Composite coating slurry special for high-strength flame-retardant type fiberglass composite mesh material as well as preparation method and application thereof

A composite coating and glass fiber composite technology, used in fire-resistant coatings and other directions, can solve the problems of increasing the safety protection cost of building construction units, casualties and property, and low fire rating, so as to avoid casualties and property losses, and prevent fire safety. The effect of accident occurrence and high safety protection level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A special composite coating slurry for high-strength flame-retardant glass fiber composite mesh materials, the components of which include water-soluble PP emulsion with a solid content ≥ 30%, phosphorus-nitrogen halogen-free flame retardants, paint colorants and water, The weight content of each component is: 30% to 35% of water-soluble PP emulsion with solid content ≥ 30%, 5% to 10% of phosphorus and nitrogen halogen-free flame retardants; 0.5% to 1% of paint colorants, and the rest is water.

Embodiment 2

[0026] The difference from Example 1 is that the weight content of each component in the special composite coating slurry for high-strength flame-retardant glass fiber composite mesh material is: 60% to 70% of water-soluble PP emulsion with solid content ≥ 30%; Phosphorus and nitrogen halogen-free flame retardant 20% to 25%; paint color paste 3% to 5%, and the rest is water.

[0027] The preparation method of embodiment 1 and embodiment 2 is identical, as Figure 4 As shown, the preparation steps of the special composite coating slurry for the high-strength flame-retardant glass fiber composite mesh material are: first pour the phosphorus-nitrogen halogen-free flame retardant into water and mix thoroughly, and then add PP emulsion in the stirring state And the color paste, after stirring evenly, the composite coating paste can be obtained.

