Tool clamp for penetration welding of T-shaped structure and clamping method

A tooling fixture and penetration welding technology, applied in manufacturing tools, welding equipment, welding accessories, etc., can solve the problems of not being able to ensure gas protection and deformation control at the same time, low welding quality, etc., to achieve a solid and stable fixed structure and improve welding quality. , the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

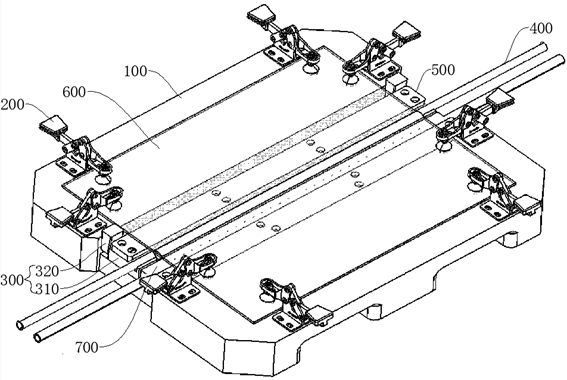

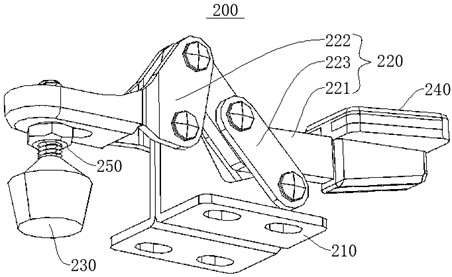

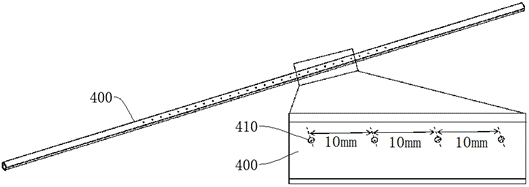

[0036] refer to Figure 1-Figure 3 , this embodiment provides a tooling fixture for penetration welding of T-shaped structures, including a base 100, multiple groups of pressing mechanisms 200, a jacking mechanism 300 and a trachea 400. The top of the base 100 is provided with a strip-shaped groove, and multiple groups of The pressing mechanism 200 is arranged around the top of the base 100, the pressing mechanism 200 is used for pressing the flat plate 600 in the T-shaped plate, the pressing mechanism 300 is arranged in the strip groove, and the pressing mechanism 300 is provided with a mounting groove, The top tightening mechanism 300 is used to fix the vertical plate 700 in the T-shaped plate in the strip groove, so that the vertical plate 700 is pressed against the bottom surface of the flat plate 600. A plurality of air outlet holes 410 are opened in the direction, and the air outlet holes 410 are all close to the contact position of the flat plate 600 and the vertical pl...

Embodiment 2

[0062] refer to Figure 1-Figure 3 , this embodiment provides a clamping method based on the tooling fixture for penetration welding of T-shaped structures described in Embodiment 1, comprising the following steps:

[0063] Step S1: selecting the vertical plate 700 of the corresponding size and specification, and placing the vertical plate 700 in the strip groove of the base 100;

[0064] Step S2: press the top tightening block 310 against the vertical plate 700;

[0065] Step S3: According to the width of the free space between the side wall of the top tightening block 310 and the inner side wall of the strip groove, select the wedge block 320 corresponding to the width size, and clamp the selected wedge block 320 in the free space, so that the top The tightening block 310 fixes the vertical plate 700;

[0066] Step S4: placing the flat plate 600 on the base 100 to make the flat plate 600 fit on the top of the vertical plate 700;

[0067] Step S5 : pressing the top edge of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com