Laser-cladded composite wear-resisting layer on surfaces of copper and copper alloys and preparation method

A laser cladding and copper alloy technology, applied in the field of material science, can solve the problems of high price, complex process, insufficient coating toughness, etc., and achieve the effect of compact structure, high efficiency and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

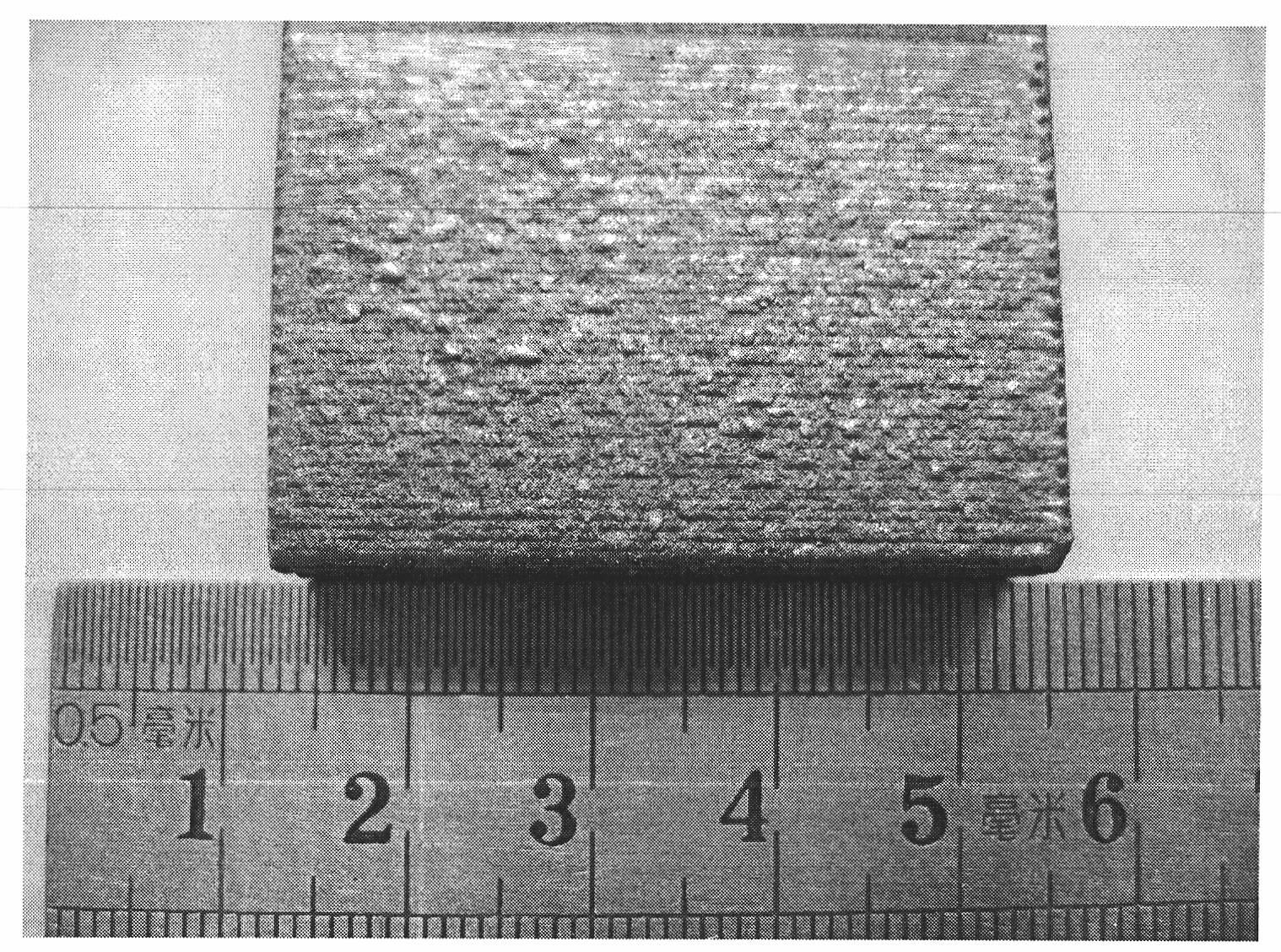

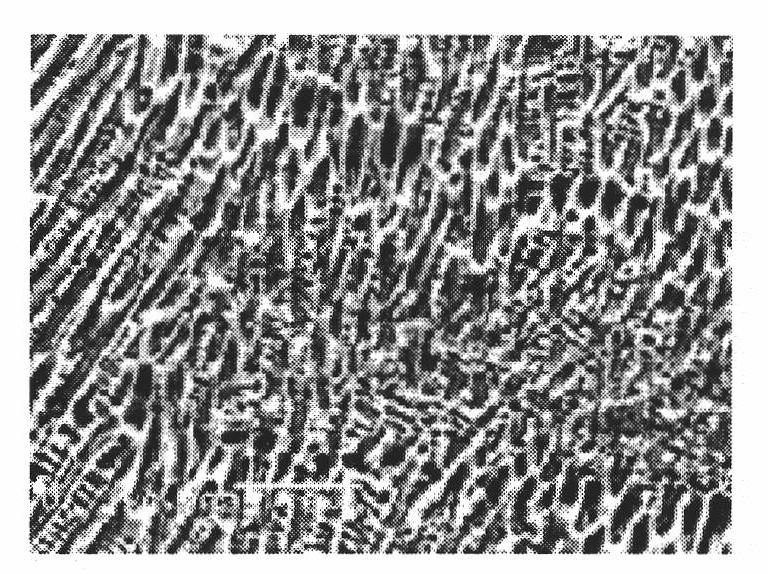

[0030] In this embodiment, a pulsed Nd:YAG laser is used on the surface of a red copper plate of 500×200×10mm to carry out laser cladding of a composite wear-resistant layer, and its preparation method is carried out according to the following steps:

[0031] 1. Copper plate surface activation treatment

[0032] Sand blast the surface of the copper plate with a thickness of 10mm or use 60# coarse sandpaper to roughen the copper plate to remove surface rust to enhance the bonding strength between the copper alloy surface and the cladding layer, and then clean it with acetone to remove oil and carry out Dry at low temperature (<100°C) or air dry naturally.

[0033] 2. Preparation of nickel-based alloy raw materials, preset transition layer

[0034]The nickel-based alloy raw materials for the transition layer are prepared according to the following composition (weight percentage): Cu 20.0%, Al 6.0%, Si 0.3%, Zr 1.7%, and the balance is Ni. The particle size of each of the above...

Embodiment 2

[0045] In this embodiment, a pulsed Nd:YAG laser is used to laser clad a composite wear-resistant layer on the surface of the copper plate of the continuous casting slab crystallizer. The copper plate is a Cr-Zr-Cu alloy. One end requires a coating thickness of 0.8mm, and the other end requires a thickness of 2.0mm. . The preparation method proceeds as follows:

