Composite screen plate based on steel sheet and processing technology thereof

A composite screen and processing technology, which is applied in printing plate preparation, screen printing machines, rotary printing machines, etc., can solve the problems of small bonding area, influence of printing use, and easy falling off of steel sheets, etc., to achieve firm bonding, The effect of increasing the contact area and increasing the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

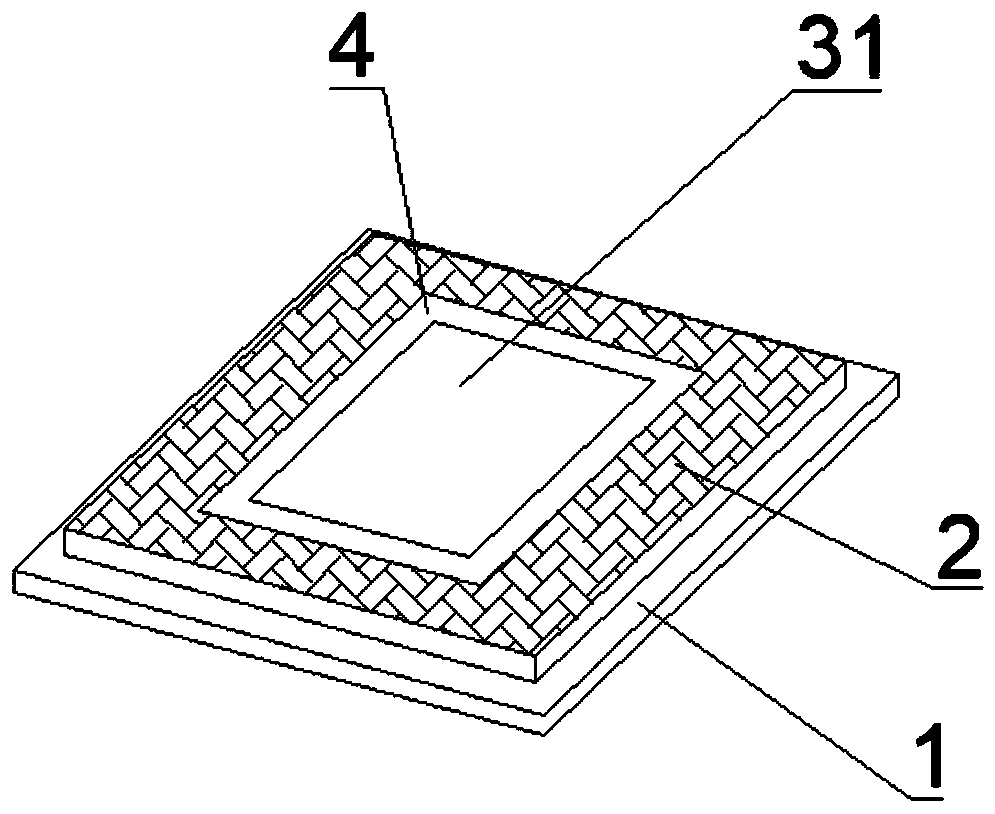

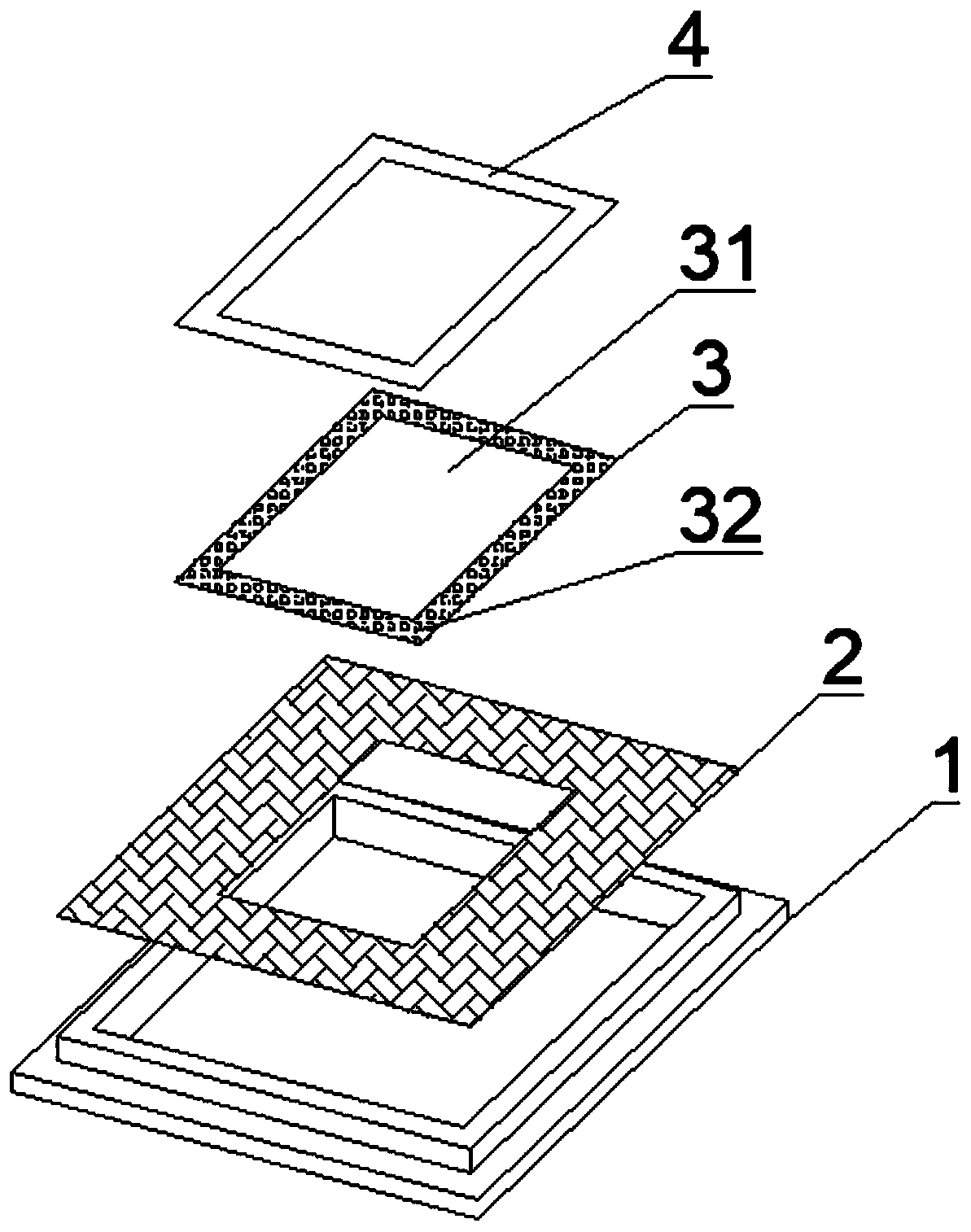

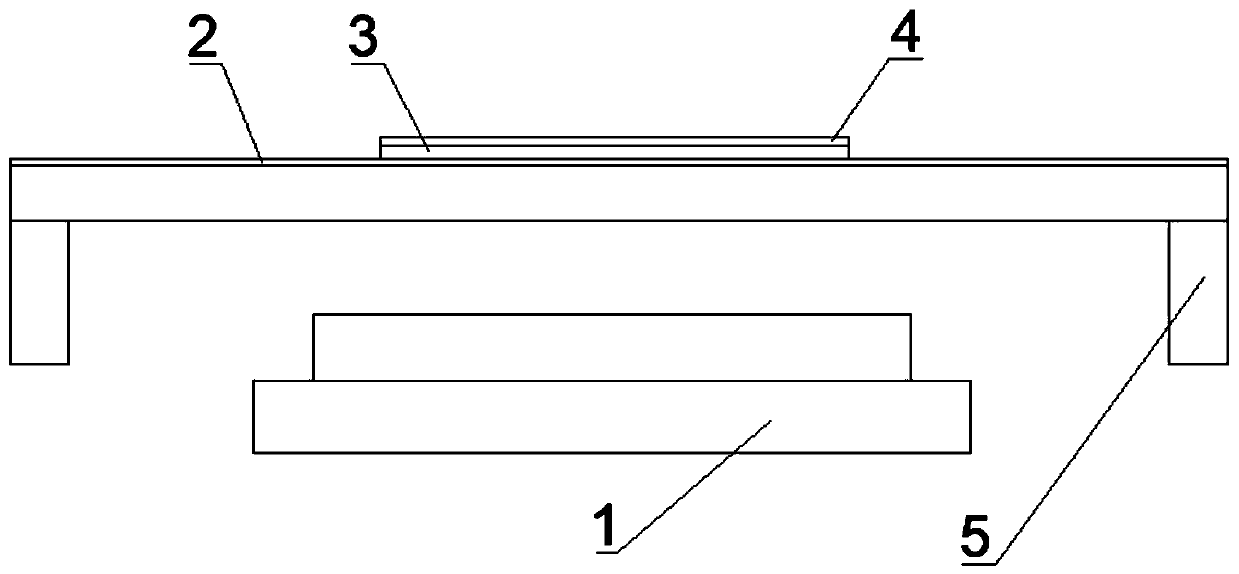

[0026] Aiming at the deficiencies of the prior art, the present invention provides a steel sheet-based composite screen and its processing technology, using a steel sheet with mesh holes on the edge, and the bottom-up polyester mesh 2, steel sheet 3 and The structure of the PE film 4 is hot-melt compounded, and the PE film 4 is melted into the through hole of the steel sheet 3 and combined with the polyester mesh 2 below the steel sheet 3, which solves the problem of glue bonding between the edge area of the steel sheet 3 and the polyester mesh 2. This directly leads to the problem that the composite screen is easy to deform and fall off.

[0027] Such as figure 1 As shown, a composite screen based on steel sheet includes steel sheet 3, polyester mesh 2 surrounding steel sheet 3 and steel sheet 3, and polyester mesh 2 surrounding polyester mesh 2. The frame 1, the key is: the steel sheet 3 includes a pattern area 31 in the middle and a connection area 32 around the edge of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com