Polymeric membrane screen printing plate with optimized S-face coated structure

A technology of polymer film and polymer film layer, which is applied in the printing plate, printing plate preparation, printing, etc., can solve the problems of uneven mesh distribution, affecting client printing, and prone to glue overflow, etc., to improve the printing height Insufficient, improve printing efficiency, increase the effect of wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

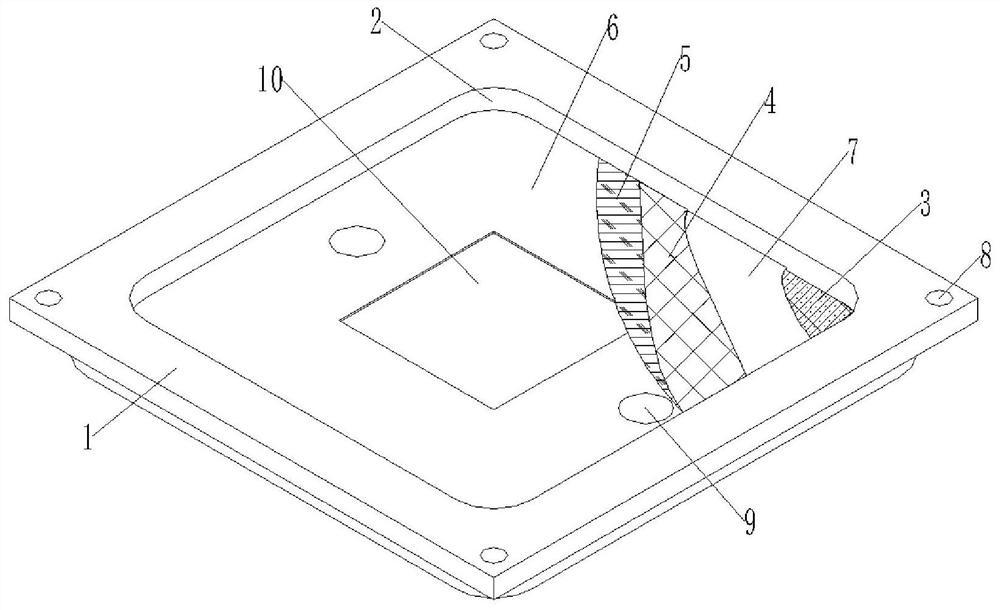

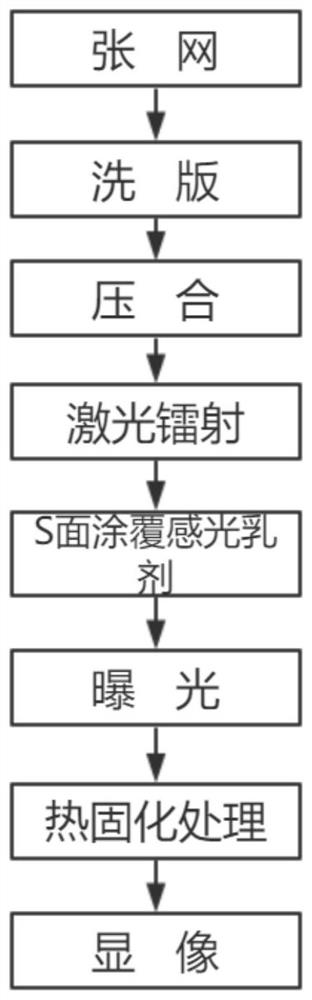

[0031] First of all, the original design intention of the present invention is explained. As one of the core technologies of solar energy research, solar cells have also obtained rapid development in recent years. Improving the conversion efficiency of solar cells is the main research object of solar cells at present. In addition to the selection of battery substrate materials and In addition to requirements such as optimization and improvement of the cell manufacturing process, the conversion efficiency of solar cells can also be improved by adopting a suitable high-precision and high-stability printing method. Traditional solar cell printing adopts the production method of composite screen. The existing plate structure mainly includes: screen frame-polyester mesh-hot melt adhesive-steel mesh-polymer film-pattern. The screen has the following limitations: 1 1. Polyester mesh and steel mesh are compounded together by hot melt adhesive, and the adhesive layer of the polymer film...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coating thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com