensional electrospun nonwoven scaffold materials, can solve the problems of inability to form in one step, complicated production process, low yield, etc. Fluffy support structure and improved yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

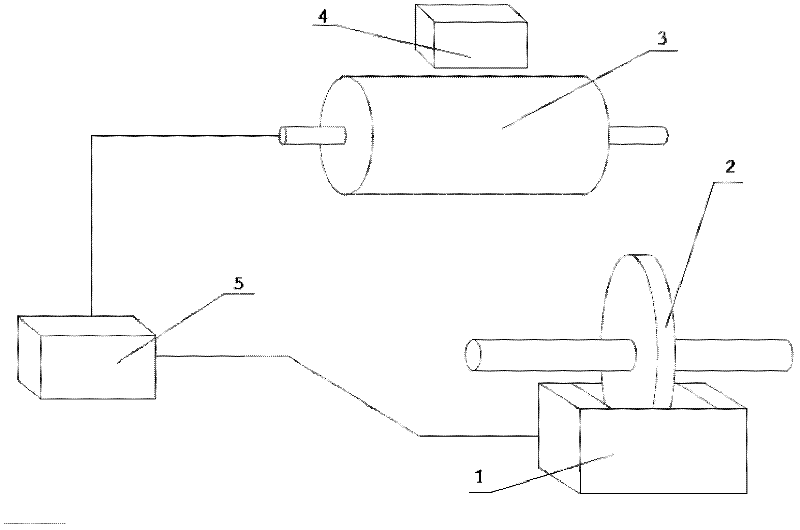

[0031] According to the aforementioned preparation of the three-dimensional electrospinning nonwoven support material in the present invention, including the preparation of the spinning solution, the setting of the electrospinning parameters, the steps of fiber collection and vacuum drying, the following process conditions are adopted:

[0032] (1) Cellulose acetate butyrate is dissolved in the mixed solvent of acetone / dimethylformamide (volume ratio 2 / 1), obtains the spinning solution that concentration is 1.2 g / ml after stirring;

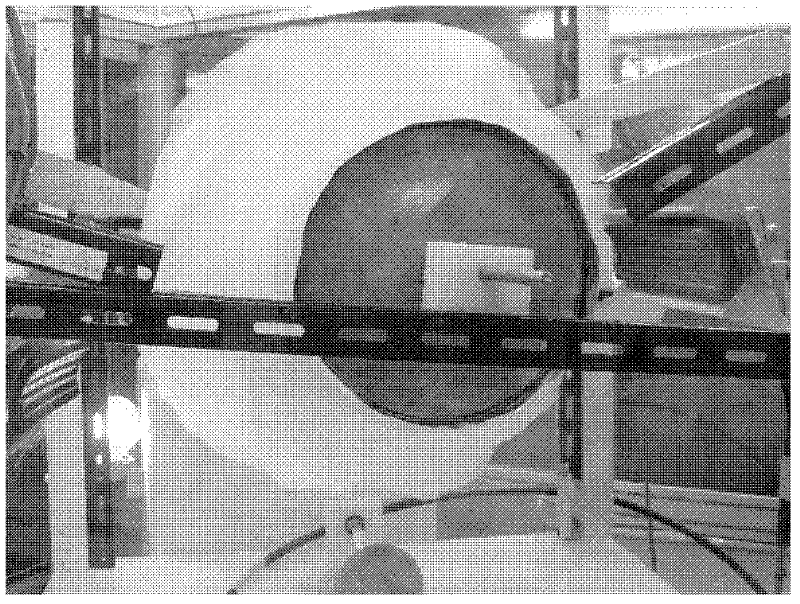

[0033] (2) Pour the spinning solution into the solution tank, ground the receiving roller, apply 50 kilovolts of high-voltage static electricity to the spinning solution to carry out electrospinning, the rotating speed of the spinning turntable is 50 rpm, and the rotating speed of the receiving roller is 20 rpm , the distance between the turntable and the roller is 18 cm, and the peripheral temperature of the receiving roller is controlled at 120 d...

Embodiment 2

[0038] According to the aforementioned preparation of the three-dimensional electrospinning nonwoven support material in the present invention, including the preparation of the spinning solution, the setting of the electrospinning parameters, the steps of fiber collection and vacuum drying, the following process conditions are adopted:

[0039] (1) Cellulose acetate butyrate is dissolved in the mixed solvent of acetone / dimethylformamide (volume ratio 2 / 1), obtains the spinning solution that concentration is 1.4 g / ml after stirring;

[0040] (2) Pour the spinning solution into the solution tank, ground the receiving roller, apply 50 kilovolts of high-voltage static electricity to the spinning solution to carry out electrospinning, the rotating speed of the spinning turntable is 50 rpm, and the rotating speed of the receiving roller is 40 rpm , the distance between the turntable and the roller is 25 cm, and the peripheral temperature of the receiving roller is controlled at 80 de...

Embodiment 3

[0045] According to the aforementioned preparation of the three-dimensional electrospinning nonwoven support material in the present invention, including the preparation of the spinning solution, the setting of the electrospinning parameters, the steps of fiber collection and vacuum drying, the following process conditions are adopted:

[0046] (1) polystyrene is dissolved in the mixed solvent of acetone / dimethylformamide (volume ratio 2 / 1), obtains the spinning solution that concentration is 1.0 g / ml after stirring;

[0047] (2) Pour the spinning solution into the solution tank, ground the receiving roller, apply 60 kilovolts of high-voltage static electricity to the spinning solution to carry out electrospinning, the rotating speed of the spinning turntable is 50 rpm, and the rotating speed of the receiving roller is 60 rpm , the distance between the turntable and the roller is 18 cm, and the peripheral temperature of the receiving roller is controlled at 110 degrees Celsius ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com