Patents

Literature

35results about How to "Achieve pre-assembly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Two-row roller bearing and bearing system with such a roller bearing and a lubricating device

ActiveCN101846129AImprove the lubrication effectFirmly connectedRolling contact bearingsShaftsRolling-element bearingMechanical engineering

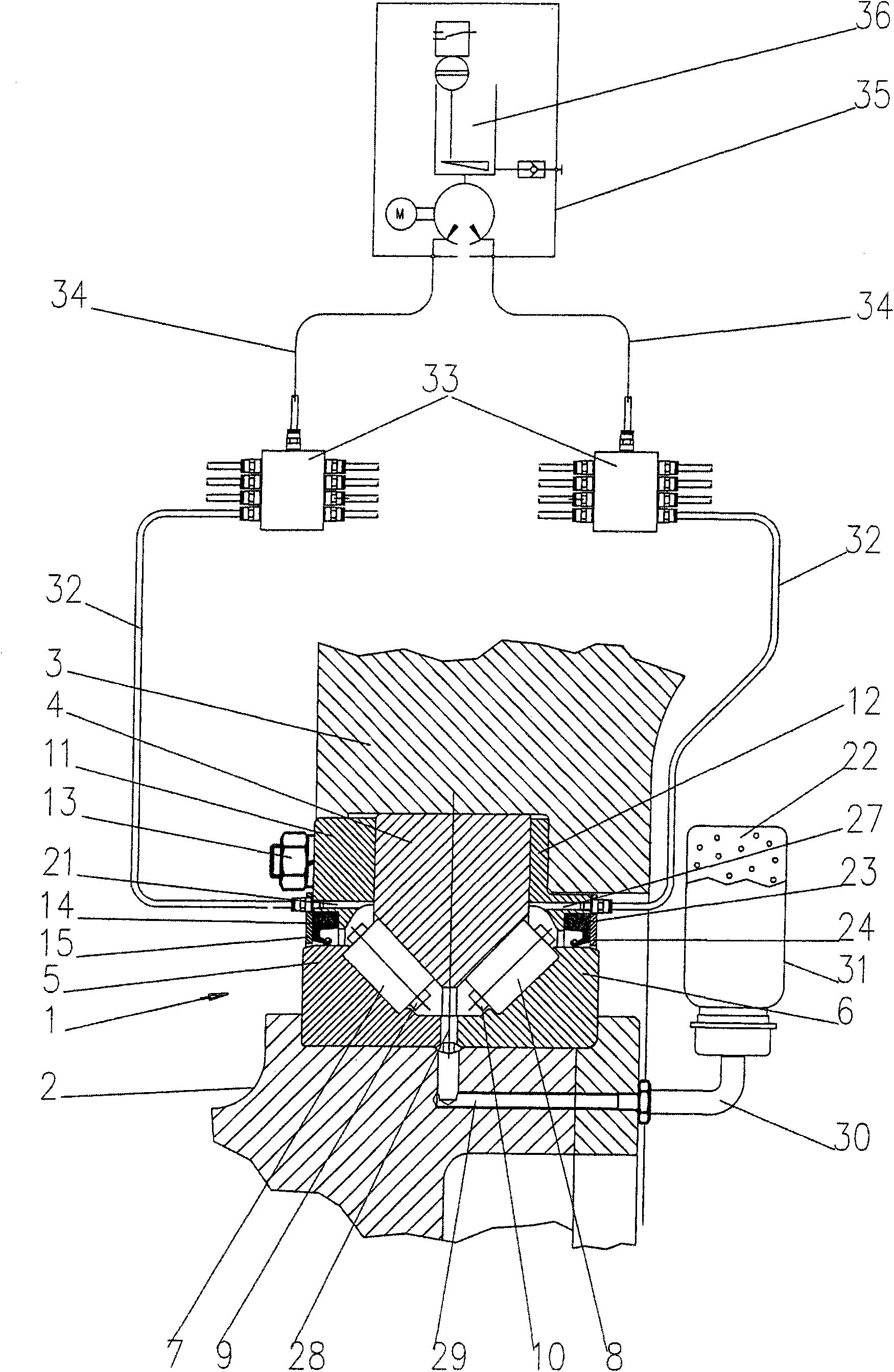

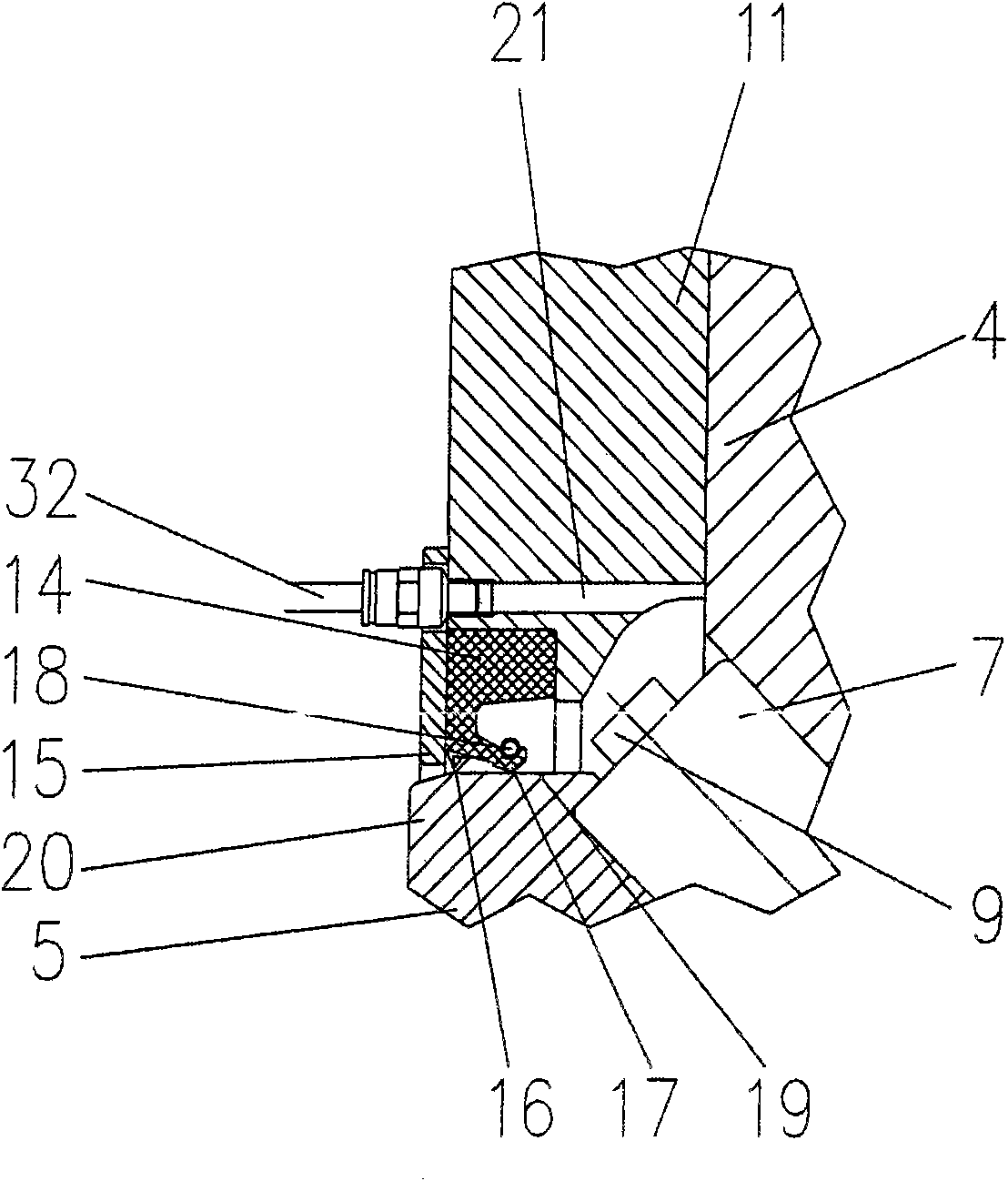

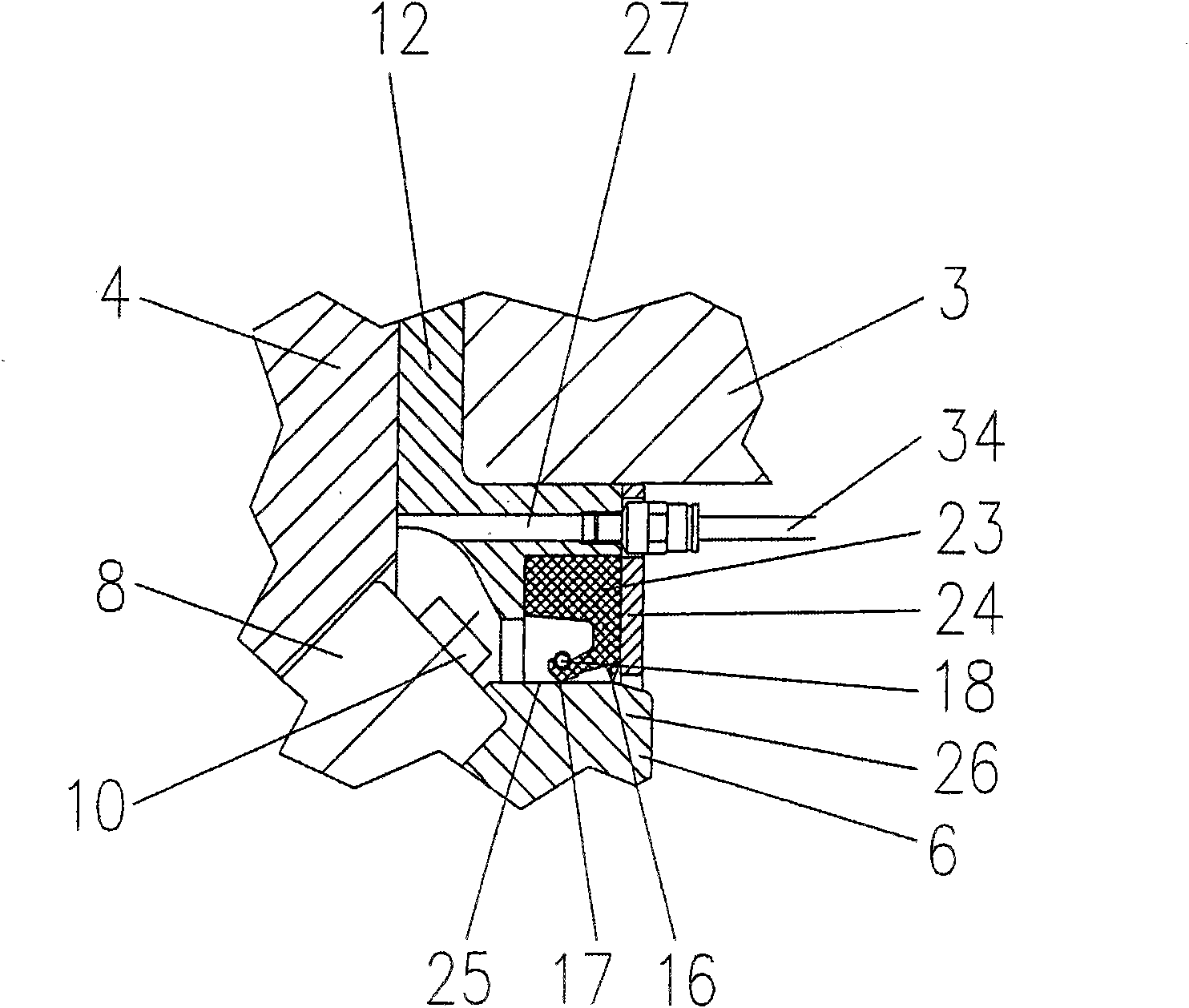

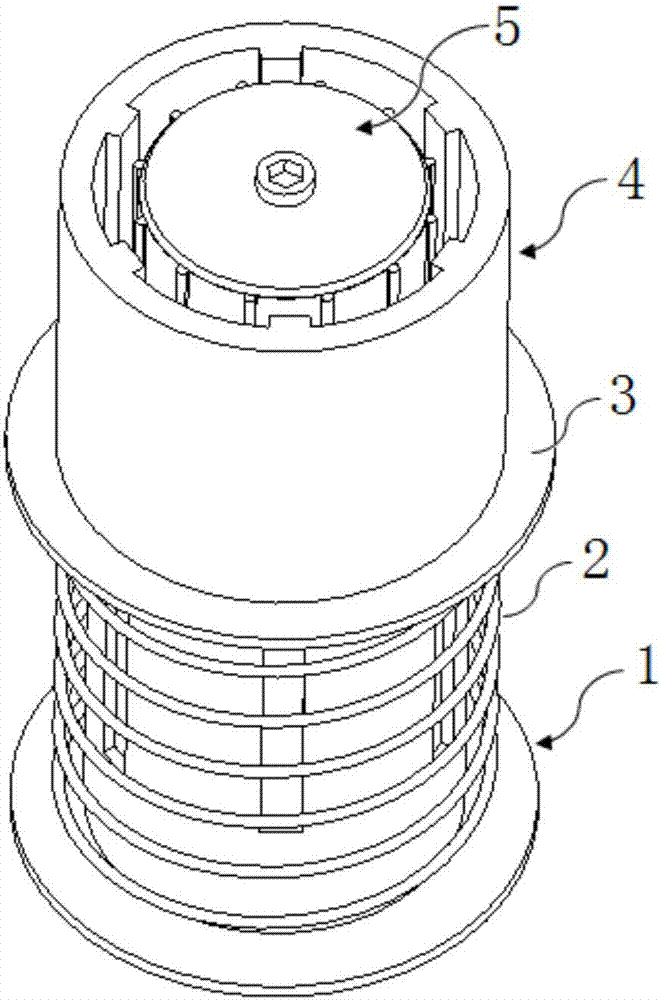

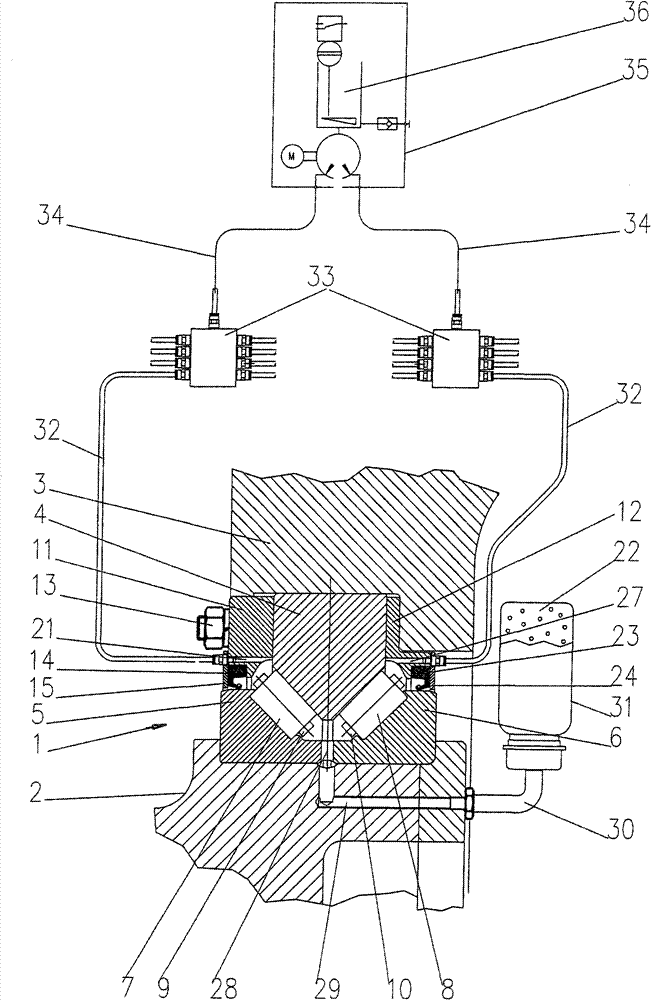

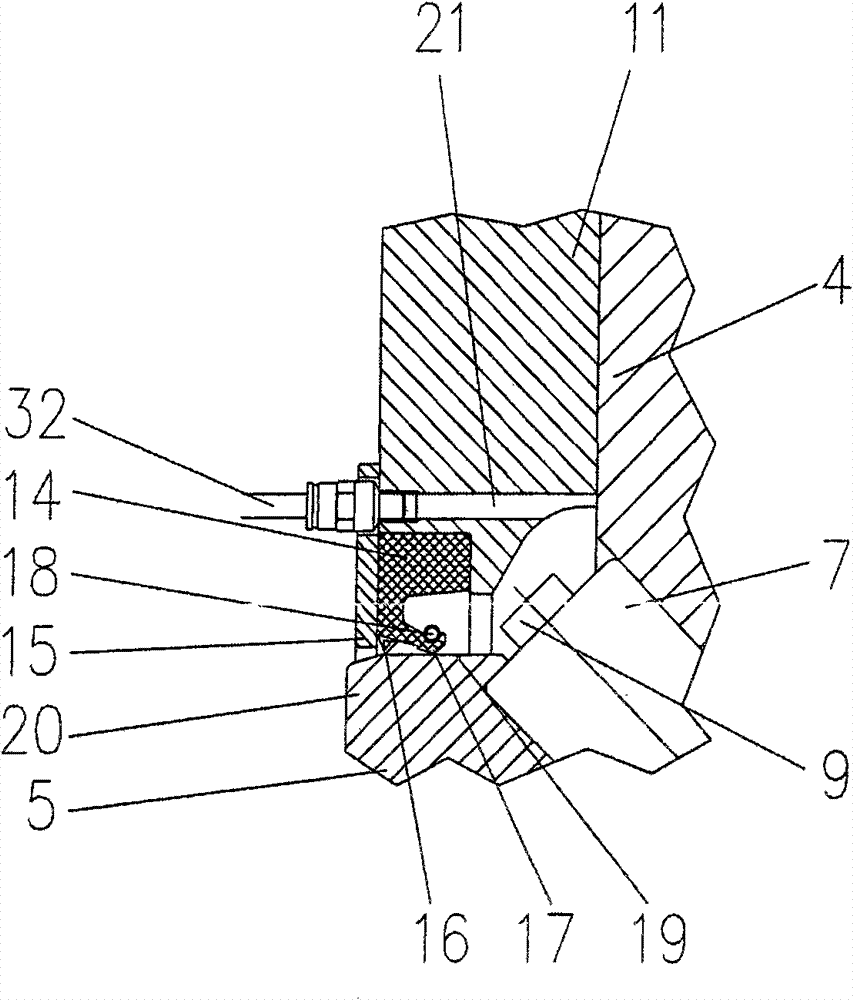

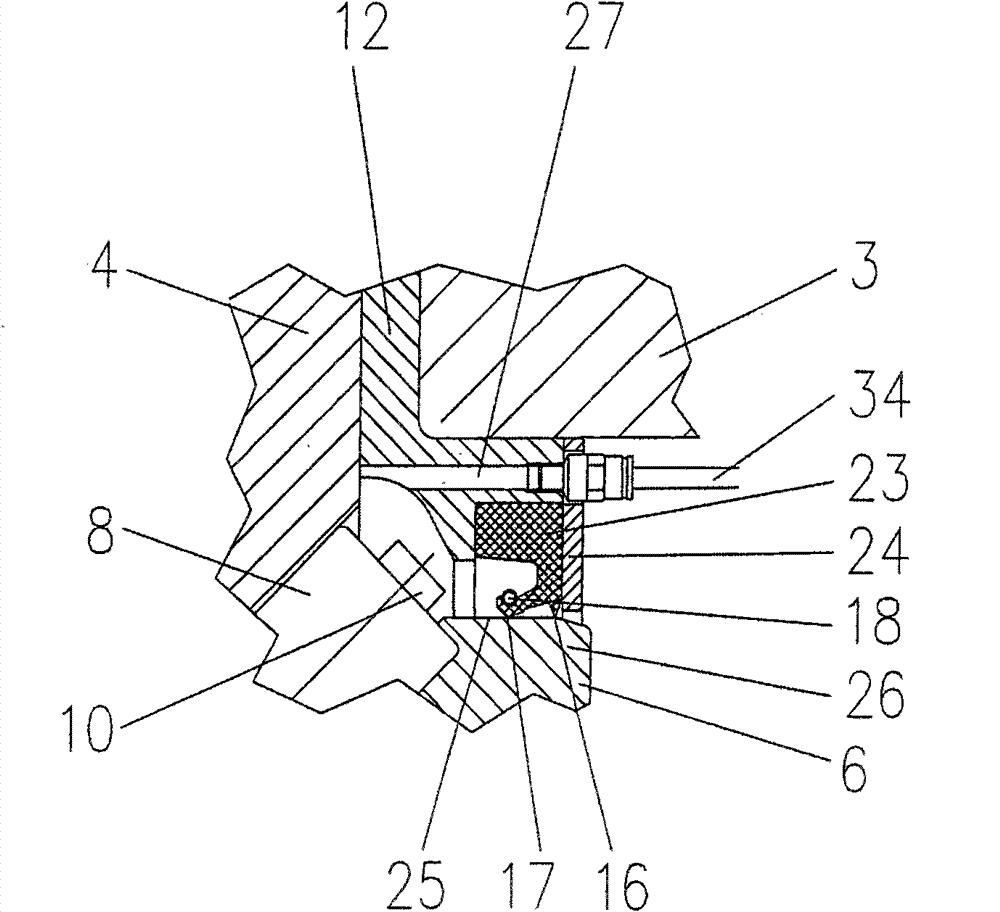

The invention relates to a two-row roller bearing (1) for supporting a mechanical part (2) rotatably relatively to a rotation axis. According to the invention, the roller bearing (1) has an outer ring (4) with the outer diameter of at least 1 m, a first inner ring (5), a second inner ring (6) arranged at the side of the first inner ring (5) axially relatively to the rotation axis, a group of first rolling bodies (7) rolling between the outer ring (4) and the first inner ring (5), a group of second rolling bodies (8) arranged at the side of the first rolling bodies (7) along the axial direction relatively to the rotation axis and rolling between the outer ring (4) and the second inner ring (6). The roller bearing (1) is characterized in that a first lubricating grease conveyor (21) is arranged at the first axial side of the outer ring (4) with respect to the rotation axis for supplying the first roller body with lubricating grease (22) and a second lubricating grease conveyor (27) is arranged at the second axial side of the outer ring (4) with respect to the rotation axis for supplying the second roller body with lubricating grease (22).

Owner:AB SKF

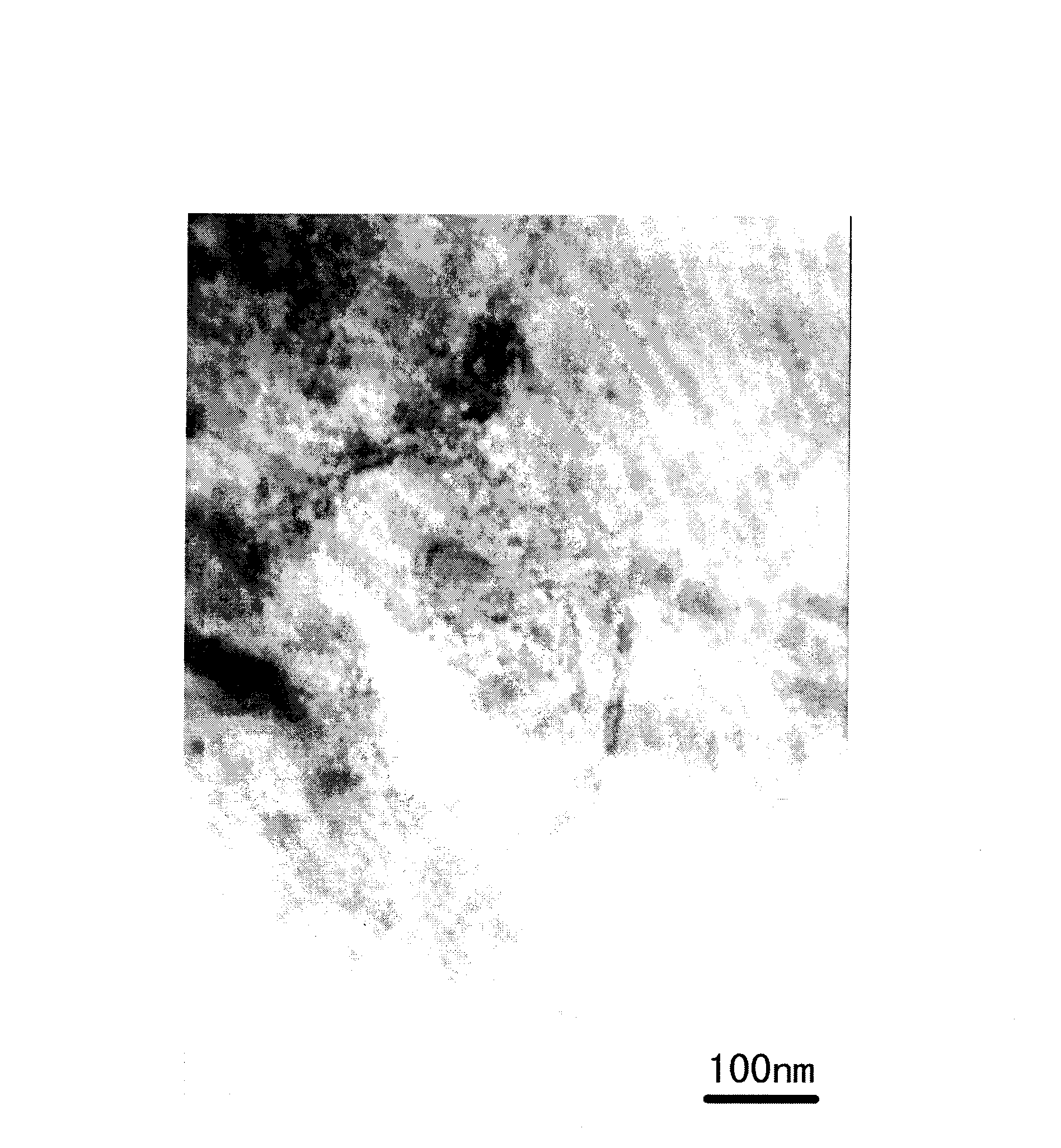

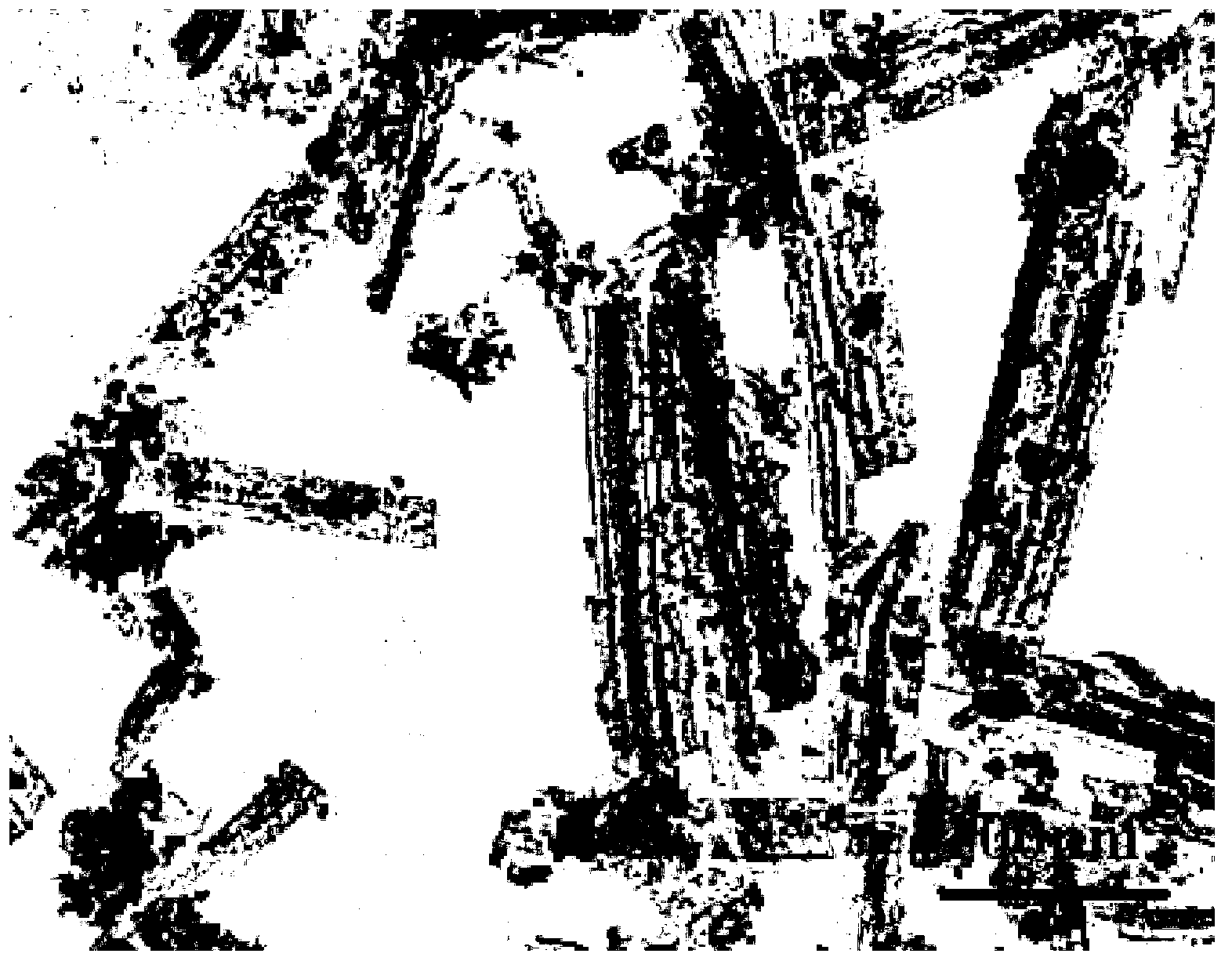

Attapulgite clay-Ni/Fe nano composite material, preparation method and applications thereof

