An integrated double-membrane wastewater treatment system

A sewage treatment system and double-membrane technology, applied in water/sewage treatment, water/sewage multi-stage treatment, biological water/sewage treatment, etc., can solve the problem of limited treatment effect, shorten the construction period and realize modularization , the effect of enhancing the processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

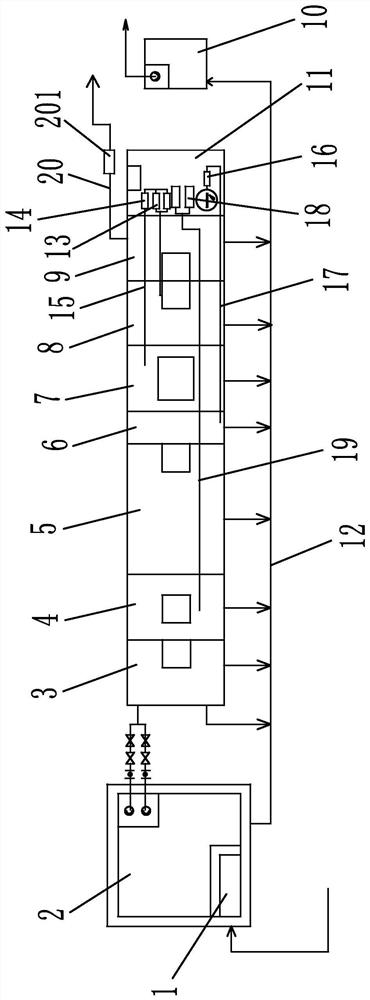

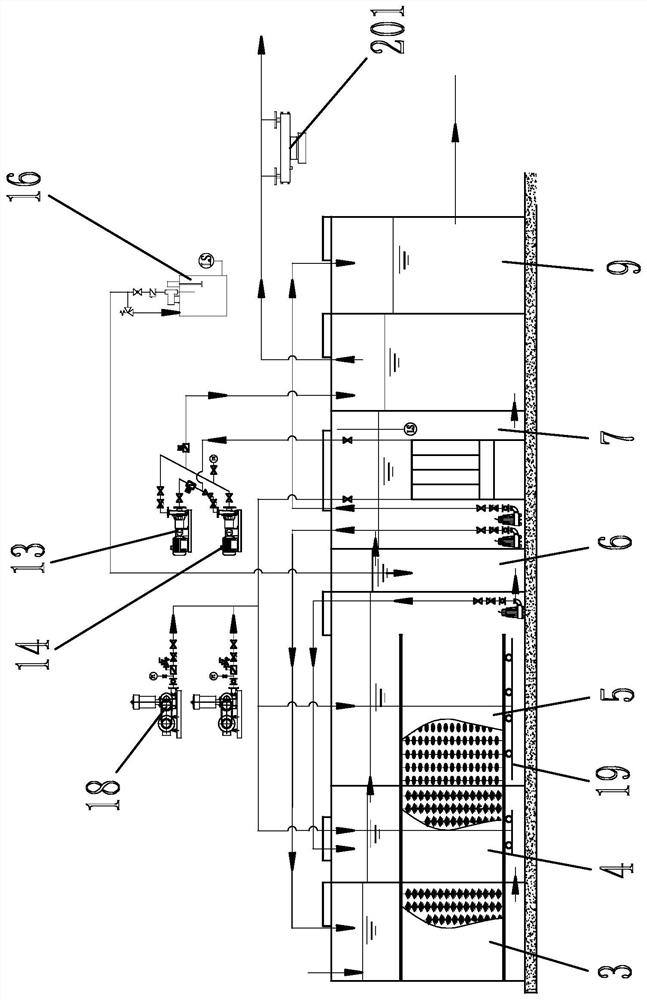

[0022] Embodiment 1: as figure 1 , 2As shown, an integrated dual-membrane sewage treatment system includes: several first-level biofilm treatment units, several second-level ultrafiltration membrane treatment units, a sludge collection unit 9 for collecting sludge, and an emergency water collection unit 10. The control system 11 and emergency pipeline 12 used to control the operation of the entire system are arranged in sequence between several first-level biofilm treatment units; several second-level ultrafiltration membrane treatment units are located behind the first-level biofilm treatment unit and Set up in sequence; one end of the emergency pipeline is connected to the emergency water collection unit, and several first-level biofilm treatment units and several second-level ultrafiltration membrane treatment units are connected to the emergency pipeline through maintenance and emptying pipes. It also includes a pretreatment unit. The pretreatment unit includes a suspende...

