Sponge composite gridding sanding block and production method thereof

A sponge and grid technology, which is applied in the field of sponge composite grid sanding block, can solve the problems affecting the construction progress and quality, hand discomfort, etc., and achieve great practical and promotional value, not easy to fall off, and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

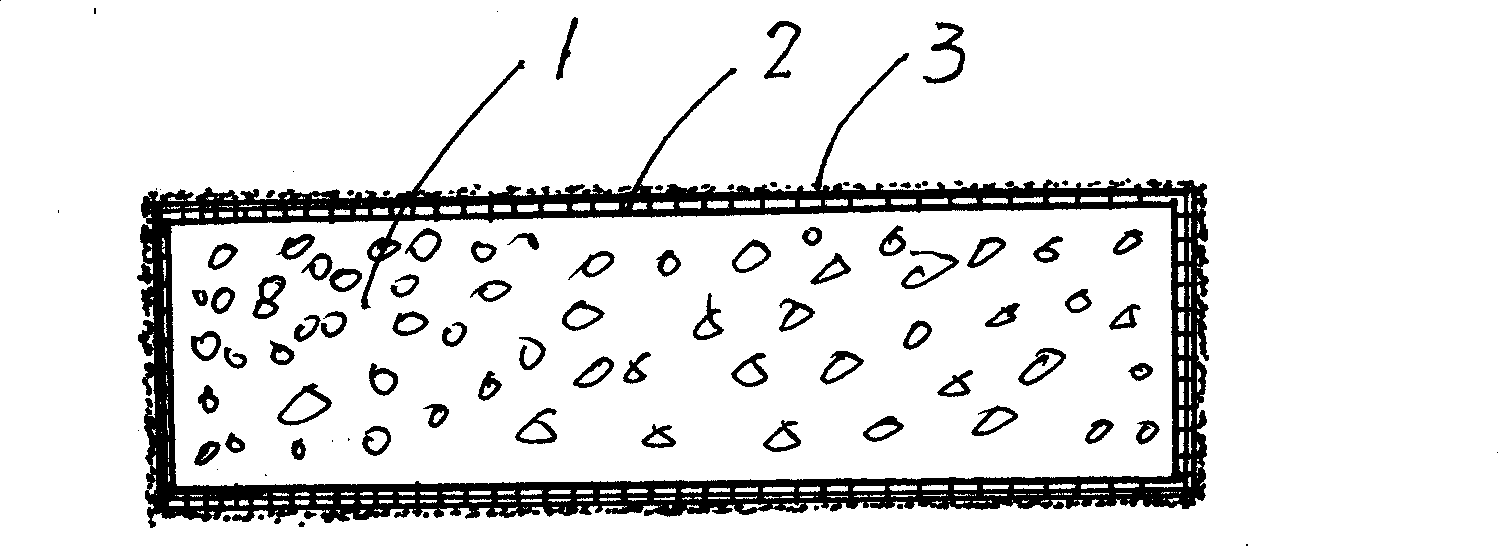

[0032] Refer to attached figure 1, The sponge composite grid sanding block of the present invention comprises an inner core 1 made of sponge, a mesh cloth 2, and a sand layer 3, and the outer surface of the inner core 1 is covered with a mesh cloth 2; the sand Layer 3 is glued on the surface of grid cloth 2 . The inner core 1 can be made into different geometric shapes, and the inner core 1 of this embodiment is rectangular. The outer surface of the inner core 1 is covered with mesh cloth 2, which means that the mesh cloth can be fixed on the surface of the inner core 1 by an adhesive, or can be fixed on the surface of the inner core 1 by a structural member, or can be set inside On the surface of the core 1, the mesh cloth of this embodiment is fixed on the surface of the inner core 1 by an adhesive. The different surfaces of the mesh cloth 2 of the inner core 1 may be mesh cloths of the same specification or mesh cloths of different specifications, and the mesh cloths of ...