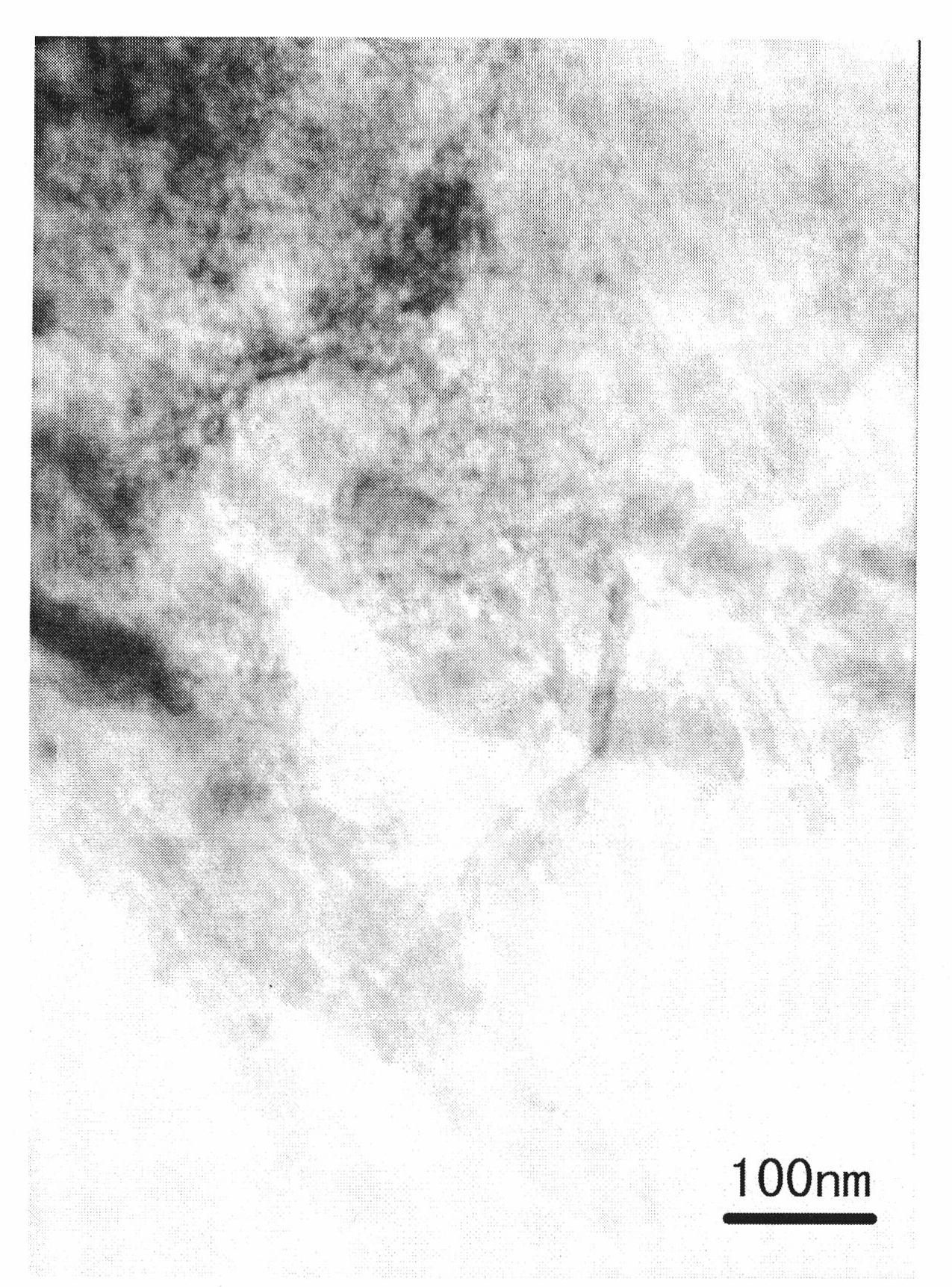

InactiveCN101537356APromote depolymerizationGood dispersionCatalytic crackingOther chemical processesCatalytic pyrolysisNickel salt

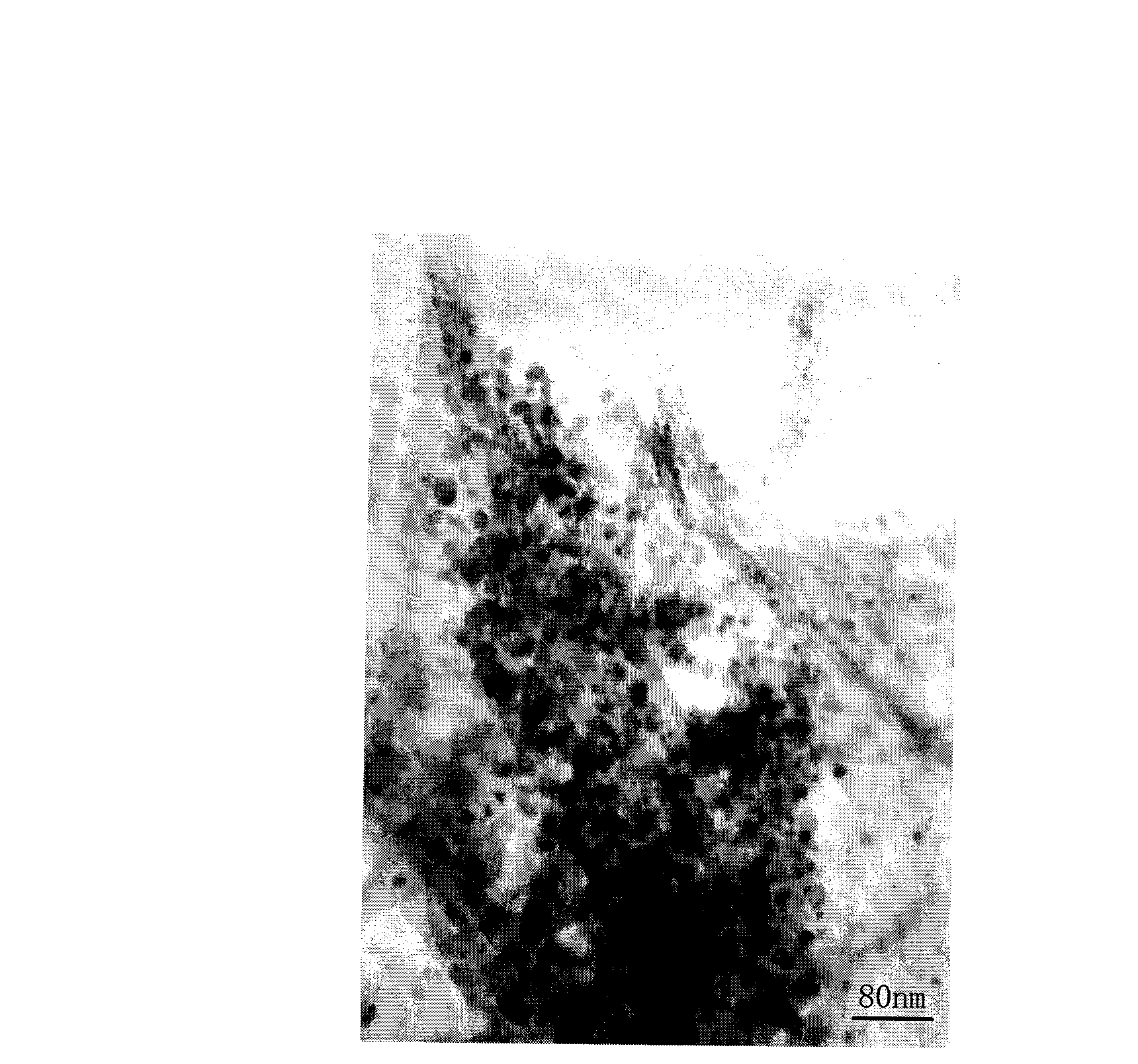

An attapulgite clay-Ni / Fe nano composite material, a preparation method and applications thereof are characterized in that the attapulgite clay is taken as the raw material; metallic nickel and / or metallic iron particles with the diameter less than 20nm are loaded on the surface of attapulgite rhabdolith with the diameter between 40 and 50nm; the preparation method is that the attapulgite clay is prepared into suspension liquid, then the suspension liquid is hydrolyzed with iron salt and nickel salt and loaded on the surface of attapulgite crystal in the precipitation form of hydroxide, and finally the composite material is prepared through washing, dehydration, forming, drying and hydrogen reduction and calcination. With a nano structure, the composite material has low activation energy, high catalytic activity and strong resistance to carbon deposit, and can be applied to catalytic pyrolysis and purification of thermal gas and tar of a biomass gasification furnace and the catalytic pyrolysis of other various organisms.

Owner:HEFEI UNIV OF TECH

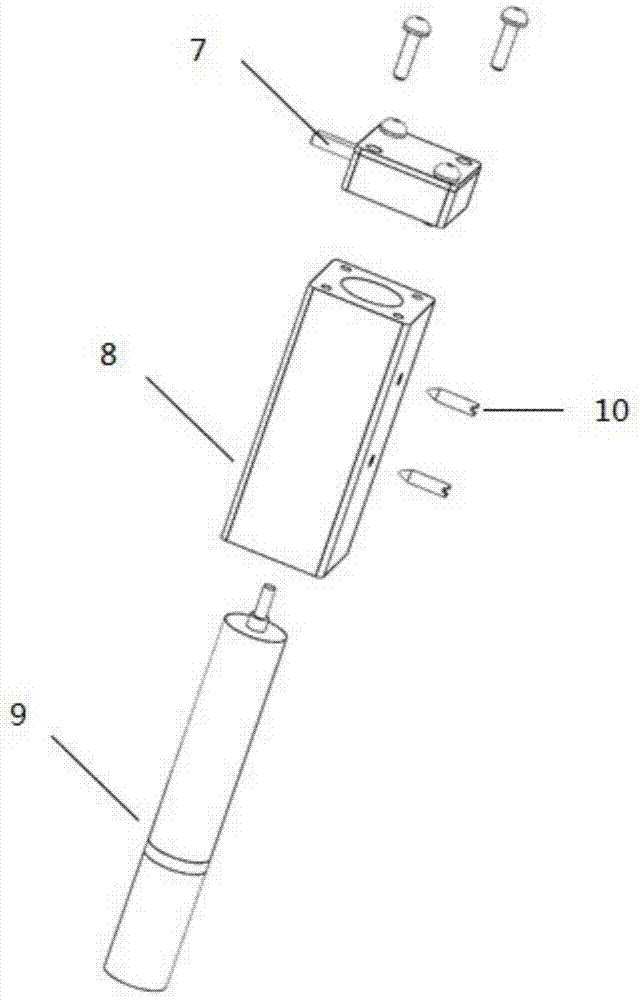

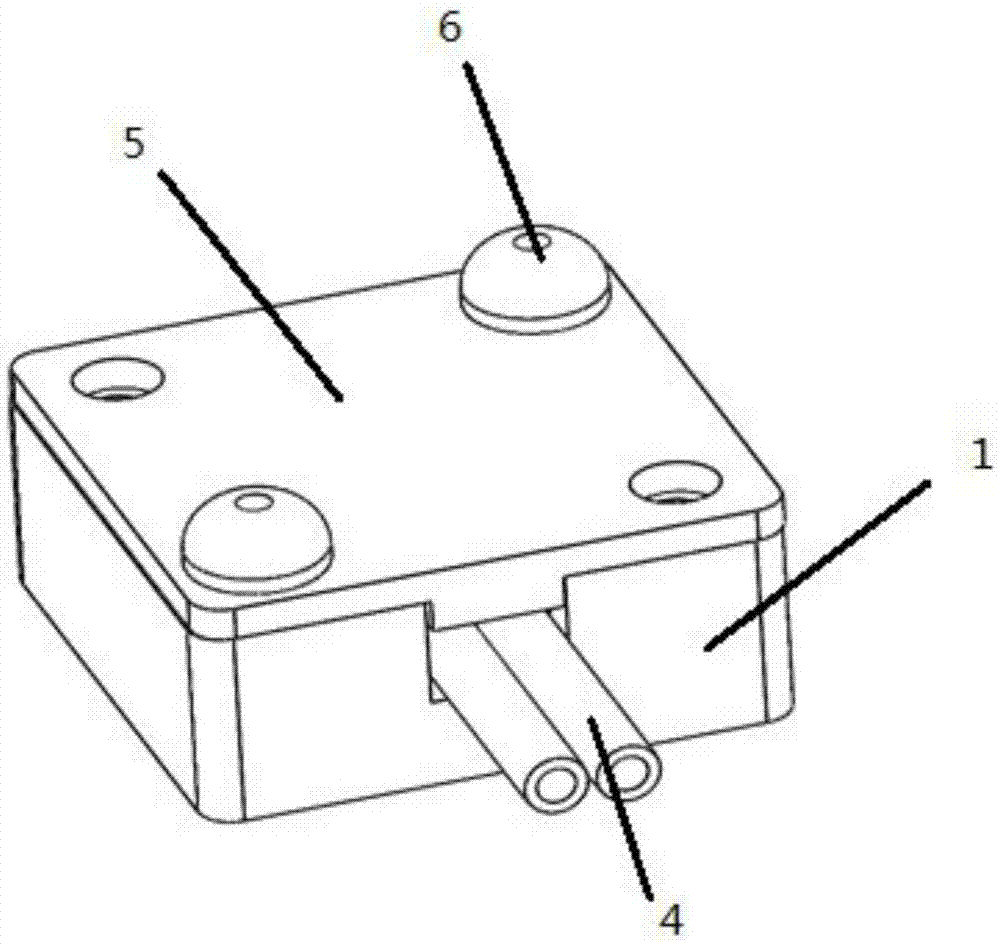

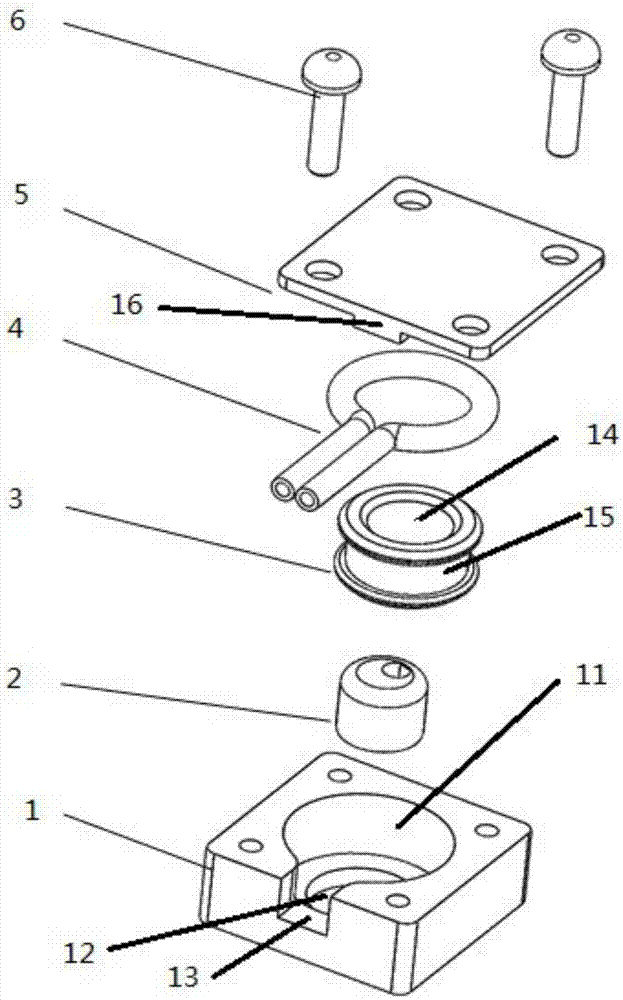

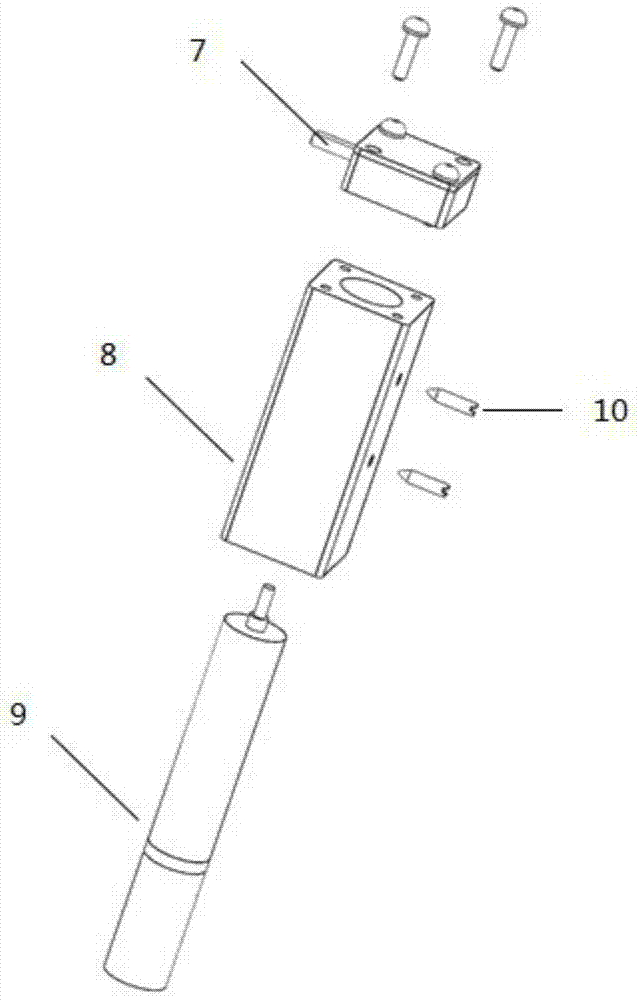

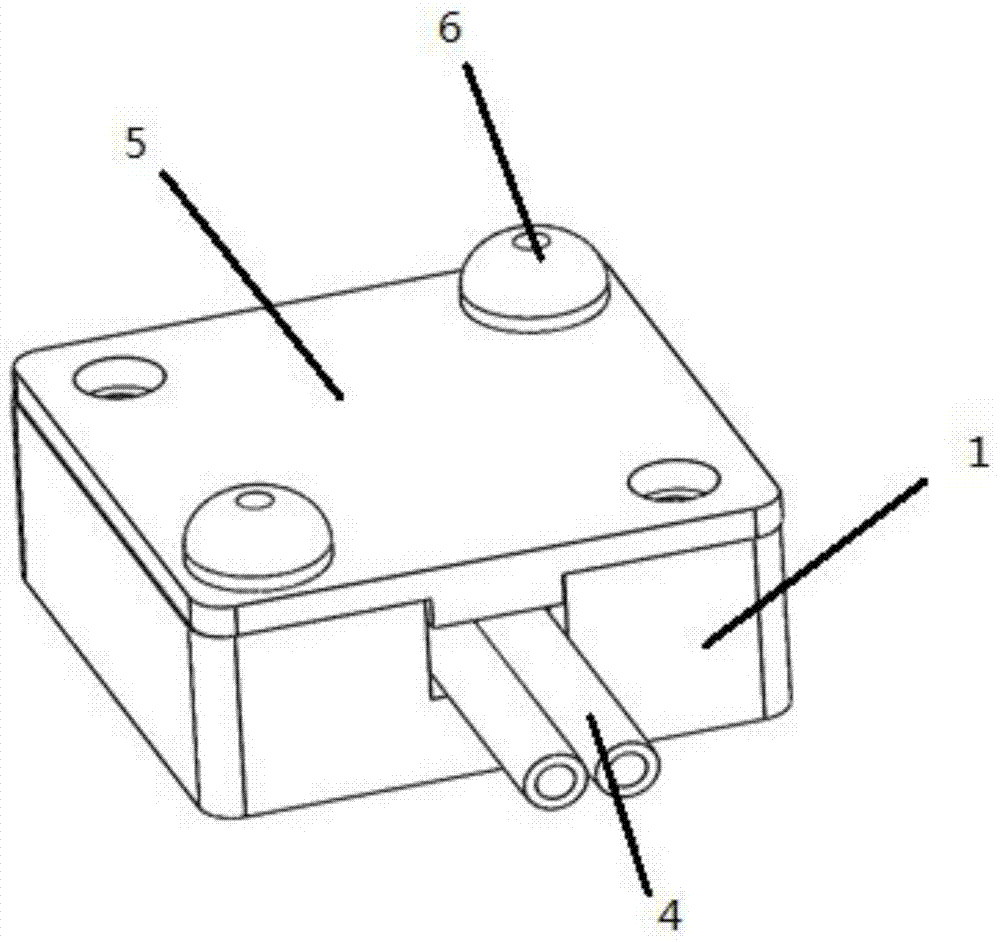

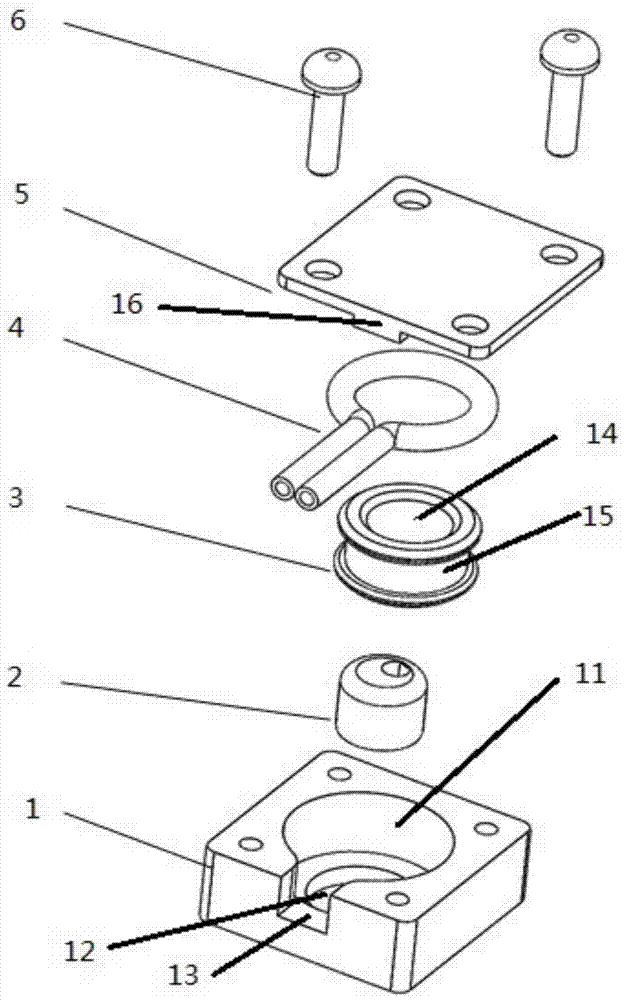

Single-use pipeline and pump head integrated split type micropump

ActiveCN105443363ACompact structureReduce volumeFlexible member pumpsPositive-displacement liquid enginesPeristaltic pumpMicropump

The invention relates to a split type miniature peristaltic pump, in particular to a miniature peristaltic pump, wherein a pipeline is integrated to a pump head, and both the pump head and the pipeline can be used for one time. The micropump comprises a pump body, a motor and a pump head and pipeline assembly. The pump head and pipeline assembly comprises a pump head seat, an eccentric wheel, a pump head roller and a circumferential pressing pipeline; a pump head seat center hole is formed in the pump head seat, a through hole is coaxially formed in the bottom of the pump head seat center hole, and a pipeline inlet / outlet groove is formed in one side of the pump head seat; the pump head roller is arranged in the pump head seat center hole, a pump head roller center hole is formed in the pump head roller, and the eccentric wheel is arranged in the pump head roller center hole and connected with an output shaft of the motor through an eccentric hole; and a pump head roller groove is formed in the outer wall of the pump head roller, and the circumferential pressing pipeline is sleeved with the pump head roller groove along the outer wall of the pump head roller. According to the micropump, the structure of the assembly formed by the pump head and the pipeline can guarantee that the pump is compact in structure and small in size; and the single-use purpose can be achieved, the pollution risk is lowered effectively, and the experiment success rate is increased to a great extent.