[0046] 1. Copper plate surface pretreatment

[0047] Use 60# coarse sandpaper to manually polish the surface of the crystallizer copper plate to remove oxides and rust, and then clean the surface with acetone to remove oil.

[0048] 2. Preparation of nickel-based alloy raw materials

[0049] The nickel-based alloy raw material for the transition layer is prepared according to the following composition (weight percentage): Cu 30.0%, Al 8.0%, Si 0.6%, Zr 2.4%, and the balance is Ni. The particle size of the above-mentioned raw materials is 200-400 mesh, and they are uniformly mixed.

[0050] 3. Prepare transition la...

Embodiment 3

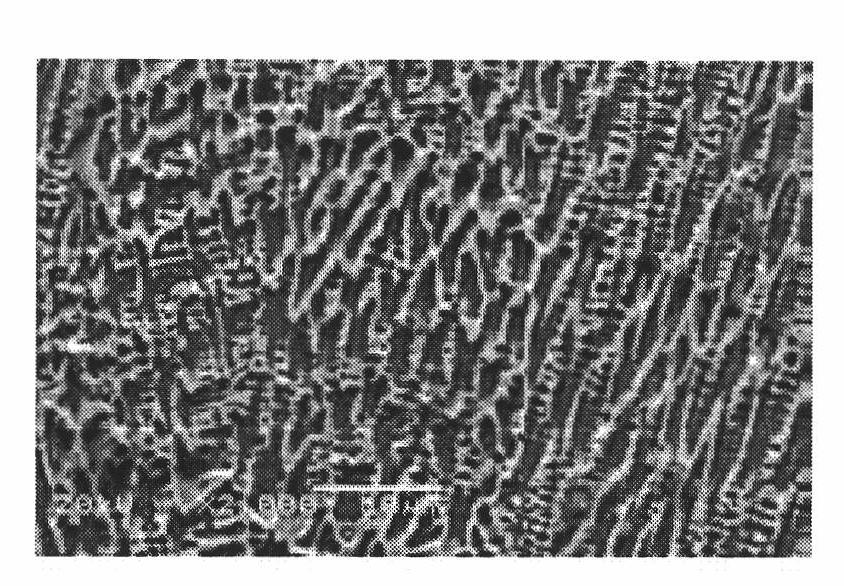

[0059] The present invention carries out laser laser cladding composite wear-resistant layer on the surface of phosphorus deoxidized copper (TP1), and the preparation method is carried out according to the following steps:

[0060] 1. Copper plate surface pretreatment

[0061] The surface is sandblasted to remove oxides and rust, and then the surface is cleaned with acetone to remove oil.

[0062] 2. Preparation of nickel-based alloy raw materials, preset, laser cladding to prepare transition layer

[0063] The nickel base alloy raw material for the transition layer is prepared according to the following composition (weight percentage): Cu 25%, Al 7%, Si 0.5%, Zr 2.0%, and the balance is Ni. The particle size of the above-mentioned raw materials is 200-400 mesh, and they are uniformly mixed.

[0064] 3. Prepare transition layer by presetting and laser cladding

[0065] The above-mentioned nickel-based alloy powder is sent into the laser melting pool by a roller-type negativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com