Two-row roller bearing and bearing system with such a roller bearing and a lubricating device

A rolling bearing and lubricating device technology, applied to rolling contact bearings, rotating bearings, bearings, etc., to achieve the effect of reliable lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

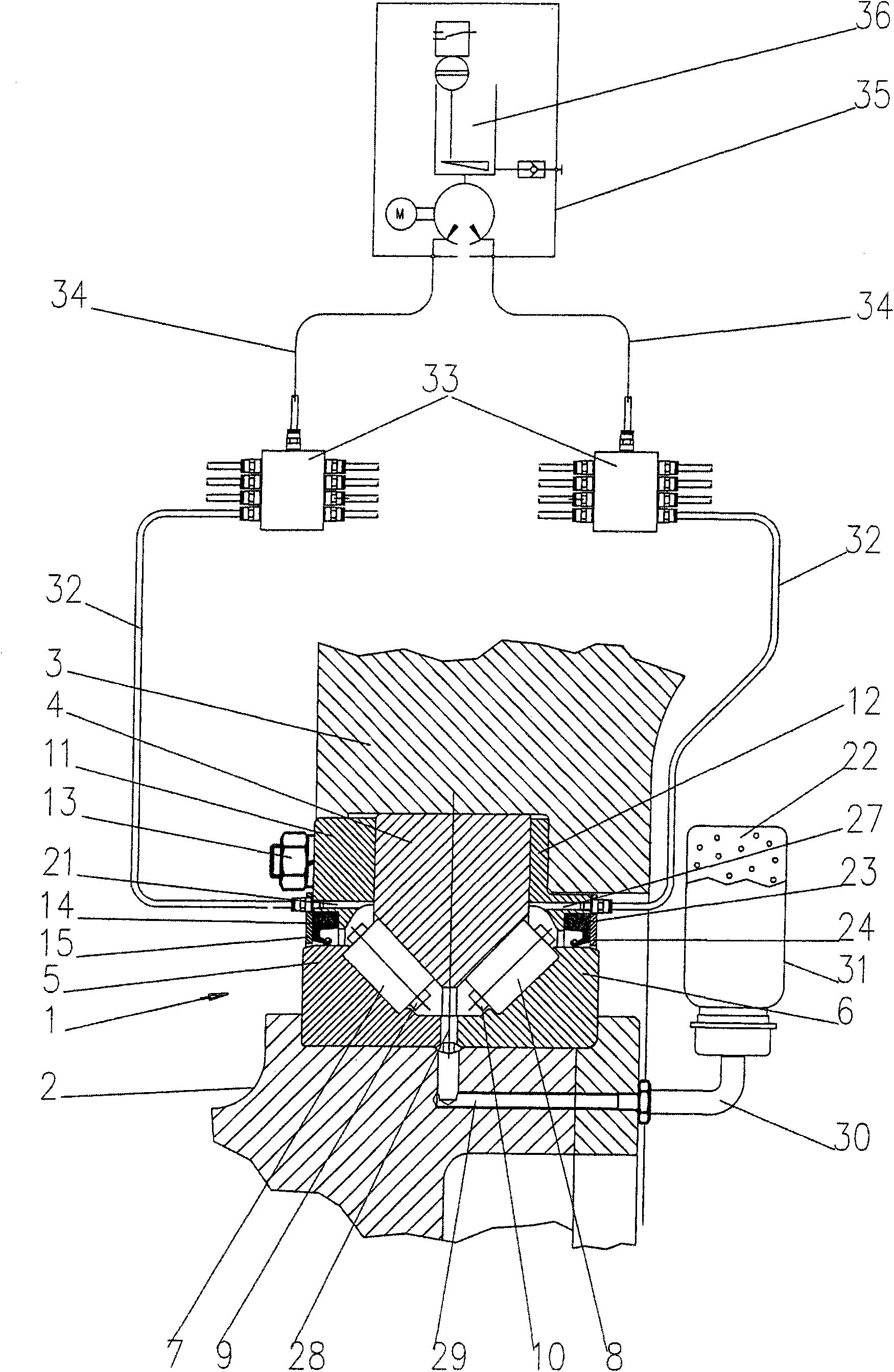

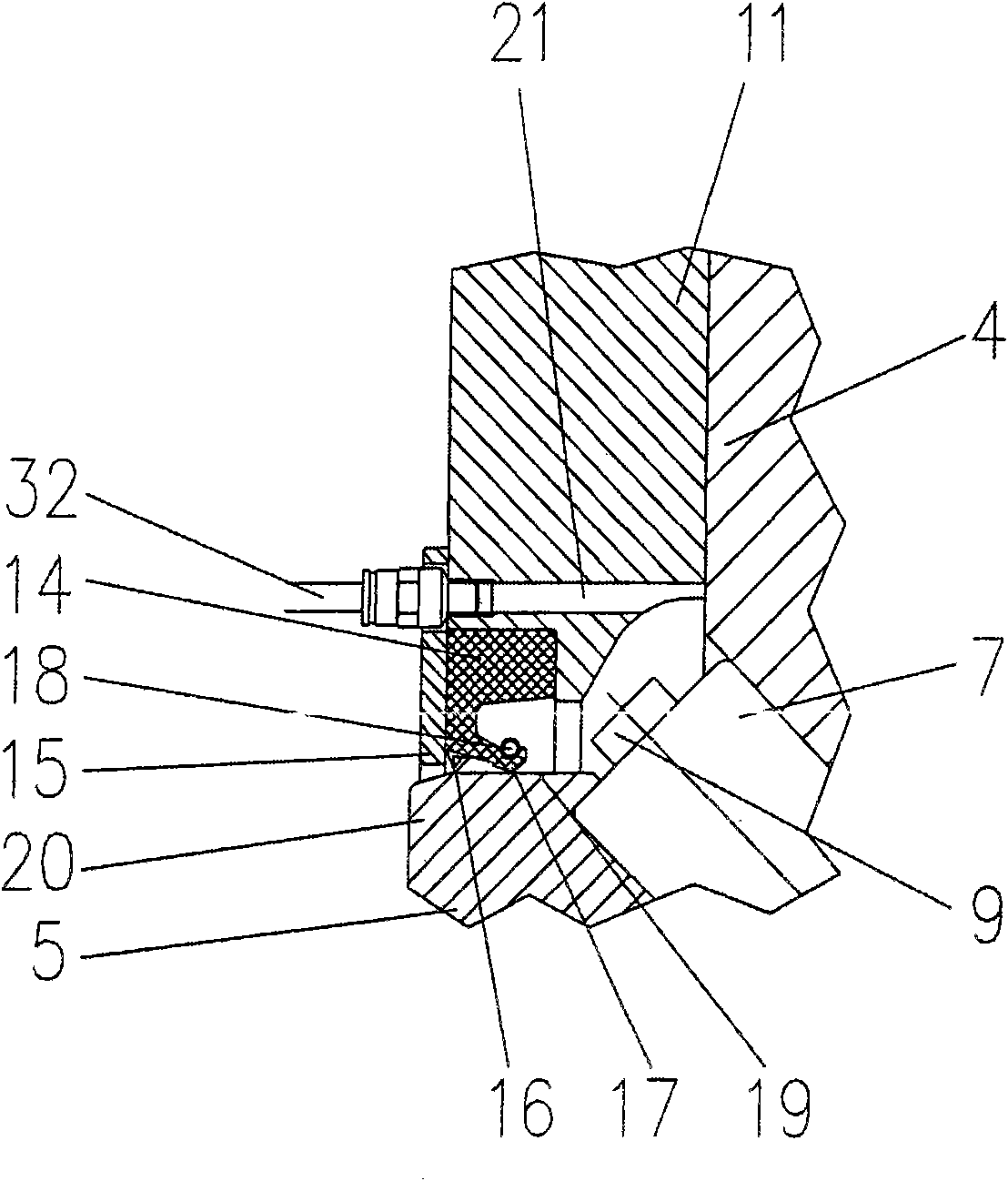

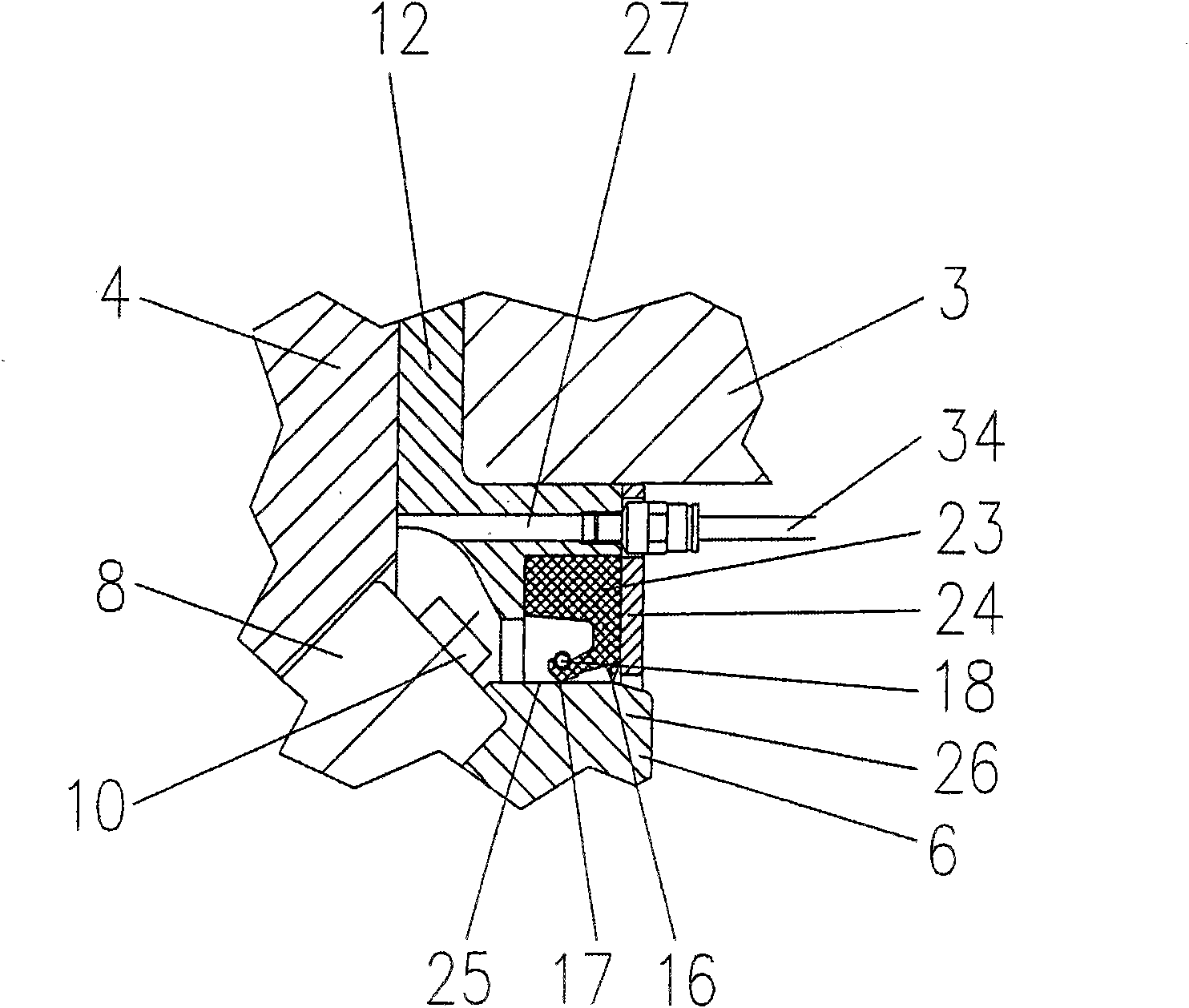

[0027] figure 1 An embodiment of a bearing system designed according to the invention is shown in a sectional view. exist figure 2 with 3 shown in figure 1 A partially enlarged cutaway view of . The illustrated embodiment of the bearing system has an X-shaped tapered roller bearing 1 designed with double row rollers. The tapered roller bearing 1 is used, for example, to rotatably mount a rotor shaft 2 of a wind power plant relative to a bearing housing 3 about an axis of rotation indicated by dotted lines.

[0028] The tapered roller bearing 1 has a fixed outer ring 4 which is arranged in a housing bore of the bearing housing 3 and has two tapered raceways. The outer ring has an outer diameter of at least one meter. Furthermore, the tapered roller bearing 1 has two rotating inner rings 5 and 6 which are arranged axially adjacent to each other on the rotor shaft 2 and each have a conical raceway. In the embodiment shown, the outer ring 4 and the two inner rings 5 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com