Owner:SCI RES TRAINING CENT FOR CHINESE ASTRONAUTS

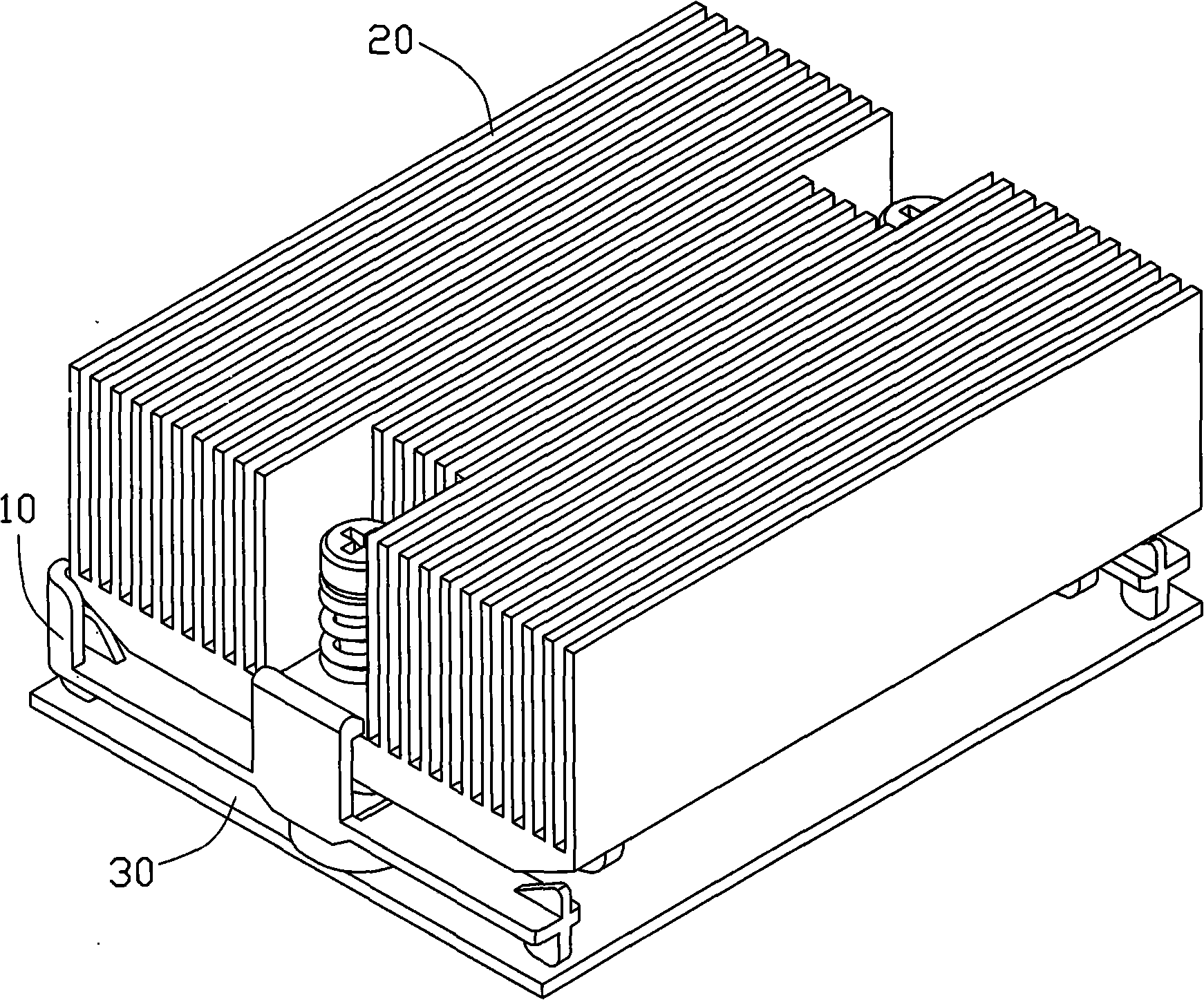

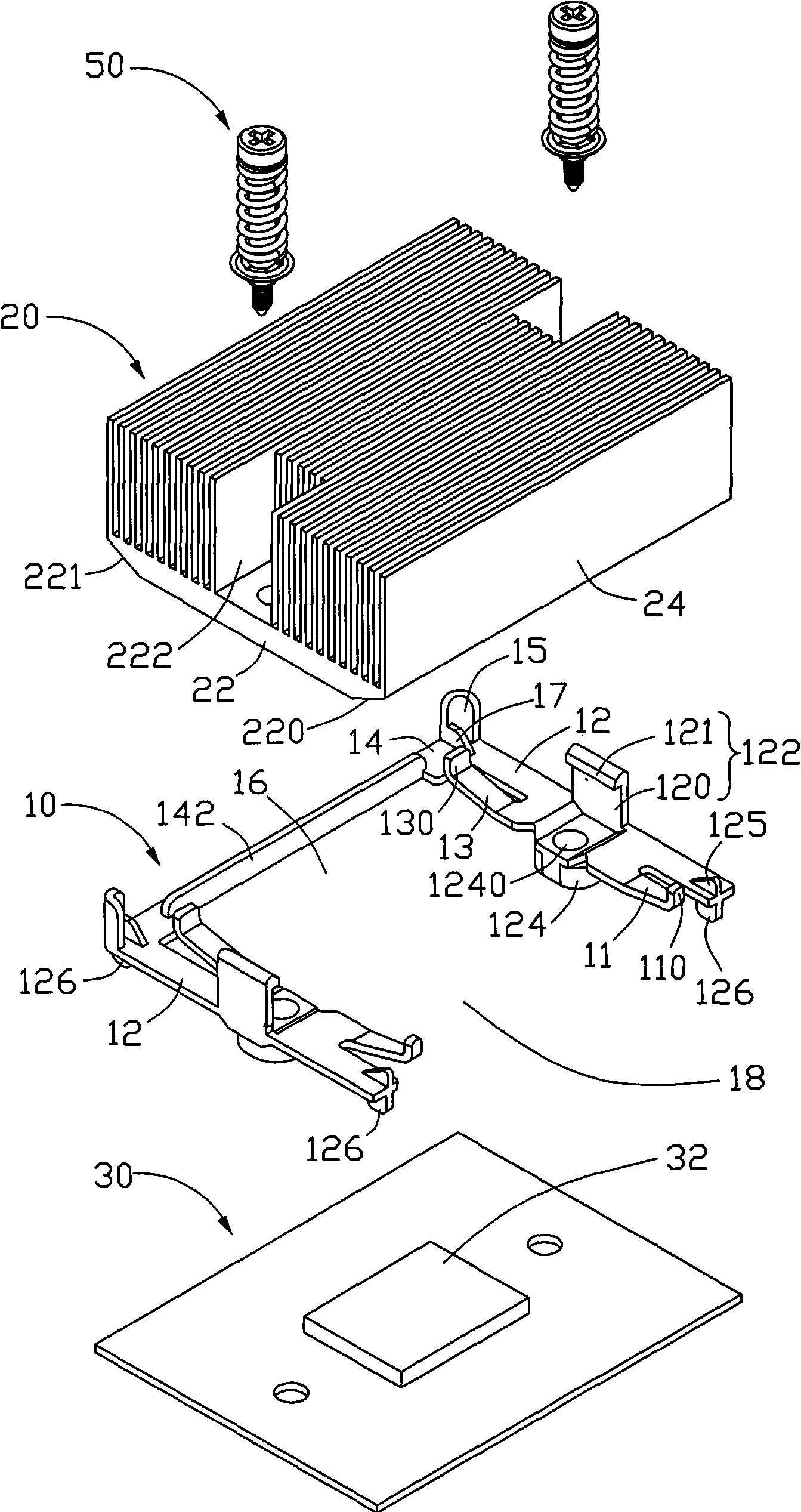

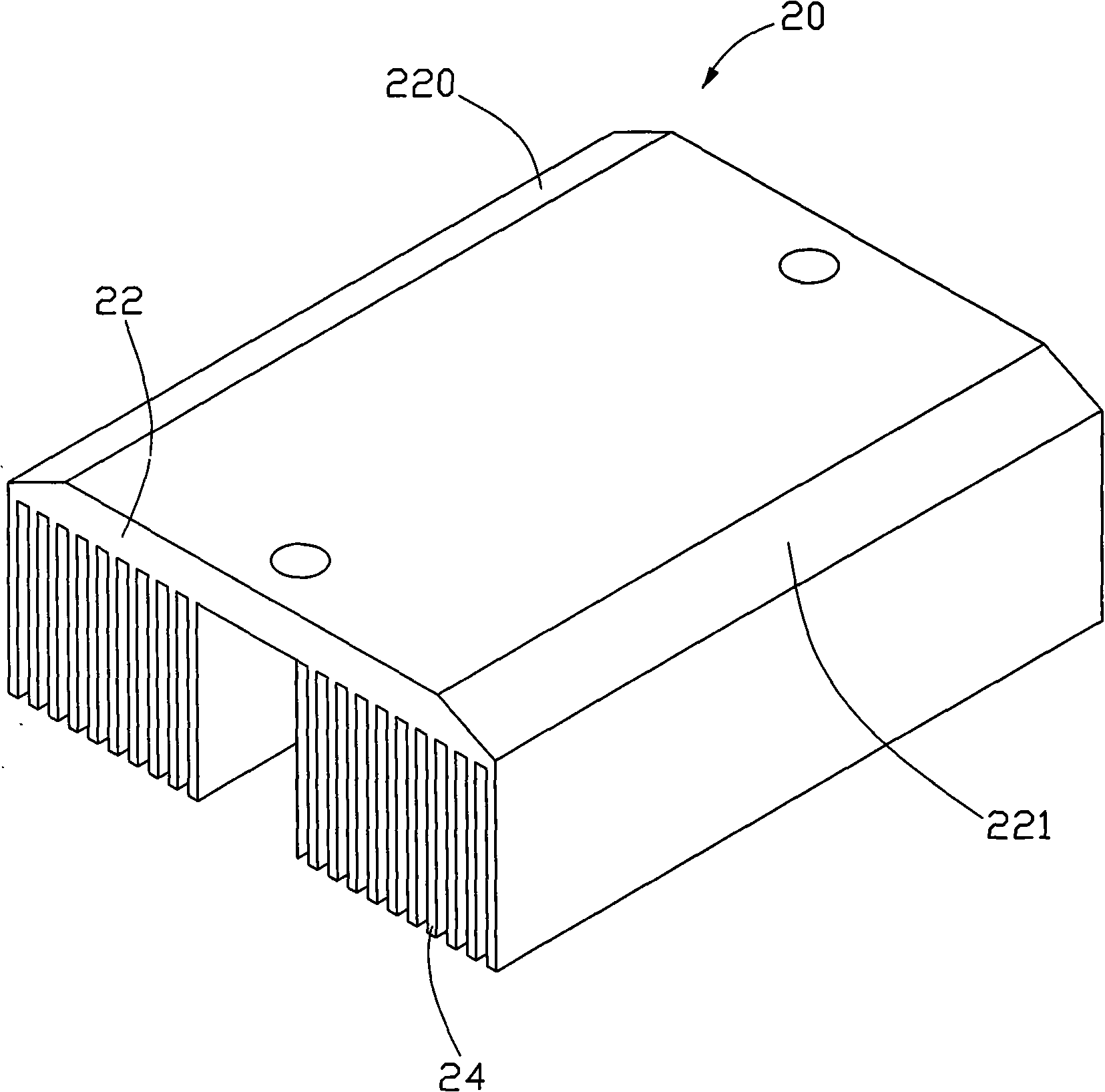

Heat radiation device

InactiveCN101267723AAchieve pre-assemblyImprove assembly efficiencyDigital data processing detailsSemiconductor/solid-state device detailsHeat spreaderElectrical and Electronics engineering

Owner:FU ZHUN PRECISION IND SHENZHEN +1

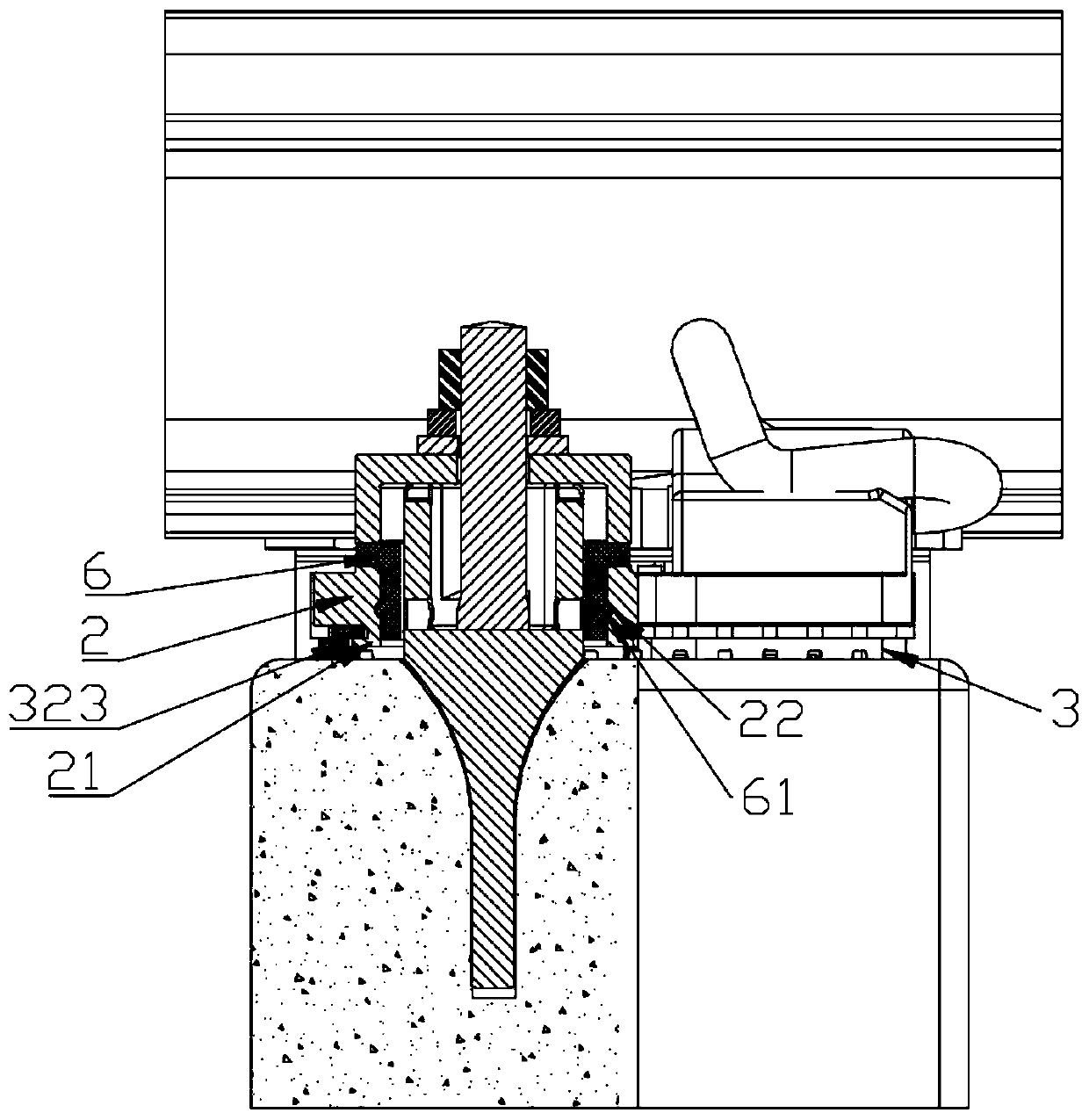

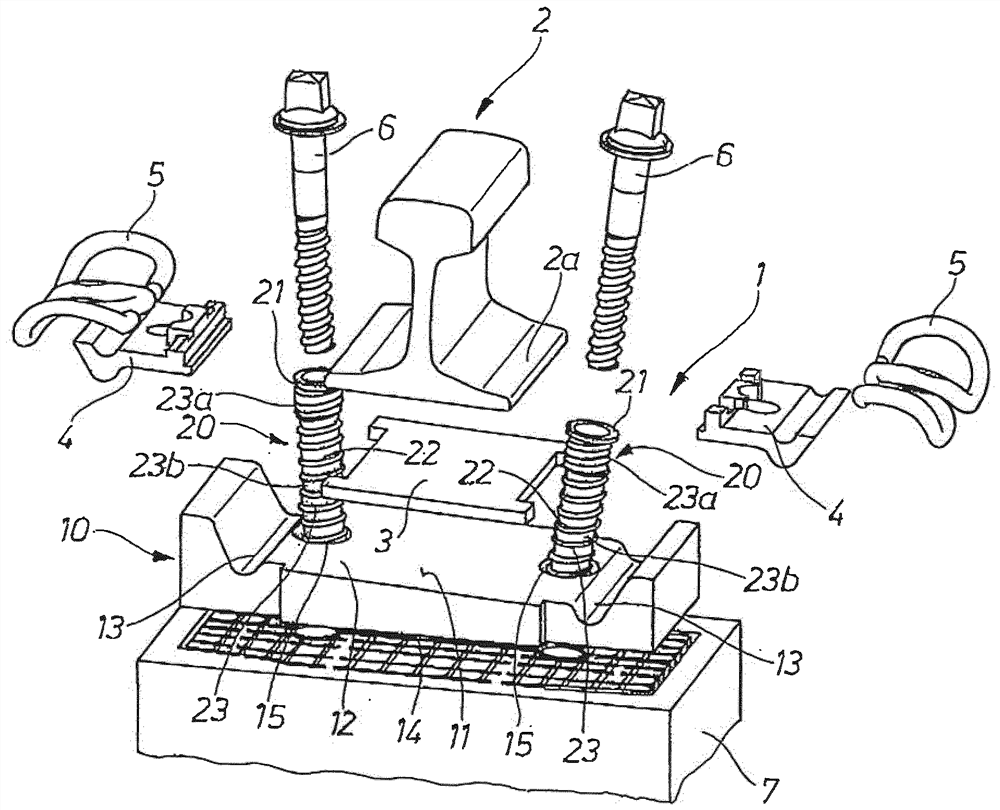

Rail damping fastener

PendingCN110863394AIncrease lateral stiffnessReduce vertical stiffnessRail fastenersClassical mechanicsEngineering

The invention discloses a rail damping fastener. The rail damping fastener comprises an upper base plate, a lower base plate, an intermediate elastic base plate and an under-rail elastic base plate, the intermediate elastic base plate is arranged between the upper base plate and the lower base plate, the under-rail elastic base plate is arranged on the upper base plate, a boss is arranged on the lower base plate, the upper base plate is externally arranged on the boss in a sleeving mode, a longitudinal first transverse limiting surface is arranged on the upper base plate, a transverse blockingshoulder extending upwards is arranged on the lower base plate, a longitudinal blocking shoulder extending towards the first horizontal limiting surface is arranged at the upper end of the transverseblocking shoulder, the rail damping fastener further comprises a transverse clamping block, and the transverse clamping block is arranged between the first transverse limiting surface and the transverse blocking shoulder. According to the rail damping fastener, by arranging a transverse blocking shoulder structure, the integration of the higher transverse stiffness and the lower vertical stiffness of the rail damping fastener can be achieved without affecting the damping effect of the rail damping fastener.

Owner:CHINA RAILWAY ENG CONSULTING GRP CO LTD

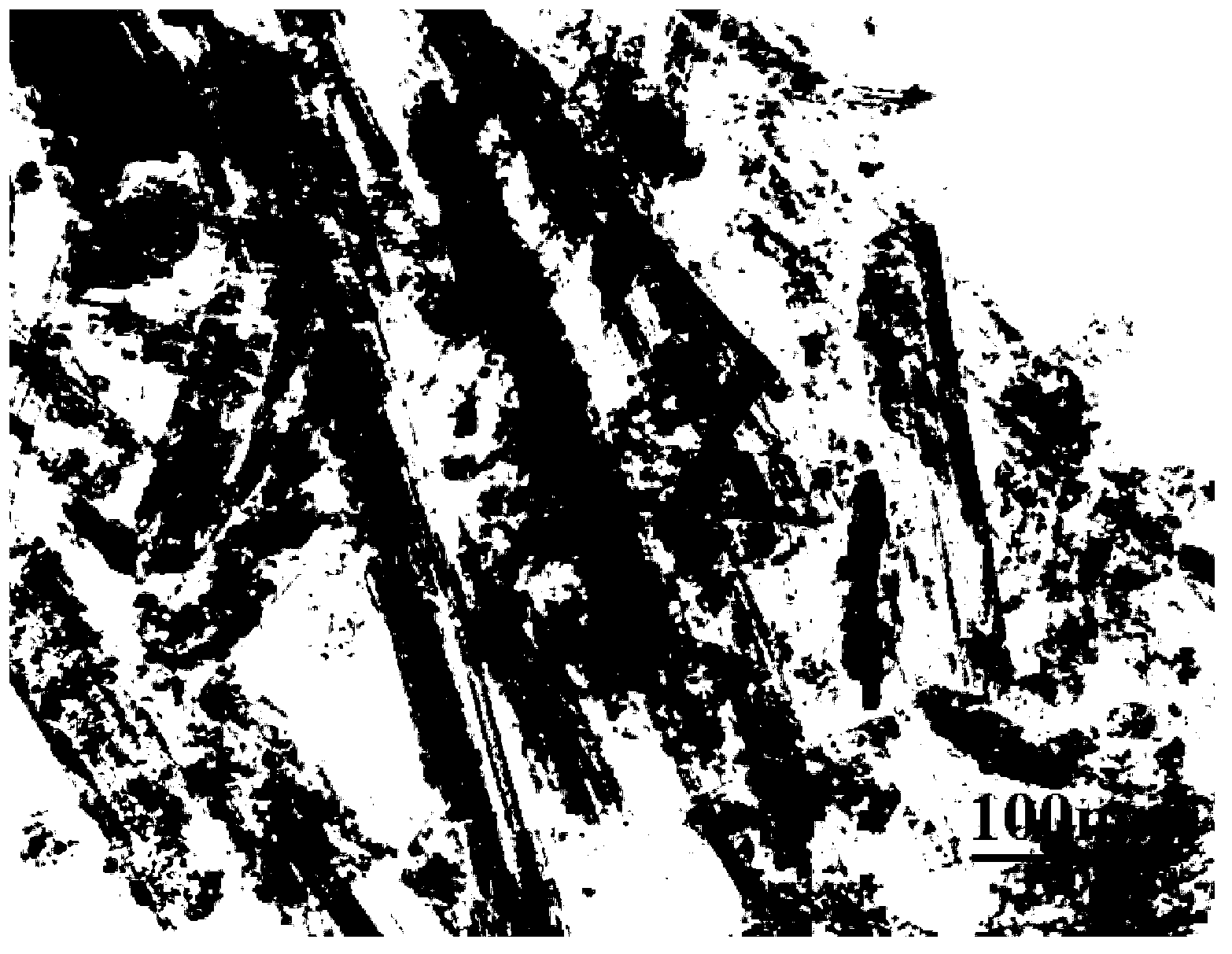

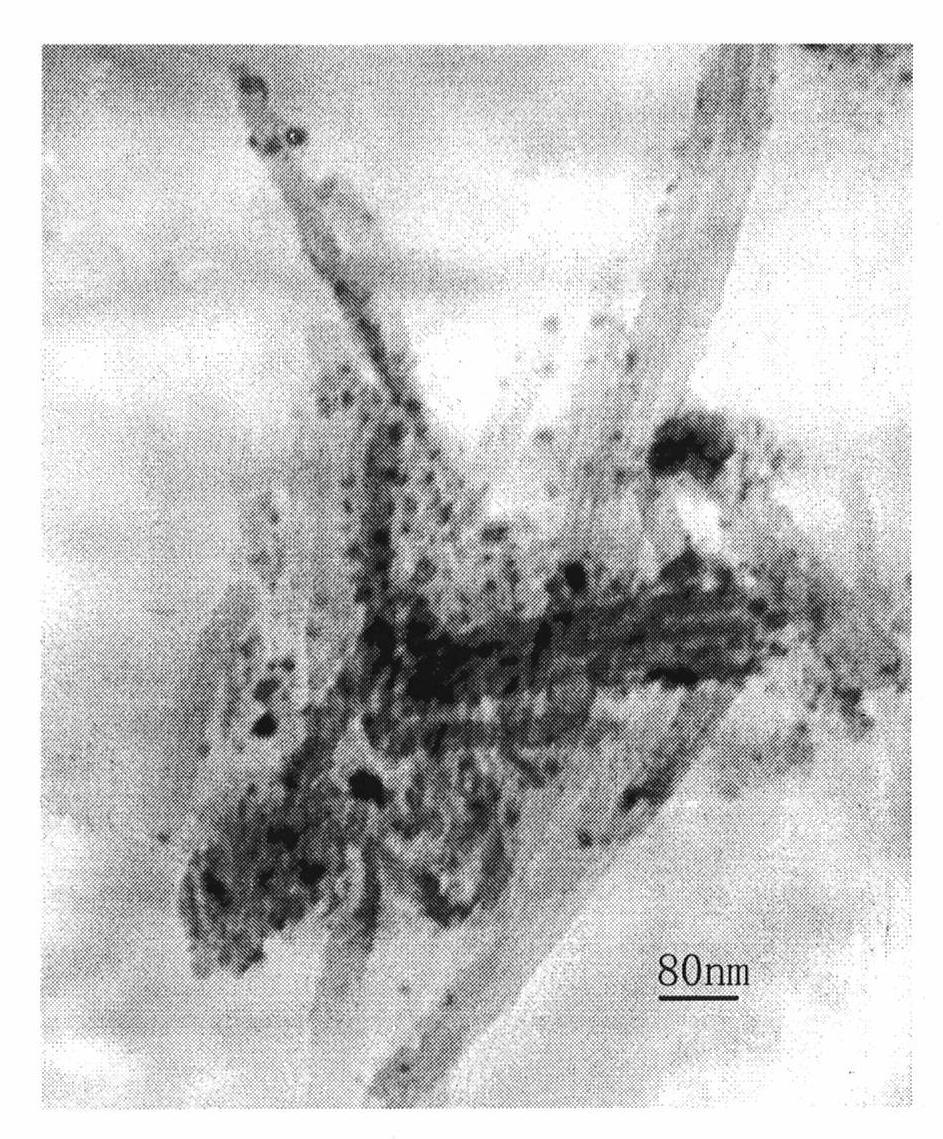

Attapulgite-perovskite composite material, preparation method and application thereof

ActiveCN102794169APromote depolymerizationGood dispersionDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCatalytic oxidationOrganic matter

The invention discloses an attapulgite-perovskite composite material, a preparation method and application thereof, wherein the attapulgite-perovskite composite material is a composite material obtained by loading perovskite particles on the surface of attapulgite by taking attapulgite clay as a carrier, and the load capacity of the perovskite is 6-12 percent of the mass of the attapulgite clay. The composition of the composite material is mu%La1-xSrxMnO3 / PG, wherein mu is 6-12, and x is 0, 0.1 or 0.3. The composite material disclosed by the invention is of a nano structure, has the advantages of low activation capacity, high catalyst activity and strong capacity of resisting inactivation and can be applied to the purification of volatile organic pollutants such as toluene and the like and the catalysis and oxidization of other various organic matters.

Owner:HEFEI UNIV OF TECH

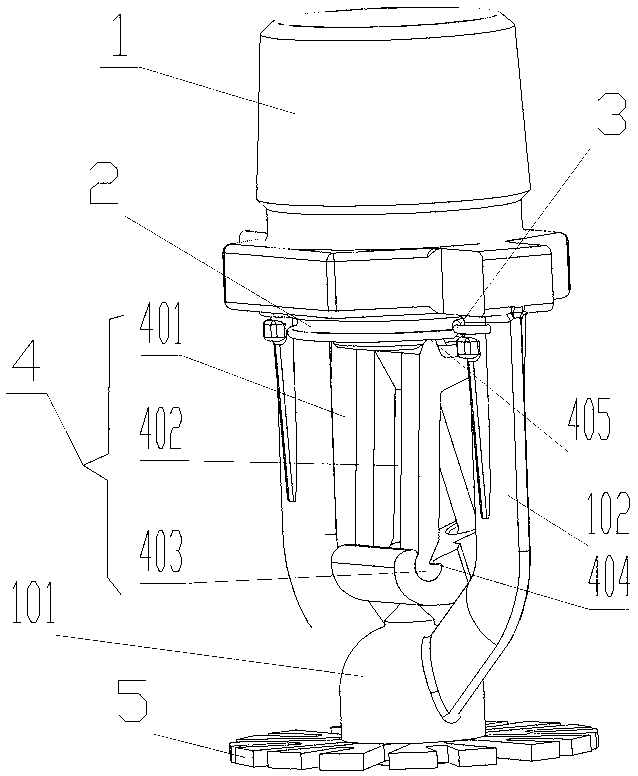

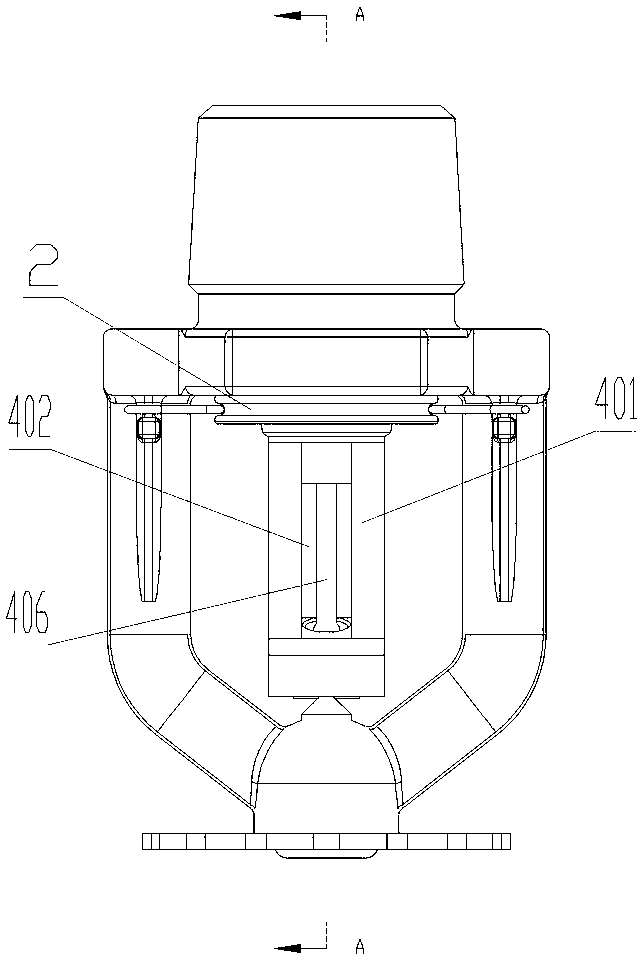

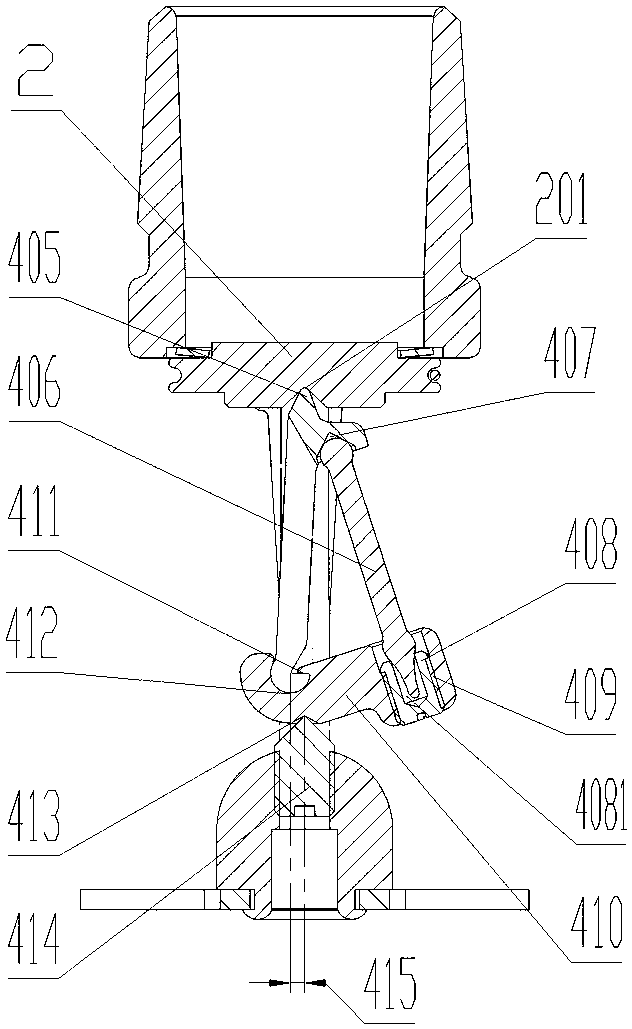

Fire-fighting sprinkler head

The invention discloses a fire-fighting sprinkler head. The fire-fighting sprinkler head comprises a body and a choke plug. A base is arranged on the lower end of a frame of the body, a splashing disc is arranged on the lower end of the base, the choke plug is in seal connection with the water outlet end of the body, a releasing device is arranged at the position, between the choke plug and the base, on the body, and comprises a supporting plate, one end of the supporting plate is connected with the lower end of the choke plug, the other end of the supporting plate is rotatably connected with a pressing plate, the end, close to the choke plug, of the supporting plate is connected with one end of a glass ball, the other end of the glass ball is connected to the end, away from the supporting plate, of the pressing plate, the pressing plate is supported by an adjusting screw screwed in the base, the eccentric distance exists between the rotating center on the connecting position of the supporting plate and the pressing plate and the center of the axis of the adjusting screw. The advantages of being stable in bearing, sensitive in temperature inducing, high in trigger speed, and convenient to assemble are achieved.

