Spunlaced nonwoven fabric for clothing and production method and equipment thereof

A non-woven fabric and production method technology, applied in the field of non-woven fabrics, can solve the problems of high input cost, high product price, high raw material requirements, etc., and achieve the effect of reducing equipment re-investment costs and low manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

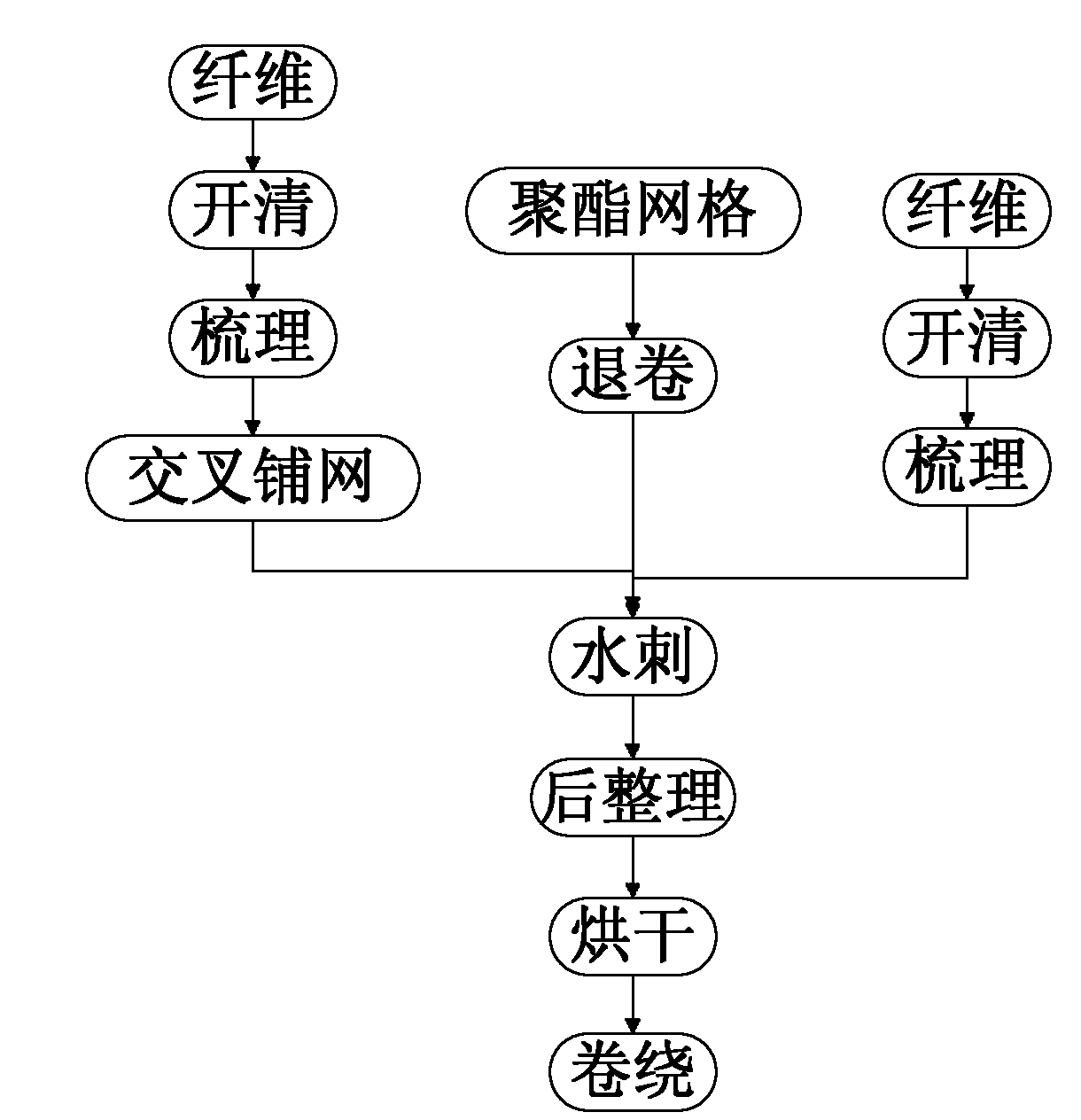

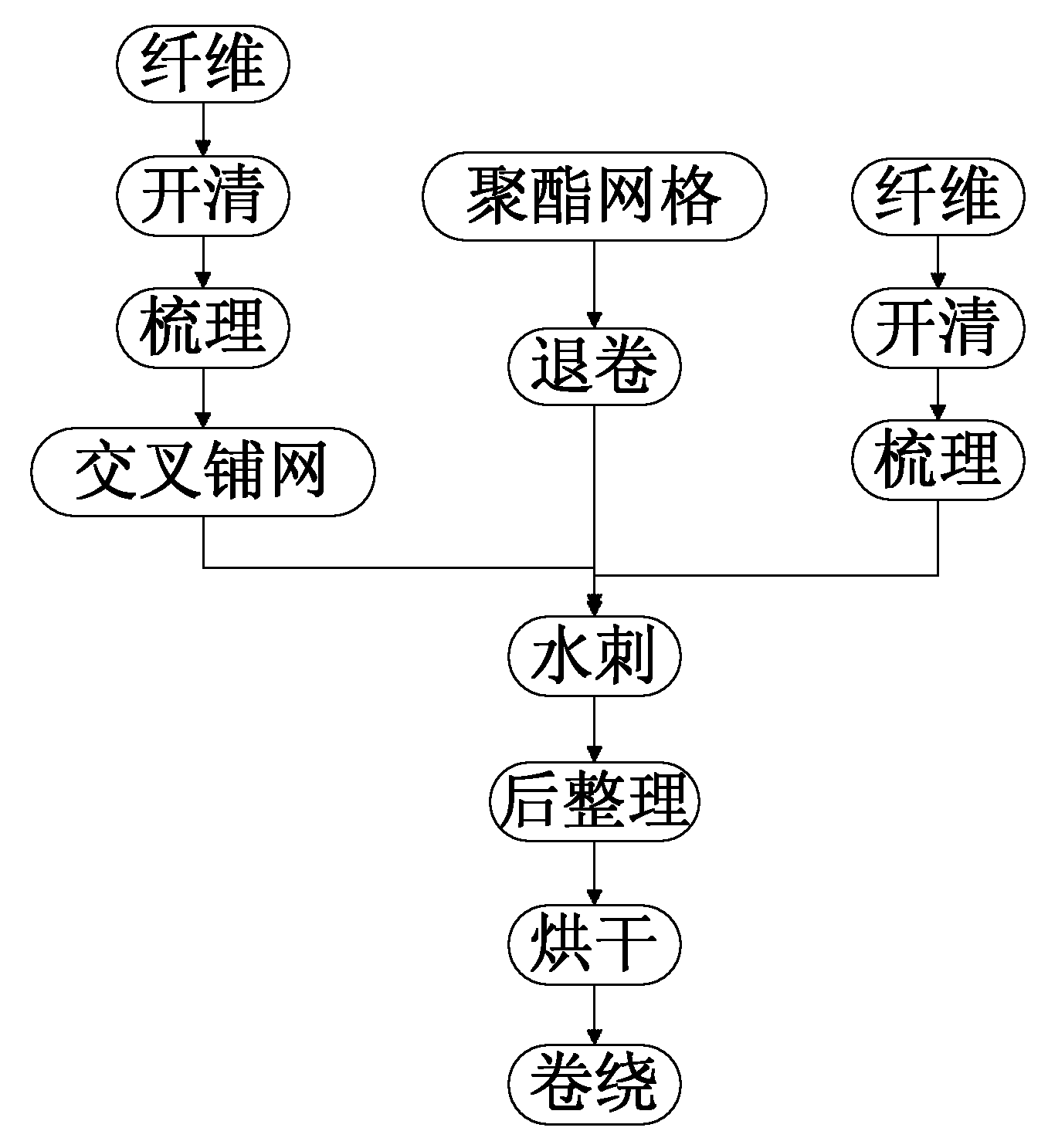

[0024] Please refer to figure 1 , a method for producing a garment spunlace nonwoven, comprising the following processes:

[0025] The synthetic fiber (marked as fiber in the figure) is opened, cleaned and carded, and then laid to form an upper fiber web and a lower fiber web, wherein the upper fiber web is formed by straight laying (direct carding), and the lower fiber web is carded and then cross-laid. Of course, the structure of the upper and lower fiber webs can be interchanged, or both are fiber web structures made of cross-laid fibers or fiber web structures made of straight-laid fibers, or even other structures, and the preferred method is adopted here. The cross-lapping method can improve the lateral strength of the finished product.

[0026] The upper fiber net, polyester grid and lower fiber net are stacked successively to form a three-layer composite structure; the polyester grid is added in the middle of the upper and lower fiber nets to play the role of reinforce...

