Disposable pipeline integrated pump head split micropump

An integrated pump, one-time technology, applied in the direction of liquid displacement machinery, pumps with flexible working elements, pumps, etc., can solve the problems of inconvenient disinfection and cleaning, pollution, pipeline movement, etc., to improve the success of experiments efficiency, reduce the risk of contamination, and stabilize the pipeline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiments of the present invention will be described in further detail below in conjunction with the drawings and embodiments. The following examples are used to illustrate the present invention, but not to limit the scope of the present invention.

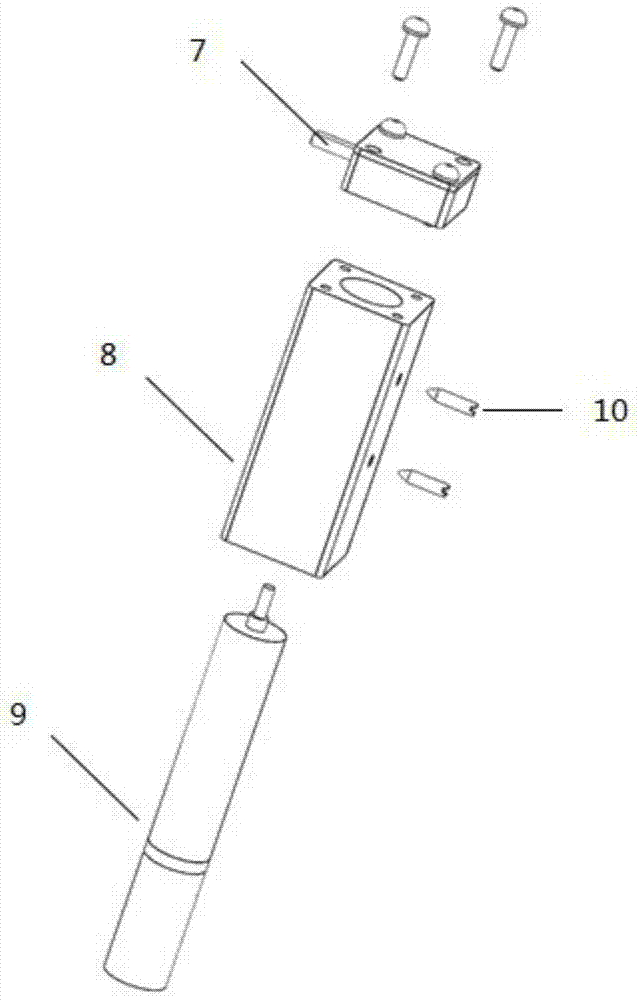

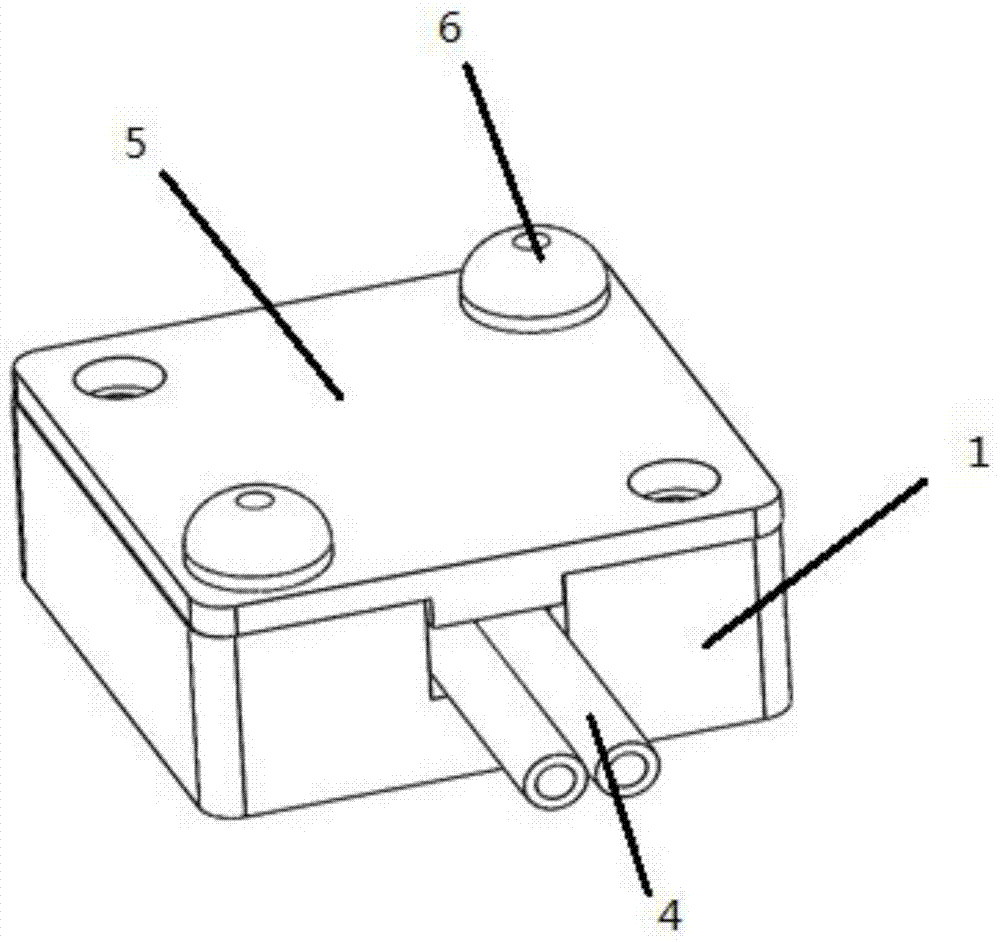

