Multi-layer hernia repairing patch and preparation method thereof

A technique for hernia repair and patch, applied in the field of multilayer hernia patch and its preparation, which can solve the problems of cumbersome preparation process, many chemical reactions, poor softness, etc., and achieve simple process, firm combination, and good anti-adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

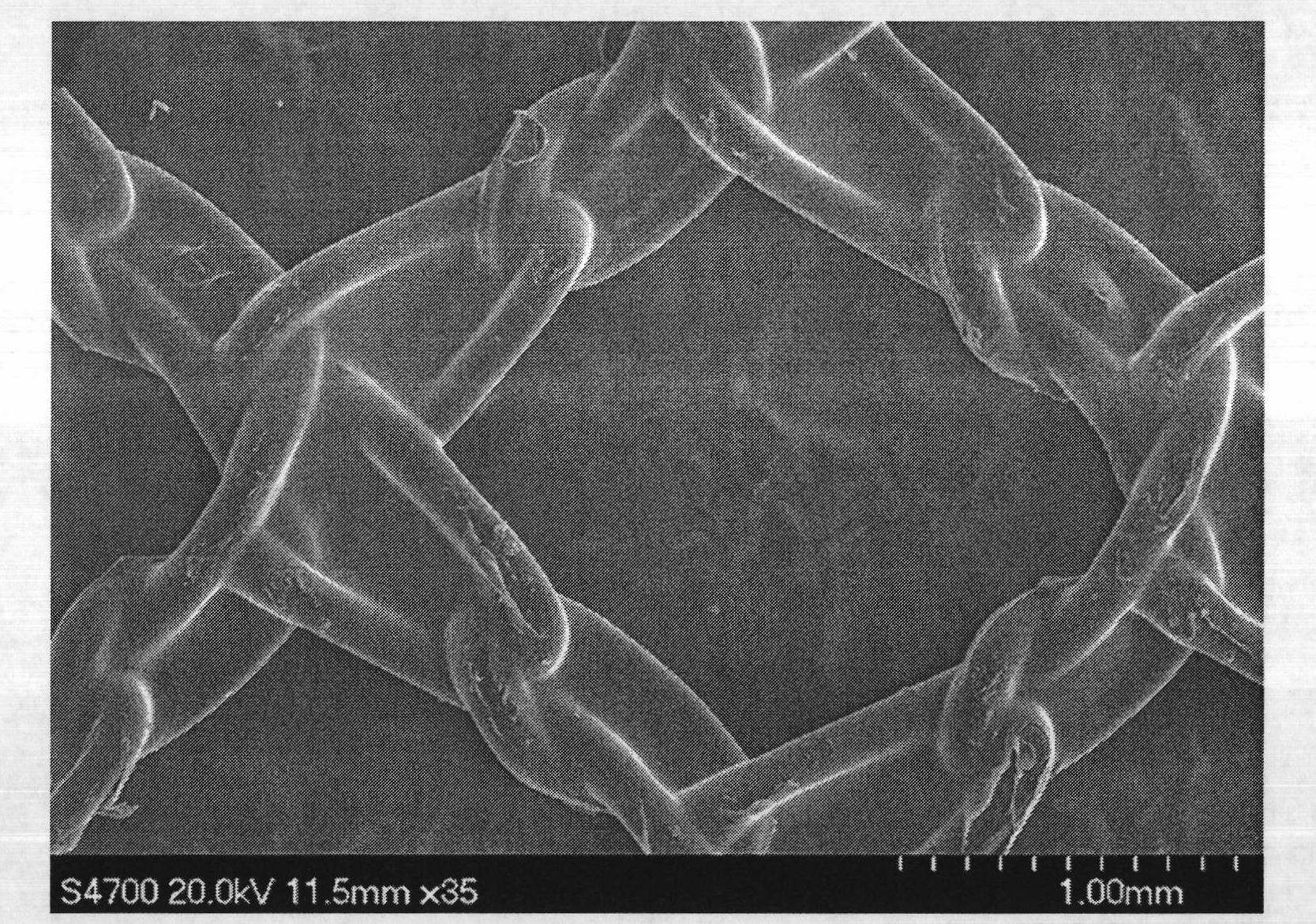

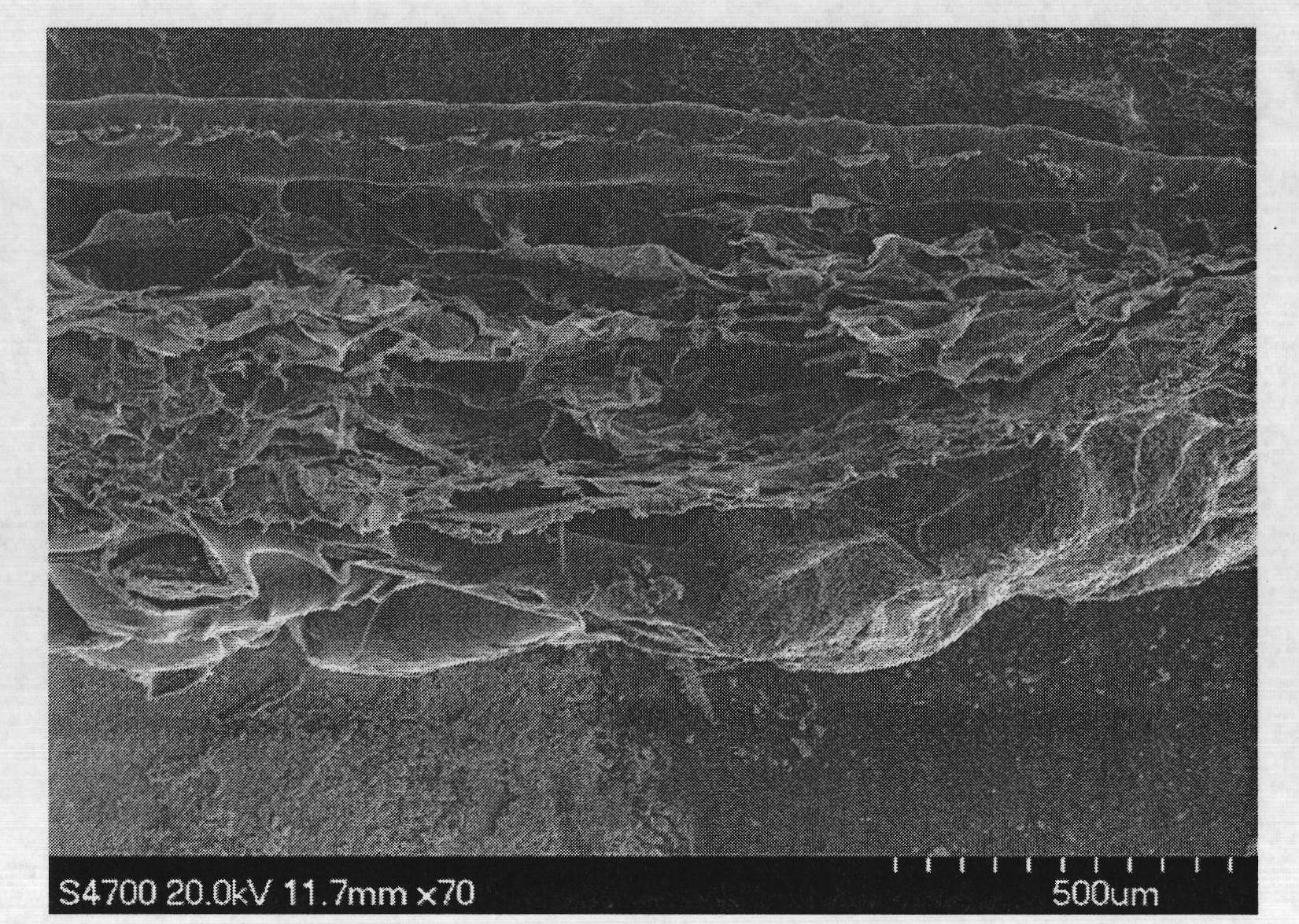

[0033] The configuration mass fraction is the PLCL acetone solution of 10%, pours on the polypropylene (PP) mesh that is placed in the mould, smears evenly, ventilates and volatilizes solvent, obtains PP / PLCL composite mesh, PLCL film is on the polypropylene mesh One side forms a polyester layer.

[0034] The mesh was placed in a vessel containing evenly spaced grooves filled with PLCL acetone. After partial dissolution, the patch is taken out to obtain a PP / PLCL composite mesh with a PLCL layer in a uniform void area. Preferably, the ratio of the area of the void area of the obtained PLCL layer to the area of the mesh sheet is 10%-80%, preferably 30%, 40%, 50% or 60%.

