Cable feedthrough

A cable and threading technology, which is applied in the field of rail vehicles, can solve complex problems, achieve the effect of improving the standardization level and improving production safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

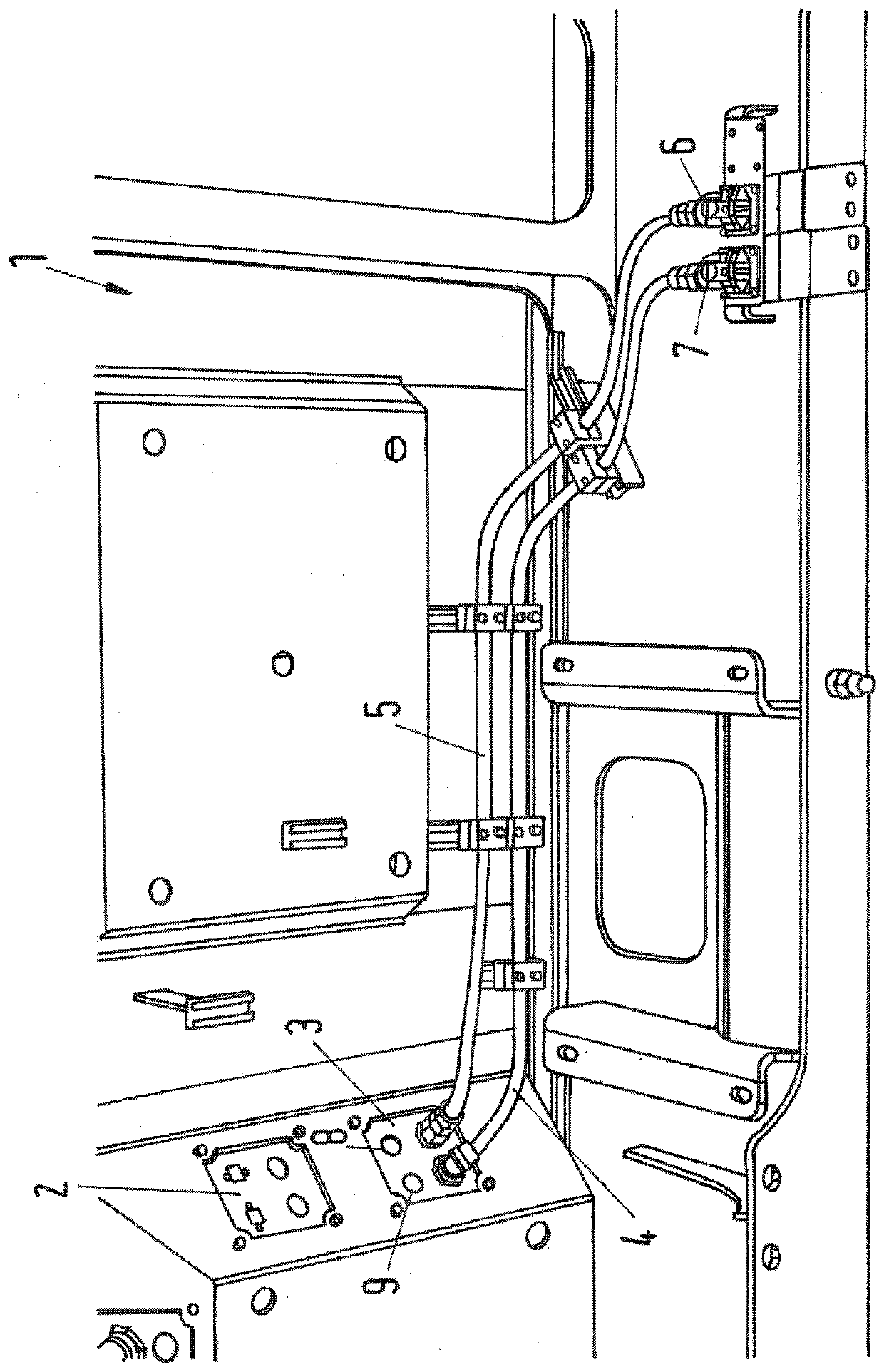

[0087] figure 1 Show the bottom 1 of the locomotive. The line of sight falls from below to the bottom or substructure of the locomotive. Two cable threading devices 2, 3 can be seen in the bottom 1, which have four holes 8, 9 respectively. The cable threading devices 2 and 3 are realized as simple one-piece metal plates. On the side of the chassis, protect the cables in protective hoses 4, 5 up to the plug. The mentioned holes are provided on the plate for fixing the threaded connection part, so the hose obtains a fixed and mainly sealed fixing point. The holes 8, 9 for fixing the threaded connection part of the hose are smaller than the plugs 6, 7 in the chassis. This means that the cable must first be guided through the cable threading device, and then the plug 6 or 7 can be connected.

