Magnetic super-hydrophobic fabric and preparation method thereof

A super-hydrophobic, fabric technology, applied in plant fibers, animal fibers, textiles and papermaking, etc., can solve the problems of complex preparation process, single function, harsh reaction conditions, etc., and achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Add 2g of iron ferric oxide nanoparticles with a particle size of 20-40nm to 75g of ethanol for ultrasonic dispersion for 10min, then add 0.5g of tridecafluorooctyltriethoxysilane and 1g of water, and mechanically stir at room temperature for 12h. Then centrifuge at 8000rpm for 40min, and vacuum-dry the obtained product at 60°C for 1h to obtain modified ferric oxide nanoparticles;

[0028] Add 0.22g of modified iron ferric oxide nanoparticles, 0.5g of Sylgard 184 A component and 0.05g of B component into 6.875g of toluene for ultrasonic dispersion for 30min, then put a 2cm×2cm polyester fabric into the room temperature Stir mechanically at a speed of 300rpm for 30min, take out the fabric and place it 2mm below a magnet with a circular cross section and a radius of 2cm for 10min; finally place the fabric at a temperature of 80°C for 2h to obtain a micro-nano rough surface Structured magnetic superhydrophobic fabric.

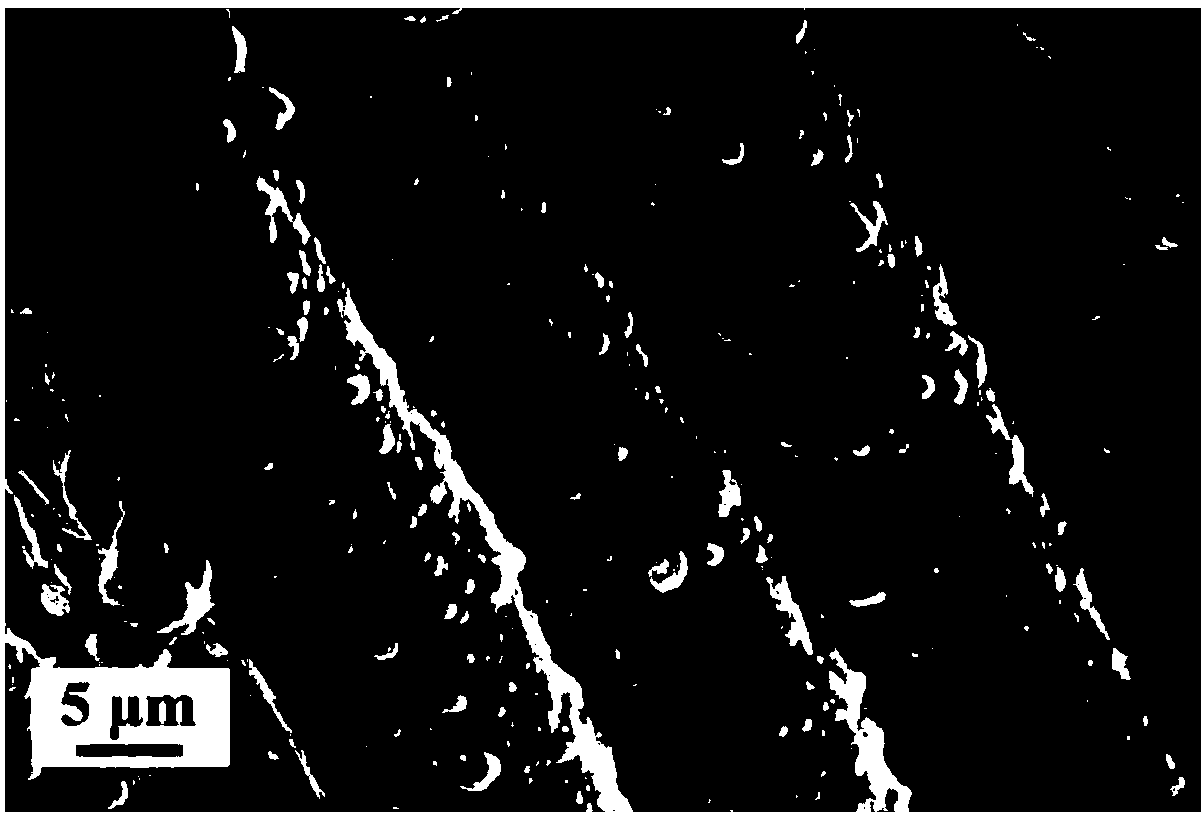

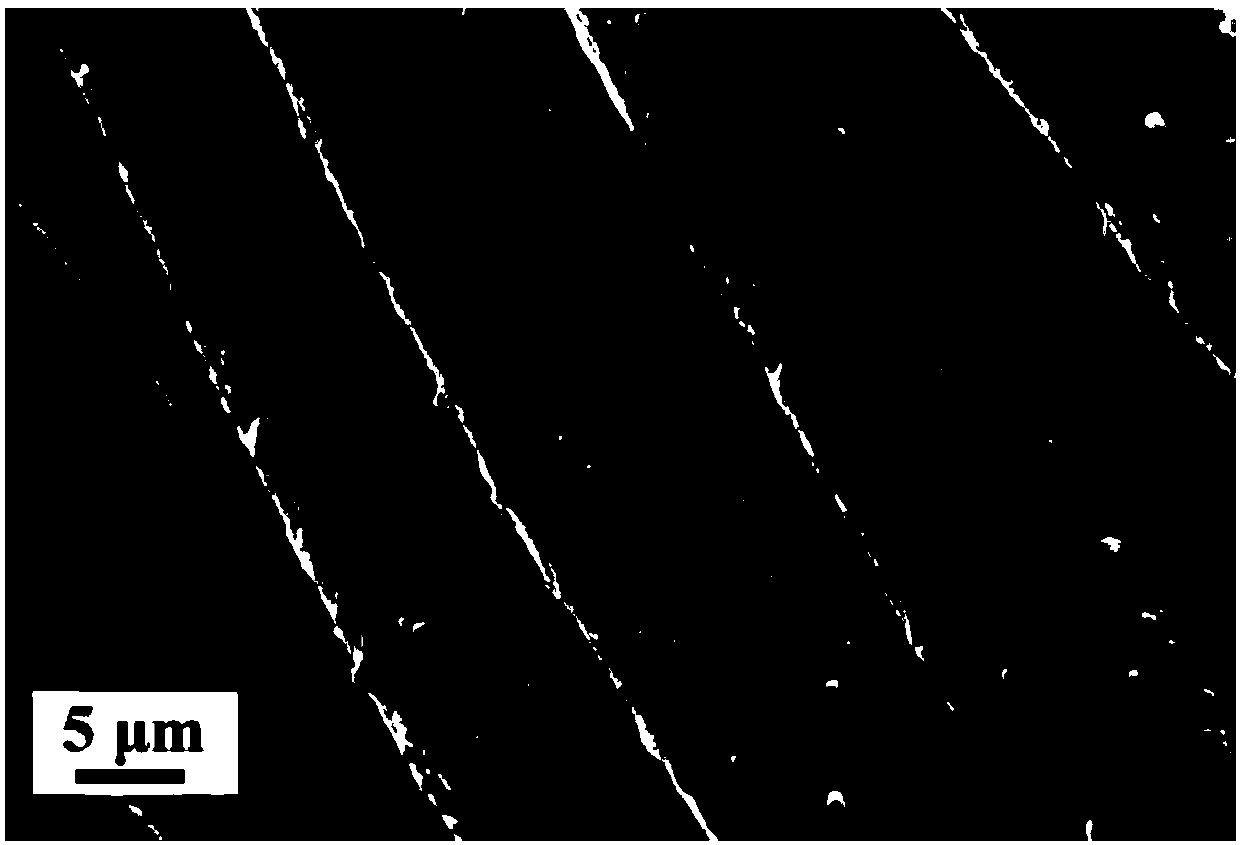

[0029] The front scanning electron microscope image ...