Owner:SHANGHAI RUITAI FIRE FIGHTING EQUIP MFG CO LTD

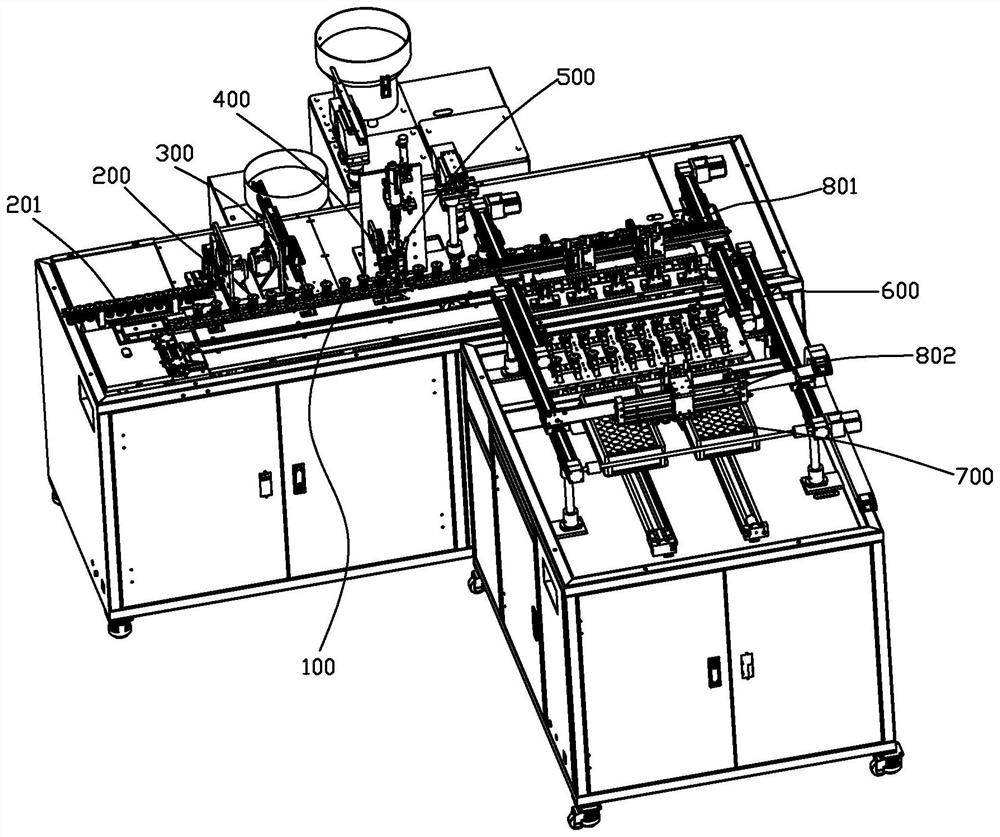

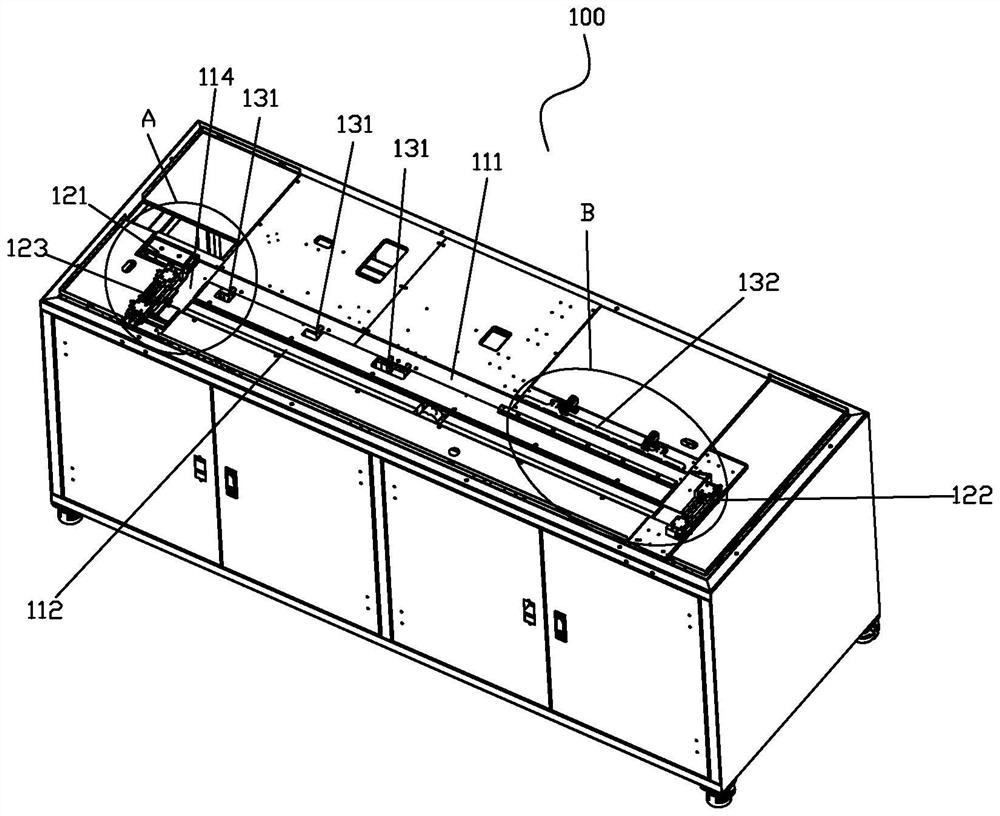

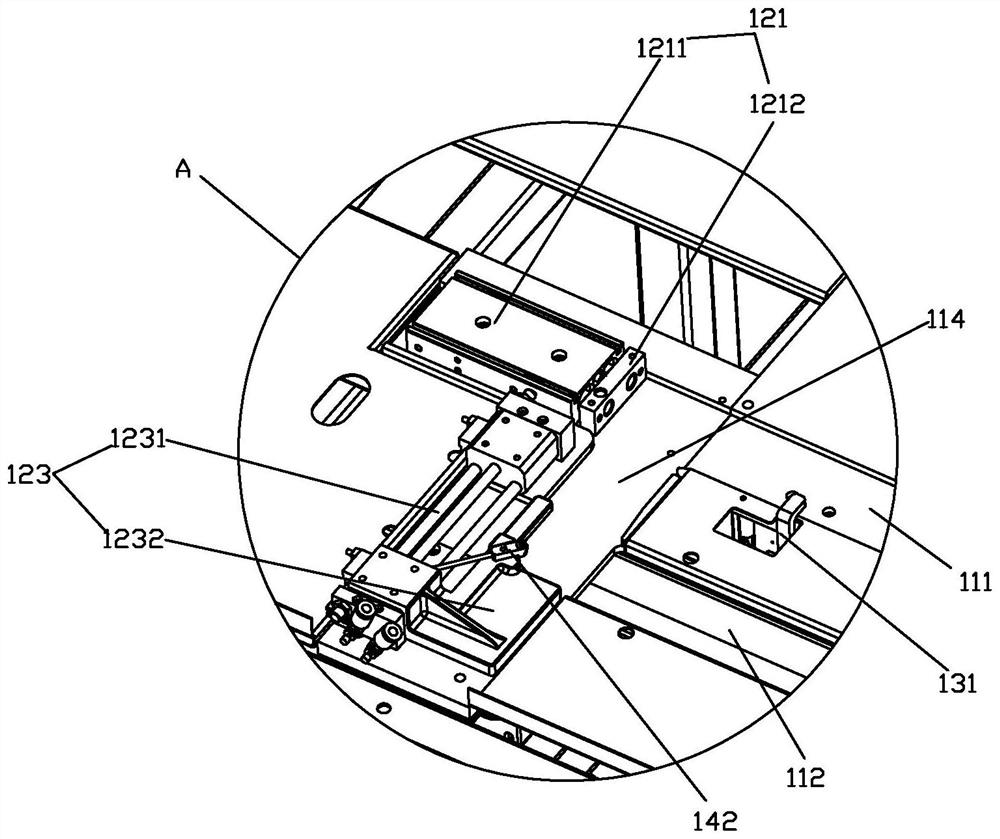

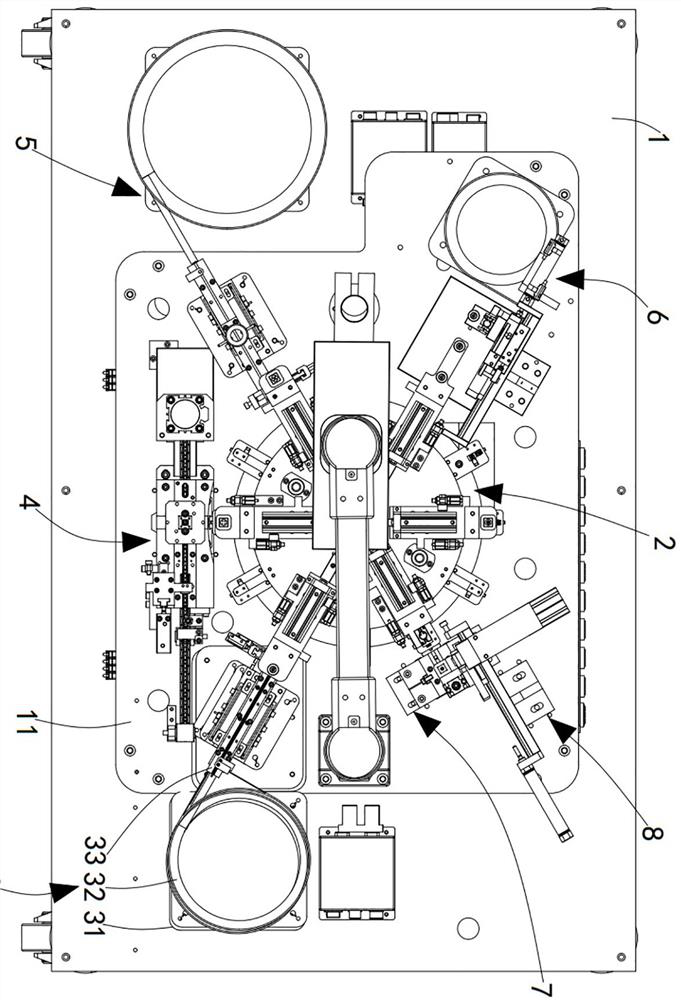

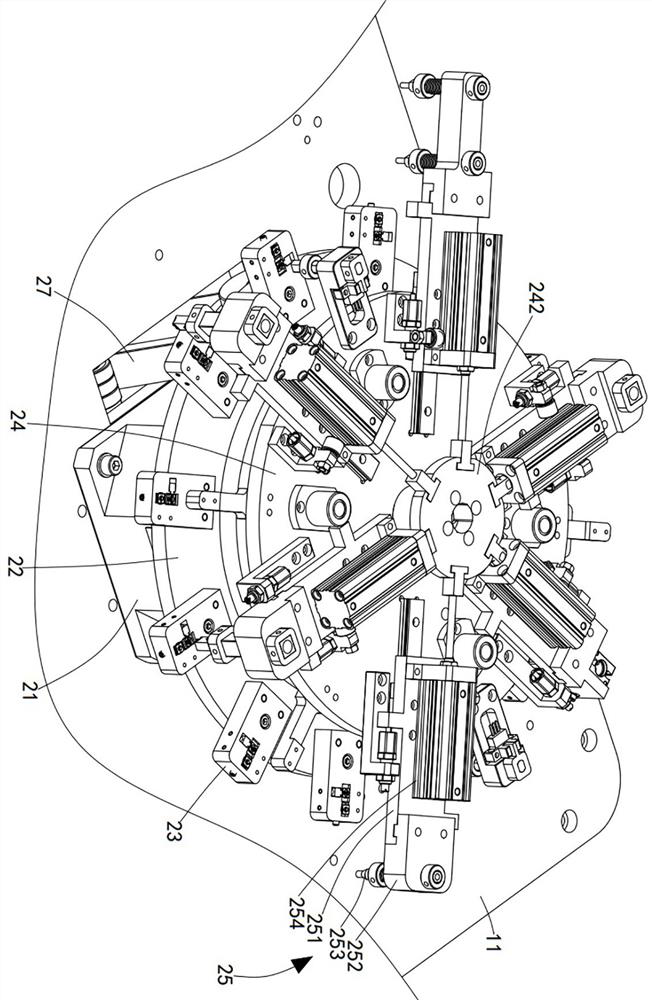

Production line of fire-fighting spray header

ActiveCN114799870AAvoid timeAvoid pass rateAssembly machinesMetal working apparatusProduction lineFire sprinkler

The invention provides a fire sprinkler head production line which comprises a control system and an operation system connected with the control system, and the operation system comprises a conveying mechanism used for conveying sprinkler head valve bodies, and a valve plate feeding mechanism, a dispensing mechanism and an assembling mechanism which are sequentially arranged in the conveying direction of the conveying mechanism. Spray header valve bodies are conveyed by the conveying mechanism, and the valve plate feeding mechanism firstly transfers valve plates to the spray header valve bodies on the conveying mechanism; then entering the dispensing mechanism, and dispensing through the dispensing mechanism; then entering an assembling mechanism; the assembling mechanism is used for assembling and locking the glass beads, so that the mechanical assembling of the spray header is completed; therefore, the problems of long assembly time and low qualification rate during manual assembly are solved.

Owner:XIAMEN UNIV TAN KAH KEE COLLEGE

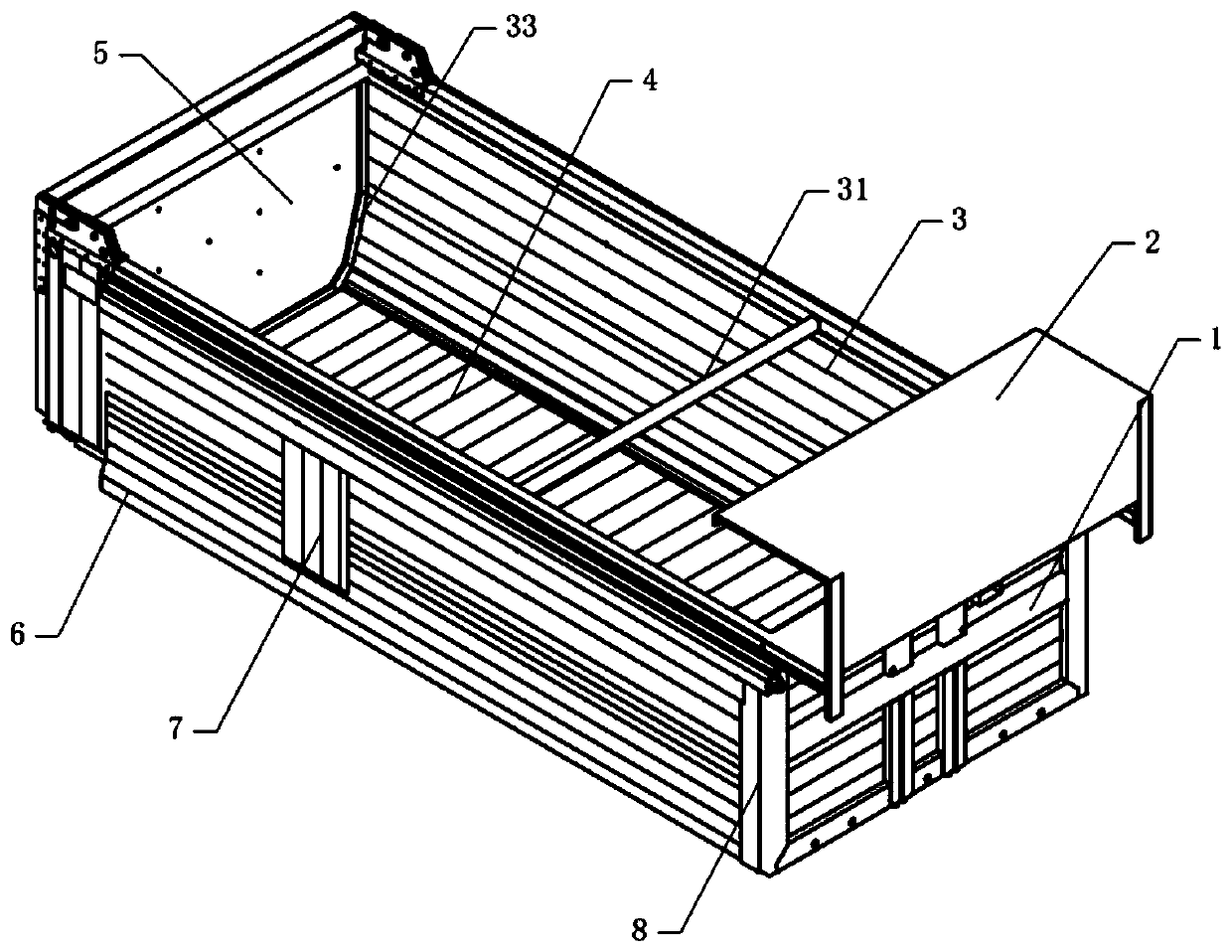

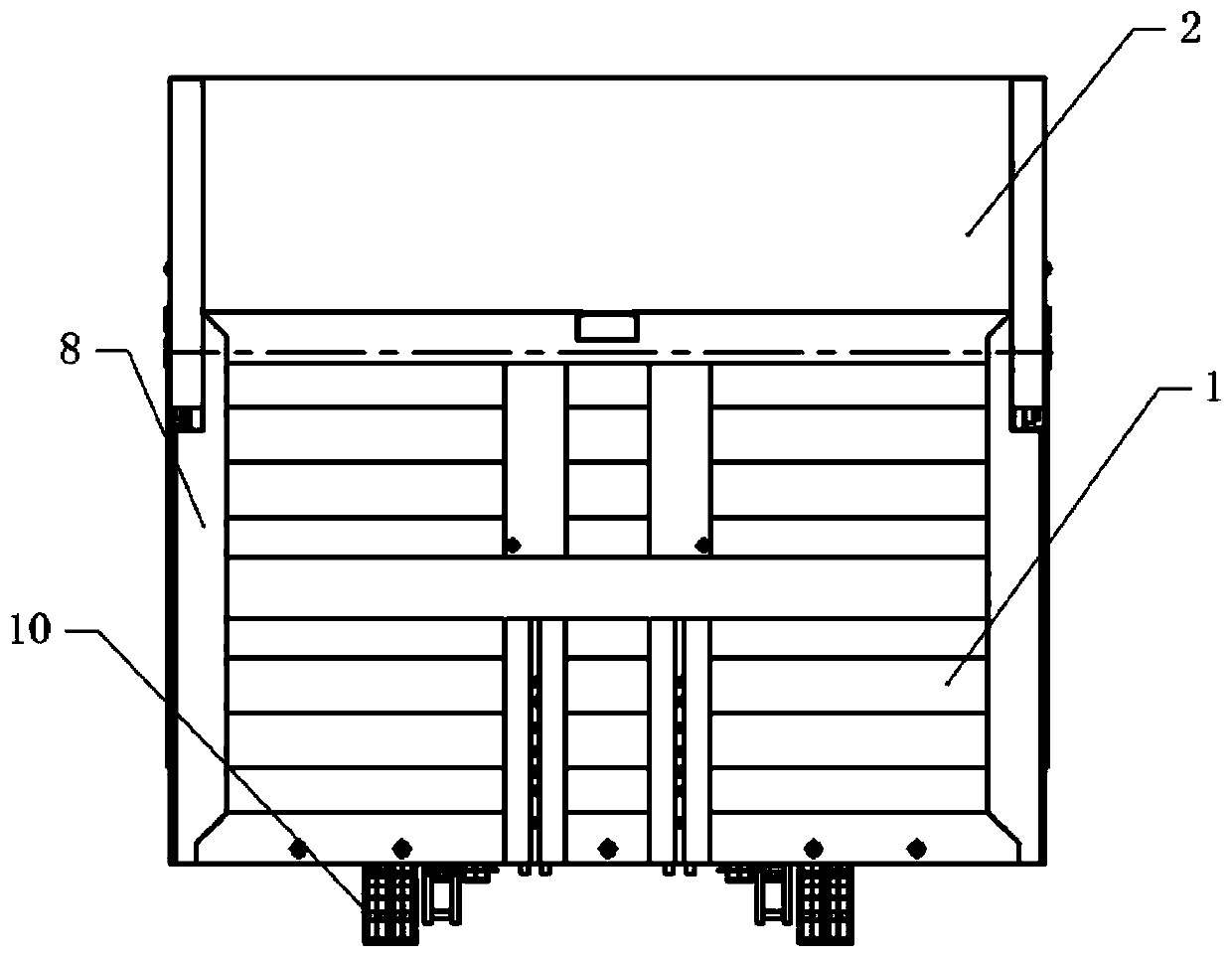

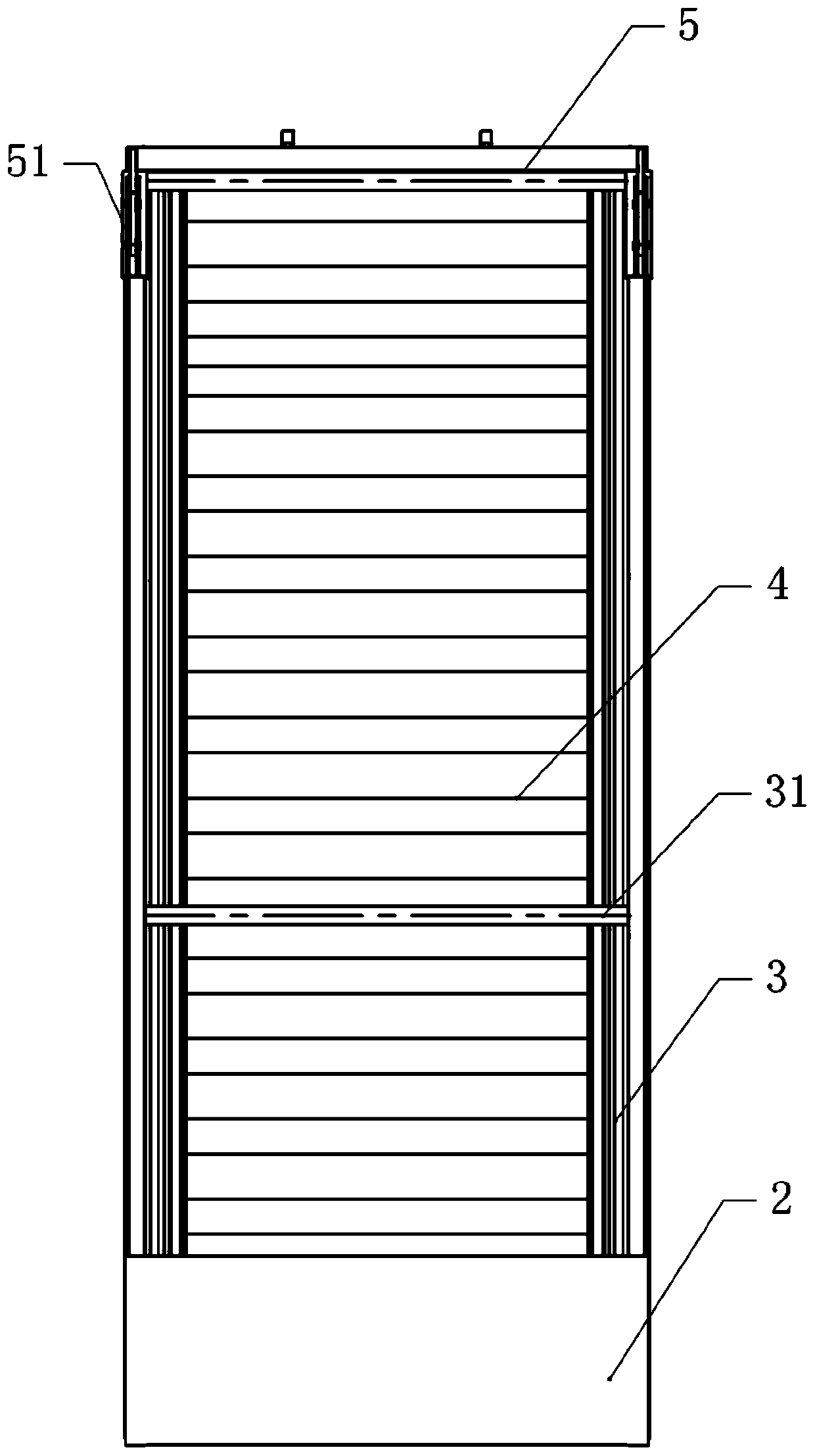

Assembly type lightweight carriage

PendingCN110949545AHigh precisionAvoid forceLoading-carrying vehicle superstructuresEngineeringCarriage

The invention relates to the technical field of carriage assembly, and discloses an assembly type lightweight carriage. The assembly type light-weight carriage comprises a front plate composed of an opening plate, side plates composed of an opening plate and a bottom plate composed of an opening plate; convex plates are fixed to the two sides of the bottom plate, concave plates fixedly matched with the convex plates are fixed to the two sides of the side plates, and locking components used for bearing force are arranged between the convex plates and the concave plates. Locking structures for connecting the side plates and the front plate are arranged between the side plates and the front plate; the side plates are fixedly connected with the bottom plate, and the front plate is fixedly connected with the side plates and the bottom plate. The assembly type lightweight carriage is simple in structure, on one hand, the carriage can be rapidly assembled, on the other hand, acting force borne by carriage weld joints can be reduced, and the strength of the carriage is integrally enhanced.

Owner:重庆铝器时代科技有限公司

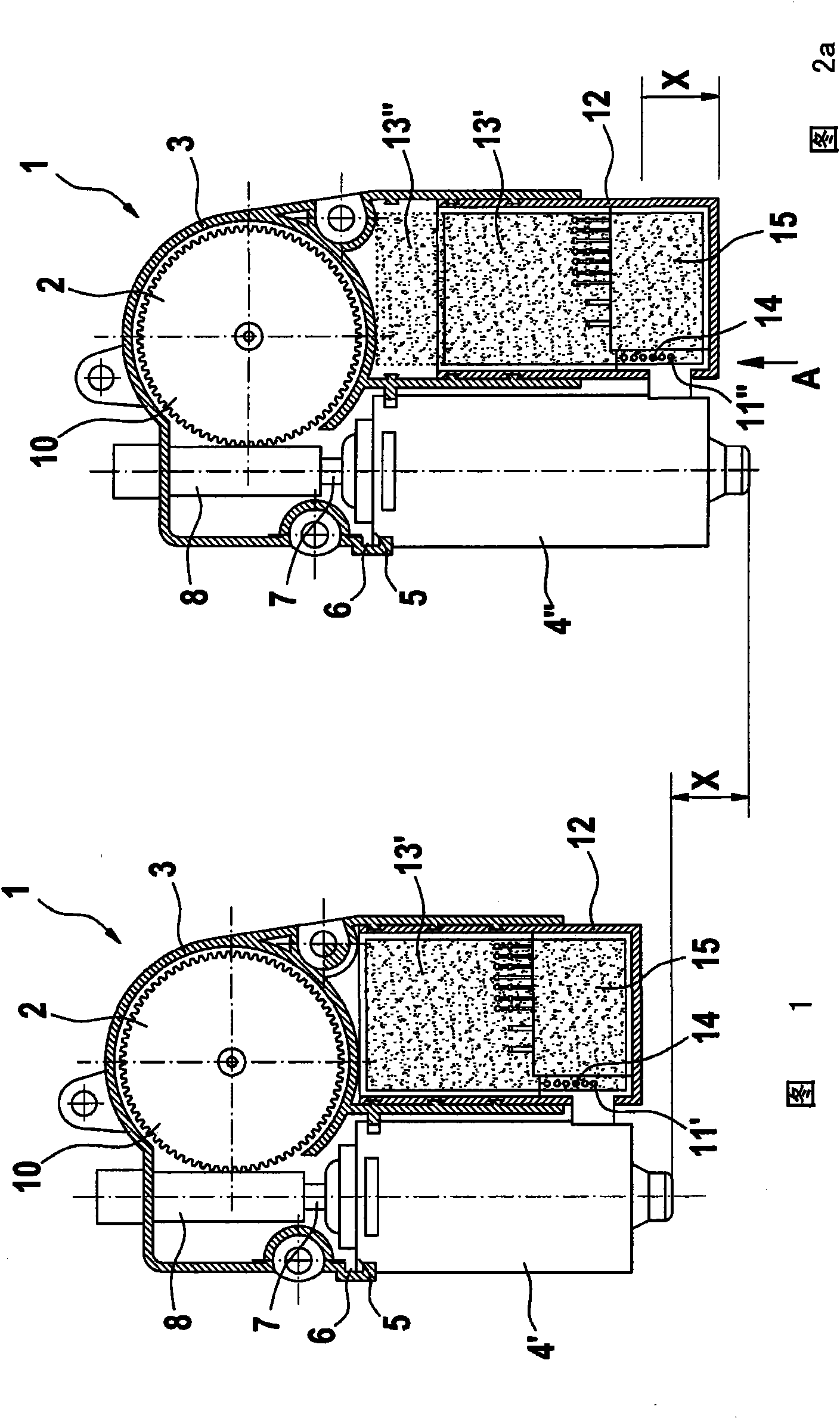

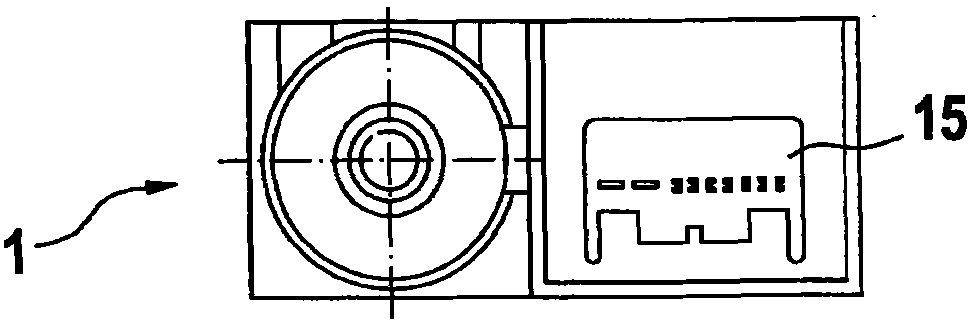

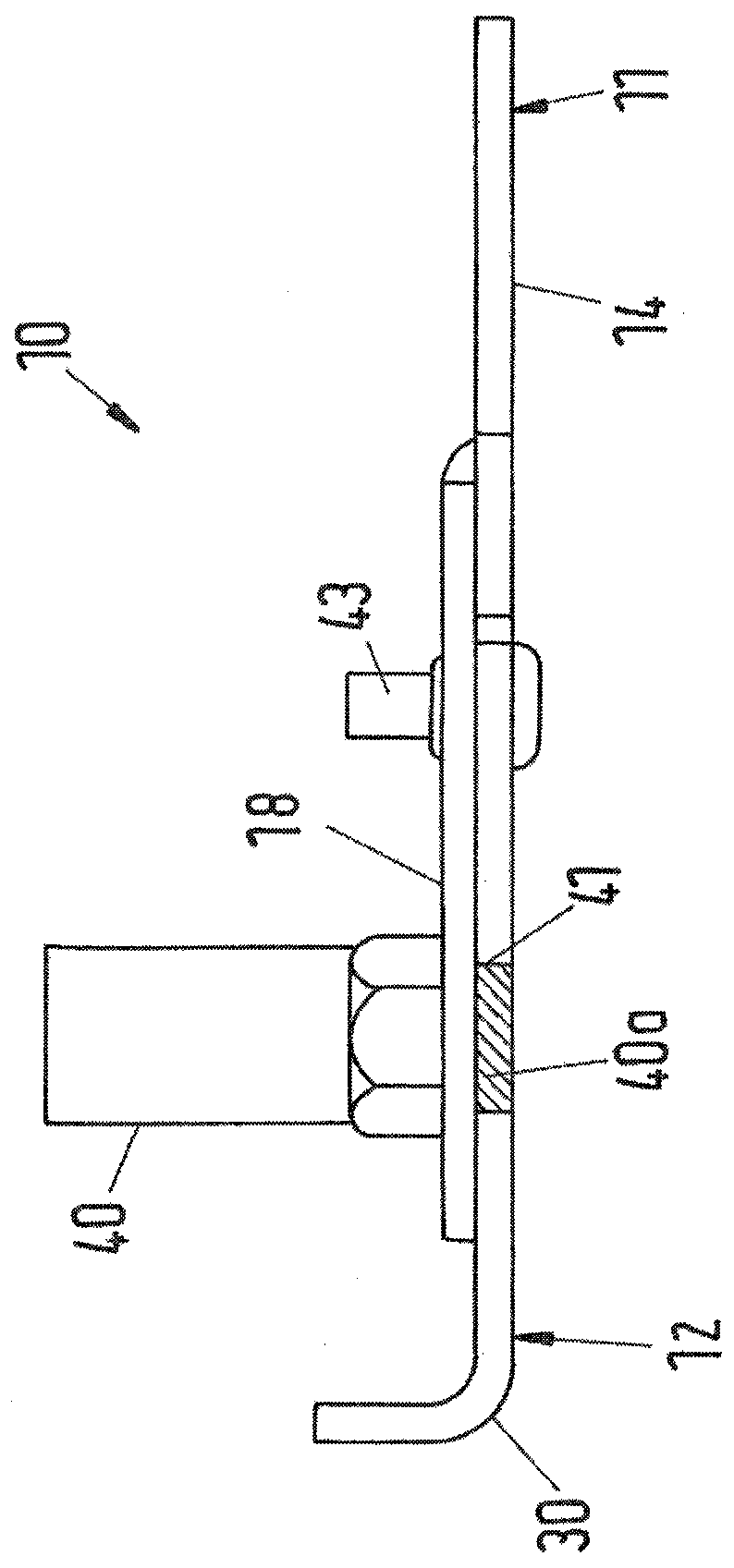

Motor/transmission unit and modular system

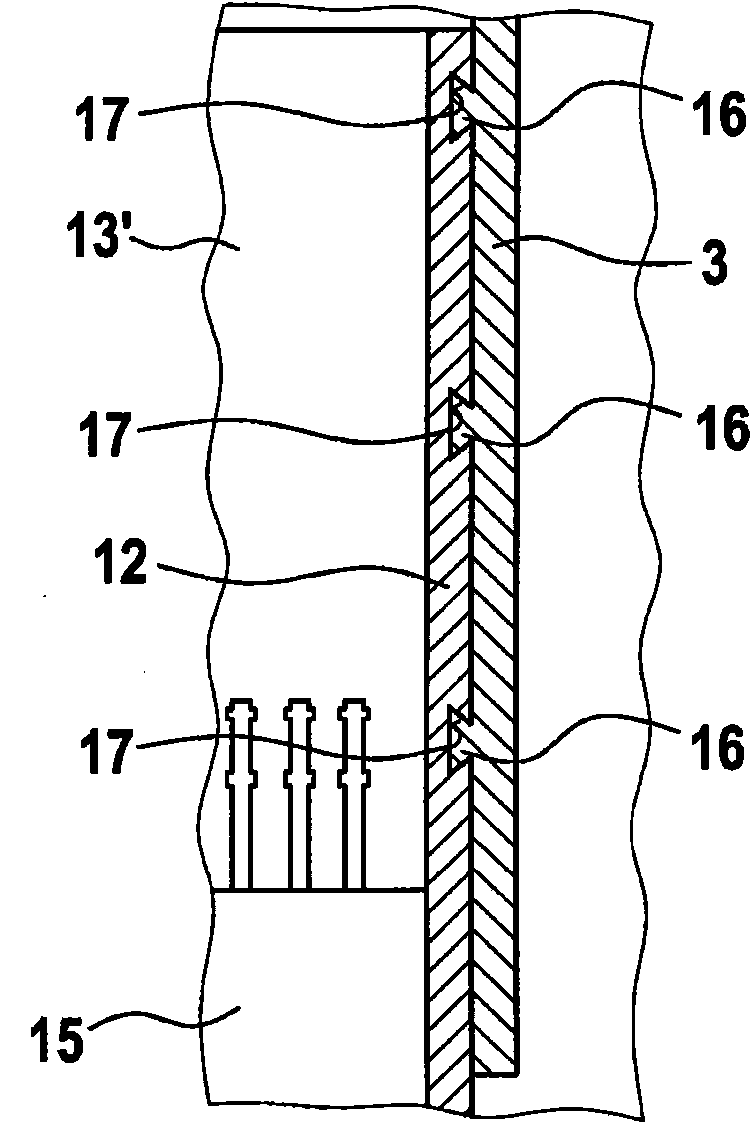

InactiveCN101971465AContact automaticAchieve pre-assemblyAssociation with control/drive circuitsMechanical energy handlingModularityPrinted circuit board

The invention relates to a motor / transmission unit (1), especially for automotive applications, comprising a printed circuit board housing (12) for a printed circuit board (13', 13''), which housing can be fixed to a transmission housing (3) and / or a motor casing (4', 4''). The motor / transmission unit is characterized in that the printed circuit board housing (12) can be fixed in different fastening positions. The invention further relates to a modular system.

