Attapulgite clay-Ni/Fe nano composite material, preparation method and applications thereof

A technology of attapulgite clay and nano-composite materials, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, refined hydrocarbon oil, etc., can solve the problems of changing the surface properties of palygorskite, low catalytic activity, environmental hazards, etc., and achieve Reduce preparation cost, improve catalytic performance, and improve performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

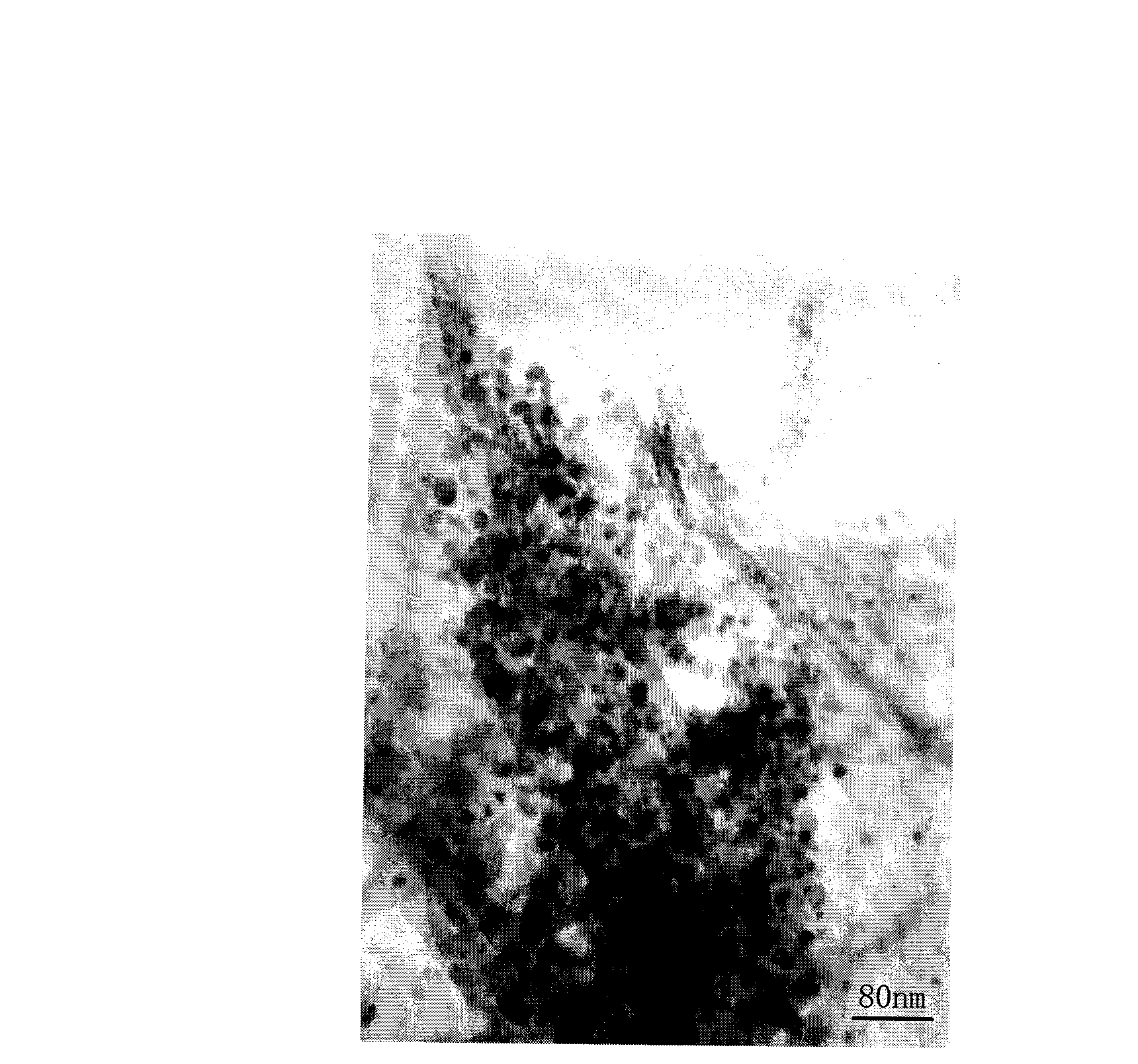

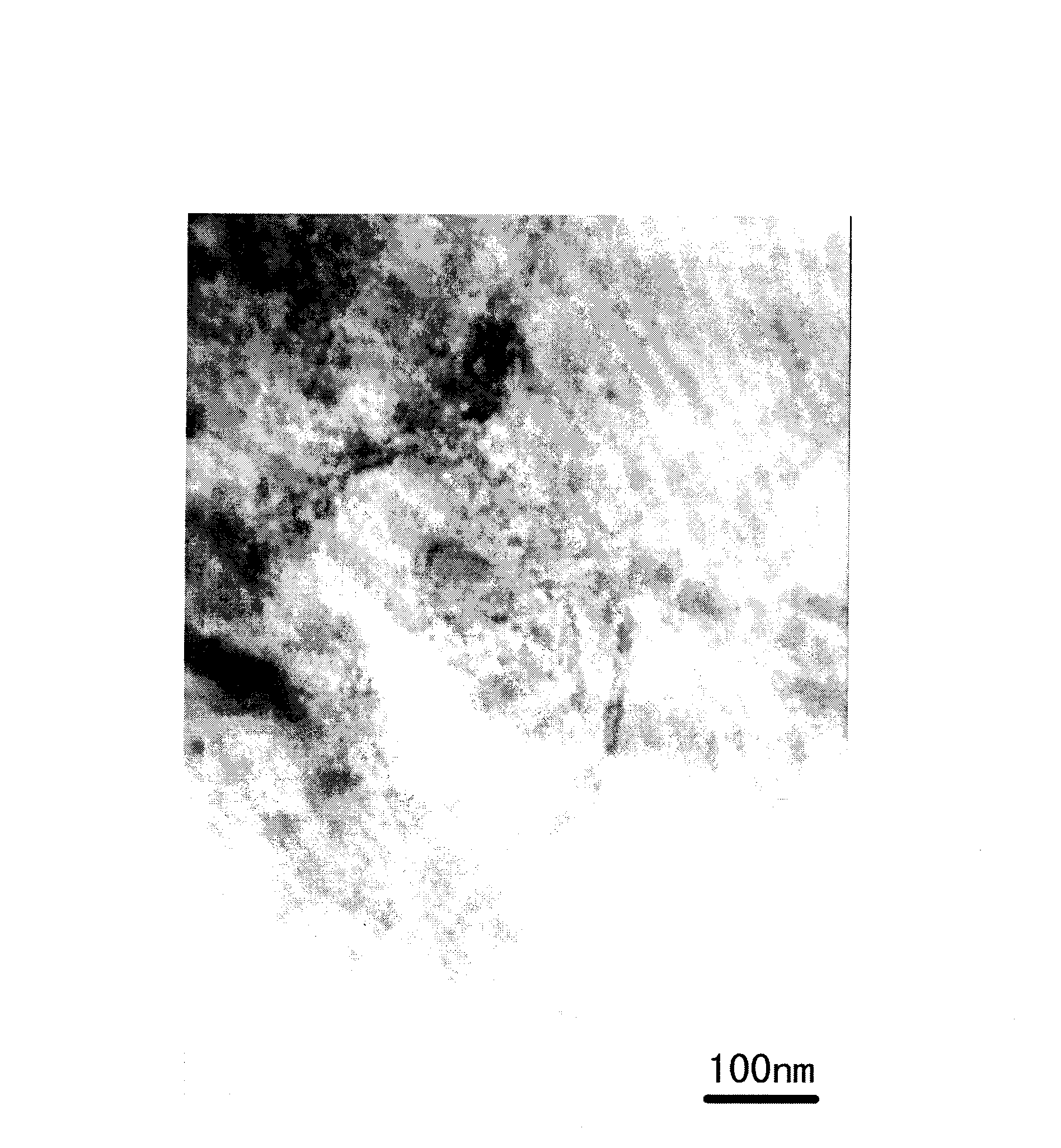

Image

Examples

Embodiment 1

[0036] Select attapulgite clay ore that meets the requirements for pre-stacking and homogenization;

[0037] Add water to the stocked and homogenized attapulgite clay raw materials, adjust the water content of the attapulgite clay to a mass ratio of 30-50%, and shear and extrude the attapulgite clay flakes by a pair of rollers and a multi-roll extruder. It promotes the depolymerization and dispersion of attapulgite crystal beam;

[0038] The attapulgite clay flakes are dried and then pulverized into attapulgite clay powder passing through a 200-mesh sieve;

[0039] Add 100g of attapulgite powder to 500ml of water, aging for 24 hours, then use a high-speed mixer to stir at 10000r / min for 0.5 hours, the attapulgite clay becomes a uniform slurry, add 20g ferric nitrate, stir for 20 minutes, add 10g Nickel nitrate, keep stirring until no bubbles are generated, then add 10% sodium hydroxide solution dropwise, stir at high speed at 10000r / min for 5min, adjust the pH of the suspension to...

Embodiment 2

[0046] Select attapulgite clay ore that meets the requirements for pre-stacking and homogenization;

