Two-component sound absorption and heat insulation cotton based on polypropylene superfine fibers and polyester staple fibers and preparation method thereof

A polyester staple fiber, polypropylene fiber technology, applied in textiles, papermaking, non-woven fabrics and other directions, can solve the problems of high air resistance, brittleness, skin irritation, etc., to increase service life, good filtering effect, and improve sound absorption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

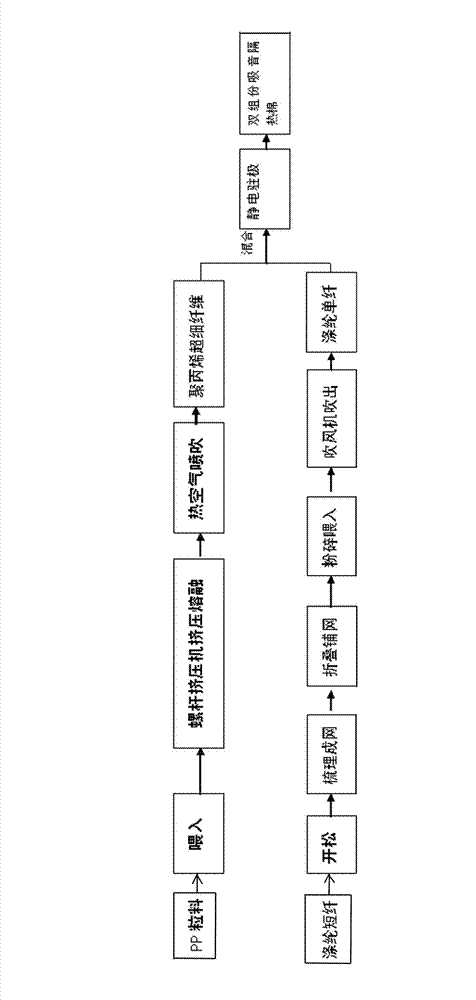

[0021] Refer to attached figure 1 The composition of the two-component sound-absorbing and heat-insulating cotton based on polypropylene superfine fiber and polyester staple fiber includes polypropylene superfine fiber and polyester staple fiber, wherein the average fineness of polypropylene fiber is 1-2 μm, and the polyester staple fiber The fineness is 25-35μm. The two-component material mixed with these two components is subjected to electrostatic electret to form a two-component sound-absorbing and heat-insulating cotton. The electrostatic electret voltage is 50-70KV.

[0022] The content of the polypropylene superfine fiber accounts for 65%-80% of the whole sound-absorbing and heat-insulating cotton.

[0023] The mass ratio of the polypropylene superfine fiber and polyester staple fiber is 70:30.

[0024] The preparation method of the two-component sound-absorbing and heat-insulating cotton based on polypropylene microfiber and polyester staple fiber is as follows:

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com