Filtering rod capable of reducing smoke temperature and preparation method of filtering rod

A flue gas temperature and filter rod technology, which is used in the manufacture of paper cigarettes, etc., can solve the problems of reducing the shape of the filter rod, unable to smoke the cigarette, destroying the shape and structure of the filter rod, etc., so as to improve the formula grade, improve the fullness and Elegance, the effect of improving aroma quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

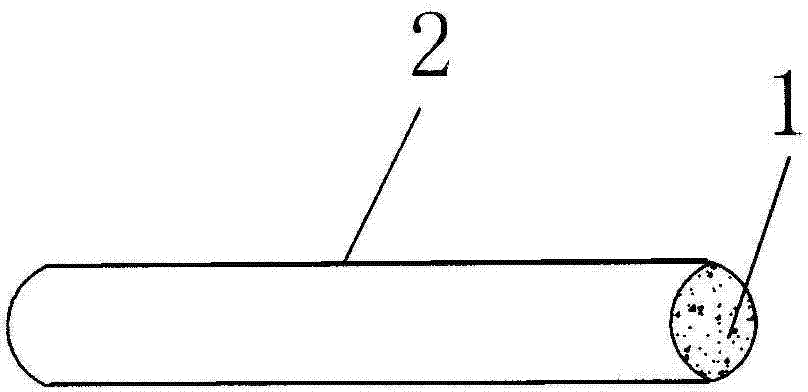

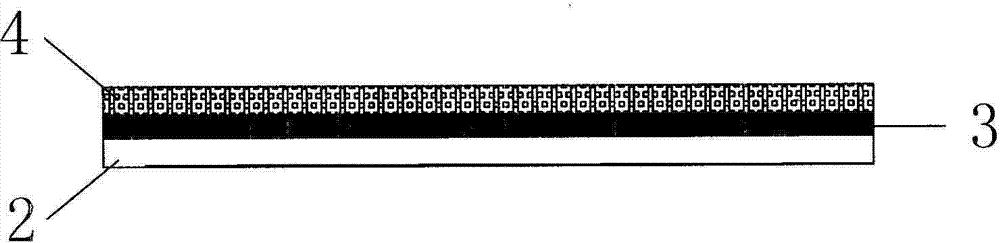

[0026] Embodiment 1: A kind of filter tip that can reduce flue gas temperature, it is made up of tow mandrel 1 and the molding paper 2 that outer layer wraps, and is attached with 3g / m2 through glue layer 3 on the front of common molding paper 2 2 The microporous aluminum layer 4.

[0027] The preparation method of the filter rod capable of reducing the flue gas temperature comprises the following steps:

[0028] A. Material preparation: ordinary forming paper, microporous aluminum, tow, filter rod forming machine;

[0029] B. Preparation of microporous aluminum ordinary molding paper: use PET film or BOPP film as the transfer substrate, place it in an evaporation boat, heat it with resistance, high frequency or electron beam, and heat the aluminum wire to 1400°C to vaporize and adhere to the transfer On the base material, the front side of ordinary forming paper is glued and then compounded with the transfer base material, and then the film is peeled off, and the aluminum mo...

Embodiment 2

[0032] Embodiment 2: A filter rod that can reduce the temperature of flue gas, which is composed of tow mandrel 1 and outer layer wrapped molding paper 2, and passes through the glue layer 3 on the reverse side of the high-permeable molding paper 2 with an air permeability of 3000cu Attached with 5g / m 2 The microporous aluminum layer 4.

[0033] The preparation method of the filter rod capable of reducing the flue gas temperature comprises the following steps:

[0034] A. Material preparation: high permeability forming paper with an air permeability of 3000cu, microporous aluminum, tow, filter rod forming machine;

[0035] B. Preparation of microporous aluminum high-transparency forming paper: use PET film or BOPP film as the transfer substrate, place it in an evaporation boat, heat it with resistance, high frequency or electron beam, and heat the aluminum wire to 1300 ° C to vaporize and adhere to it On the transfer base material, the reverse side of the high-transparency f...

Embodiment 3

[0038] Embodiment 3: A filter rod that can reduce the temperature of flue gas, it is made up of tow mandrel 1 and outer wrapping molding paper 2, passes through the glue layer 3 on the front of high permeability molding paper 2 with an air permeability of 6000cu Attached with 4g / m 2 The microporous aluminum layer 4.

[0039] The preparation method of the filter rod capable of reducing the flue gas temperature comprises the following steps:

[0040] A. Material preparation: high permeability forming paper with an air permeability of 6000cu, microporous aluminum, tow, filter rod forming machine;

[0041] B. Preparation of microporous aluminum high-transparency molding paper: use PET film or BOPP film as the transfer substrate, place it in an evaporation boat, heat it with resistance, high frequency or electron beam, and heat the aluminum wire to 1450 ° C to vaporize and adhere to it On the transfer base material, the front side of the high-transparency forming paper is glued a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com