Connecting rod-piston assembly comprising a connecting rod having a spherical small end

An assembly and connecting rod technology, applied in the direction of piston, piston rod, cylindrical piston, etc., can solve complex assembly and other problems, achieve the effects of simplified production, optimized formulation and design, and saved storage space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

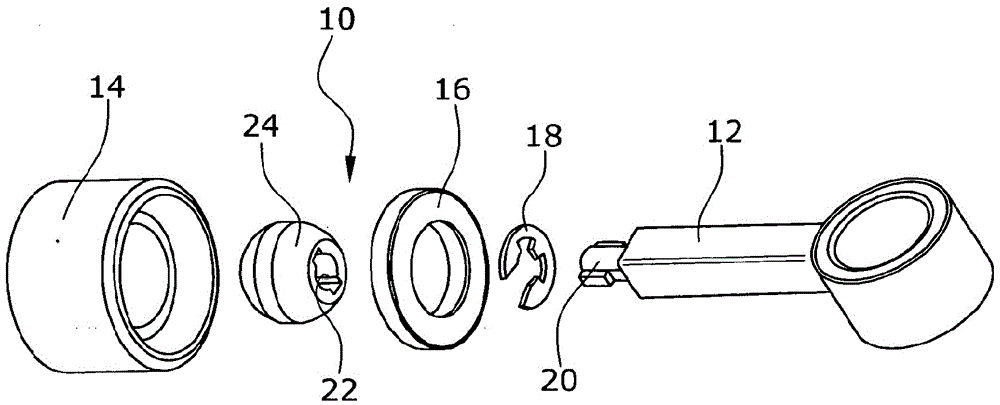

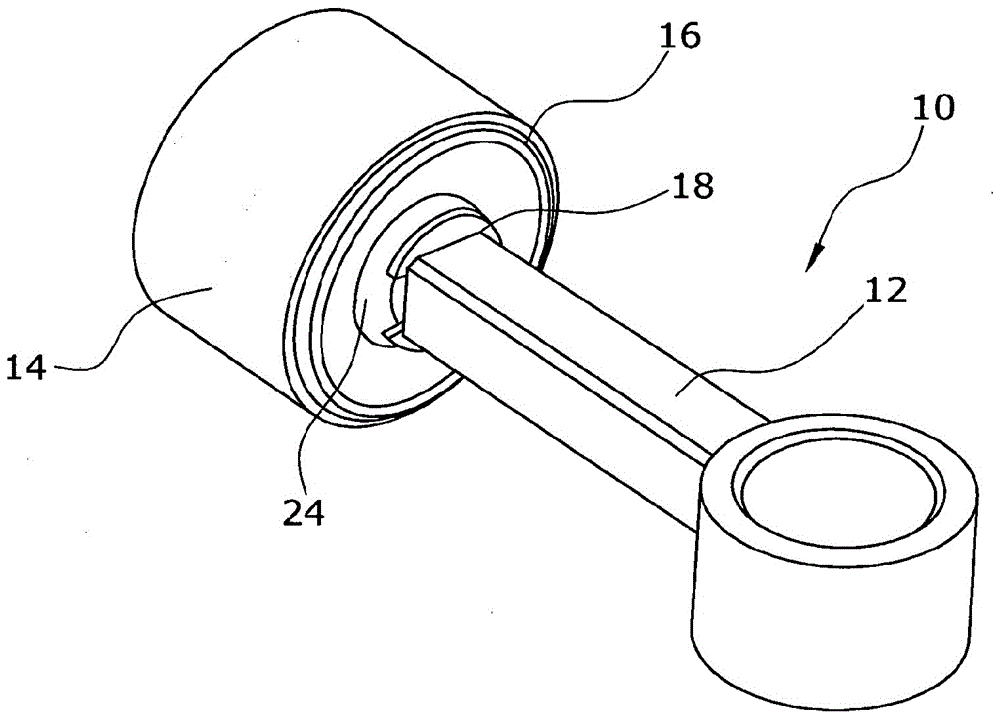

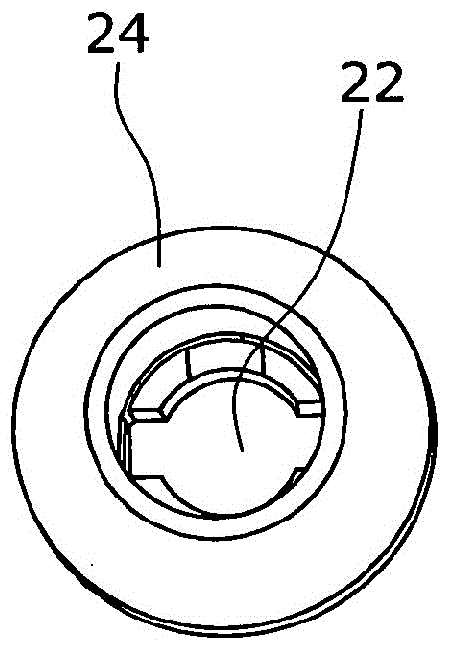

[0038] figure 1 An isometric view of the connecting rod-piston assembly 10 is shown. The connecting rod-piston assembly 10 comprises a connecting rod body 12 , a ball 24 , a piston 14 , a fastening element 16 in the form of a ring, and a thrust ring 18 . The connecting rod body 12 , the ball 24 , the piston 14 and the fastening element 16 can each be produced by powder metallurgy methods, whereby they can be produced cost-effectively and machining of the individual components can largely be dispensed with. The connecting rod body 12 has a pin 20 in the form of a T-pin at its side facing the ball 24 . Such a pin 10 can be accommodated in a recess 22 of a ball 24 . The connecting rod with the ball head is formed by fitting together the pin 20 with the notch 22 . To secure the connecting rod body 12 in the ball 24, the thrust ring 18 is fixed at the connecting rod body 12 after fitting together. To form the connecting rod-piston assembly 10 , a ball 24 is inserted into the pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com