Wet-process non-woven fabric manufacturing method and manufacturing equipment

A manufacturing method and technology of non-woven fabrics, which are applied in textiles and papermaking, papermaking, papermaking machines, etc., can solve the problems of long production lines, low production efficiency, and uneven thickness of non-woven fabrics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings.

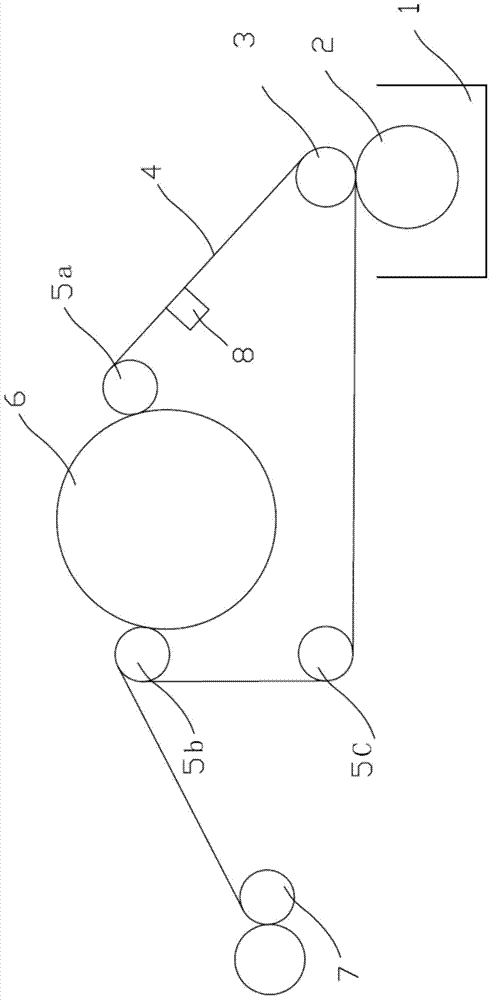

[0019] Such as figure 1 The shown wet process manufacturing device includes a raw material trough 1, a cage roll 2, a suction roll 3, a polyester mesh belt 4, a work roll 5, a drying cylinder 6, a winding roll 7, and a dehydration device 8. Wherein the work rolls include 5a, 5b, 5c and so on.

[0020] The shown polyester mesh belt 4 turns around and between the work rolls 5a, 5b, 5c and the suction roll, any one of which is set as a power roll, so that the polyester mesh belt 4 can turn around in the counterclockwise direction. This device replaces the complex web forming equipment in the prior art by directly setting the mesh cage roller 2 in the raw material tank 1, shortening the production process and production line. Contact with the polyester mesh belt 4 under rotation, and the negative pressure environment in the suction roller 3 ensures that the fiber web c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com