Owner:ROBERT BOSCH GMBH

Attapulgite-perovskite composite material, preparation method and application thereof

ActiveCN102794169BPromote depolymerizationGood dispersionDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsNano structuringCatalytic oxidation

The invention discloses an attapulgite-perovskite composite material, a preparation method and application thereof, wherein the attapulgite-perovskite composite material is a composite material obtained by loading perovskite particles on the surface of attapulgite by taking attapulgite clay as a carrier, and the load capacity of the perovskite is 6-12 percent of the mass of the attapulgite clay. The composition of the composite material is mu%La1-xSrxMnO3 / PG, wherein mu is 6-12, and x is 0, 0.1 or 0.3. The composite material disclosed by the invention is of a nano structure, has the advantages of low activation capacity, high catalyst activity and strong capacity of resisting inactivation and can be applied to the purification of volatile organic pollutants such as toluene and the like and the catalysis and oxidization of other various organic matters.

Owner:HEFEI UNIV OF TECH

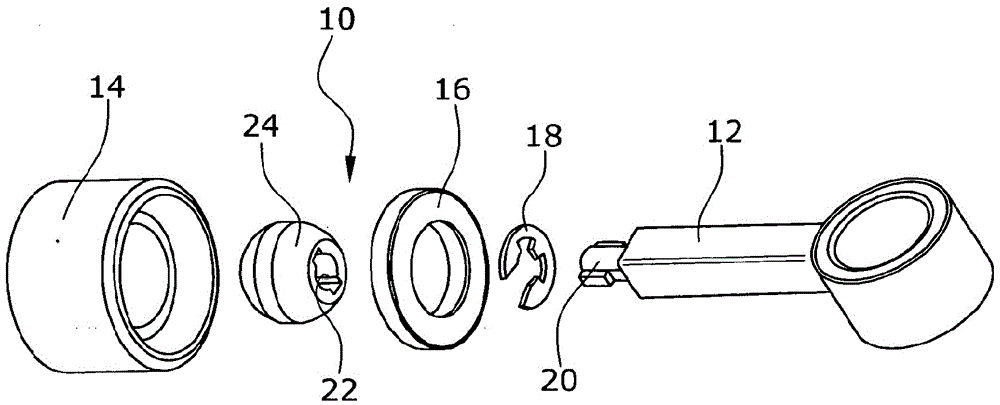

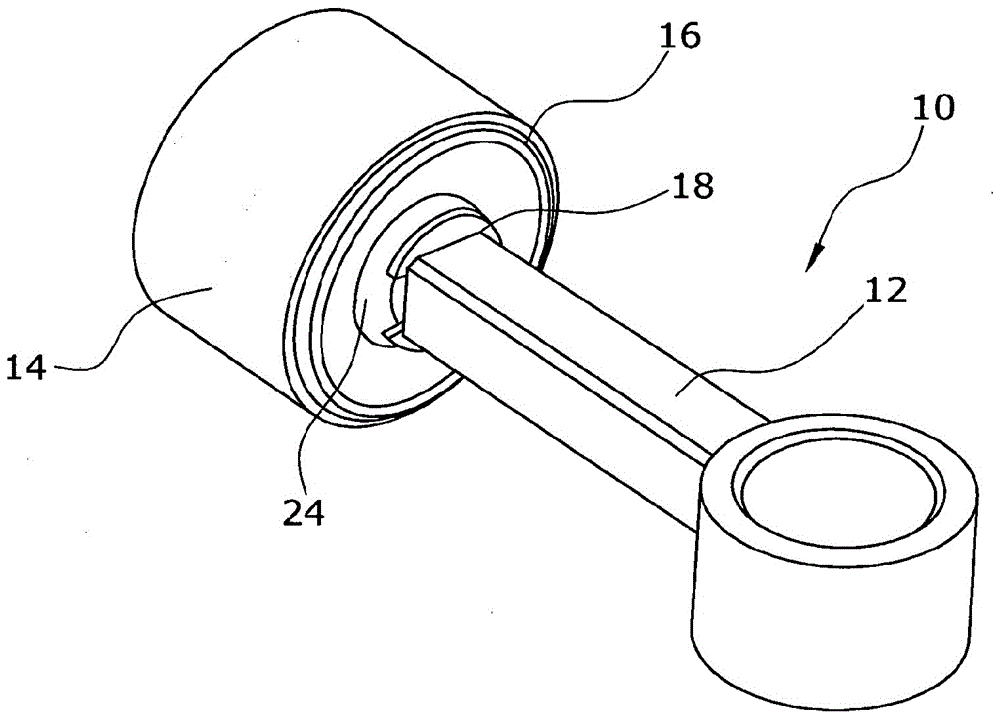

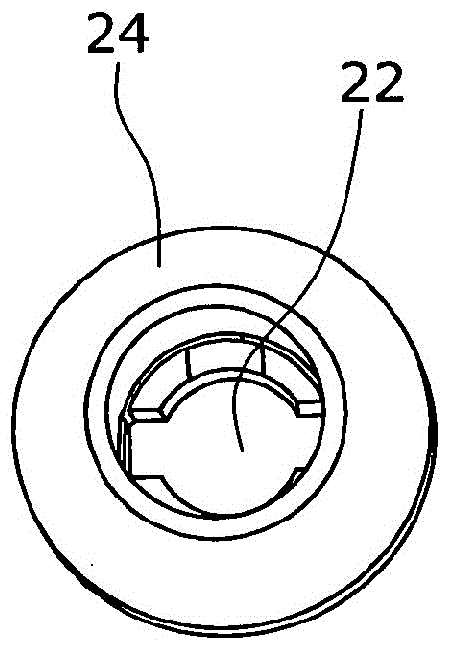

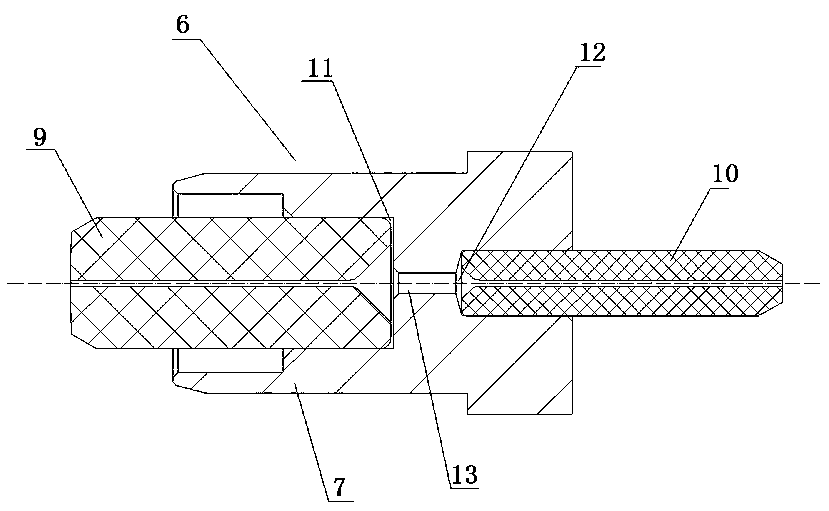

Connecting rod-piston assembly comprising a connecting rod having a spherical small end

InactiveCN106104104AEasy to produceSave storage spacePositive displacement pump componentsPlungersEngineeringMechanical engineering

Owner:GKN POWDER METALLURGY ENG GMBH

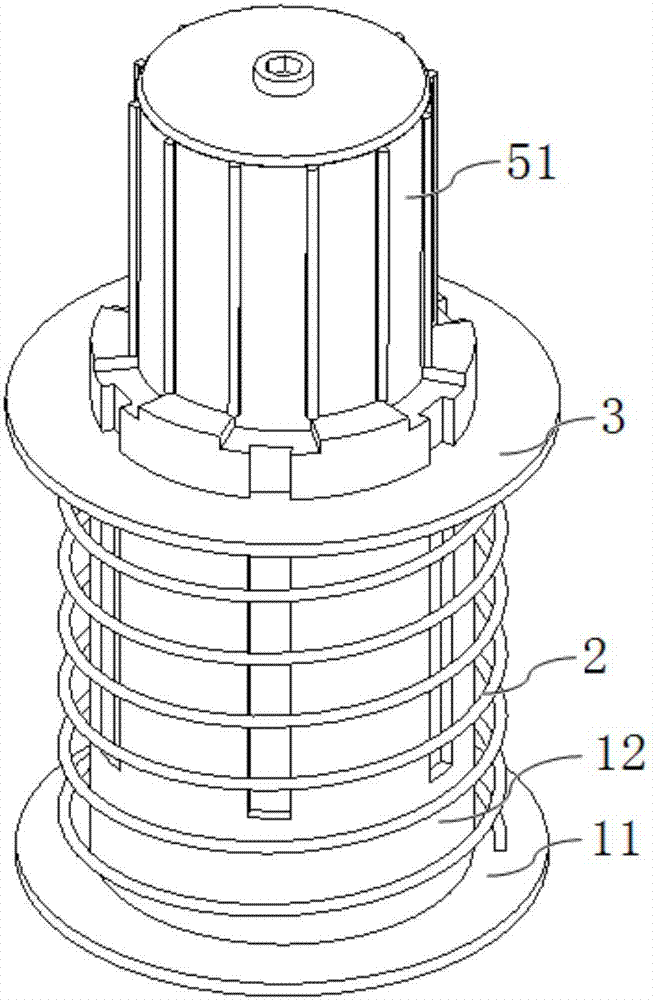

Assembly device of starter stator assembly

PendingCN107394973AImprove processing efficiencyImprove assembly qualityManufacturing stator/rotor bodiesStatorStructural engineering

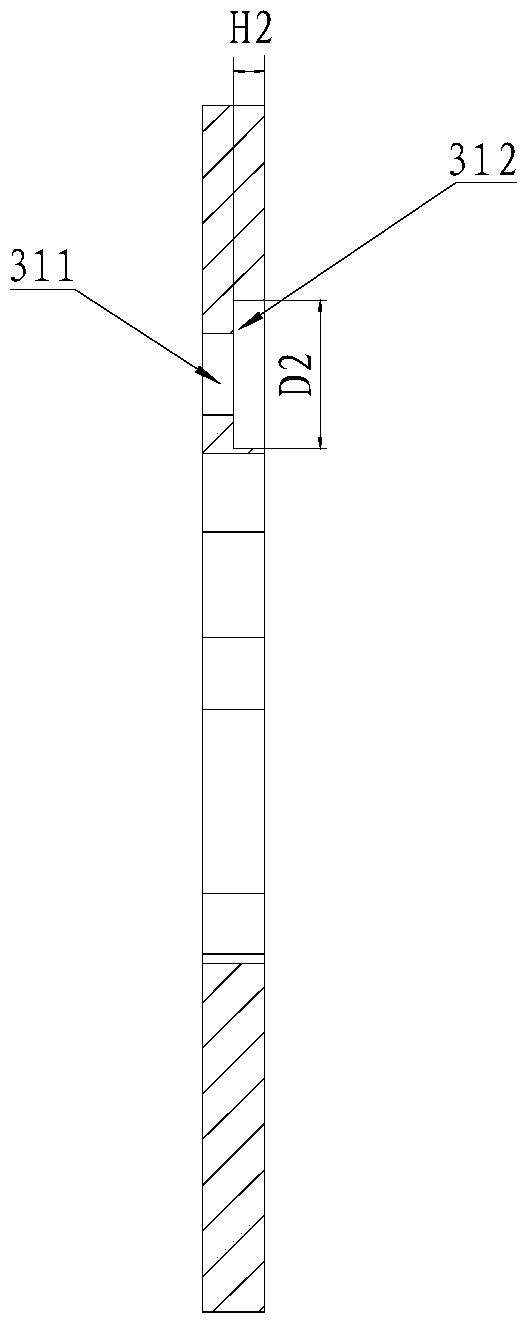

The invention discloses an assembly device of a starter stator assembly, which belongs to the field of assembly dies. The assembly device of the starter stator assembly comprises a support column, a sliding sleeve and an expansion mechanism. The sliding sleeve is in sliding connection with the support column and supports the sliding sleeve through a return spring. The expansion mechanism matches the sliding sleeve, and is used for fixing a magnetic tile and a magnetic tile clamp. The expansion mechanism mainly comprises a central column and struts. The struts are uniformly arranged along the circumferential direction of the central column, and the struts can telescope and extend along the radial direction of the central column. The struts are in a stripe structure, and are arranged along the length direction of the central column. Strut grooves are arranged in the central column, and the struts are located in the strut grooves. According to the invention, the magnetic tile and the magnetic tile clamp are pre-installed between the sliding sleeve and the expansion mechanism; the stator casing can be pressed in once; the assembly efficiency is greatly improved; glue bonding is not needed; and the assembly quality is better.

Owner:MAANSHAN HETENG AUTO PARTS

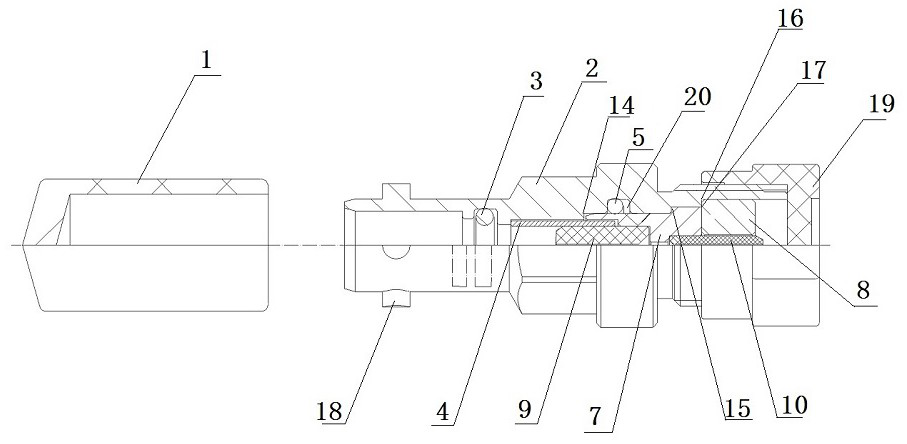

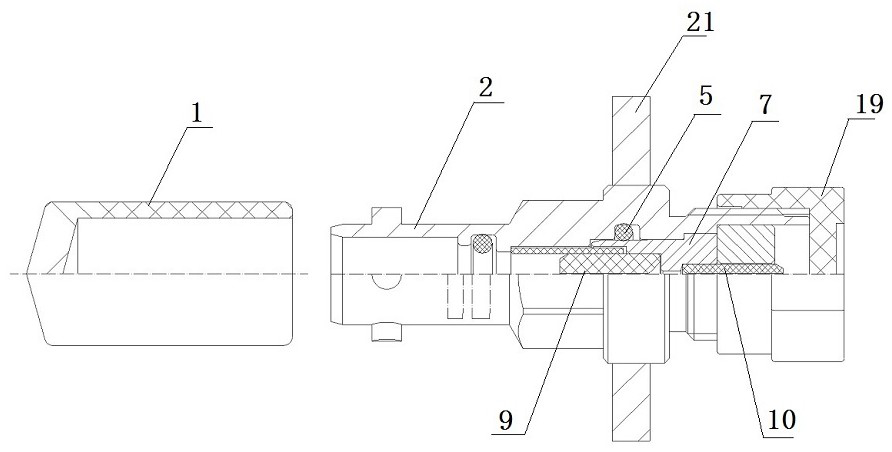

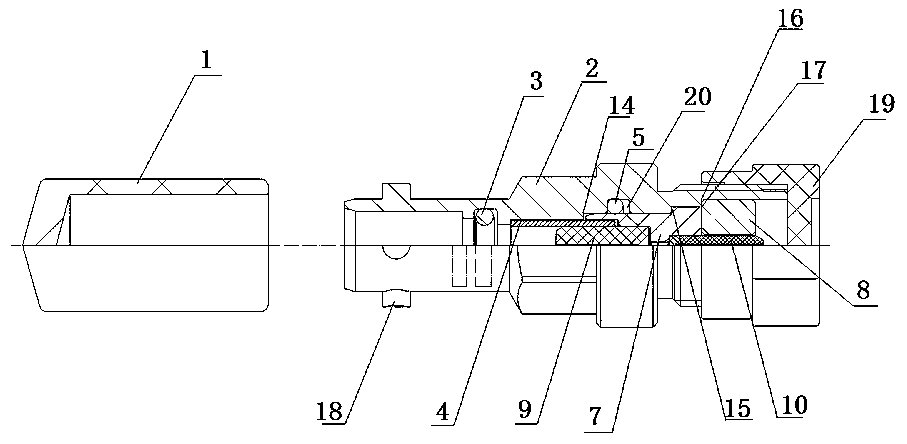

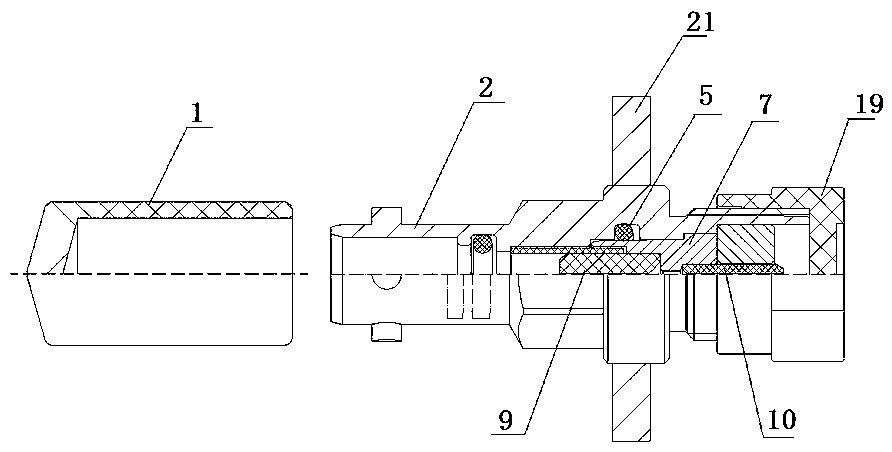

An optical fiber connector socket for ignition and detonation

ActiveCN110632705BGuaranteed tightnessExtended service lifeCoupling light guidesEngineeringLight signal

The invention relates to an optical fiber connector socket for ignition and detonation. The optical fiber connector socket for ignition and detonation comprises a hollow socket shell, and the front end of the socket shell forms a butt end for plugging with a matching optical fiber connector plug , the rear end of the socket housing forms a connection end for connecting the detonator, the socket housing is provided with a pin component, and the pin component includes a pin structure for receiving the optical signal output by the optical fiber connector plug and detonating the detonator , the pin component also includes a pin fixing piece inserted in the socket housing and positioned by the rear and forward stop, the pin fixing piece has a welding connection part welded and sealed with the socket housing, the pin fixing piece and the socket housing are welded and sealed. A peripheral surface sealing structure is provided between the socket housings on the side of the welded connection portion in the front-rear direction. The optical fiber connector socket for ignition and detonation is double-sealed to ensure its own sealing effect under the action of a relatively large impact force.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