[0047] Add water to the stocked and homogenized attapulgite clay raw materials, adjust the water content of the attapulgite clay to a mass ratio of 30-50%, and shear and extrude the attapulgite clay flakes by a pair of rollers and a multi-roll extruder. It promotes the depolymerization and dispersion of attapulgite crystal beam;

[0048] The attapulgite clay flakes are dried and then pulverized into attapulgite clay powder passing through a 200-mesh sieve;

[0049] Add 100g of attapulgite powder to 1000mL of water, aging for 24 hours, then use a high-speed mixer to stir at 10000r / min for 0.5 hours, the attapulgite clay becomes a uniform slurry, add 30g of ferric nitrate, and continue stirring until no bubbles are generated. Then 10% sodium hydroxide solution was added dropwise, and stirred with a high-speed mixer at 10,000 r / min for 5 minutes, and the pH value of the suspension wa...

Embodiment 3

[0055] Select the attapulgite clay ore that meets the requirements, and crush it into attapulgite clay powder that passes through a 200-mesh sieve;

[0056] According to the ratio of 100g attapulgite powder to 1000mL water, add water soaking and aging for 48 hours, stir with a high-speed mixer at 10000r / min for 0.5 hours, the attapulgite clay becomes a uniform slurry, add 20g nickel nitrate, and continue stirring until nothing Bubbles are generated, and then 10% sodium hydroxide solution is added dropwise, and stirred with a high-speed mixer at 10,000 r / min for 5 minutes, and the pH value of the suspension is adjusted to be greater than 8, so that the added nickel ions are completely hydrolyzed.

[0057] The suspension is filtered, washed and dehydrated into a mud cake with a plate and frame filter press with washing function, dried, crushed and sieved as needed to obtain different particle sizes of 0.1-0.2mm, 0.2-0.5mm, 0.5-1.0mm Particles to meet the requirements of the catalyti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com