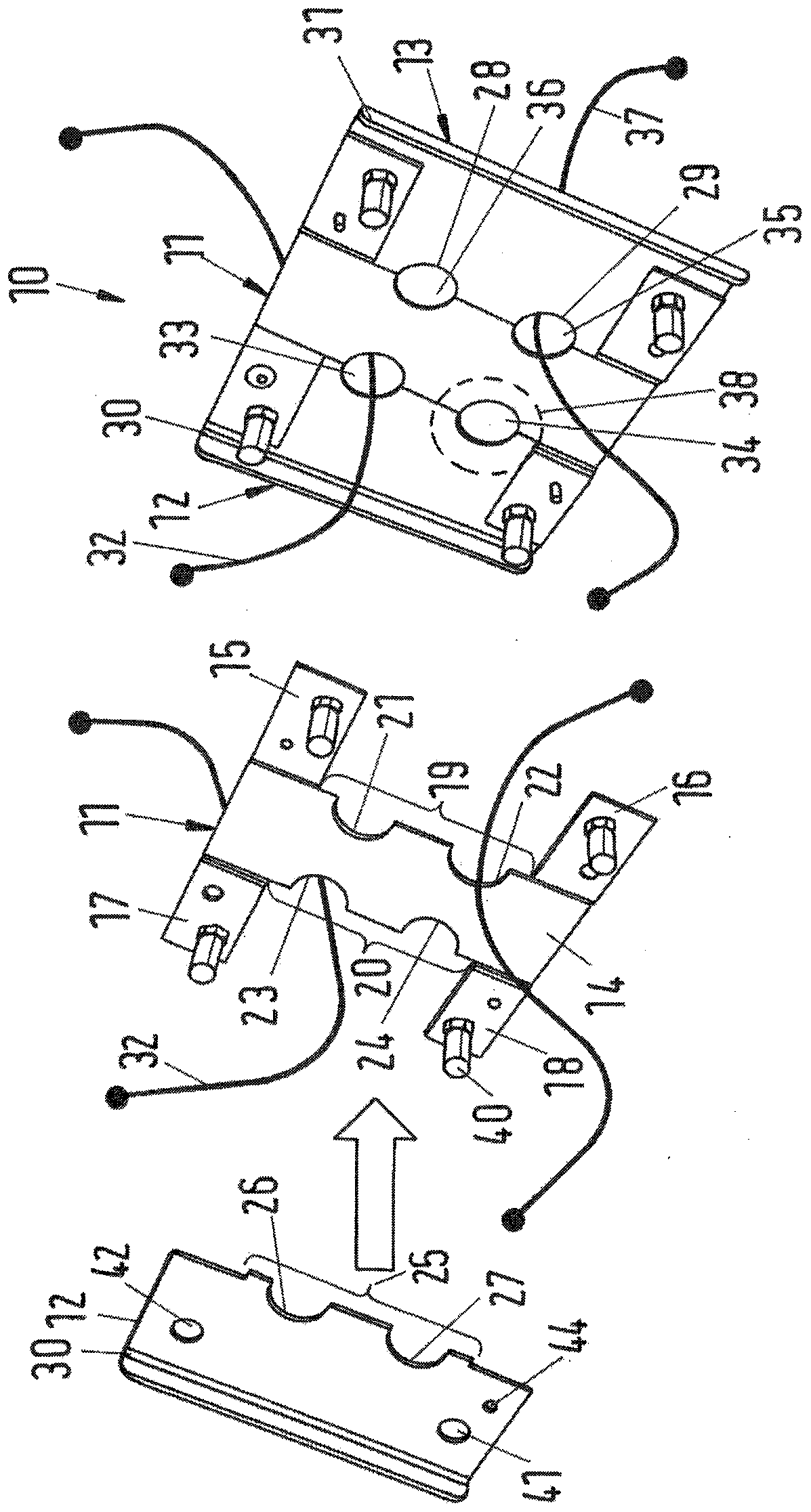

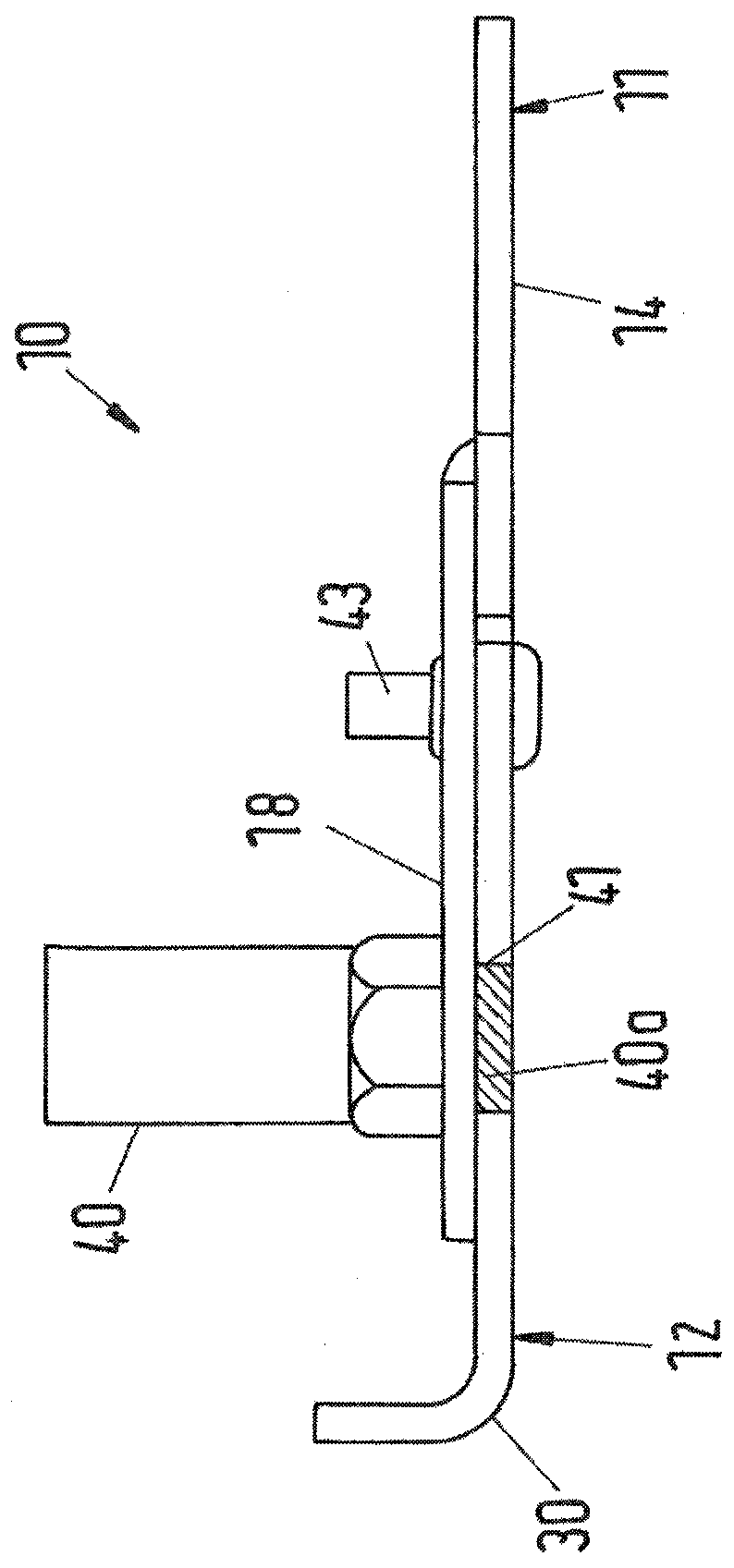

[0088] figure 2 The solution according to the invention is shown, which is based on the solution of clamping half pairs. The hole for cable guidance is divided into two halves here. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com