Metal mesh printing plate and preparation method thereof

A printing plate and metal technology, which is applied in the field of metal mesh printing plate and its preparation, can solve the problems of incomplete lines, unevenness, part of the graphic area blocked by the screen, etc., to improve printing quality, clear and accurate graphics, and uniform ink leakage and rich effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The invention also discloses a method for preparing a metal mesh printing plate, comprising the following steps:

[0047] 1) Provide a primary metal mesh printing plate, the primary metal mesh printing plate includes metal mesh and polyester mesh, the metal mesh is located in the hollowed out area of the polyester mesh, the metal mesh The mesh cloth includes interweaving weft threads and warp threads, the weft threads are arranged horizontally, and the warp threads are arranged longitudinally, and the weft threads and warp threads have the same or different wire diameters;

[0048] Specifically, the preparation method of the above-mentioned primary metal mesh screen comprises the following steps:

[0049] 11) Stretch the polyester mesh to a certain tension and fix it on the first screen frame to form an elastic screen;

[0050] 12) bonding the screen to the middle region of the polyester mesh by glue, and cutting off the middle region where the polyester mesh and the...

Embodiment 1

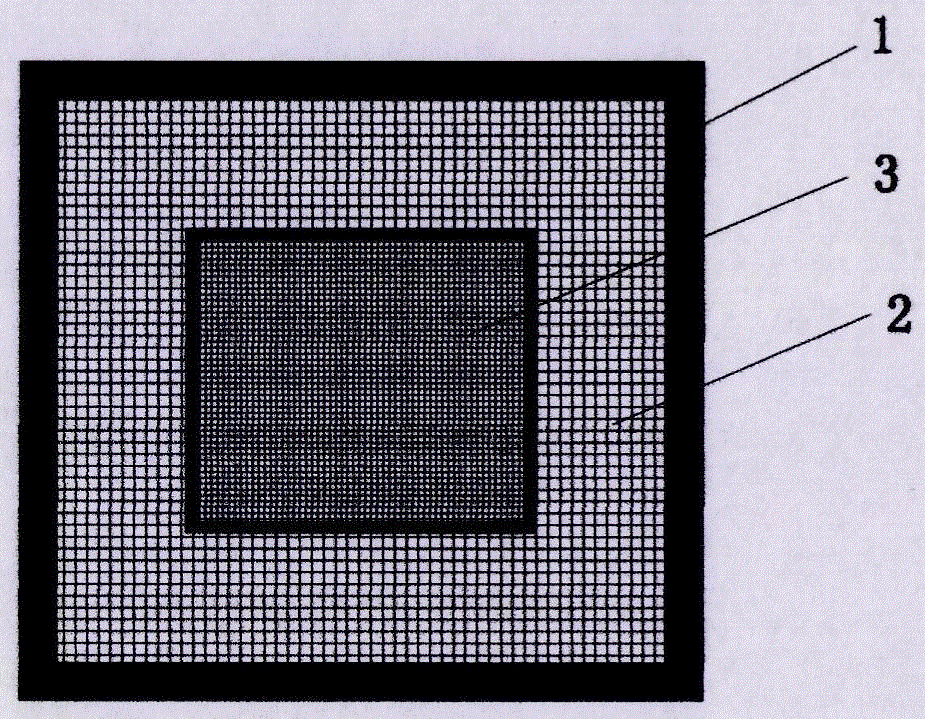

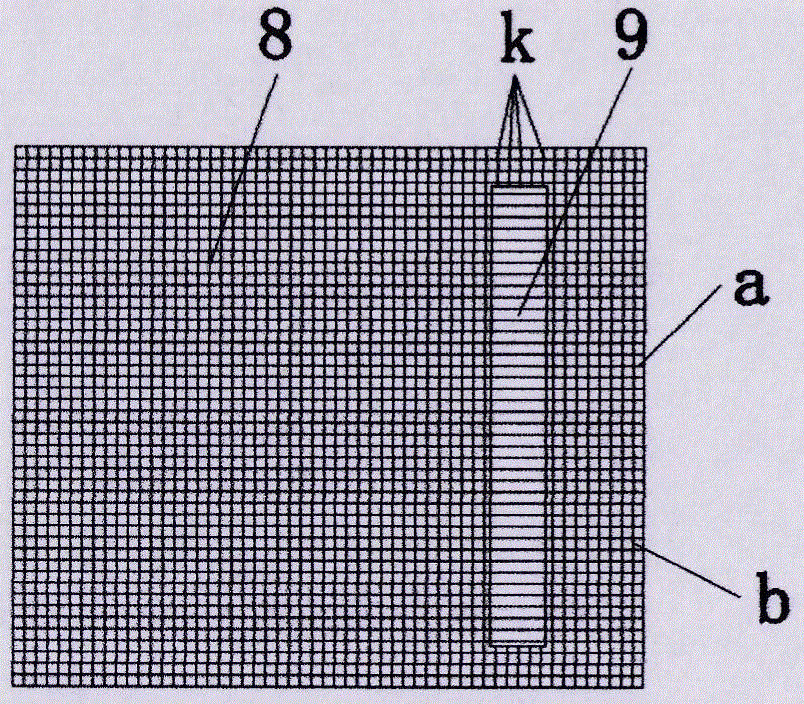

[0068] see Figure 1-5 As shown, this embodiment 1 discloses a metal mesh printing plate, which is used to print the edge sub-grid of solar cells, which includes a metal mesh 3 and a polyester mesh 2, and the metal mesh 3 is located on the polyester mesh. 2 In the hollowed-out area, the metal mesh cloth 3 includes interwoven wefts a and warp b, a number of wefts a are arranged in the horizontal direction, a number of warps b are arranged in the longitudinal direction, and the diameters of the weft a and the warp b are the same or different;