Embodiment 2

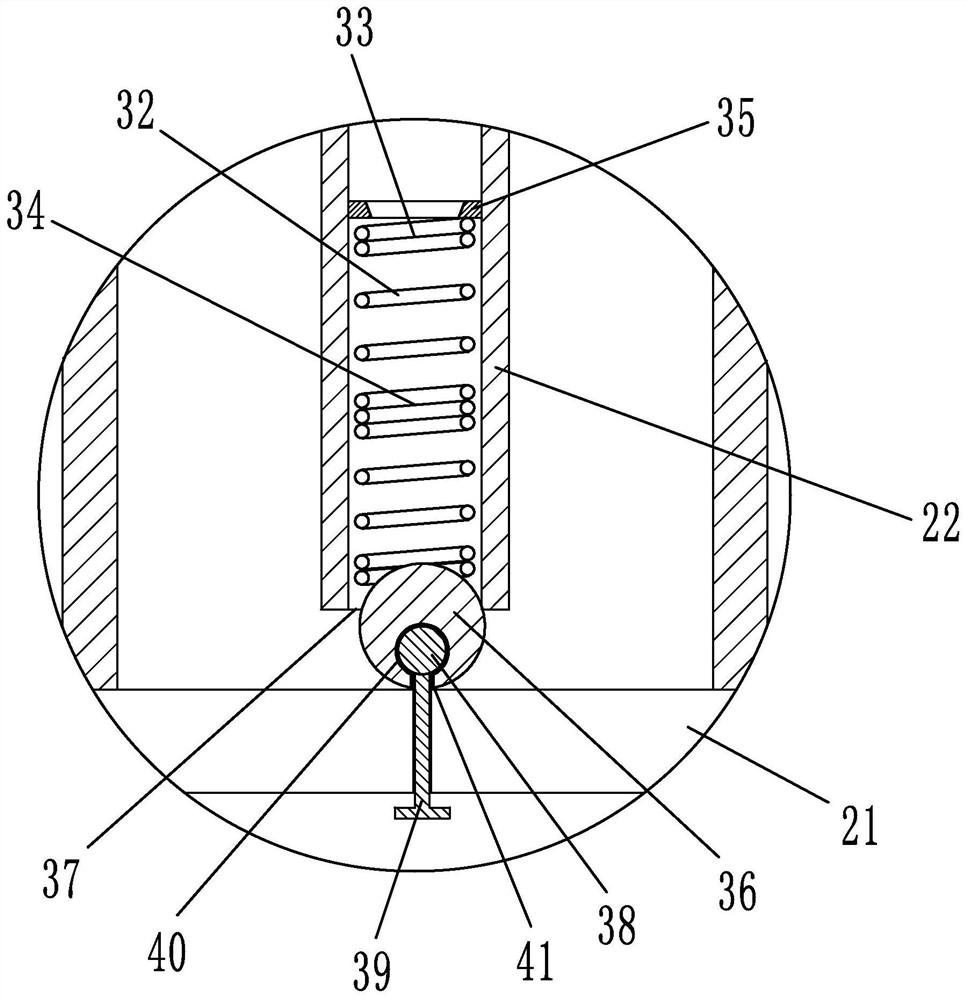

[0024] Embodiment 2: The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that the MBR membrane treatment unit includes a membrane cavity body 21 for sewage treatment, a water inlet pipe 22 and a water inlet pipe for slowing pressure and oscillating The twisting device is matched with the end of the water inlet pipe. The twisting device comprises a guide ball 36 arranged on the inner bottom surface of the film chamber body, a diversion gap 37 is provided between the end of the water inlet pipe and the outer surface of the guide ball, and a housing chamber 40 is provided inside the guide ball, and a housing chamber 40 is provided in the housing chamber. Ball head 38, the ball head is threadedly connected with the bottom surface of the tank through the adjustment rod 39, the guide ball is provided with an adjustment hole for the adjustment rod to pass through, the adjustment hole is provided with an elastic sealing ring 41, and the wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com