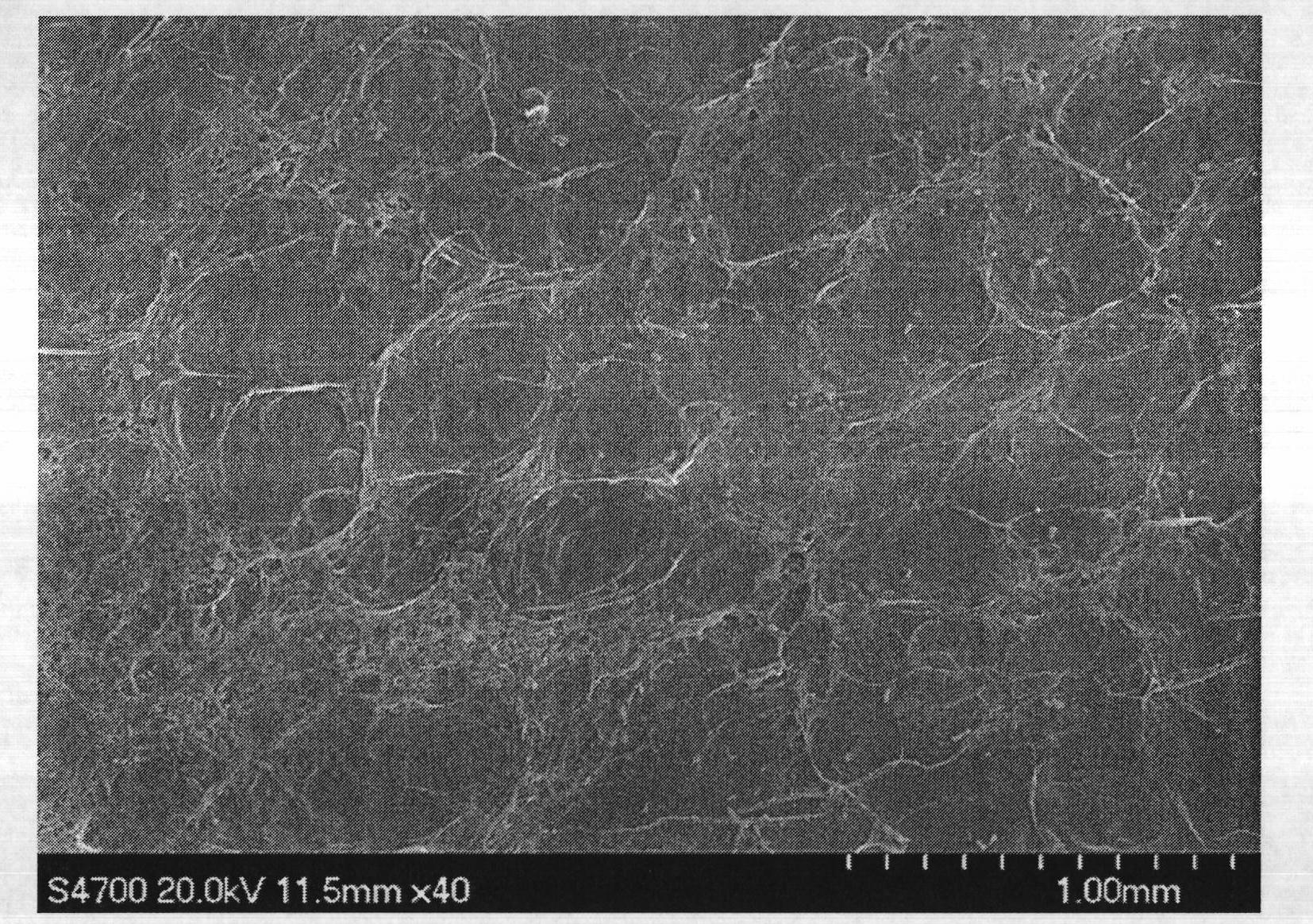

[0035]Pour the collagen solution with a mass fraction of 2% into a mold with a depth of 1 mm, and freeze-dry to obtain a spongy collagen film layer with a thickness of 1 mm;

[0036] Configure PLCL acetone solution with a mass fraction of 5%, take 25mL and pour it on 250cm 2 Spread the spongy collagen...

Embodiment 2

[0040] Configuration mass fraction is 10% PLCL chloroform solution, casts on the polypropylene (PP) mesh that is placed in the mould, smears evenly, ventilates and volatilizes solvent, obtains PP / PLCL composite mesh, and PLCL film is on the polypropylene mesh one side of the cambium.

[0041] The mesh was placed in a vessel containing evenly spaced grooves filled with chloroform. After partial dissolution, the patch is taken out to obtain a PP / PLCL composite mesh with a PLCL layer in a uniform void area. The ratio of the area of the void area of the obtained PLCL layer to the area of the mesh sheet is 10%-80%, preferably 30%, 40%, 50% or 60%.

[0042] Pour a hyaluronic acid solution with a mass fraction of 1% (crosslinked by EDC and NHS, the same below) into a mold with a depth of 2 mm, and freeze-dry to obtain a hyaluronic acid sponge with a thickness of 2 mm.

[0043] Configure a PLCL chloroform solution with a mass fraction of 5%, take 25mL and pour it on 250cm 2 S...

Embodiment 3

[0046] Configuration mass fraction is 10% PLGA tetrahydrofuran solution, casts on the polypropylene (PP) mesh that is placed in the mould, smears evenly, ventilates and volatilizes solvent, obtains PP / PLGA composite mesh, PLGA film is on the polypropylene mesh One side cambium.

[0047] The mesh was placed in a vessel containing evenly distributed grooves in which PLGA tetrahydrofuran was placed. After partial dissolution, the patch is taken out to obtain a PP / PLGA composite mesh with a PLGA layer in a uniform void area. The ratio of the area of the void area of the obtained PLGA layer to the area of the mesh sheet is 10%-80%, preferably 30%, 40%, 50% or 60%.

[0048] A hyaluronic acid solution with a mass fraction of 1% (crosslinked by EDC and NHS, the same below) was poured into a mold with a depth of 2 mm, and freeze-dried to obtain a hyaluronic acid sponge with a thickness of 2 mm.

[0049] Configure a PLGA tetrahydrofuran solution with a mass fraction of 5%, take ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com