Embodiment 2

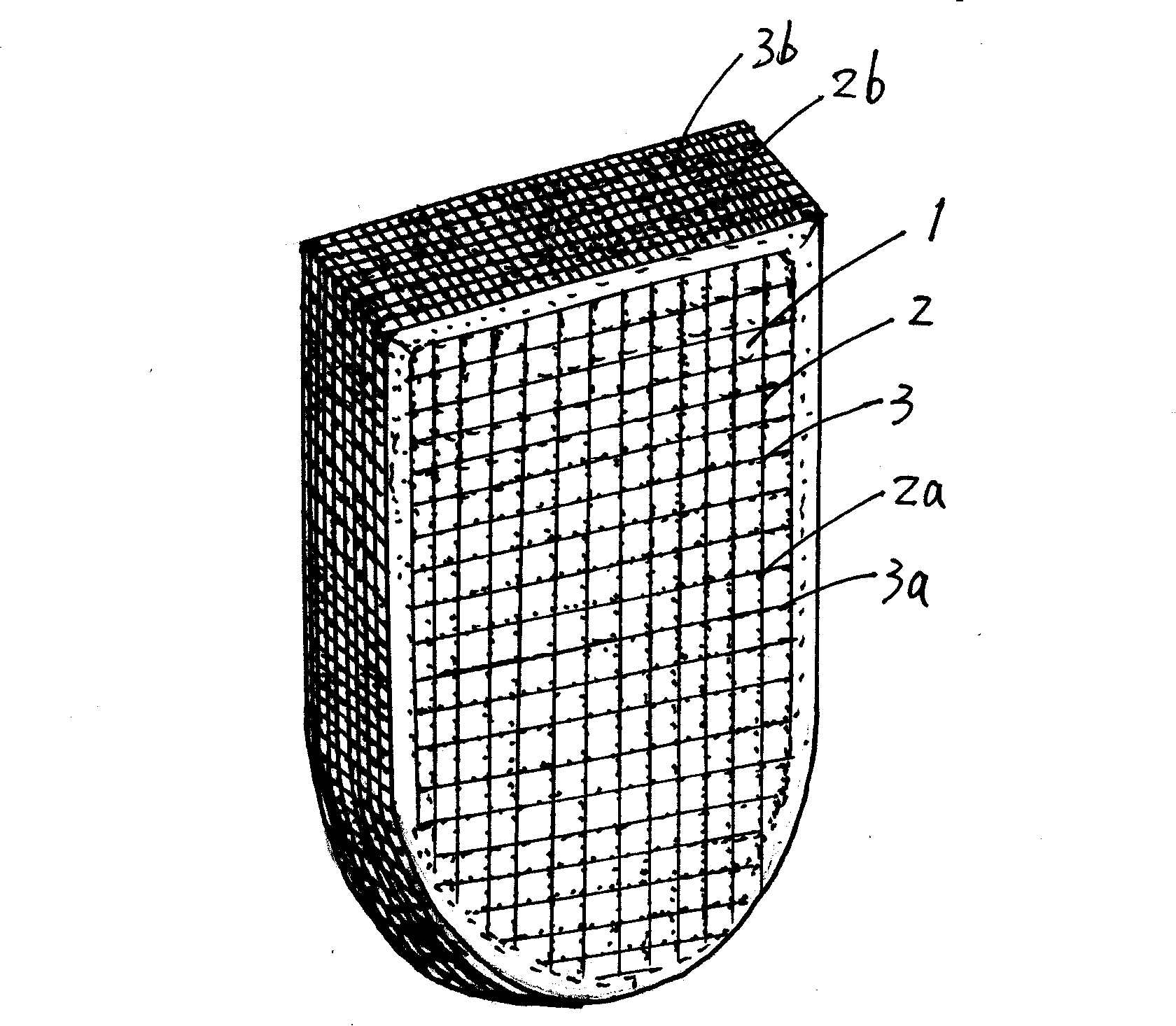

[0040] Refer to attached figure 2, The sponge composite grid sanding block of the present invention comprises an inner core 1 made of sponge, a grid cloth 2, and a sand layer 3, and the outer surface of the inner core 1 is covered with a grid cloth 2; the sand layer 3 is bonded to the mesh Gable 2 on the surface. The inner core 1 of this embodiment is a combination of a cuboid and a circle, and the periphery is rounded. The mesh cloth 2 of this embodiment adopts two kinds of mesh cloths of different specifications and are respectively glued on different surfaces of the inner core 1 by an adhesive to form the mesh cloth 2a and the mesh cloth 2b. Coat adhesive on the surface of grid cloth 2a and grid cloth 2b and plant emery grains of 80 mesh and 150 mesh respectively to form sand layer 3a and sand layer 3b.

[0041] The method for producing the above-mentioned sponge composite grid sanding block comprises the following steps:

[0042] ① Make the inner core 1 of the required...

