Preparation method of sunshade mesh cloth with insect-proof efficacy

A pest control and efficacy technology, applied in enzyme/microbial biochemical treatment, textile, biochemical fiber treatment, etc., can solve the problems of reduced service life, loss of sunshade mesh quality, etc., to achieve long service life, avoid erosion, and sunshade performance strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

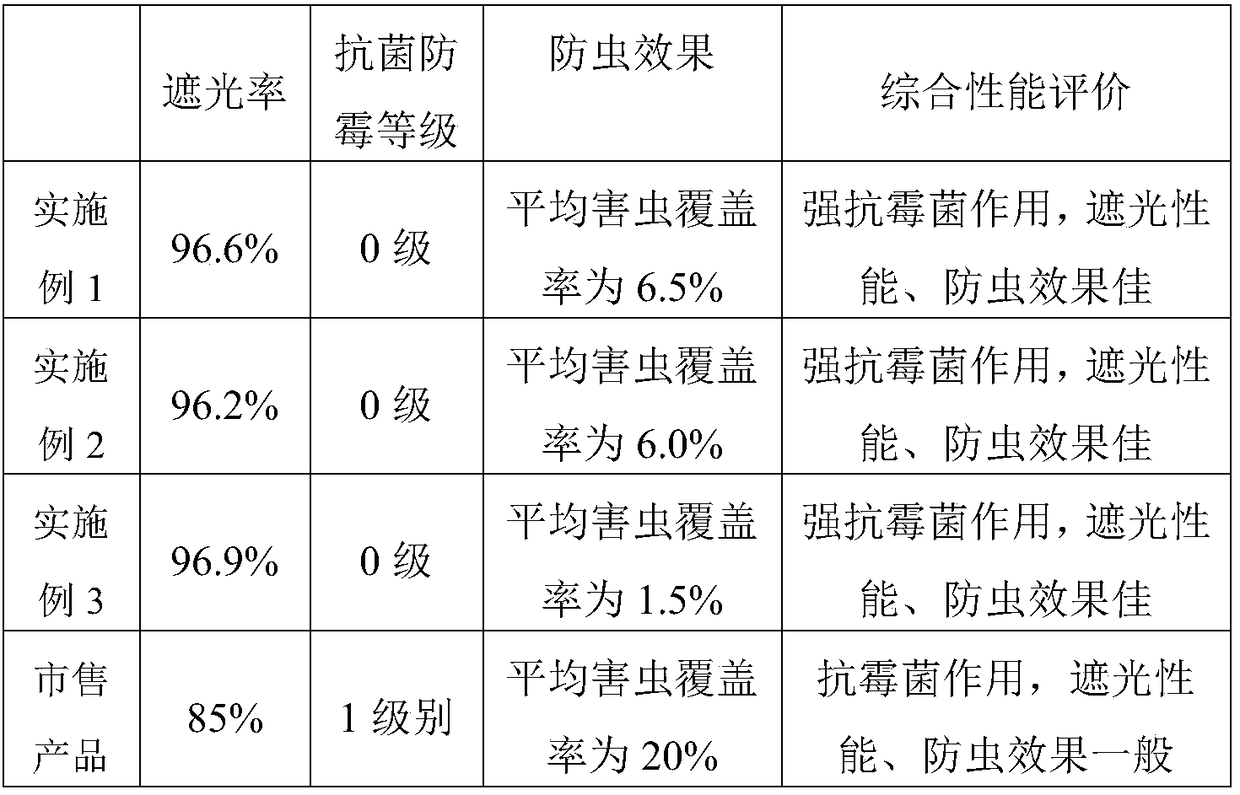

Examples

Embodiment 1

[0024] A method for processing a sunshade net cloth with insect-proof effect, comprising the following steps:

[0025] (1) Processing of external antibacterial and insect-proof mesh cloth:

[0026] 1-A) Firstly, the compound insect-repelling mixture was prepared, and 4 parts of sodium benzoate, 2 parts of bromofen, 3 parts of microbial bacteria, 3 parts of wormwood powder, 0.5 parts of multivitamins, and 8 parts of white vinegar were prepared by mass. Mix evenly in a mixer at low speed, heat at 60°C for 20 minutes, then cool to 40°C and keep warm for later use;

[0027] 1-B) The warp yarn in the spinning material includes by mass: 40% polyester fiber, 20% silver ion fiber, and the antibacterial plant fiber of the balance; the weft yarn material includes: 35% polyester fiber, 15% silver ion fiber, The remaining antibacterial plant fibers; the warp and weft yarns are alternately spun at an angle of 60° / 120°, the pre-crystallization temperature in the spinning process is 115°C; ...

Embodiment 2

[0033] A method for processing a sunshade net cloth with insect-proof effect, comprising the following steps:

[0034] (1) Processing of external antibacterial and insect-proof mesh cloth:

[0035] 1-A) First, prepare the compound insect-repelling mixed solution, by mass, 12 parts of sodium benzoate, 8 parts of bromofen, 12 parts of microbial bacteria, 8 parts of wormwood powder, 2 parts of multivitamins, and 20 parts of white vinegar Mix evenly in a mixer at low speed, heat at -80°C for 30 minutes, then cool to 50°C and keep warm for later use;

[0036] 1-B) The warp yarn in the spinning material comprises by mass: polyester fiber 55%, silver ion fiber 15%, the antibacterial plant fiber of the balance; the weft yarn material comprises by mass: polyester fiber 45%, silver ion fiber 5%, The remaining antibacterial plant fibers; the warp and weft yarns are alternately spun at an angle of 60° / 120°, the pre-crystallization temperature in the spinning process is 115°C; the drying ...

Embodiment 3

[0042] A method for processing a sunshade net cloth with insect-proof effect, comprising the following steps:

[0043] (1) Processing of external antibacterial and insect-proof mesh cloth:

[0044] 1-A) Firstly, the compound insect-repelling mixed solution was prepared, by mass, 9 parts of sodium benzoate, 5 parts of bromofen, 8 parts of microbial bacteria, 6 parts of wormwood powder, 1.5 parts of multivitamins, and 15 parts of white vinegar were placed in the Mix evenly in a mixer at low speed, heat at 70°C for 25 minutes, then cool to 45°C and keep warm for later use;

[0045]1-B) The warp yarn in the spinning material comprises by mass: polyester fiber 45%, silver ion fiber 18%, the antibacterial plant fiber of the balance; the weft yarn material comprises by mass: polyester fiber 40%, silver ion fiber 12%, The remaining antibacterial plant fibers; the warp and weft yarns are alternately spun at an angle of 60° / 120°, the pre-crystallization temperature in the spinning proc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com