Rail fastening system

A technology for fixing systems and guide rails, which is applied in the direction of fixing rails, tracks, friction-clamped detachable fasteners, etc., and can solve problems such as concrete main body damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

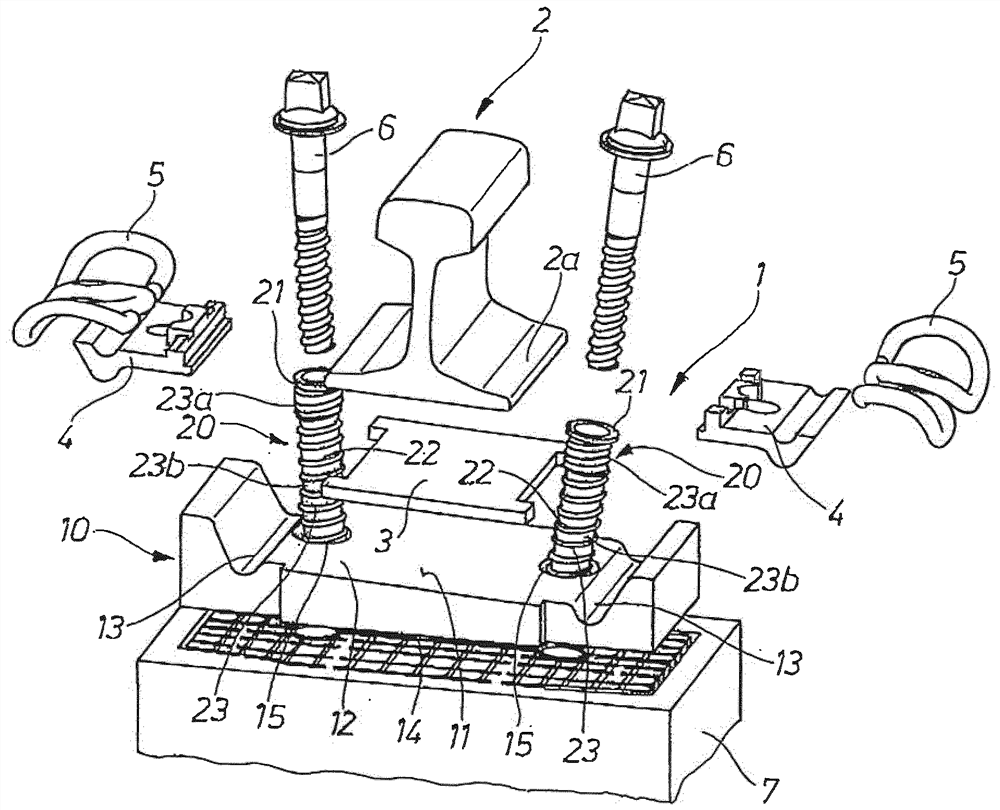

[0024] A preferred exemplary embodiment is described below with the aid of figures. In this case, identical, similar or identically acting elements are provided with the same reference symbols in the figures, and a repeated description of these elements is partially omitted in order to avoid redundancy.

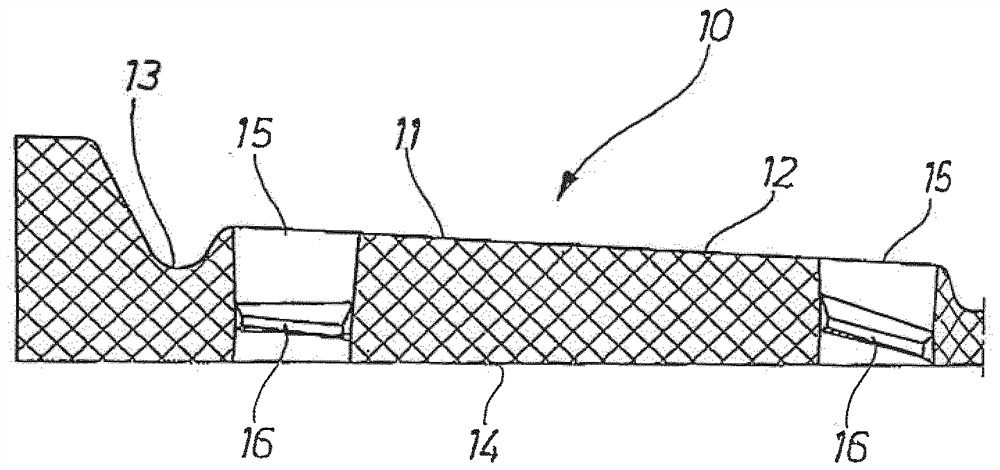

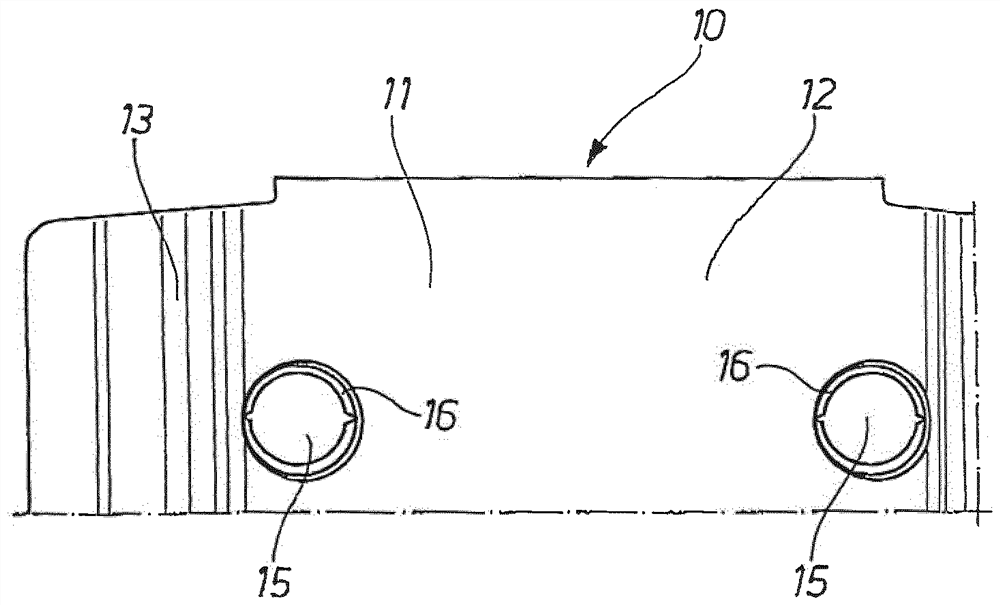

[0025] figure 1 Shown is a rail fastening system 1 with a backing plate 10 and two pins 20 connected thereto.

[0026] In the present exemplary embodiment, the backing plate 10 is a mounting plate with a contoured mounting surface 11 for fastening the rail 2 . For this purpose, the mounting surface 11 has an inclined guide rail bearing section 12 , on which the guide rail 2 rests in the fixed state, optionally via a vibration-damping and / or elastic intermediate layer 3 . Furthermore, the mounting surface 11 has a receptacle 13 which is provided for receiving the angle guide 4 . The angle guide plate 4 is in turn used together with the clamping clip 5 , which is a bent stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com