Embodiment 3

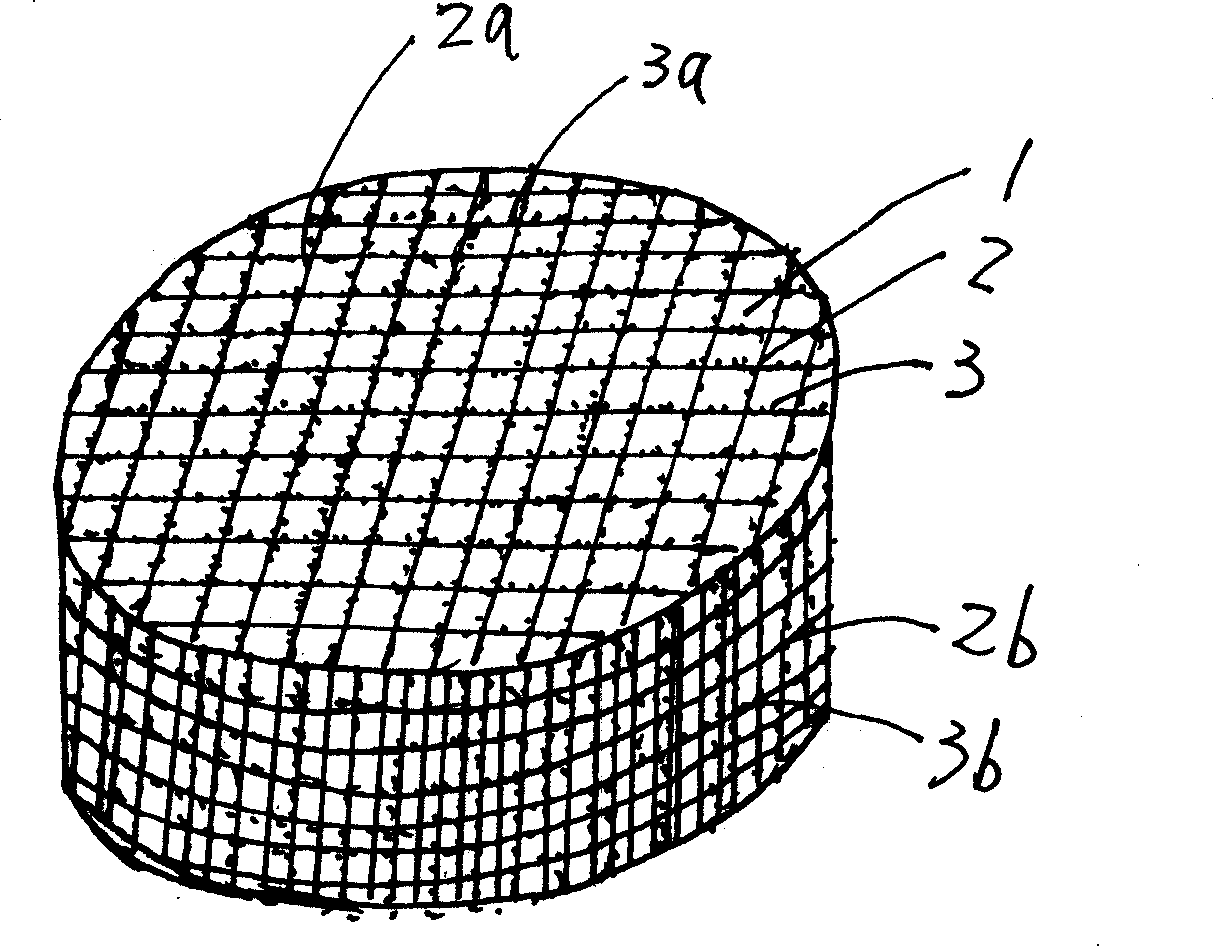

[0048] Refer to attached image 3, The sponge composite grid sanding block of the present invention comprises an inner core 1 made of sponge, a grid cloth 2, and a sand layer 3, and the outer surface of the inner core 1 is covered with a grid cloth 2; the sand layer 3 is bonded to the mesh Gable 2 on the surface. The inner core 1 of this embodiment is made into a cylindrical shape. The mesh cloth 2 of this embodiment adopts two kinds of mesh cloths of different specifications to be respectively bonded to the upper and lower circular end faces of the inner core 1 by adhesive; the arc surface of the cylinder is bonded with a mesh cloth to form a mesh Cloth 2a, mesh cloth 2b. Coat adhesive on the surface of grid cloth 2a and grid cloth 2b and plant emery grains of 80 mesh and 150 mesh respectively to form sand layer 3a and sand layer 3b.

[0049] The method for producing the above-mentioned sponge composite grid sanding block comprises the following steps:

[0050] ① Make the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com