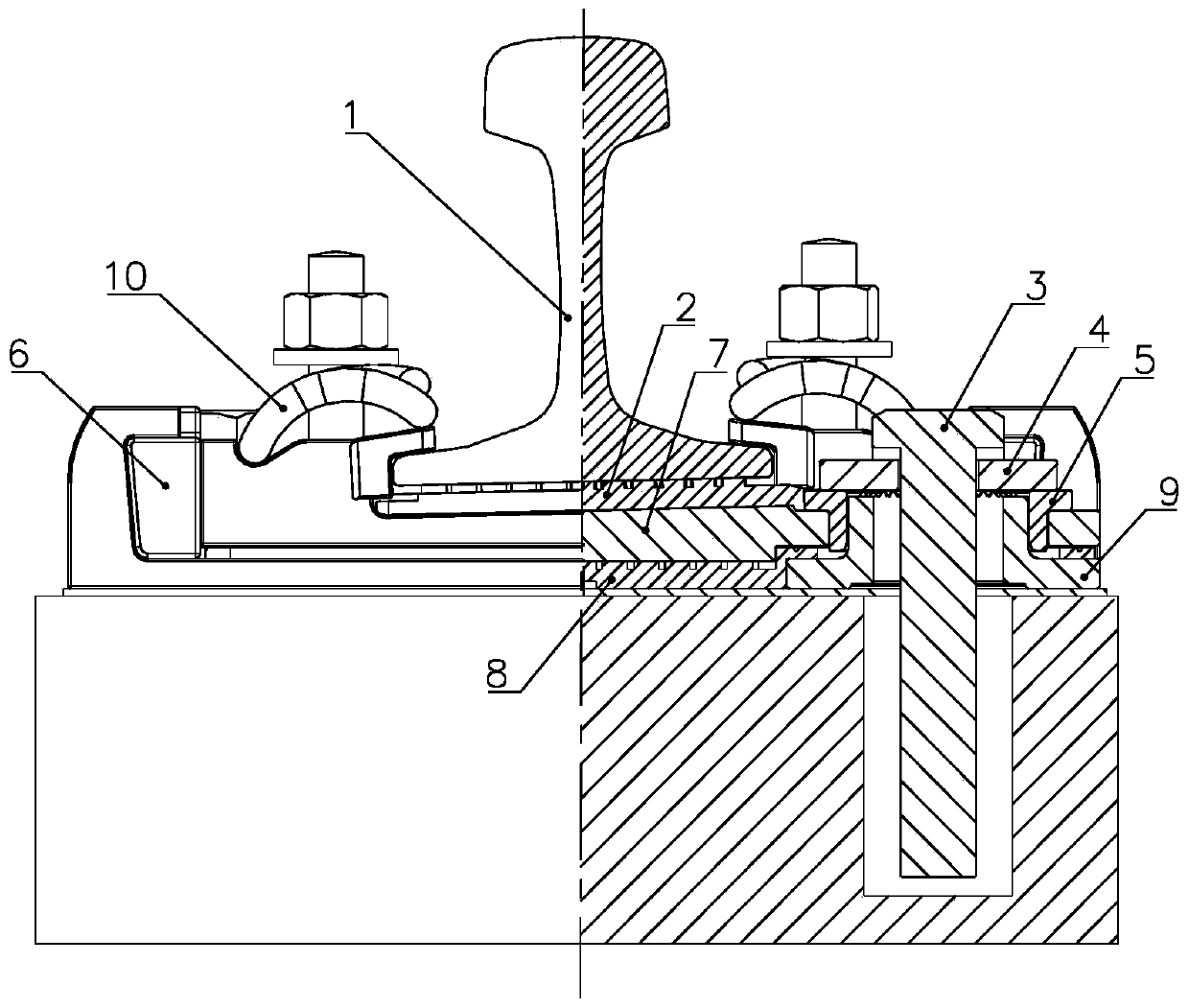

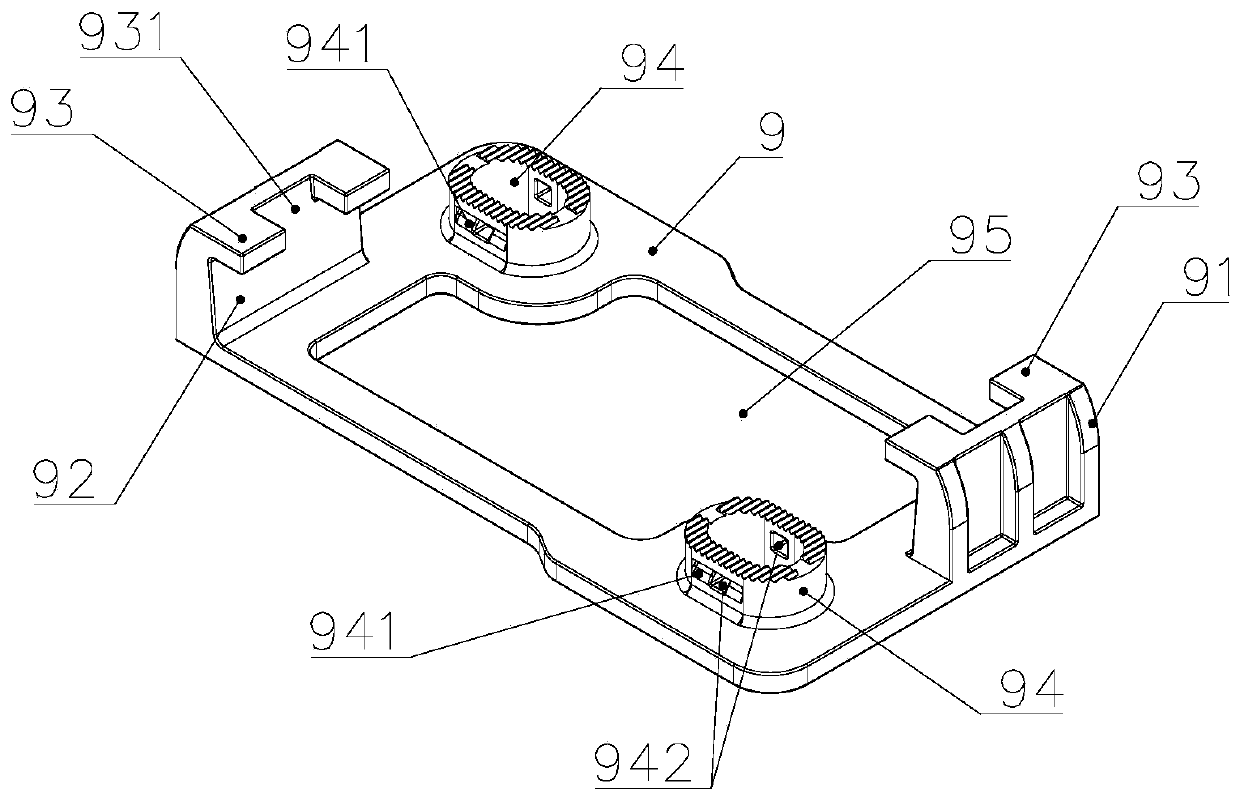

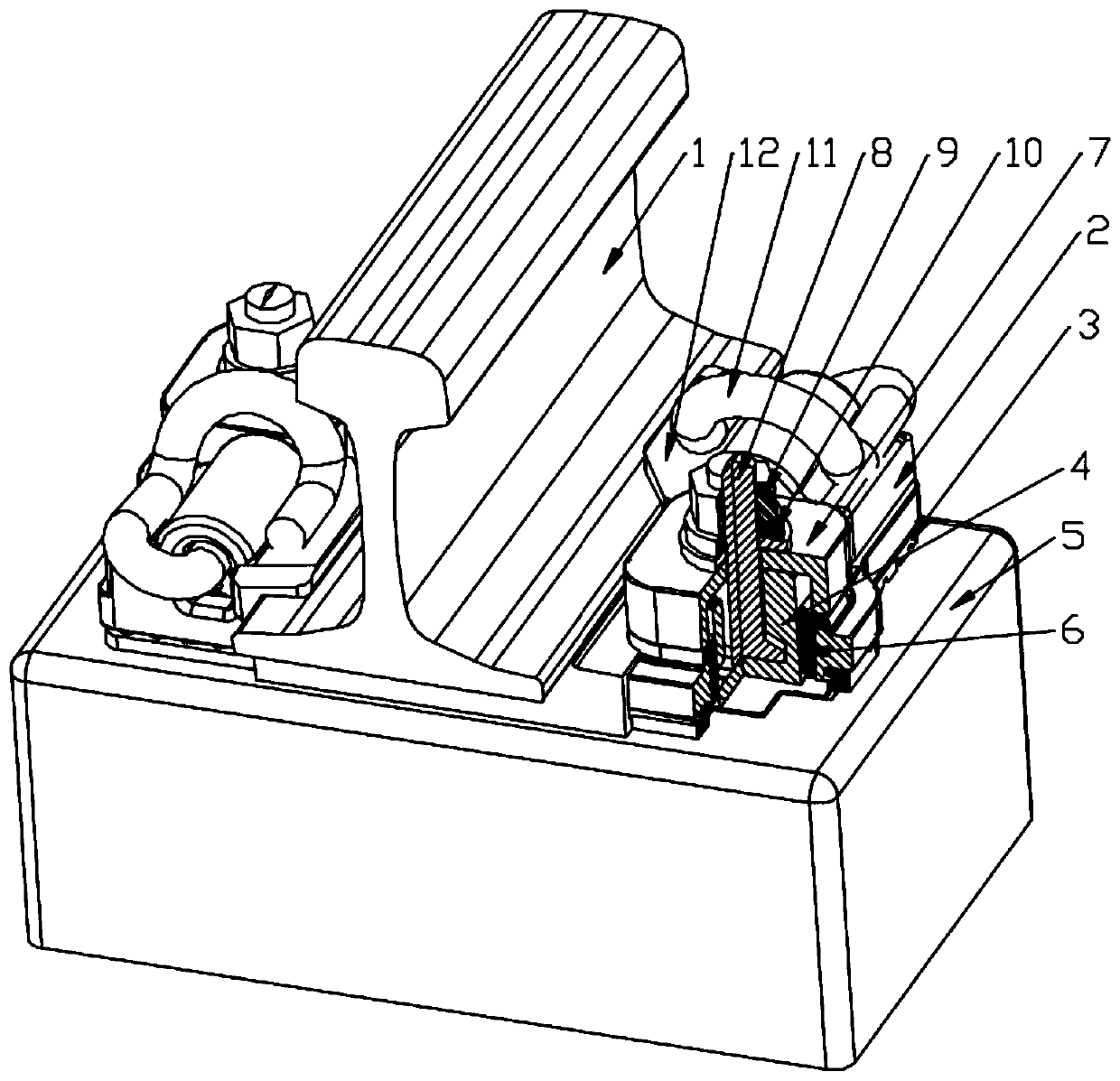

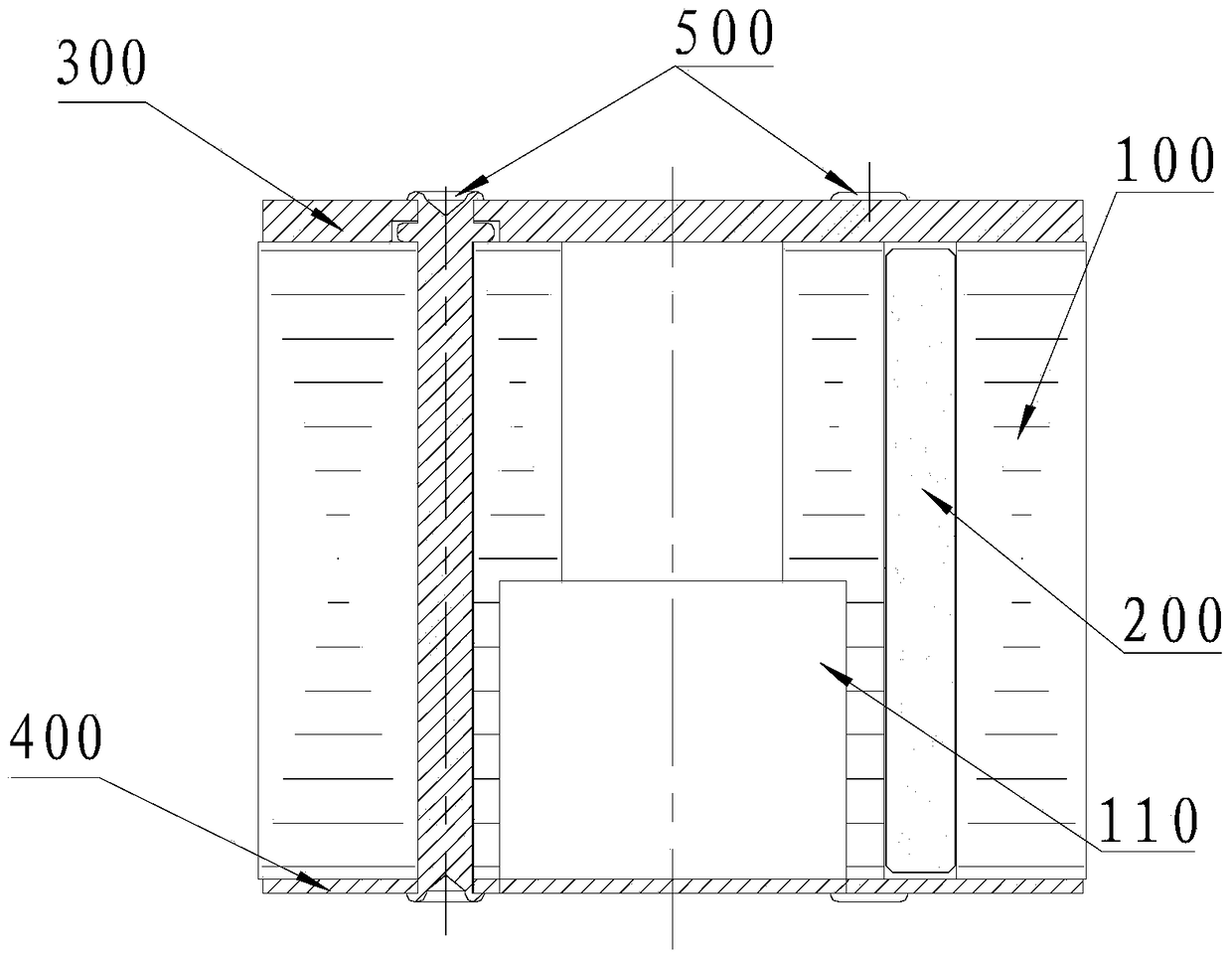

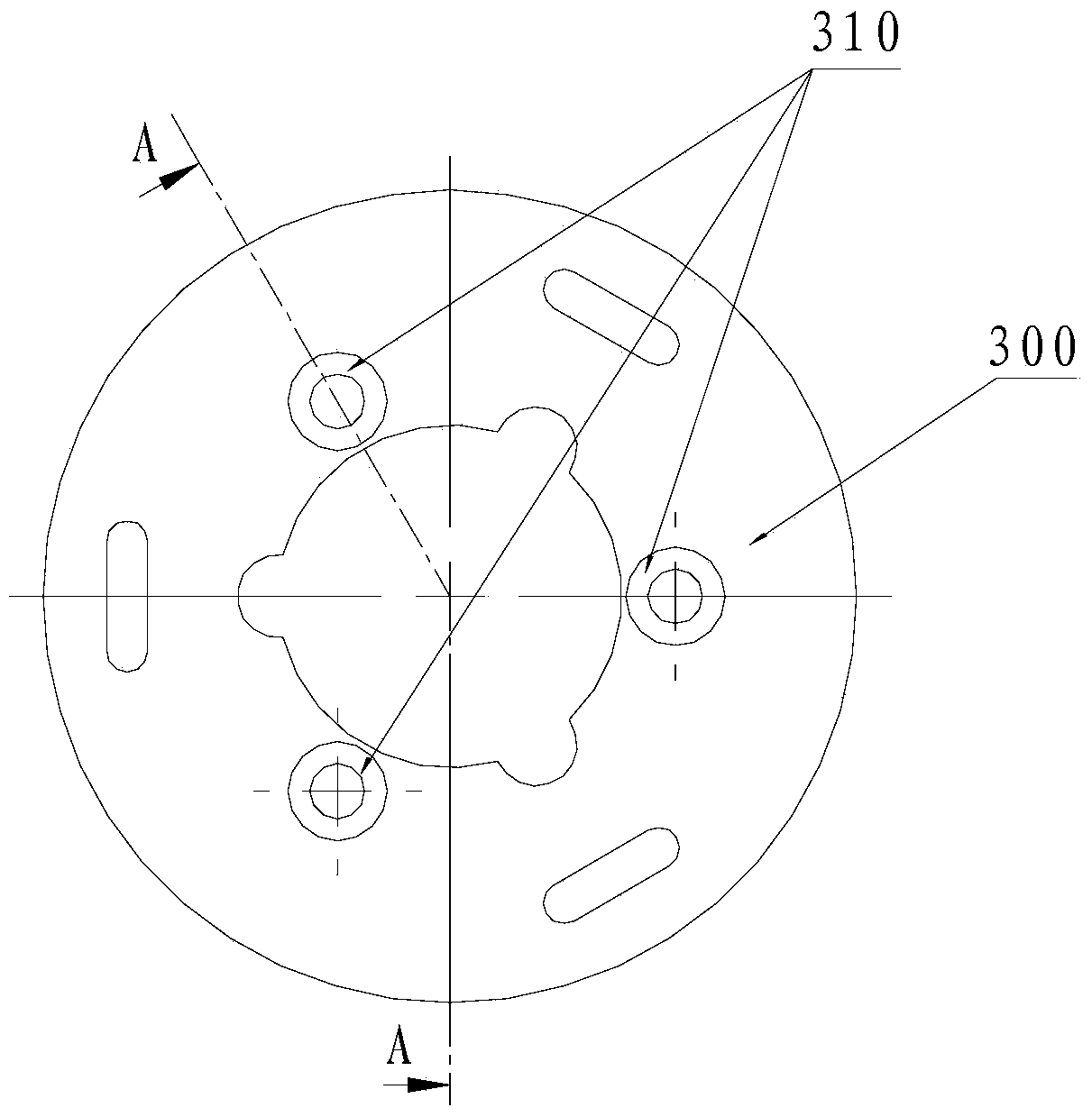

Track vibration attenuation fastener and installing method

PendingCN110468634AAchieve pre-assemblyQuick installationRail fastenersVibration attenuationLocking mechanism

The invention discloses a track vibration attenuation fastener. The track vibration attenuation fastener comprises a positioning boss (4), an elastic cushion (3) and a locking mechanism; the elastic cushion (3) comprises two layers of cushion bodies, and a track bearing plate (2) is arranged between the two layers of cushion bodies; the locking mechanism comprises a locking nylon sleeve (6), a preassembled protrusion (61) and a preassembled groove (22) are mutually buckled, a flange (62) presses the top of the track bearing plate (2), and then the elastic cushion (3), the track bearing plate (2) and the locking nylon sleeve (6) form a preassembled structure; and the preassembled structure penetrates through a boss structure of the positioning boss (4) and is arranged on the top of a trackfoundation, the locking mechanism further comprises a locking cover plate (7) and a bolt assembly, and the locking cover plate (7) and the bolt assembly jointly compress the positioning boss (4) and the preassembled structure. The invention further discloses a track vibration attenuation fastener installing method. According to the track vibration attenuation fastener, preassembling of the elasticcushion, the track bearing plate and the locking nylon sleeve before delivery is effectively achieved, and quick installation on the site is achieved.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Attapulgite clay-Ni/Fe nano composite material, preparation method and applications thereof

InactiveCN101537356BPromote depolymerizationGood dispersionCatalytic crackingOther chemical processesCatalytic pyrolysisNickel salt

An attapulgite clay-Ni / Fe nano composite material, a preparation method and applications thereof are characterized in that the attapulgite clay is taken as the raw material; metallic nickel and / or metallic iron particles with the diameter less than 20nm are loaded on the surface of attapulgite rhabdolith with the diameter between 40 and 50nm; the preparation method is that the attapulgite clay isprepared into suspension liquid, then the suspension liquid is hydrolyzed with iron salt and nickel salt and loaded on the surface of attapulgite crystal in the precipitation form of hydroxide, and finally the composite material is prepared through washing, dehydration, forming, drying and hydrogen reduction and calcination. With a nano structure, the composite material has low activation energy,high catalytic activity and strong resistance to carbon deposit, and can be applied to catalytic pyrolysis and purification of thermal gas and tar of a biomass gasification furnace and the catalytic pyrolysis of other various organisms.

Owner:HEFEI UNIV OF TECH

Beverage dispenser

PendingCN113661142AAchieve replacementAchieve pre-assemblyClosuresLiquid flow controllersHermetic sealEngineering

Owner:ASEPT INT

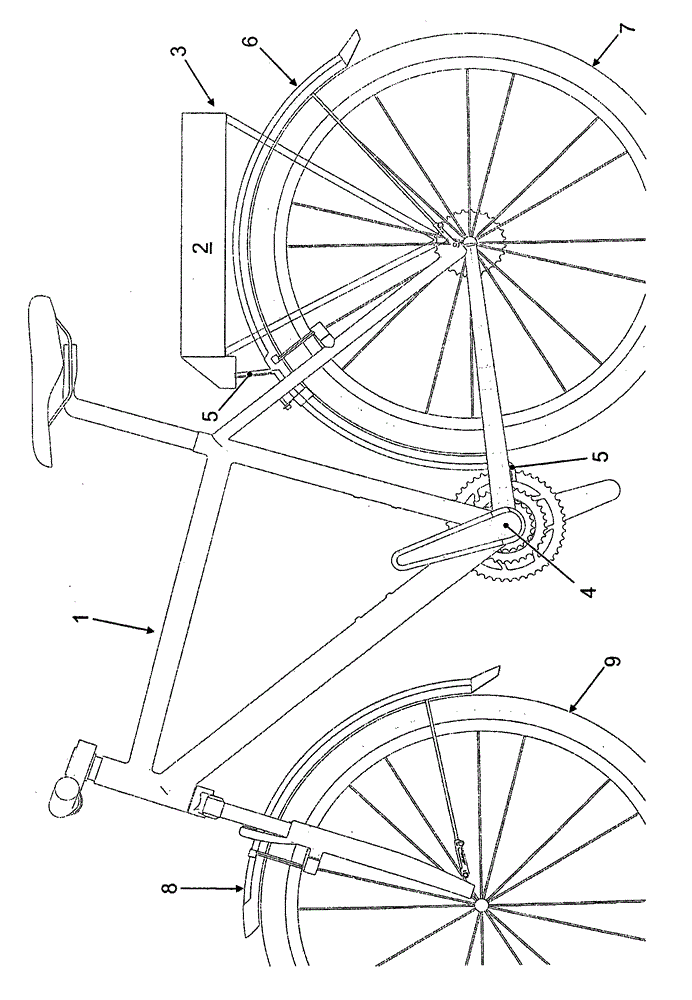

Wheel mudguard for bicycle

Owner:SKS METAPLAST SCHEFFER KLUTE

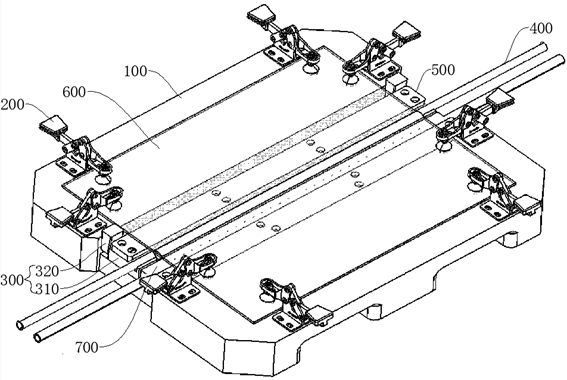

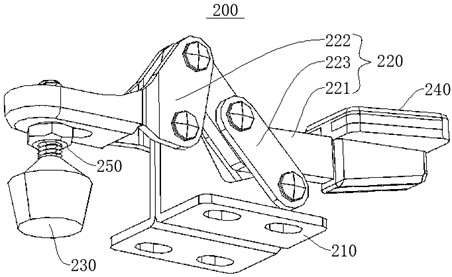

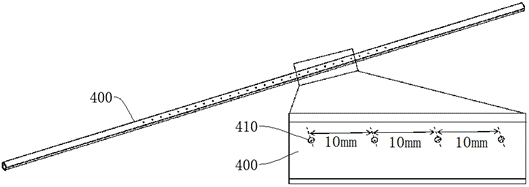

Tool clamp for penetration welding of T-shaped structure and clamping method

InactiveCN114535759AAchieve pre-assemblyAchieve fixationNuclear energy generationWelding accessoriesShielding gasStructural engineering

The invention discloses a work fixture for penetration welding of a T-shaped structure and a clamping method.The fixture comprises a base, multiple sets of pressing mechanisms, a jacking mechanism and an air pipe, a strip-shaped groove is formed in the top of the base, the multiple sets of pressing mechanisms are arranged on the periphery of the top of the base, the pressing mechanisms are used for pressing a flat plate in a T-shaped plate, the jacking mechanism is arranged in the strip-shaped groove, and the air pipe is arranged in the strip-shaped groove; a mounting groove is formed in the jacking mechanism, the jacking mechanism is used for fixing a vertical plate in the T-shaped plate in the strip-shaped groove so that the vertical plate can abut against the bottom face of the flat plate, the air pipe is arranged in the mounting groove, a plurality of air outlet holes are formed in the air pipe in the length direction of the air pipe, the air outlet holes are all close to the contact position of the flat plate and the vertical plate, and the air pipe is used for conveying protective gas. The device has the advantages that the gas protection effect can be guaranteed, deformation control is facilitated, the welding quality is high, and the penetration welding requirement of the T-shaped structure is met.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

Optical fiber connector socket for ignition and detonation

The invention relates to an optical fiber connector socket for ignition and detonation. The optical fiber connector socket for ignition and detonation comprises a hollow socket shell; a docking end for plugging an adapted optical fiber connector plug is formed on a front end of the socket shell; a connection end for connecting an electric detonator is formed on a rear end of the socket shell; a plug pin component is provided in the socket shell; the plug pin component comprises a plug pin structure for receiving an optical signal output by the optical fiber connector plug and detonating the electric detonator; the plug pin component further comprises a plug pin fixing member inserted into the socket shell and stopped and positioned from back to front; the plug pin fixing member is providedwith a welding connection part which is welded and sealed with the socket shell; and a peripheral surface sealing structure is provided on the side of front and rear directions of a welding connection part between the plug pin fixing member and the socket shell. The optical fiber connector socket for ignition and detonation guarantees the sealing effect under a large impact force through double sealing.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

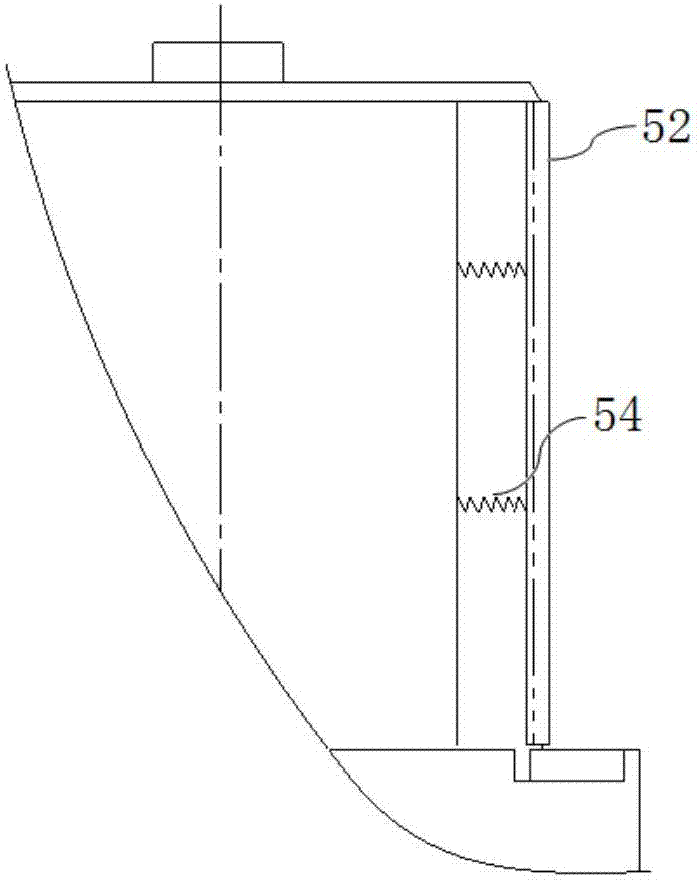

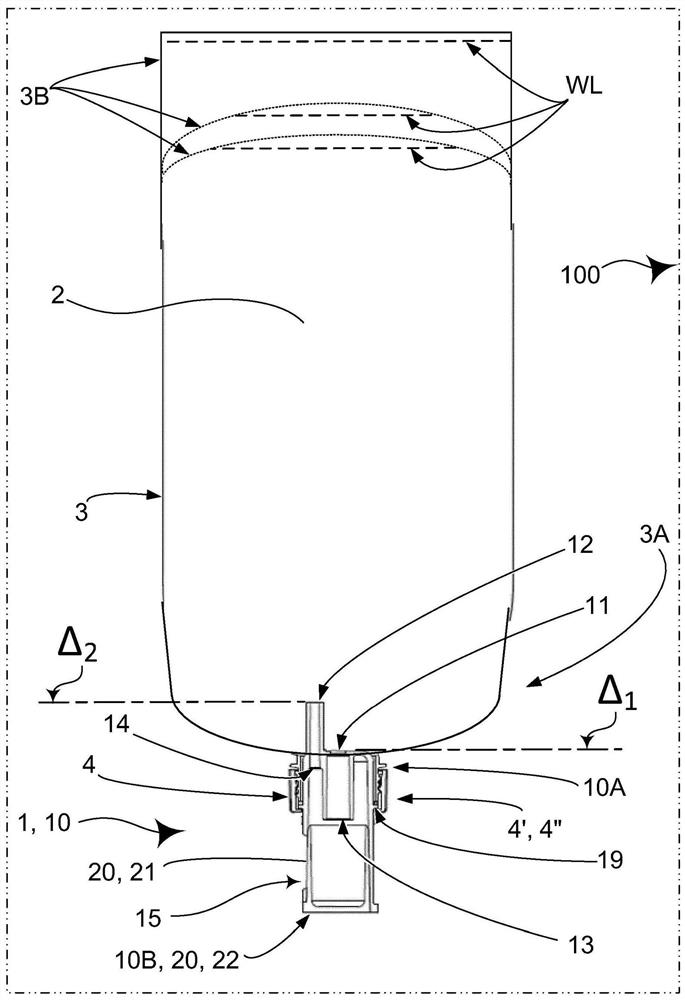

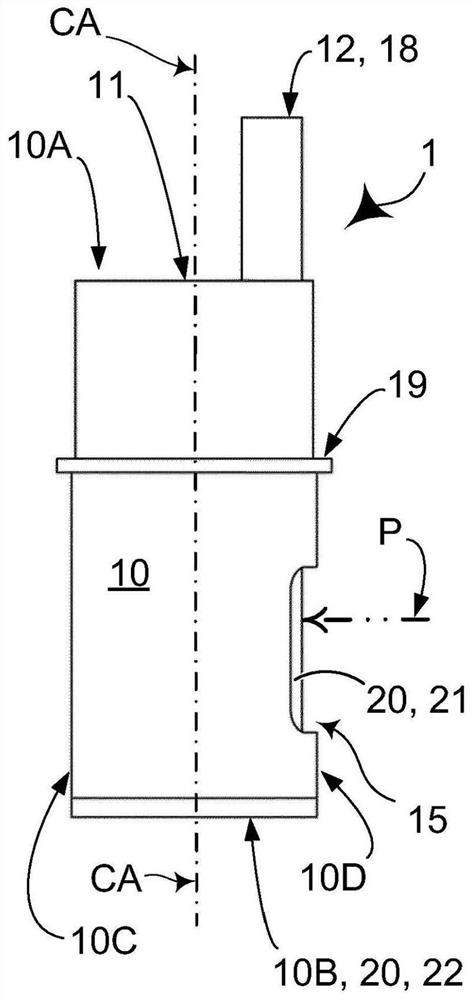

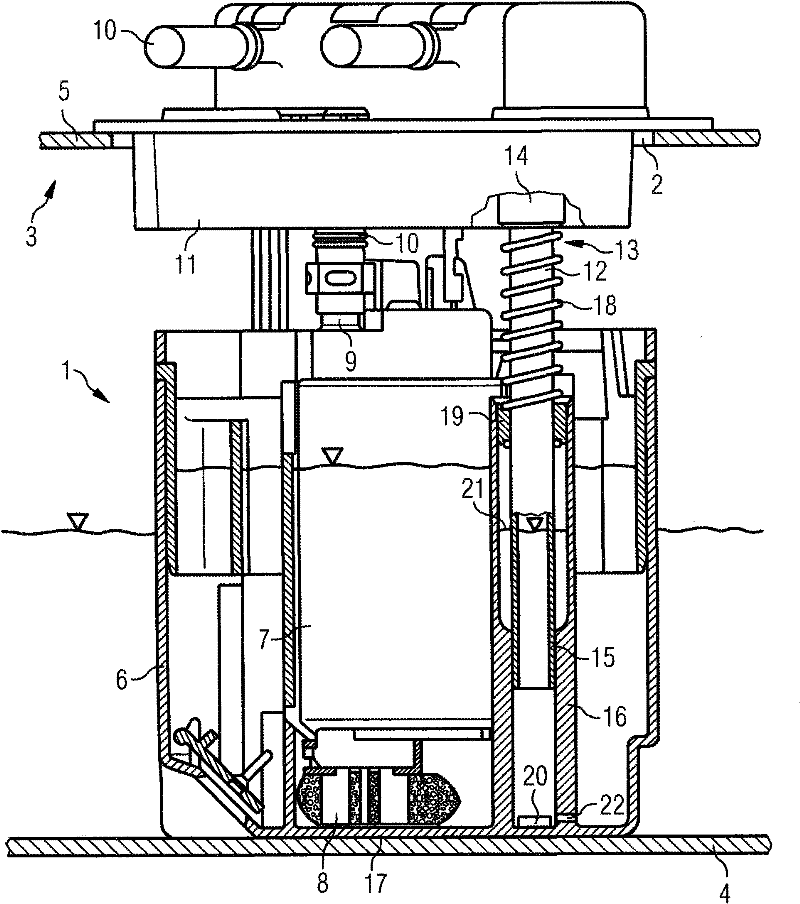

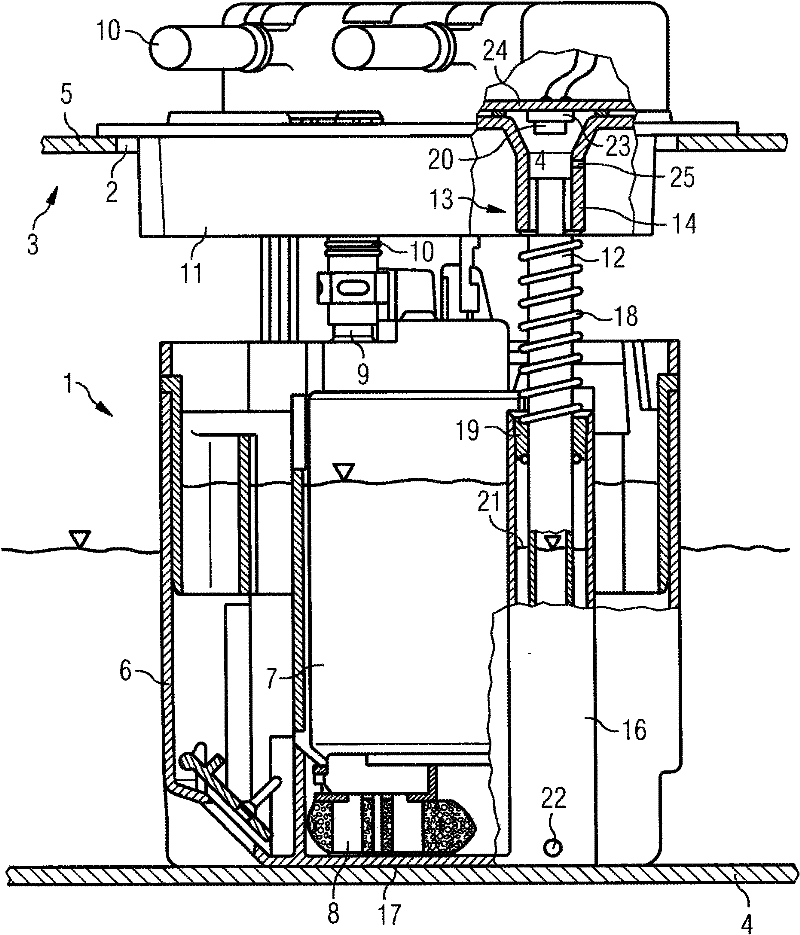

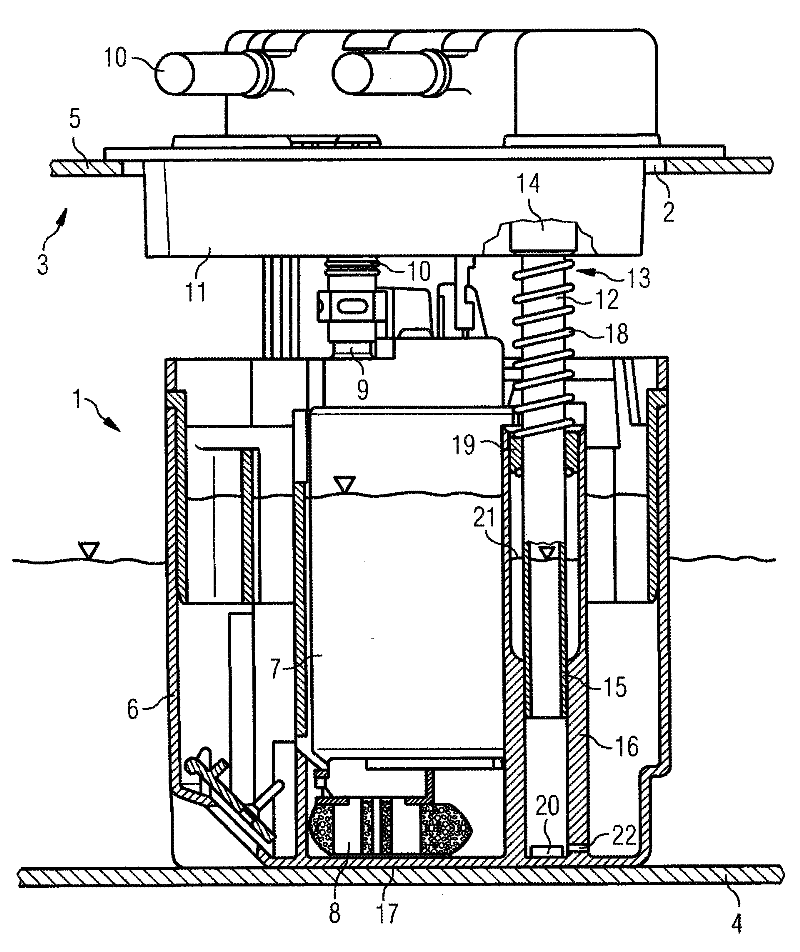

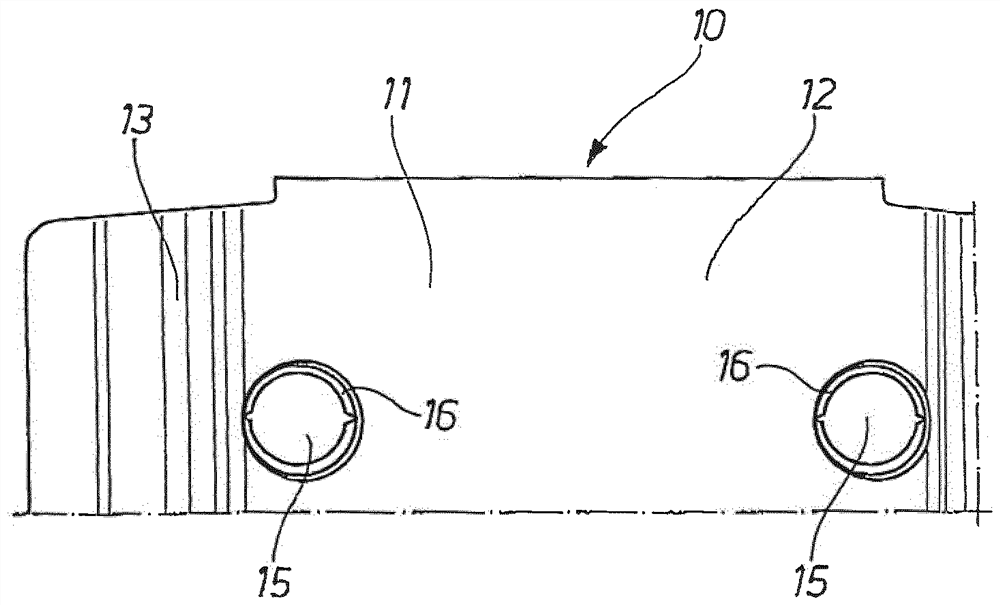

Fuel delivery unit with a filling level sensor operating with ultrasonic waves

ActiveCN101796377BPropagation ensuresCommunication OrientationMachines/enginesLevel indicatorsLevel sensorFuel tank

The invention relates to a fuel delivery unit (1), which can be inserted into the fuel tank (3) of a motor vehicle, comprising a swirl pot (6), a flange (11) for closing an opening (2) in the fuel tank (3), at least one support element (12) configured as a hollow profile, which is arranged between the flange (11) and the swirl pot (6) and prestresses the swirl pot (6) relative to the bottom (4) of the fuel tank (3), and a filling level sensor arranged on the swirl pot (6). The swirl pot (6) comprises at least one receptacle (16) for the at least one support element (12), the support element (12) gliding in said receptacle when the distance between the flange (11) and swirl pot (6) changes. The receptacle (16) extends to the bottom (17) of the swirl pot (6) and completely surrounds the periphery of the support element (12) and comprises an opening (22) in the bottom region through which fuel from the fuel tank (3) can enter the receptacle (16). The filling level sensor comprises a transmission and receiving unit (20) for ultrasonic waves, wherein the transmission and receiving unit (20) is arranged in the fuel delivery unit (1) such that the ultrasonic waves run in the receptacle (16) and the support element (12).