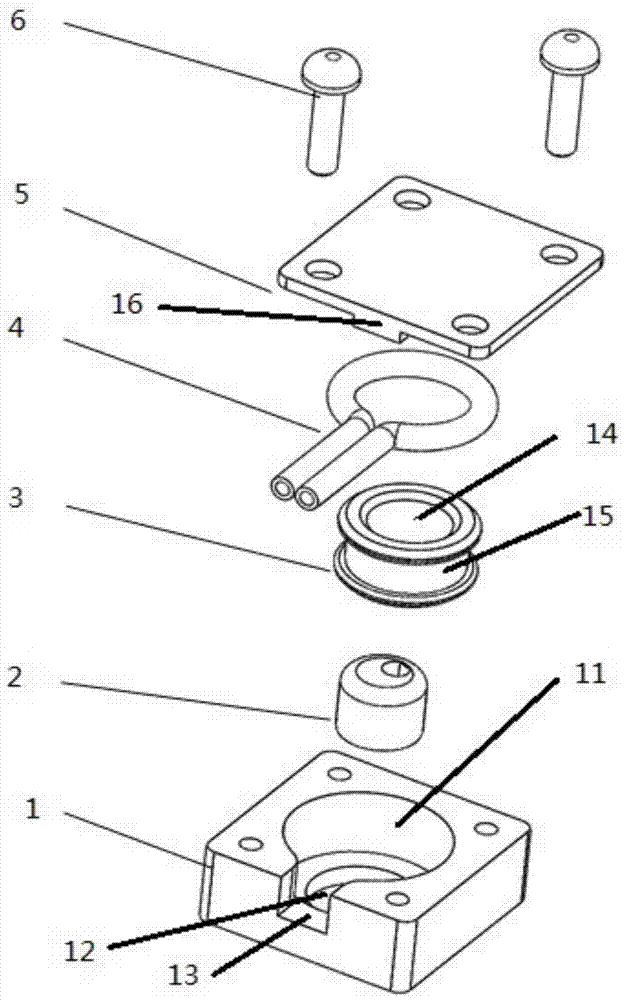

[0026] See figure 1 , figure 2 and image 3 , The disposable pipeline integrated pump head split micropump of the present invention includes a pump body 8, a motor 9 and a pump head pipeline assembly 7. The motor 9 is installed in the center hole of the pump body 8 and uses 2 M2 set screws 10Fixed; the pump head pipeline assembly 7 is installed on the upper surface of the pump body 8 with 2 M2 screws, and the motor shaft extends into the pump head pipeline assembly 7; the pump head pipeline assembly 7 is disposable, the pump head pipeline assembly 7 Including the pump head seat 1, the eccentric wheel 2, the pump head roller 3 and the circumferential compression pipeline 4, the circumferential compression pipel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com