Alginate-bonding composite anti-adhesion mesh and preparation method thereof

An alginate and anti-adhesion technology, applied in the field of biomedical textile materials, can solve the problems of poor biocompatibility and safety of adhesives, unsuitable polymer materials, high thermal fusion temperature, etc., to achieve prolonged anti-adhesion time, improve permeability, and reduce foreign body reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

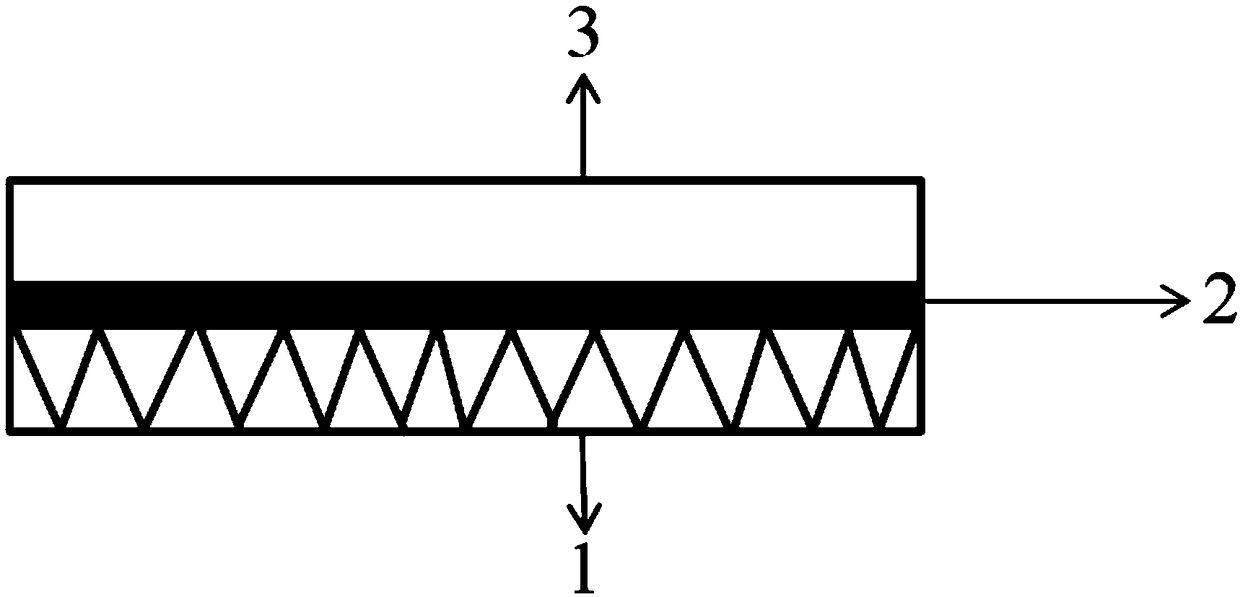

[0029] A preparation method of a composite anti-adhesion patch bonded by alginate:

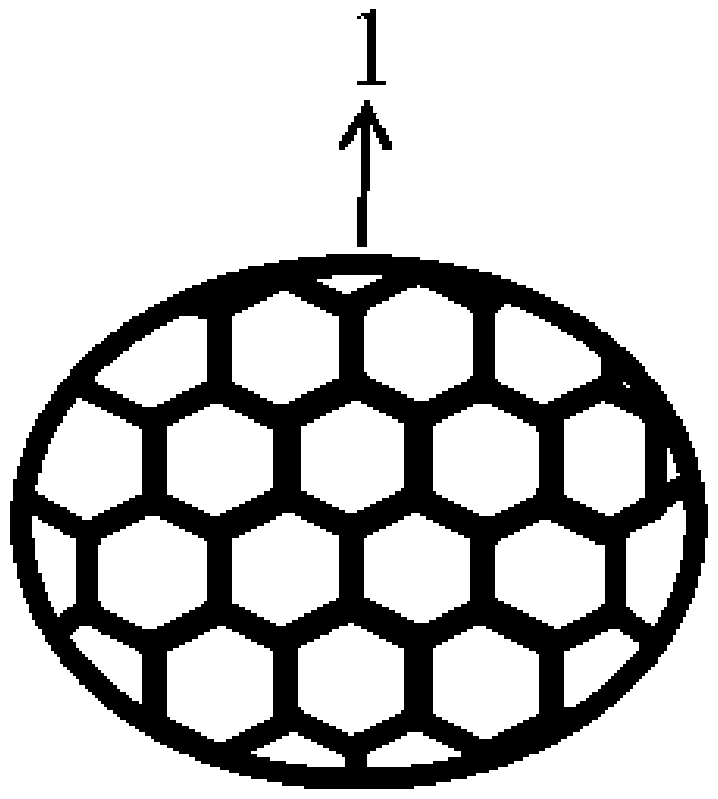

[0030] 1. The shaped polypropylene mesh is custom-provided by Changzhou Runyuan Medical Supplies Technology Co., Ltd., which is a large-pore lightweight non-absorbable material woven by polypropylene monofilament. It is washed and dried for later use.

[0031] 2. Configuration of electrospinning solution

[0032] Weigh 0.8g of polycaprolactone granules and polylactide lactide granules respectively and put them into a screw-top glass bottle with a sealed cap, mix the DMC and DMF solutions evenly at a volume ratio of 7:3, and extract 10mL of the mixed solution Pour into a glass bottle. Add a magnetic rotor, seal and stir at a constant speed for 12 hours to obtain a clear and transparent spinning solution.

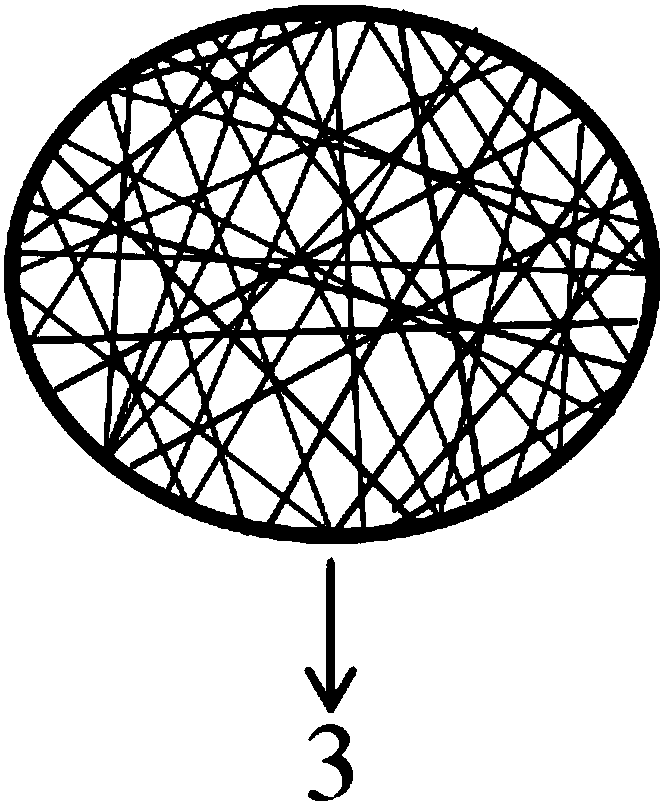

[0033] 3. Preparation of Electrospun Nanofiber Membrane

[0034] Use a 10mL syringe to draw 6mL of spinning solution and place it on the pusher. The receiving device is the ground wire al...

Embodiment 2

[0043]A preparation method of a composite anti-adhesion patch bonded by alginate:

[0044] 1. The shaped polypropylene mesh is custom-provided by Changzhou Runyuan Medical Supplies Technology Co., Ltd. That is, a macroporous lightweight non-absorbable material woven from polypropylene monofilament, washed and dried for later use.

[0045] 2. Configuration of electrospinning solution

[0046] Weigh 0.8g of polycaprolactone granules and polylactide lactide granules respectively into a screw-top glass bottle with a sealed cap, mix the DMC and DMF solutions evenly at a volume ratio of 7:3, and draw 10mL of the mixed solution Pour into a glass bottle. Add a magnetic rotor, seal and stir at a constant speed for 12 hours to obtain a clear and transparent spinning solution.

[0047] 3. Preparation of Electrospun Nanofiber Membranes

[0048] Use a 10mL syringe to draw 3mL of spinning solution and place it on the pusher. The receiving device is the ground wire aluminum foil. Turn ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com