Embodiment 2

[0033]Add 1g of iron ferric oxide nanoparticles with a particle size of 80‐100nm to 50g of ethanol for ultrasonic dispersion for 30min, then add 0.6g of mercaptopropyltriethoxysilane and 2g of water, stir mechanically at room temperature for 3h, and then Centrifuge at 12000rpm for 10min, and vacuum-dry the obtained product at 40°C for 12h to obtain modified ferric oxide nanoparticles; mix 0.033g of modified ferric oxide nanoparticles with 0.3g of Sylgard 184 A component and 0.03 g B component was added to 3.3g tetrahydrofuran and ultrasonically dispersed for 10min, then a 2cm×2cm cotton fabric was placed and mechanically stirred at a speed of 200rpm at room temperature for 20min, the fabric was taken out and placed in a cross-section of 4cm×4cm Keep 1mm below the magnet for 60min; finally, place the fabric at 130°C for 0.5h to prepare a magnetic superhydrophobic fabric with a micro-nano-rough structure on the surface.

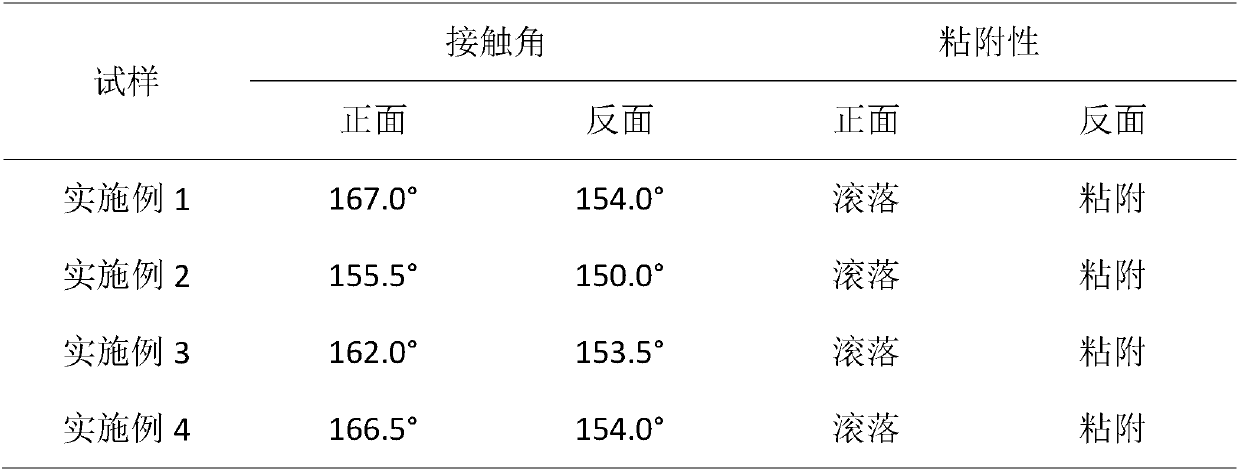

[0034] Table 1 lists the water contact angle of the front...

Embodiment 3

[0036] Add 5g of iron ferric oxide nanoparticles with a particle size of 60‐80nm to 150g of ethanol for ultrasonic dispersion for 60min, then add 1g of aminopropyltriethoxysilane and 3g of water, stir mechanically at room temperature for 12h, and then Centrifuge at a rotating speed for 20min, and vacuum-dry the obtained product at 50°C for 6h to obtain modified ferric oxide nanoparticles; mix 0.11g of modified ferric oxide nanoparticles with 0.4g of Sylgard 184 A component and 0.04g Component B was added to 12.57g of hexane and ultrasonically dispersed for 20min, then a circular nylon fabric with a radius of 2cm was put in and mechanically stirred at a speed of 100rpm at room temperature for 60min, the fabric was taken out and placed in a circular and The magnet with a radius of 3 cm is kept 5 mm below the magnet for 60 min; finally, the fabric is placed at a temperature of 100 °C for 1 h to obtain a magnetic superhydrophobic fabric with a micro-nano rough structure on the surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com