Embodiment 2

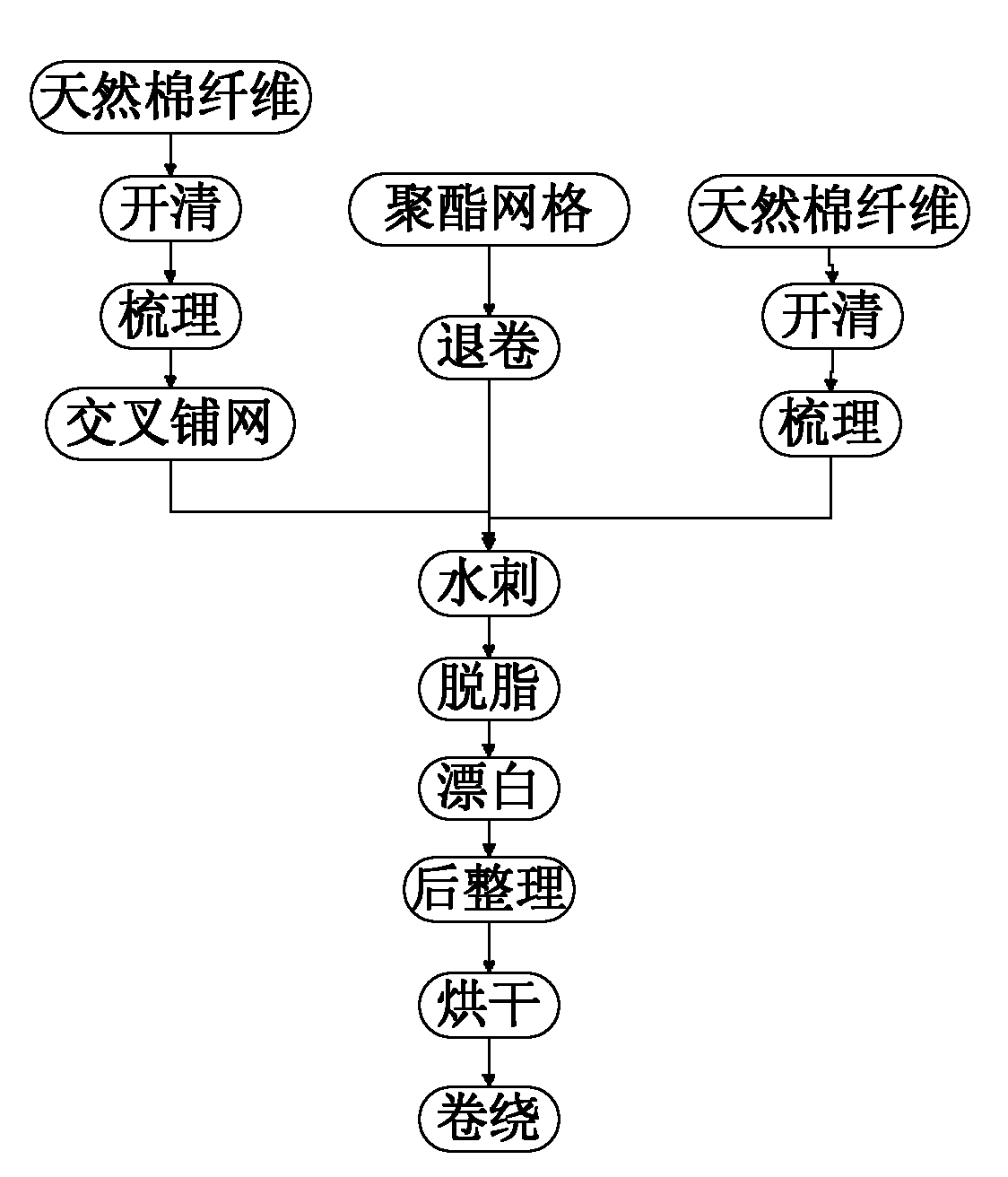

[0032] Please refer to figure 2 , a method for producing spunlaced nonwovens for clothing, the difference from Example 1 is that the upper fiber web and the lower fiber web are also made of natural cotton fibers or mixed with natural cotton fibers and synthetic fibers, so in It is necessary to add a degreasing treatment process and a bleaching treatment process between the spunlace treatment and the finishing treatment. Other processes and principles are the same. Of course, natural cotton fiber is the preferred mode among natural fibers here, and when natural absorbent cotton is used, it can be flexibly grasped whether a degreasing process is needed according to the prior art.

[0033] refer to figure 1 , figure 2 , a spunlaced nonwoven fabric for garments, which is produced through Embodiment 1 or Embodiment 2 and other similar methods that can be imagined under the generalization of the previous principles.

[0034] The preferred spunlaced nonwoven fabric for this kin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com