Owner:VTESCO TECH GMBH

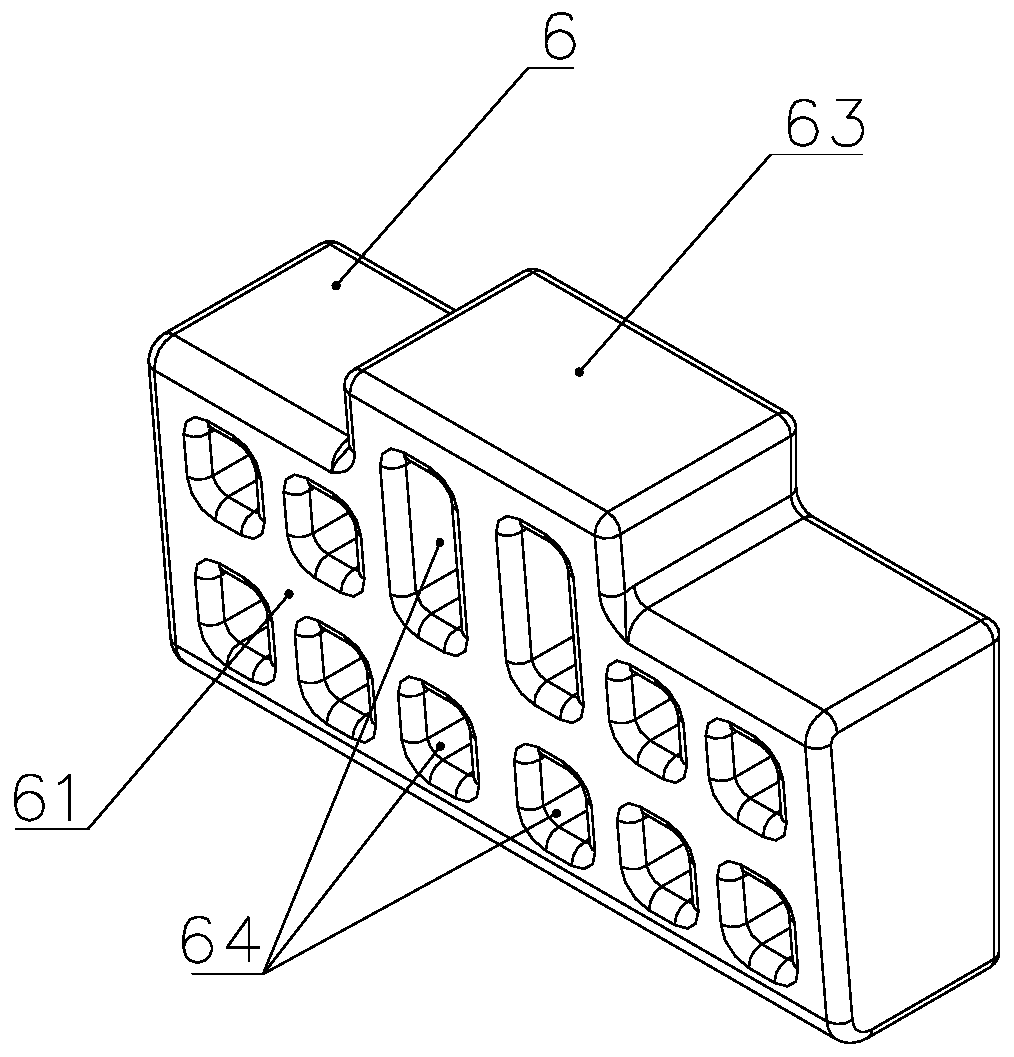

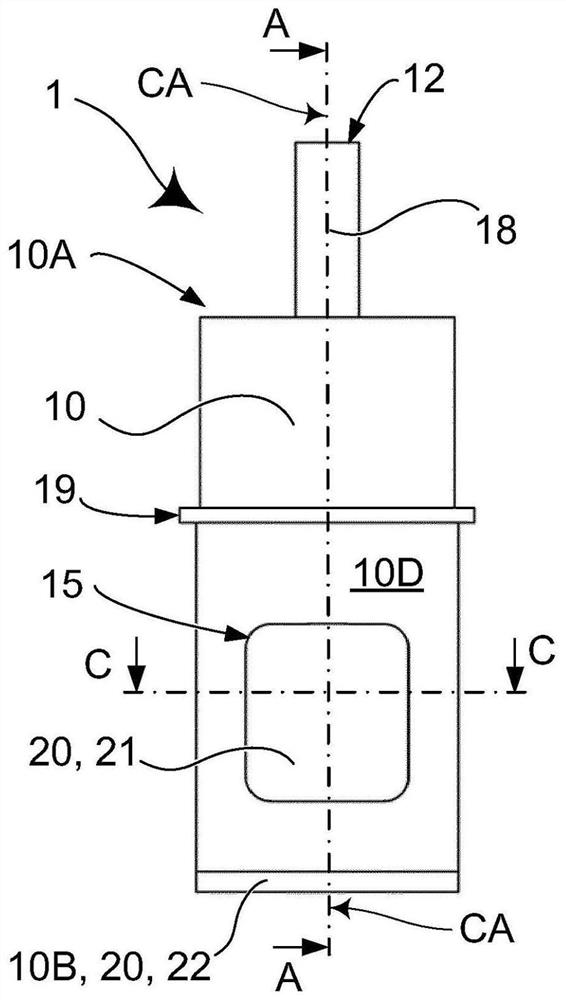

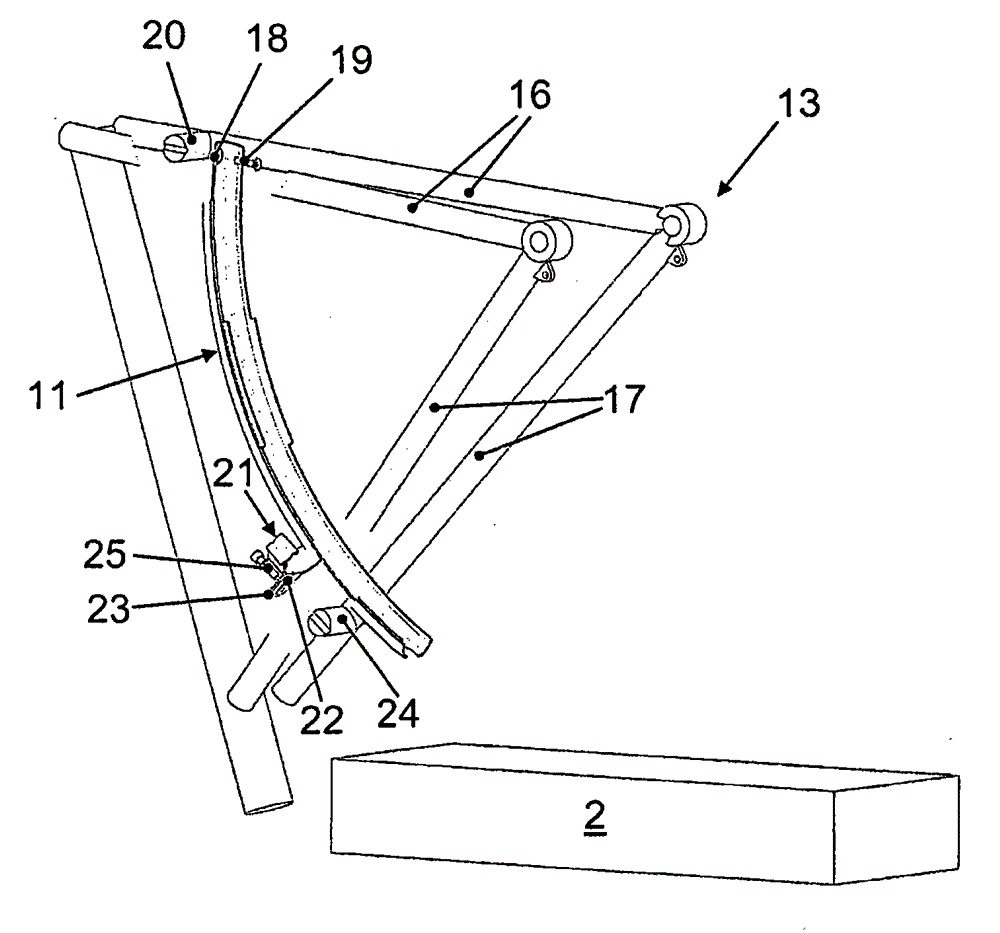

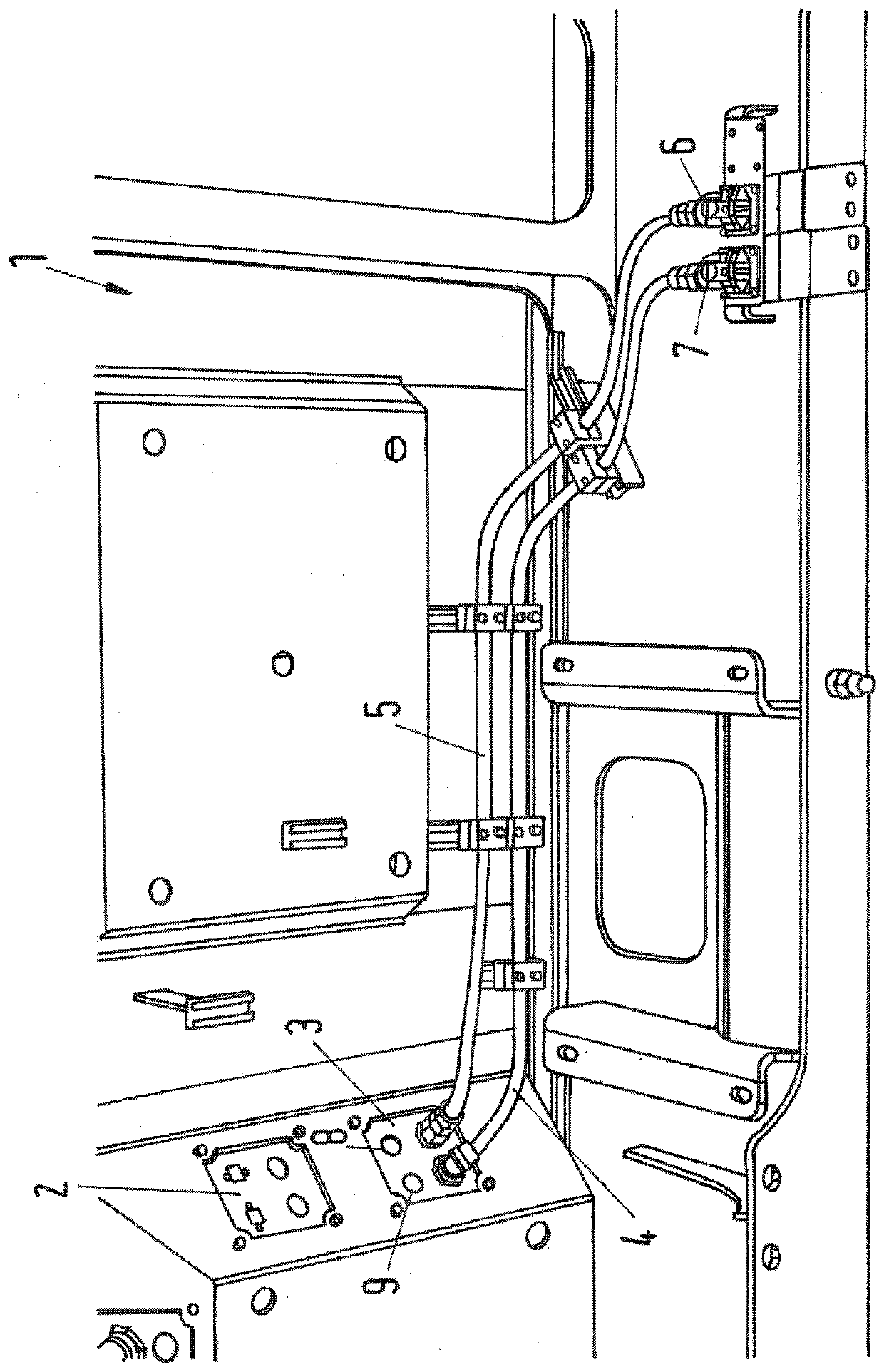

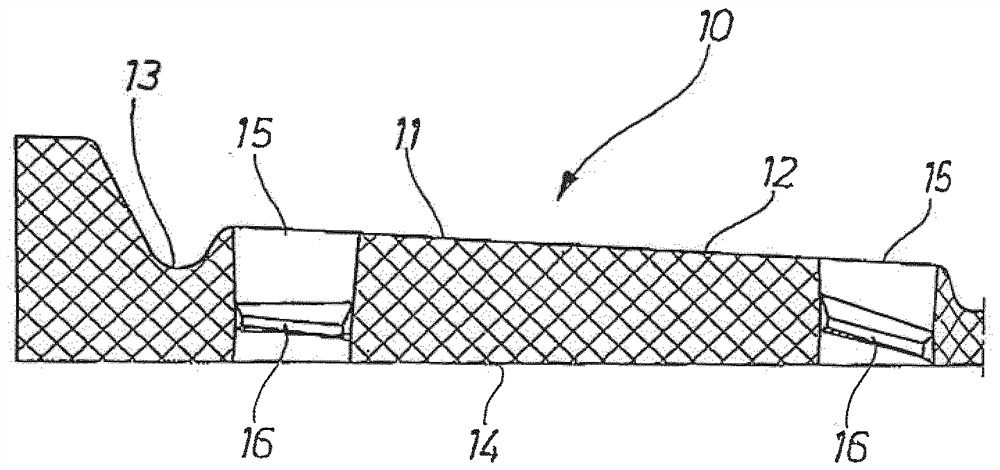

Cable feedthrough

ActiveCN110785903AAchieve pre-assemblyNeat end fixationElectrical apparatusEngineeringElectric cables

The invention relates to a cable feedthrough (10; 60) or a kit for a cable feedthrough. The cable feedthrough includes: a first plate (11; 61) which has at least one first outer edge section (19, 20);at least one second plate (12, 13; 62, 63) which has a second outer edge section (25), wherein the first and / or the second plate has at least one first indentation (21, 22, 23, 24) on the outer edgesection of the plate, and the first plate and the second plate are assembled or can be assembled so as to abut each other at the first outer edge section (20) and the second outer edge section (25) insuch a manner that a hole (33, 34, 35, 36) is formed by the indentation. The first plate has a first aligning element (15, 16, 17, 18) which interacts with the second plate (12) when the first plate(11; 61) and the second plate (12) are assembled such that the first plate and the second plate form a flat hole edge region (38) at least in a region surrounding the hole (33, 34, 35, 36).

Owner:BOMBARDIER TRANSPORTATION GMBH

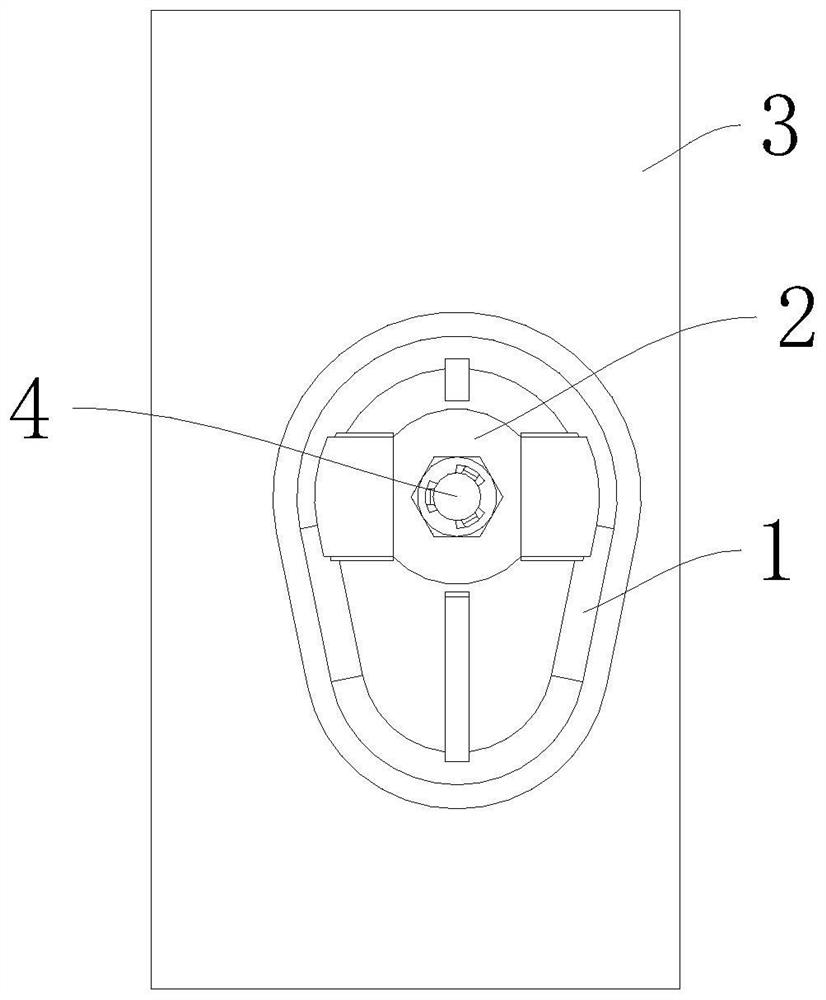

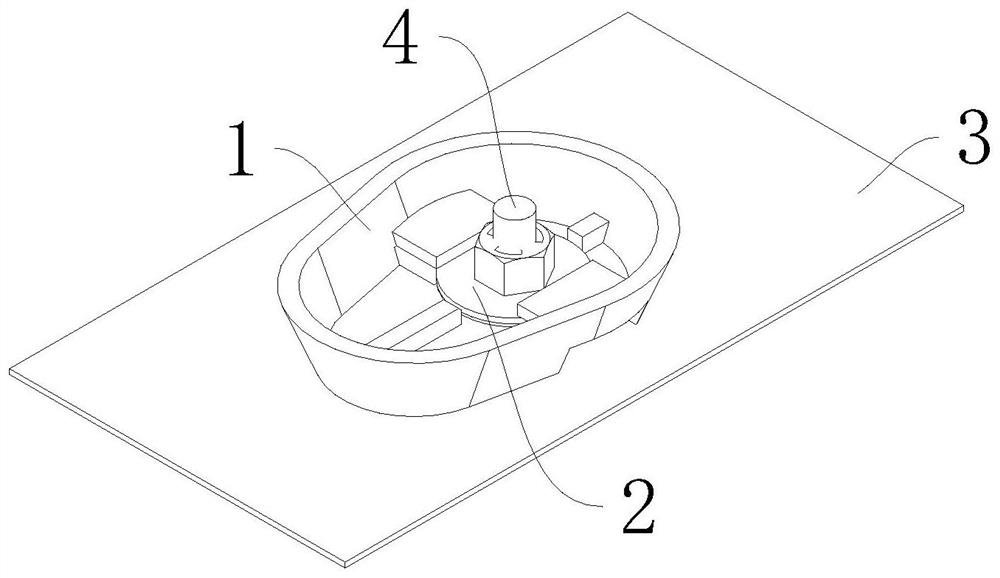

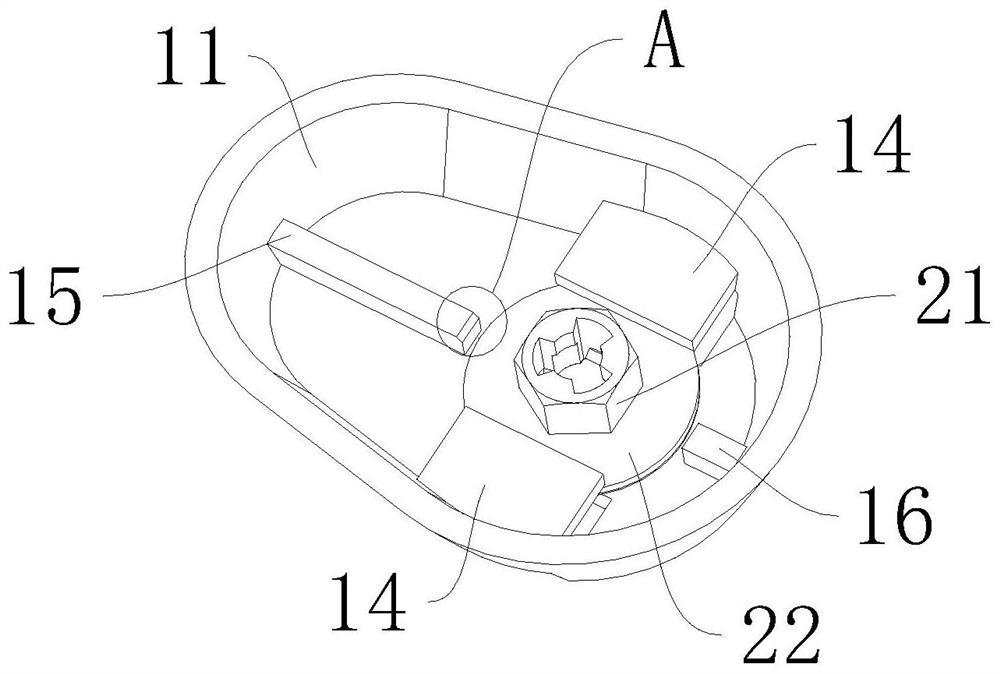

Nut mounting structure of automobile guard plate piece

PendingCN112145533AEasy to assembleReduce time to fetch assembly nutsNutsVehicle componentsStructural engineeringMechanical engineering

The invention discloses a nut mounting structure of an automobile guard plate piece in automobile parts. The nut mounting structure comprises a nut fixing seat and an assembling nut; the nut fixing seat has the outer circumferential surface extending in the circumferential direction; an opening is formed in one end of the outer circumferential surface; a fixing surface is arranged at the lower end, far away from the opening, of the outer circumferential surface; a through hole is formed in the fixing surface; the nut fixing seat further comprises at least two elastic limiting pieces; the limiting pieces are arranged on the inner wall of the outer circumferential surface; the bottom surfaces of the limiting pieces are parallel to the fixing surface and extend in the radial direction of thethrough hole; an assembling gap is formed between the bottom surfaces of the limiting pieces and the fixing surface; the assembling nut is detachably connected with the nut fixing seat, has an axial extending direction and comprises a nut body and an annular disc; the annular disc is coaxially arranged at one end of the nut body and extends in the radial direction of the assembling nut; and the outer edge of the annular disc is inserted in the assembling gap in a loose fit manner. According to the nut mounting structure, the assembling nut can be pre-assembled in the nut fixing seat, so that the time for taking the assembling nut by an assembly worker is shortened, and the assembly rhythm of an automobile is improved.

Owner:广西宁达汽车科技有限公司

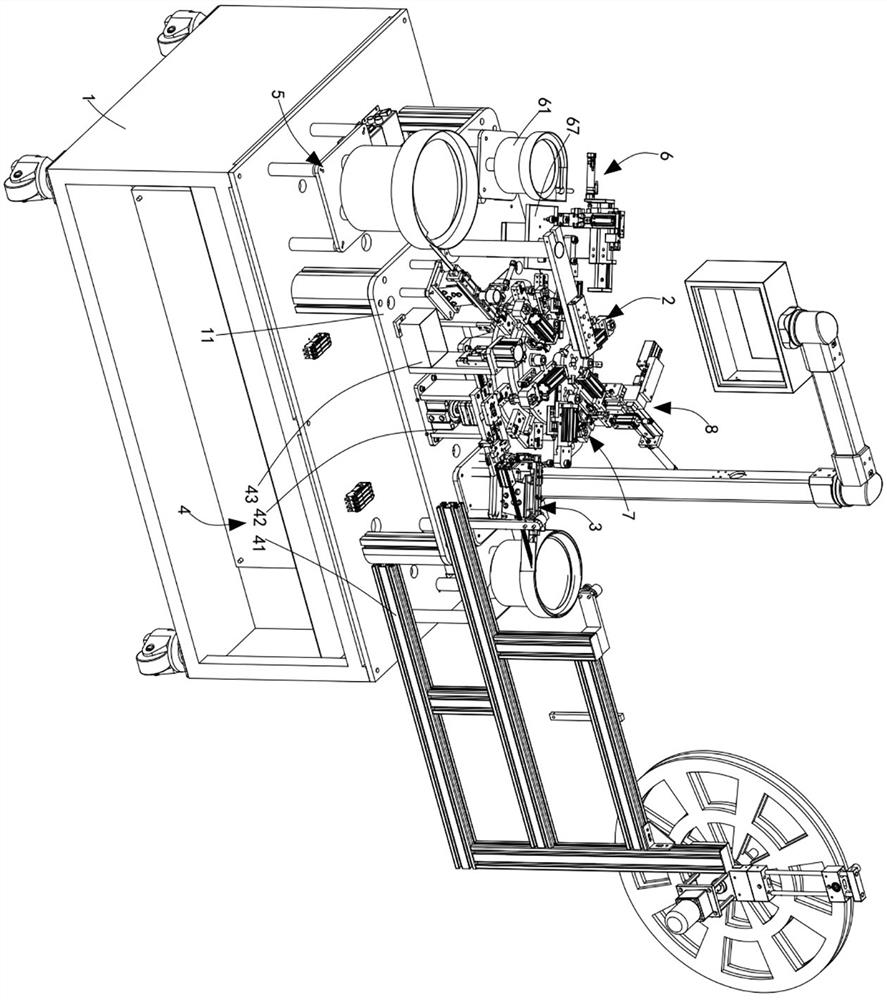

Automatic switch assembling machine

PendingCN113921309AIncrease productivityReduce manufacturing costElectric switchesProduct PartManufacturing engineering

The invention relates to an automatic switch assembling machine, which comprises a machine box, a machine table, a rotating disc mechanism, an elastic pad feeding mechanism, a shell feeding mechanism, a base feeding mechanism, an elastic piece feeding mechanism, a riveting mechanism and a product discharging mechanism, wherein the machine table, the rotating disc mechanism, the elastic pad feeding mechanism, the shell feeding mechanism, the base feeding mechanism, the elastic piece feeding mechanism and the riveting mechanism are arranged on the machine box, and the product discharging mechanism is arranged on one side of the riveting mechanism. The elastic pad feeding mechanism, the shell feeding mechanism, the base feeding mechanism, the elastic pad feeding mechanism and the riveting mechanism are sequentially arranged around the rotating disc mechanism. The elastic pad feeding mechanism, the shell feeding mechanism, the base feeding mechanism, the elastic piece feeding mechanism, the riveting mechanism and the product discharging mechanism are arranged around the rotating disc mechanism, automation of all product parts of a switch is achieved in the feeding, assembling and discharging process, the production efficiency is improved, the production cost is reduced, and the consistency of actions in the product assembling process is ensured, so that the consistency of the product assembling quality is ensured, and the yield is ensured.