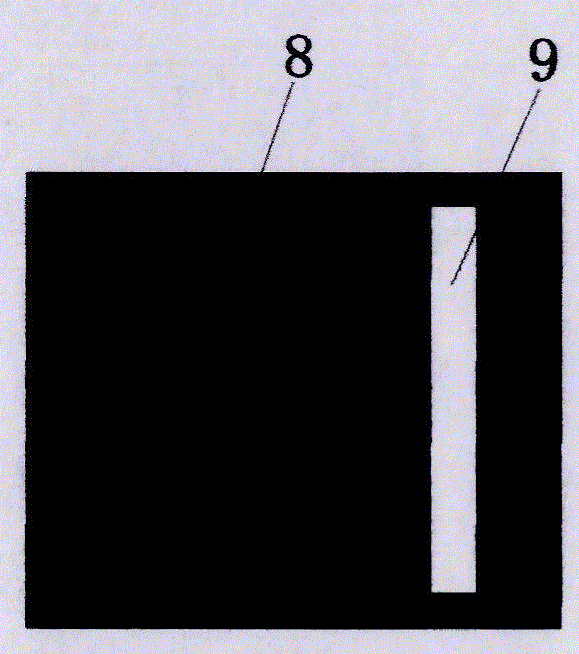

[0069] The non-graphic area on the metal mesh 3 is provided with a layer of metal layer 8, and the graphic area is located in the non-graphic area, and the weft / warp of the metal mesh 3 forms a parallel cutting state for the printed graphics. Specifically, the graphics in the graphic area are along the Rectangular lines 9 extending in the meridian direction (corresponding to the edge sub-grids of the solar cells);

[0070] like image ...

Embodiment 2

[0072] see Figure 6-13 As shown, this embodiment 2 discloses a method for preparing a metal mesh printing plate, which is used to print the edge sub-grid of the above-mentioned solar cells, including the following steps:

[0073] 1) Provide the primary metal mesh printing plate, the primary metal mesh printing plate includes metal mesh 3 and polyester mesh 2, the metal mesh 3 is located in the hollowed out area of the polyester mesh 2, and the metal mesh 3 includes Interweaving weft a and warp b, a number of weft a is arranged horizontally, and a number of warp b is arranged longitudinally, wherein the diameters of the weft a and the warp b are the same or different;

[0074] Specifically, the preparation method of the above-mentioned primary metal mesh printing plate comprises the following steps:

[0075] 11) Stretch the polyester mesh 2 to a certain tension and fix it on the first screen frame 1 to form an elastic screen;

[0076] 12) The metal mesh 3 is bonded to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com