Isolation material and preparation method thereof

A technology of isolation materials and metal braided mesh, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problems of low production efficiency and high cost, and achieve the effects of quality assurance, smooth surface and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

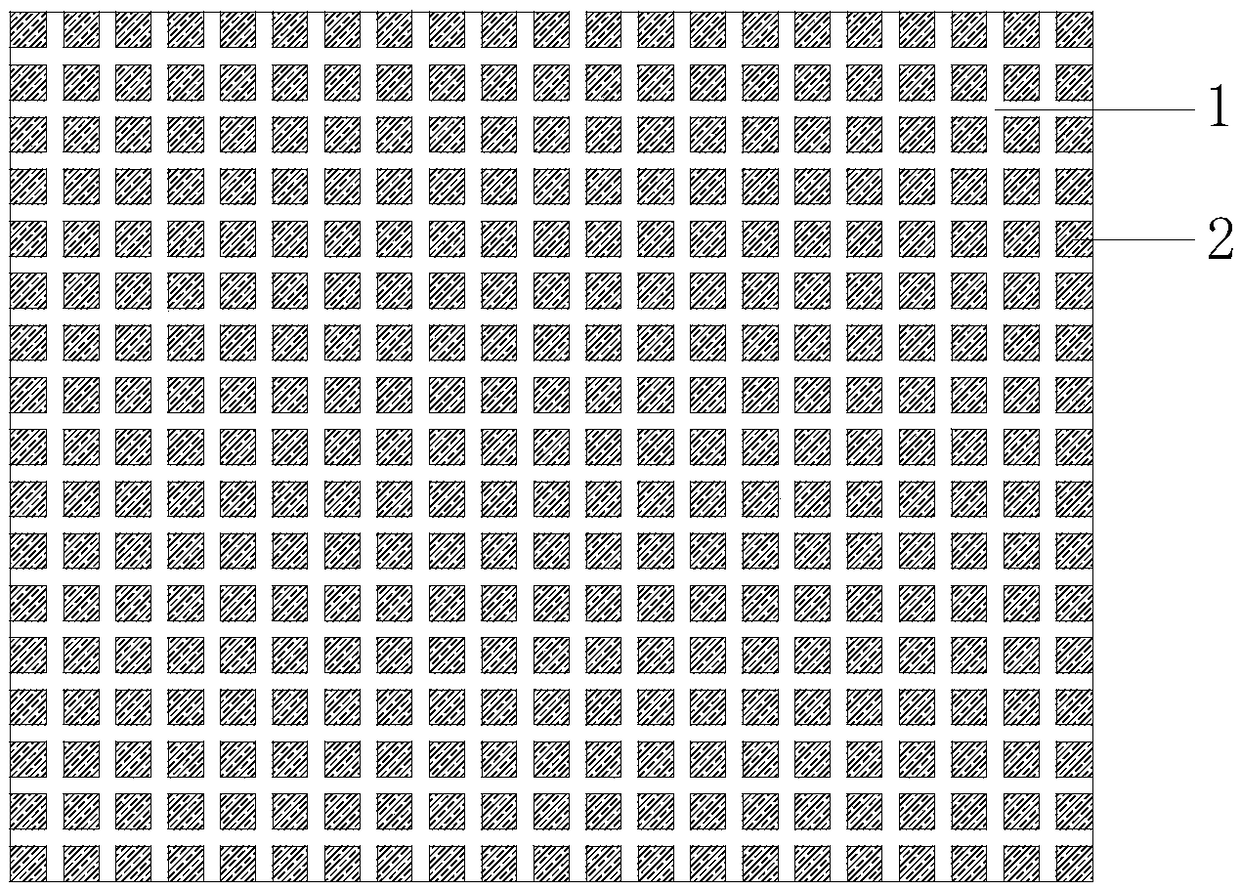

[0036] This embodiment provides an insulating material and a preparation method thereof. The insulating material includes two layers of metal braided meshes 1, a layer of stainless steel fiber mesh 2 is arranged between the two layers of metal braided meshes 1, and the metal braided meshes 1 and The stainless steel fiber mesh 2 is stacked up and down and fixed to form a composite metal mesh, and the composite metal mesh is evenly coated with an alumina coating. Wherein, the wire diameter used in the metal braided net 1 is 0.125mm, and the mesh number of the metal braided net 1 is 50 meshes. The stainless steel fiber mesh is made by air-laid stainless steel fibers with a wire diameter of 12 μm and a length of 10 mm.

[0037] The preparation method of the isolation material provided in this embodiment is used to prepare the above isolation material, and the method is carried out according to the following steps:

[0038] S01: After superimposing the prepared metal braided mesh ...

Embodiment 2

[0043] This embodiment provides an insulating material and a preparation method thereof. The insulating material includes two layers of stainless steel fiber mesh 2, a layer of metal braided mesh 1 is arranged between the two layers of stainless steel fiber mesh 2, and the metal braided mesh 1 and The stainless steel fiber mesh 2 is stacked up and down and fixed to form a composite metal mesh, and the composite metal mesh is evenly coated with an alumina coating. Wherein, the diameter of the metal wire used in the metal braided net is 1mm, and the mesh number of the metal braided net is 10 meshes. The stainless steel fiber mesh is made by air-laid stainless steel fibers with a wire diameter of 40 μm and a length of 100 mm.

[0044] The preparation method of the isolation material provided in this embodiment is used to prepare the above isolation material, and the method is carried out according to the following steps:

[0045] S01: After superimposing the prepared metal braid...

Embodiment 3

[0050] This embodiment provides an insulating material and a preparation method thereof. The insulating material includes a layer of stainless steel fiber mesh 2 and two layers of metal braided mesh 1. The two layers of metal braided mesh 1 are stacked and fixed up and down, and one layer of stainless steel fiber mesh 2 is fixed on the One side of the superimposed metal braided net forms a metal composite net, and the aluminum oxide coating isolation material is evenly coated on the metal composite net. Wherein, the wire diameter of the metal braided net is 0.19 mm, and the mesh number of the metal braided net is 30 mesh. The stainless steel fiber mesh is made by air-laid stainless steel fibers with a wire diameter of 30 μm and a length of 12 cm.

[0051] The preparation method of the isolation material provided in this embodiment is used to prepare the above isolation material, and the method is carried out according to the following steps:

[0052] S01: After superimposing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wire diameter | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com