Motor/transmission unit and modular system

A transmission device and motor technology, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve problems such as the limitation of the use of common parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

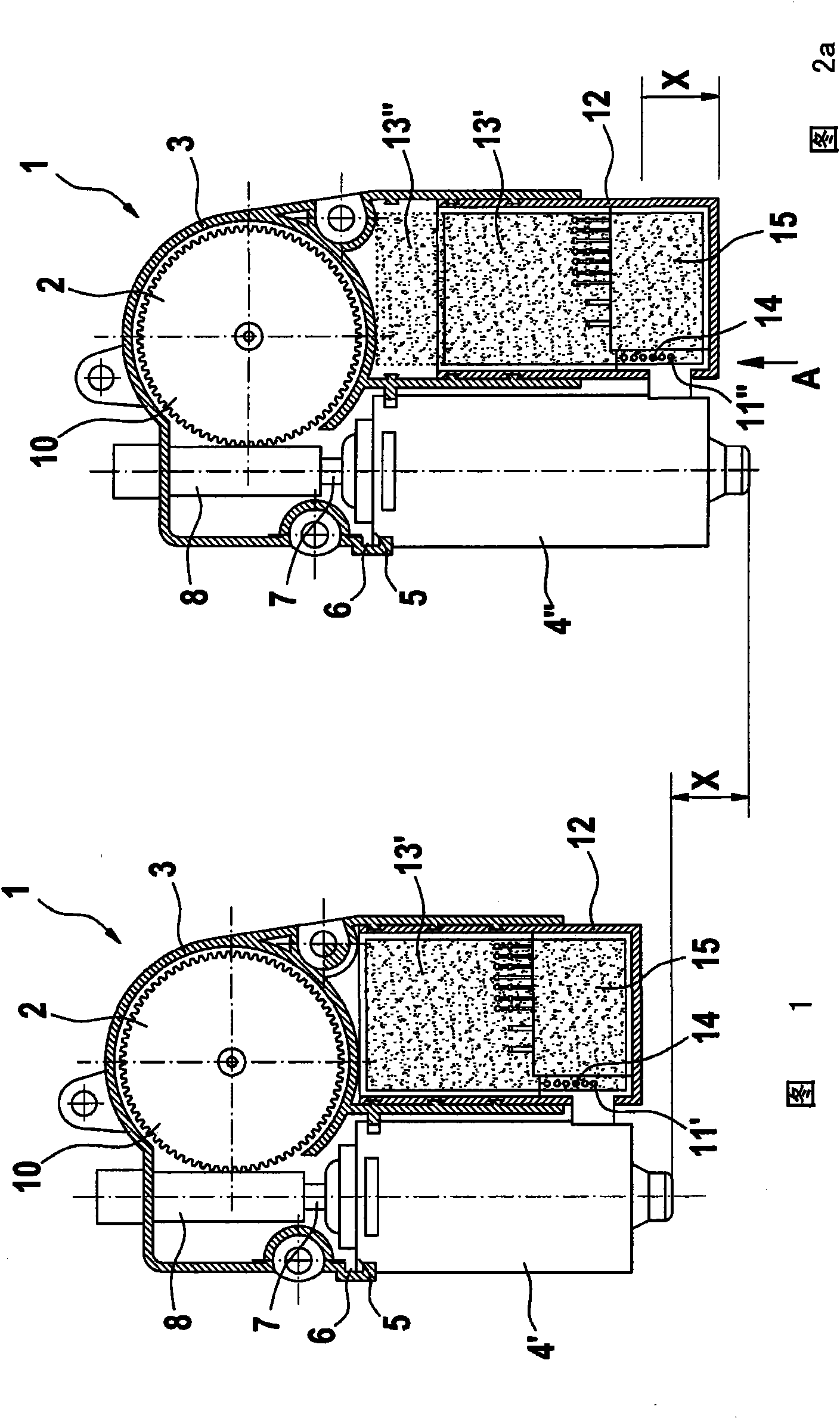

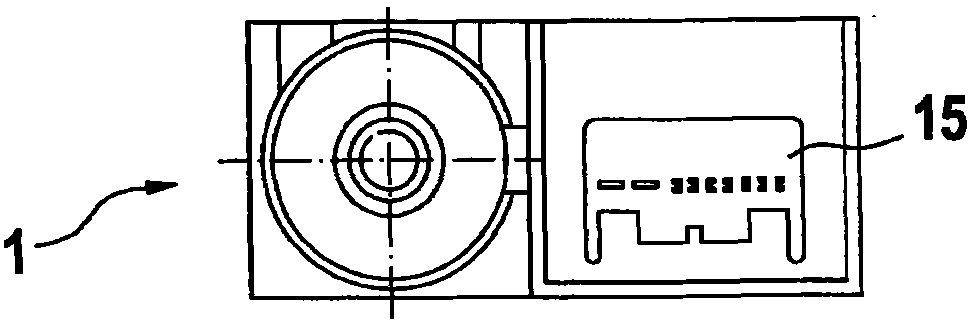

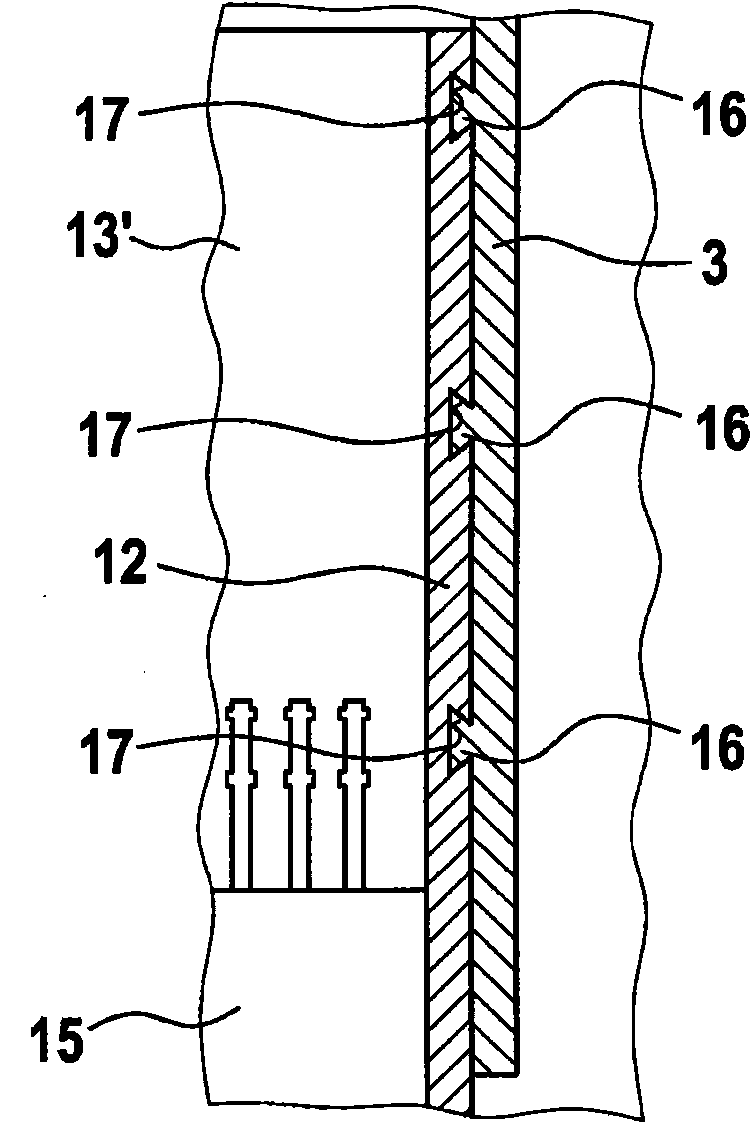

[0029] exist Figures 1 to 2b A modular system of motor-gear units 1 is shown in . The modular system comprises a gear 2 designed as a worm gear, which has a uniform gear housing 3 . Motor housings 4 ′ and 4 ″ of different sizes, here two different lengths, can be fastened to the transmission housing 3 . For this purpose, the two motor housings 4 ′, 4 ″ have a single motor housing The connection 5 is used for alternative fastening to a uniform transmission housing connection 6 . In the illustrated embodiment of the modular system, the transmission 3 comprises a transmission worm 8 connected in a rotationally fixed manner to the motor shaft 7 , which meshes with a driven gear 10 , and the driven gear 10 in turn drives mechanisms not shown, such as for adjusting the window glass, the sliding sunroof or the car seat.

[0030] The lengths, ie the axial extensions, of the motor housings 4', 4" differ from each other by a distance X. The distance X is also used to electrically co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com