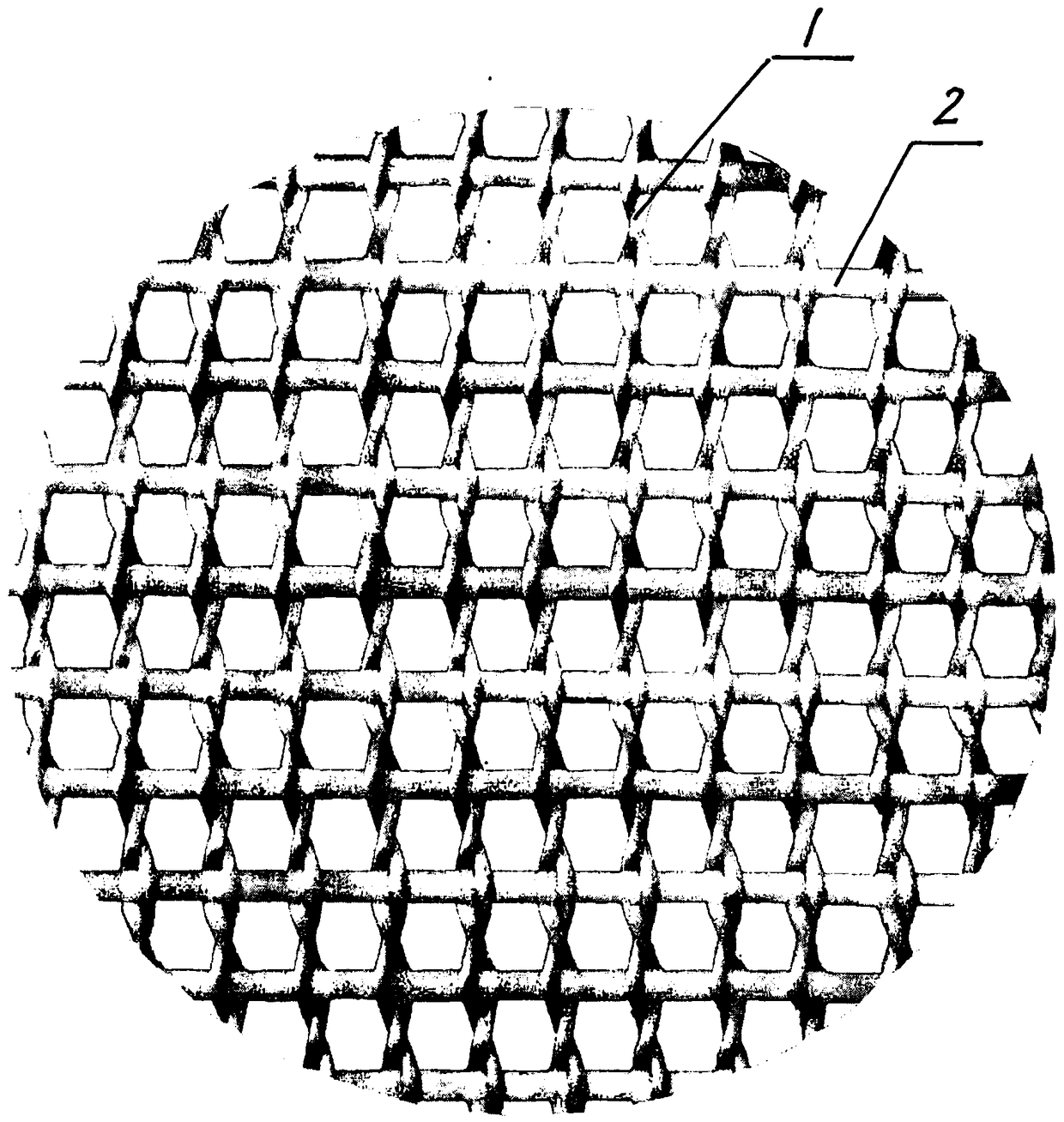

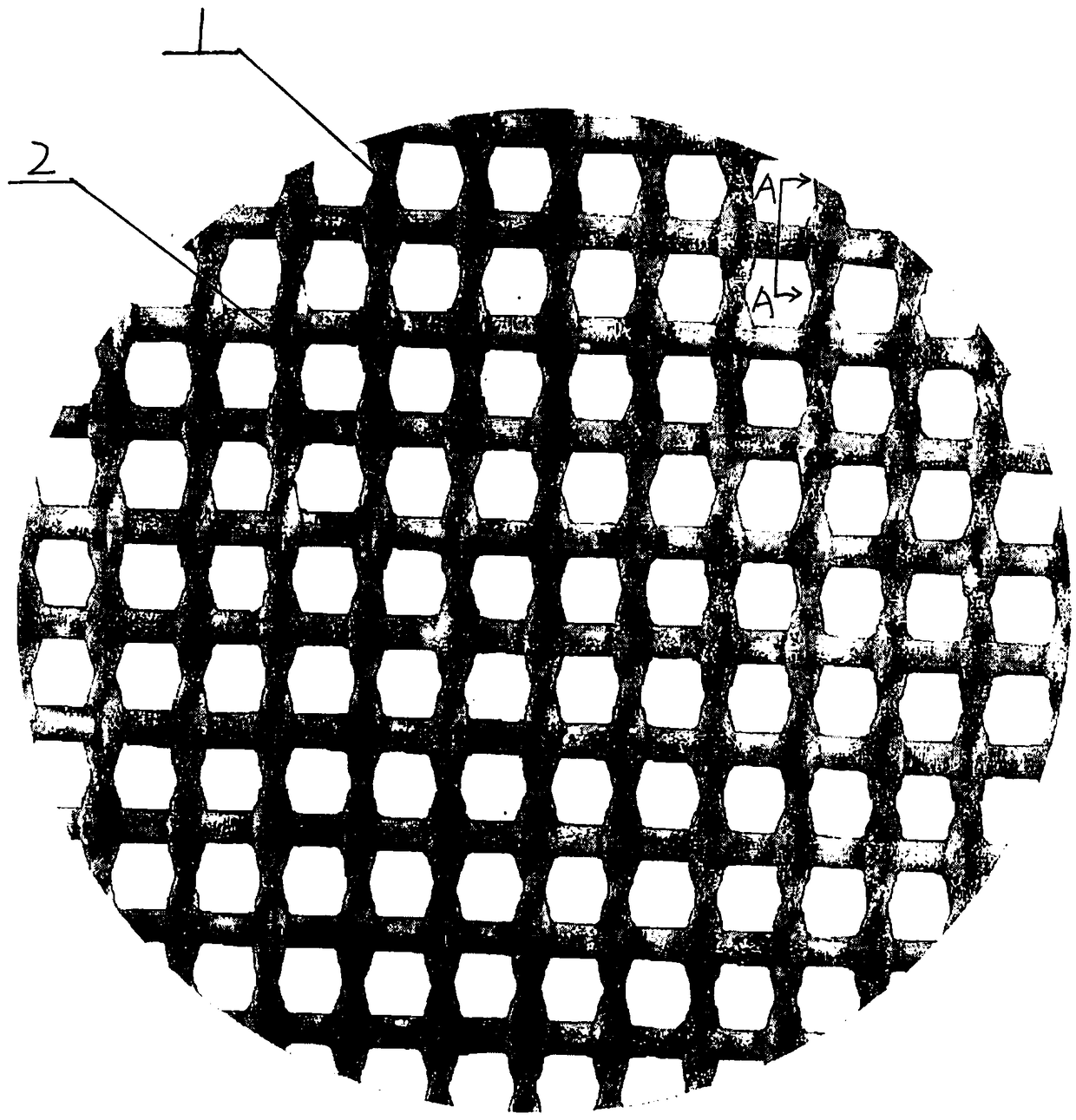

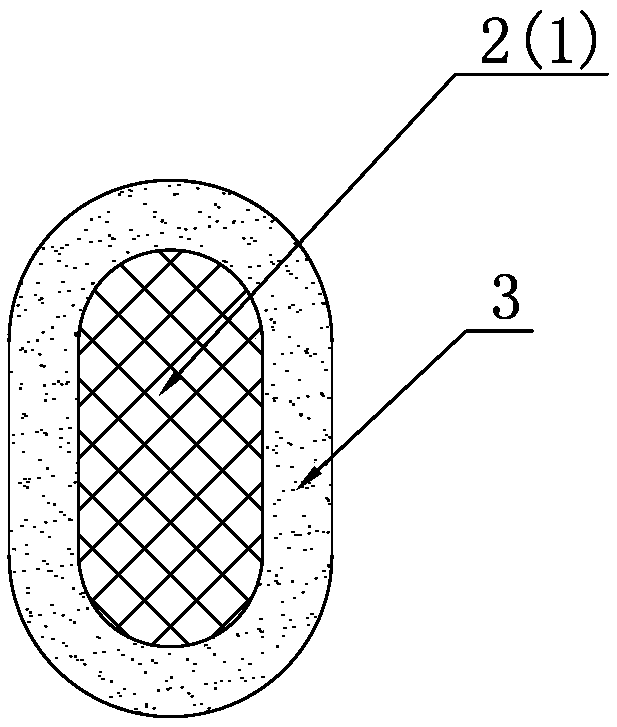

[0028] Use the present invention to make high-strength flame-retardant glass fiber composite mesh material, such as figure 1 , figure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com