Owner:HUIZHOU TRANTEK ELECTRONICS

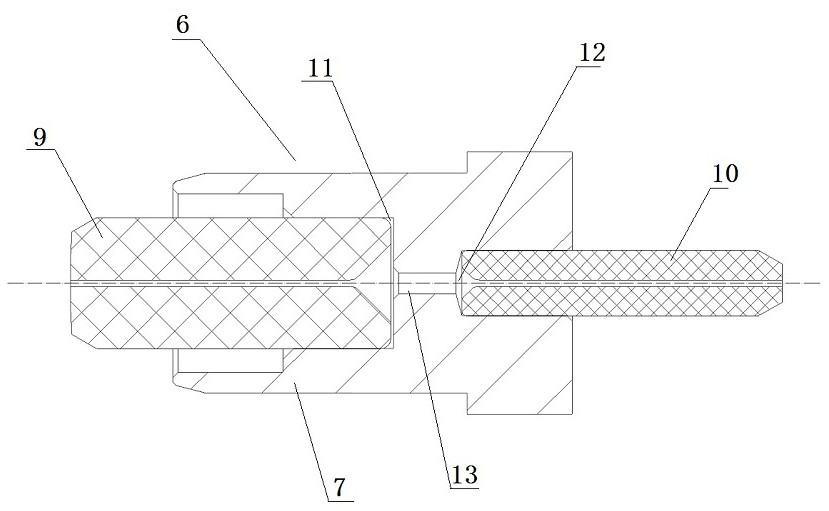

Motor rotor and magnetizing method thereof

ActiveCN106300727BAchieve pre-assemblyOptimizing the magnetization methodMagnetic circuit rotating partsManufacturing stator/rotor bodiesMagnetizationCounterbore

The invention provides a motor rotor. The motor rotor comprises a rotor core, magnetic steel, a first baffle, a second baffle, and fasteners, the first baffle is arranged at a first end of the rotor core, the first baffle is provided with counterbores for limiting the fasteners, each fastener comprises three segments in the length direction, the diameter of the second segment of the fastener is greater than the diameters of the first segment and the third segment of the fastener, the second segments of the fasteners are arranged in the counterbores, the second baffle is arranged at a second end of the rotor core, the second baffle is provided with through holes in a corresponding manner, the third segments of the fasteners can penetrate through the through holes, and the first baffle and the second baffle are fixed on the rotor core through the fasteners. The invention also provides a magnetizing method of the motor rotor. According to the motor rotor and the magnetizing method thereof, good coaxiality of the rotor and a crankshaft is guaranteed, magnetizing saturation of the magnetic steel is ensured, the magnetizing process is optimized, and the performance and the reliability of the motor are improved.

Owner:GREE ELECTRIC APPLIANCES INC

Two-row roller bearing and bearing system with such a roller bearing and a lubricating device

ActiveCN101846129BImprove the lubrication effectFirmly connectedRolling contact bearingsShaftsRolling-element bearingEngineering

The bearing i.e. tapered roller bearing (1), has a roller body (8), which is axially arranged besides another roller body (7) with respect to a rotation axis. The former roller body unrolls between an outer ring (4) and an inner ring (6). A lubricating grease inlet (21) is arranged at an axial side of the outer ring with respect to the rotation axis for supplying the latter roller body with lubricating grease (22). Another lubricating grease inlet (27) is arranged at another axial side of the outer ring for supplying the former roller body with the lubricating grease. An independent claim is also included for a bearing system comprising a roller bearing.

Owner:AB SKF

Disposable pipeline integrated pump head split micropump

ActiveCN105443363BCompact structureReduce volumeFlexible member pumpsPositive-displacement liquid enginesPeristaltic pumpMicropump

The invention relates to a split type miniature peristaltic pump, in particular to a miniature peristaltic pump, wherein a pipeline is integrated to a pump head, and both the pump head and the pipeline can be used for one time. The micropump comprises a pump body, a motor and a pump head and pipeline assembly. The pump head and pipeline assembly comprises a pump head seat, an eccentric wheel, a pump head roller and a circumferential pressing pipeline; a pump head seat center hole is formed in the pump head seat, a through hole is coaxially formed in the bottom of the pump head seat center hole, and a pipeline inlet / outlet groove is formed in one side of the pump head seat; the pump head roller is arranged in the pump head seat center hole, a pump head roller center hole is formed in the pump head roller, and the eccentric wheel is arranged in the pump head roller center hole and connected with an output shaft of the motor through an eccentric hole; and a pump head roller groove is formed in the outer wall of the pump head roller, and the circumferential pressing pipeline is sleeved with the pump head roller groove along the outer wall of the pump head roller. According to the micropump, the structure of the assembly formed by the pump head and the pipeline can guarantee that the pump is compact in structure and small in size; and the single-use purpose can be achieved, the pollution risk is lowered effectively, and the experiment success rate is increased to a great extent.

Owner:SCI RES TRAINING CENT FOR CHINESE ASTRONAUTS

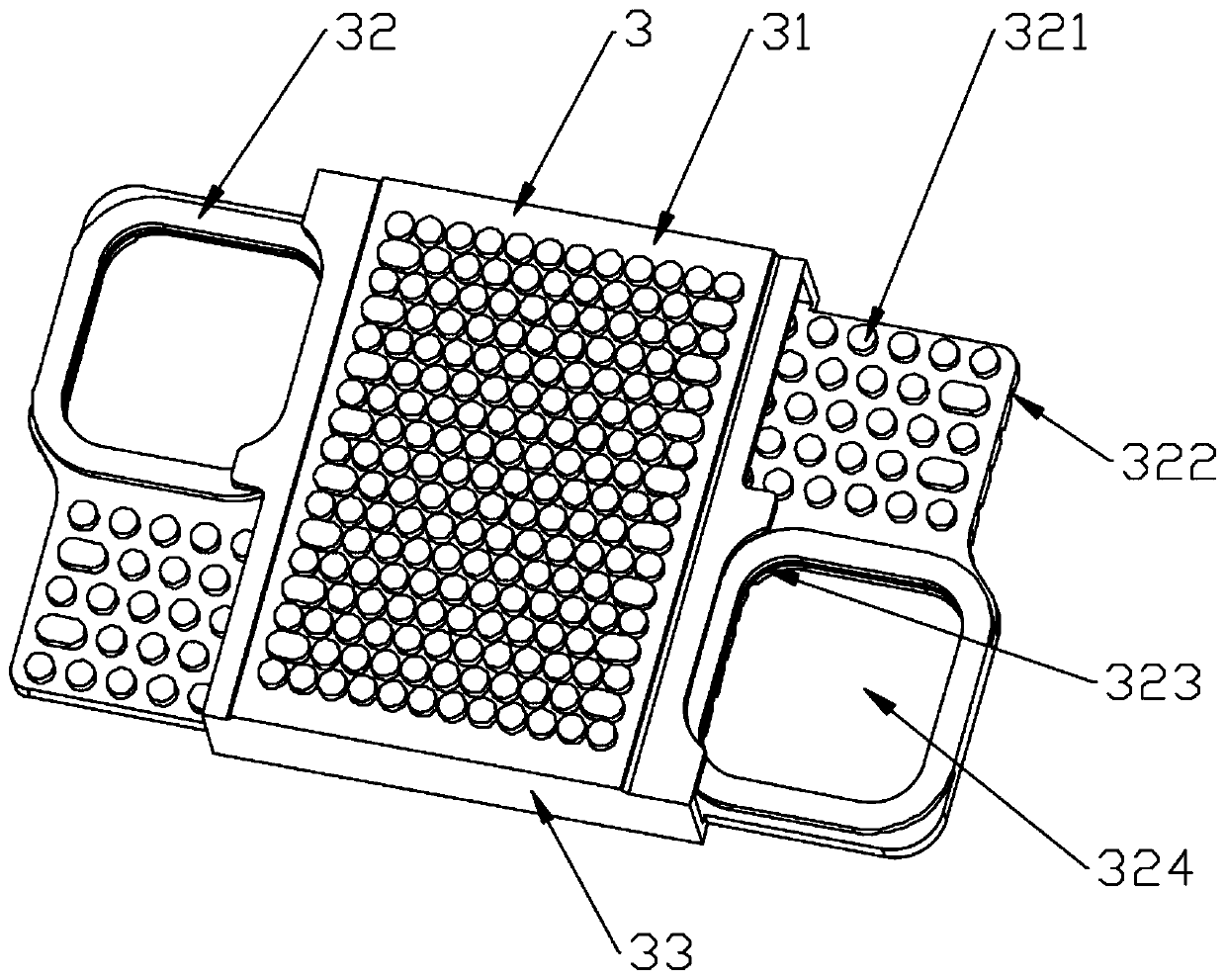

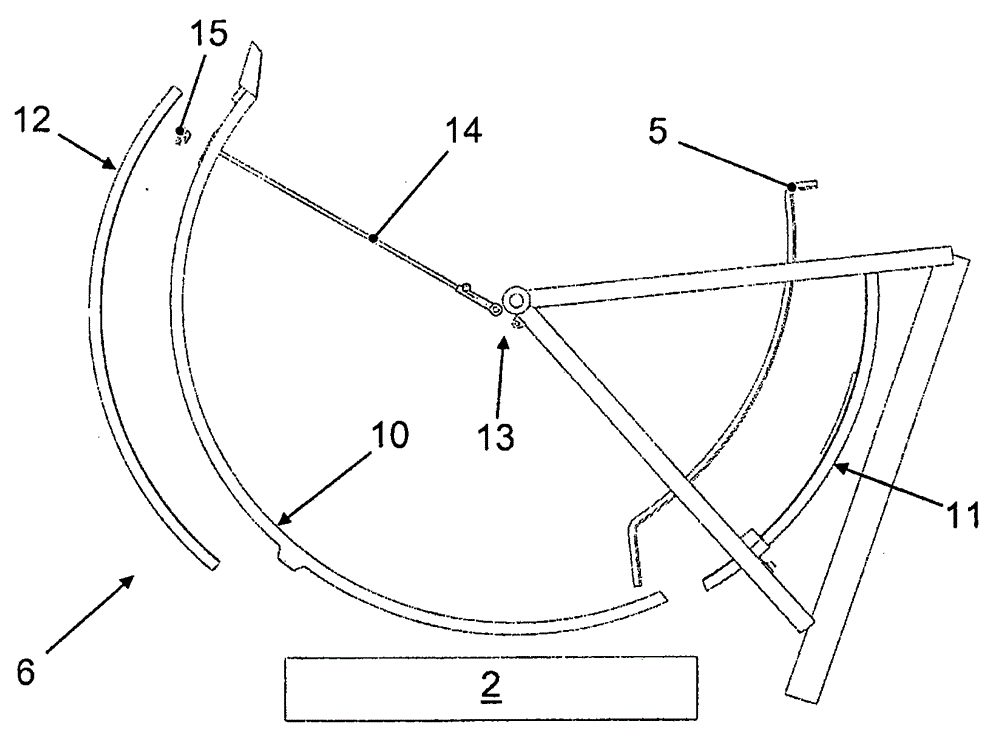

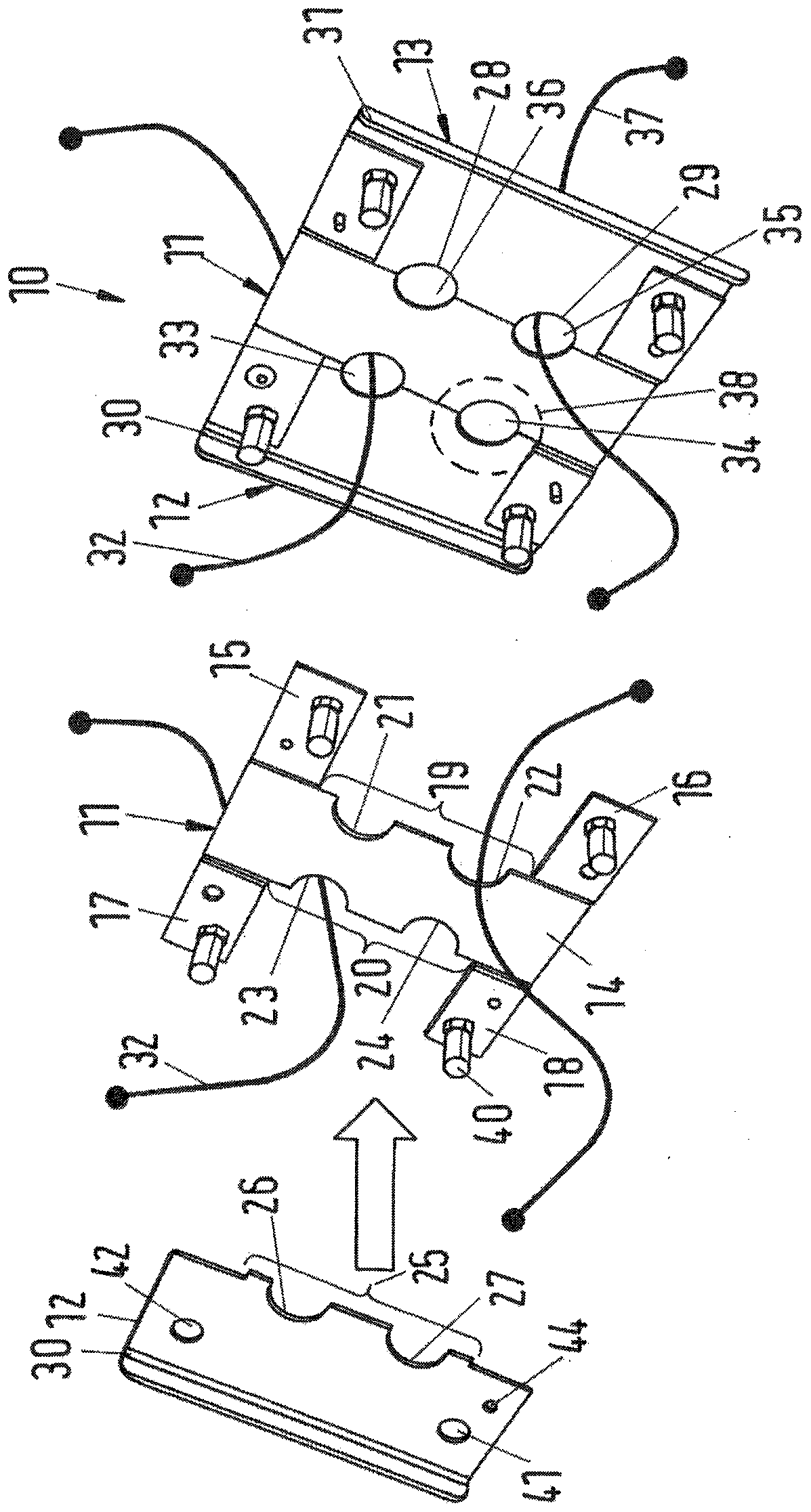

Rail fastening system

The invention relates to a rail fastening system (1) for fastening a rail (2) on a rail underlying surface, preferably for a solid roadway, which rail fastening system has a base plate (10), preferably made of plastic, and at least one dowel (20), wherein the base plate (10) has at least one opening (15), which penetrates the base plate (10) completely in the thickness direction, and wherein the dowel (20) is introduced into the opening (15), is retained therein by means of a retaining contour and, in the thickness direction, projects above the base plate (10), at least on one side.

Owner:SCHWIHAG

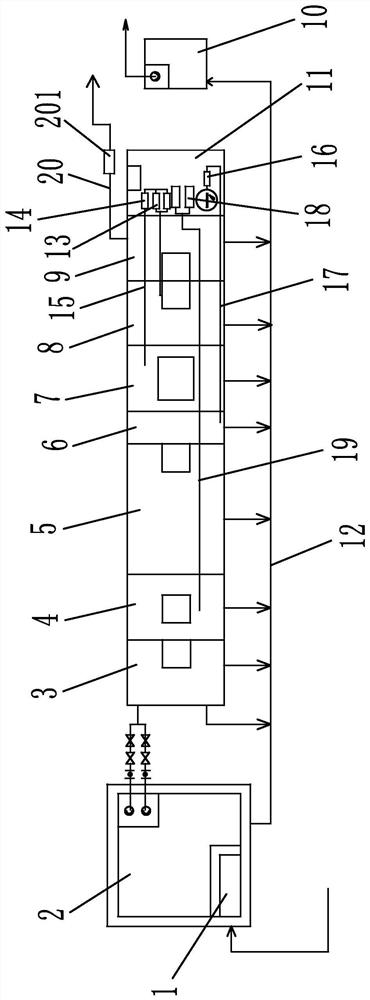

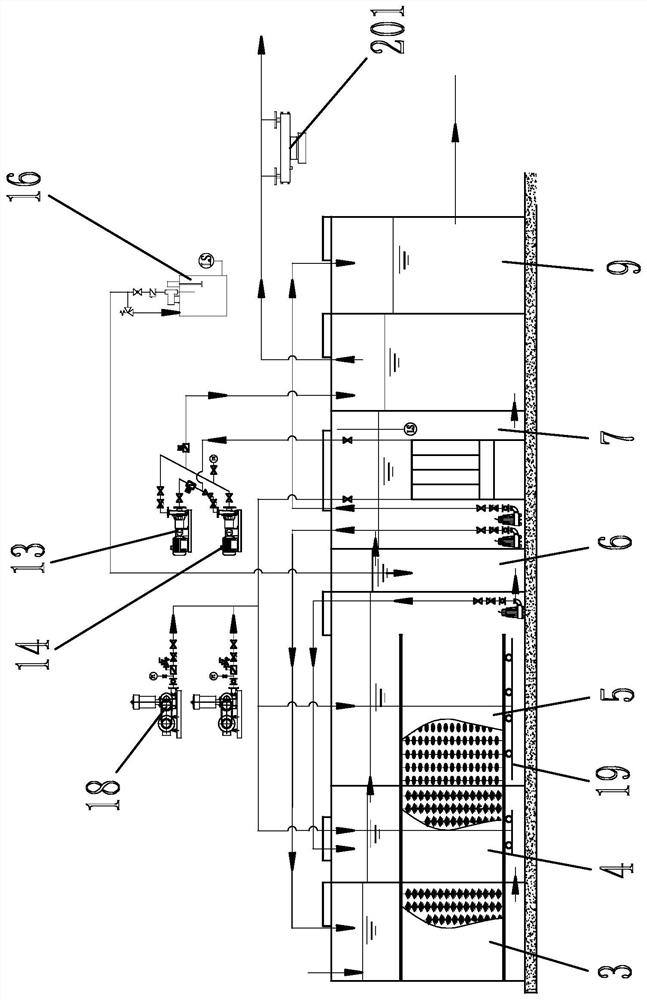

An integrated double-membrane wastewater treatment system

ActiveCN112939343BImprove processing efficiencyAchieve modularityWater contaminantsWater/sewage treatment bu osmosis/dialysisBiofilmWater treatment system

The invention relates to a sewage treatment system, in particular to an integrated double-membrane sewage treatment system. Integrated dual-membrane sewage treatment system, including: several first-level biofilm treatment units, several second-level ultrafiltration membrane treatment units, sludge collection units for collecting sludge, emergency water collection units, and control of the entire system The operating control system and emergency pipelines are arranged sequentially between several first-level biofilm treatment units; several second-level ultrafiltration membrane treatment units are located behind the first-level biofilm treatment units and are arranged in sequence; one end of the emergency pipeline is connected to At the emergency water collection unit, several first-level biofilm treatment units and several second-level ultrafiltration membrane treatment units are connected to the emergency pipeline through maintenance and emptying pipes. The invention has the beneficial effects of effectively improving the efficiency of sewage treatment, enhancing the effect of sewage treatment, reducing the area required for overall construction, and the like.

Owner:南方环境科技(杭州)有限公司

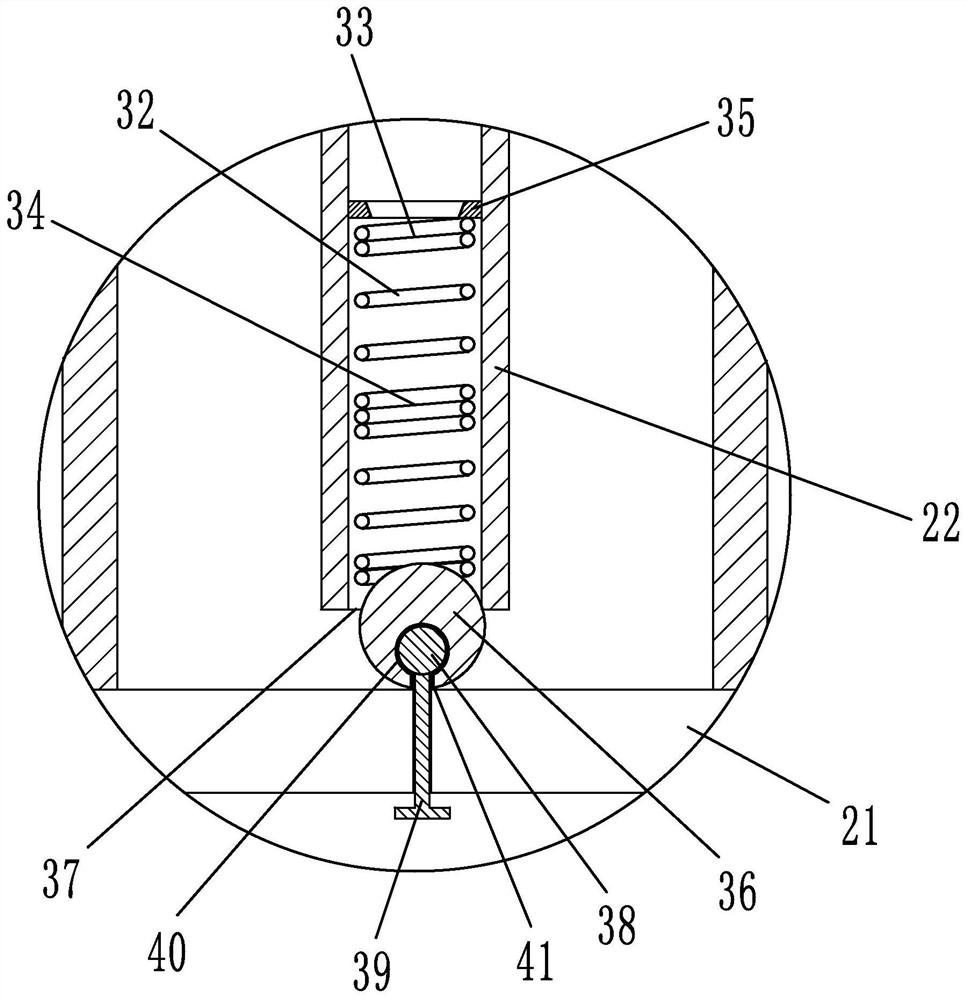

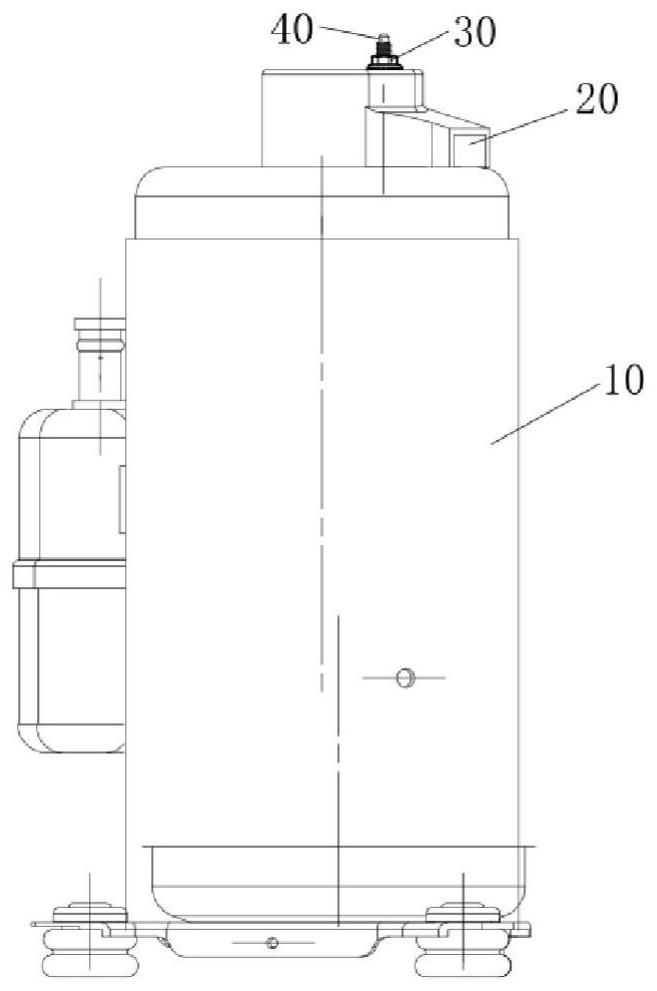

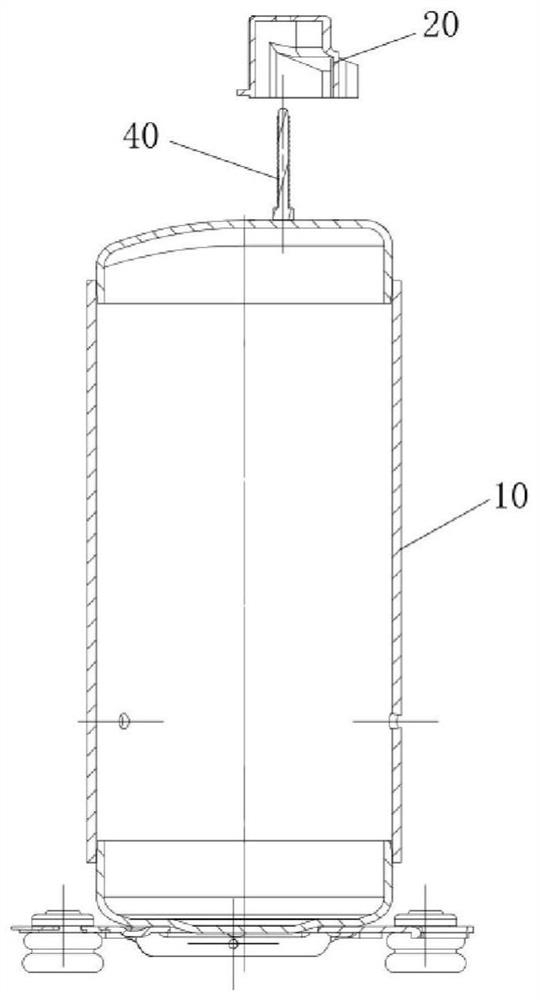

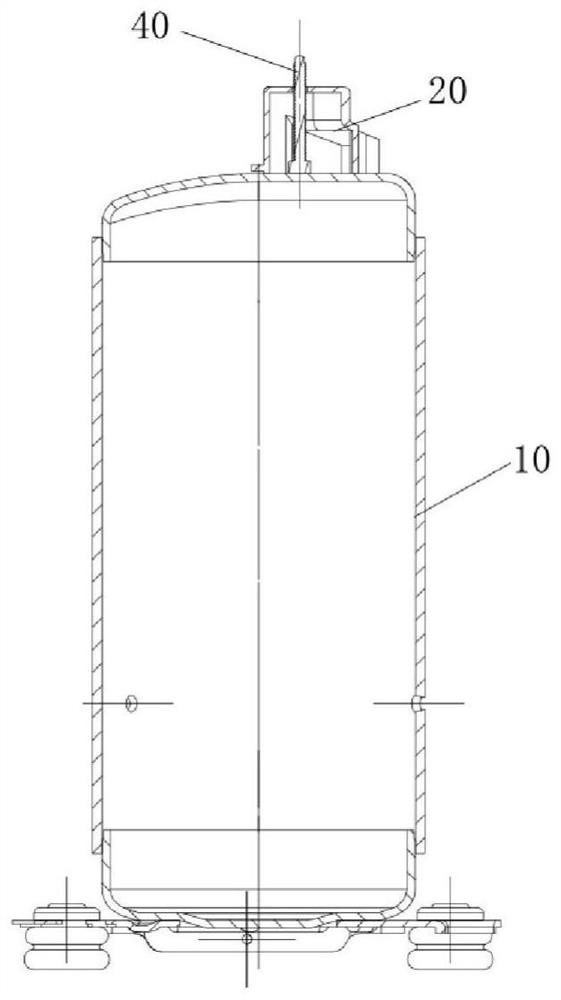

Preassembling fastening assembly and compressor

The invention discloses a preassembling fastening assembly and a compressor, and belongs to the technical field of compressor assembling. The preassembling fastening assembly comprises a first to-be-fastened piece and a fastening piece. The fastening piece comprises a second limiting structure, a connecting structure and a first limiting structure, all of which are connected in sequence. The connecting structure of the fastening piece can be assembled into a first connecting hole in the first to-be-fastened piece in advance, movement of the fastening piece in the axis direction of the fastening piece can be limited through cooperation of the first limiting structure and the second limiting structure, the connecting structure is limited in the first connecting hole, and therefore the fastening piece is prevented from falling off from the first to-be-fastened piece. Compared with a first to-be-fastened piece and a fastening piece which are designed in a split manner in the prior art, bymeans of the preassembling fastening assembly, the storage cost can be reduced, the fastening piece is prevented from being lost before assembling, the assembling efficiency of later assembling can beimproved, and the phenomenon that the fastening piece accidentally falls off in the later assembling process is avoided.

Owner:QINGDAO HAIER NEW ENERGY ELECTRIC APPLIANCE +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com