Method for measuring weft yarn tension of polyester weaving machine based on multithreading

A measurement method and technology of multi-thread technology, applied in the field of weft tension measurement of polyester mesh looms based on multi-thread, can solve the problems of no display tension curve, unsatisfactory precision and accuracy, etc., and achieve automation and informatization The effect of high degree and large amount of measurement data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

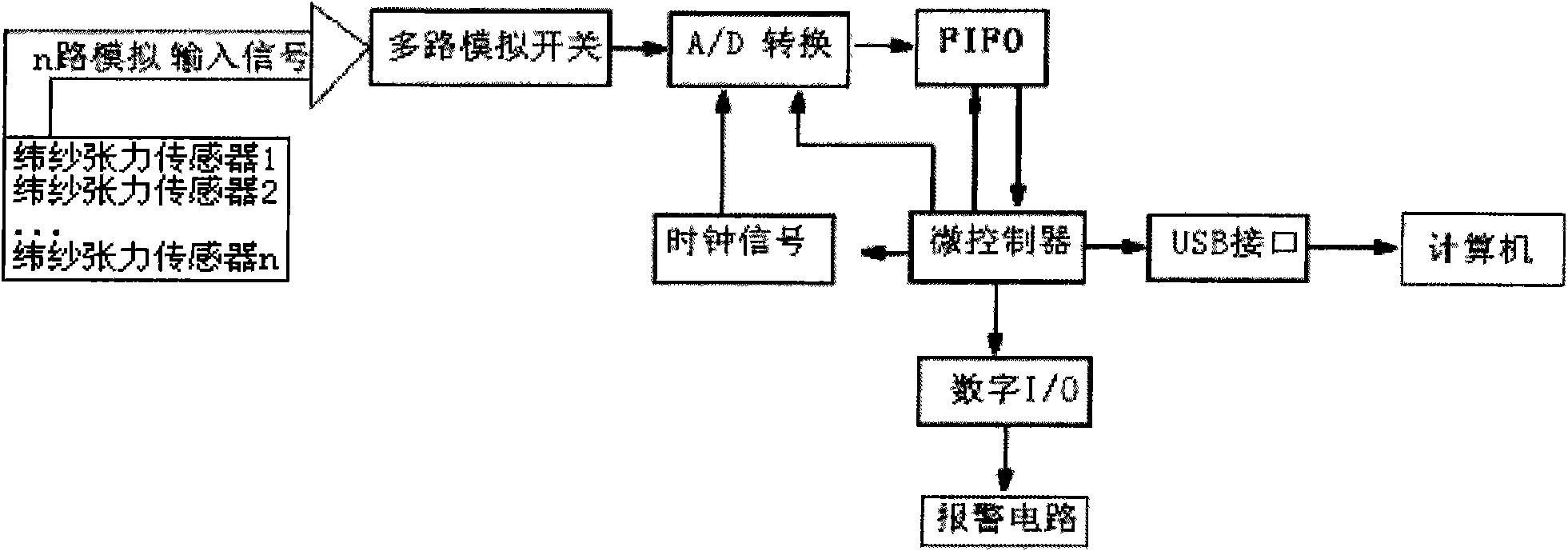

[0015] The hardware module of USB data acquisition system is mainly composed of multi-channel analog switch, A / D converter, microcontroller chip, USB interface chip, FIFO memory and clock signal circuit. The block diagram of the overall hardware structure is as follows: figure 1 shown.

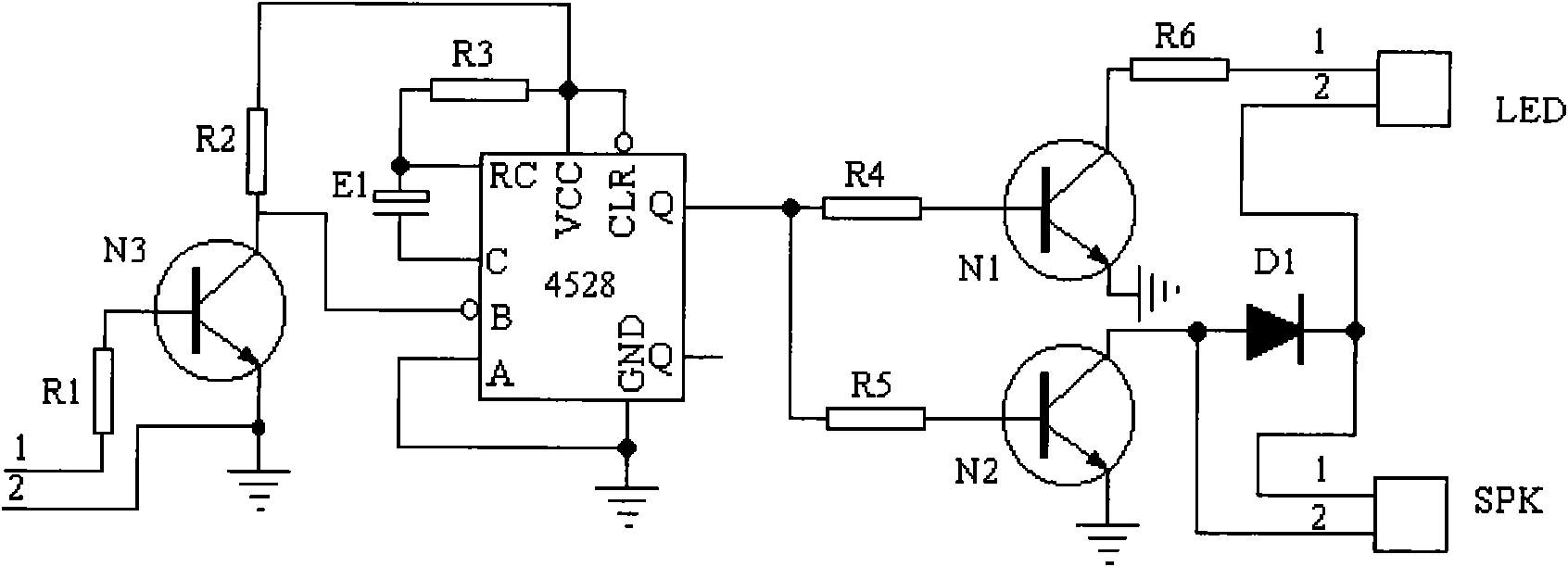

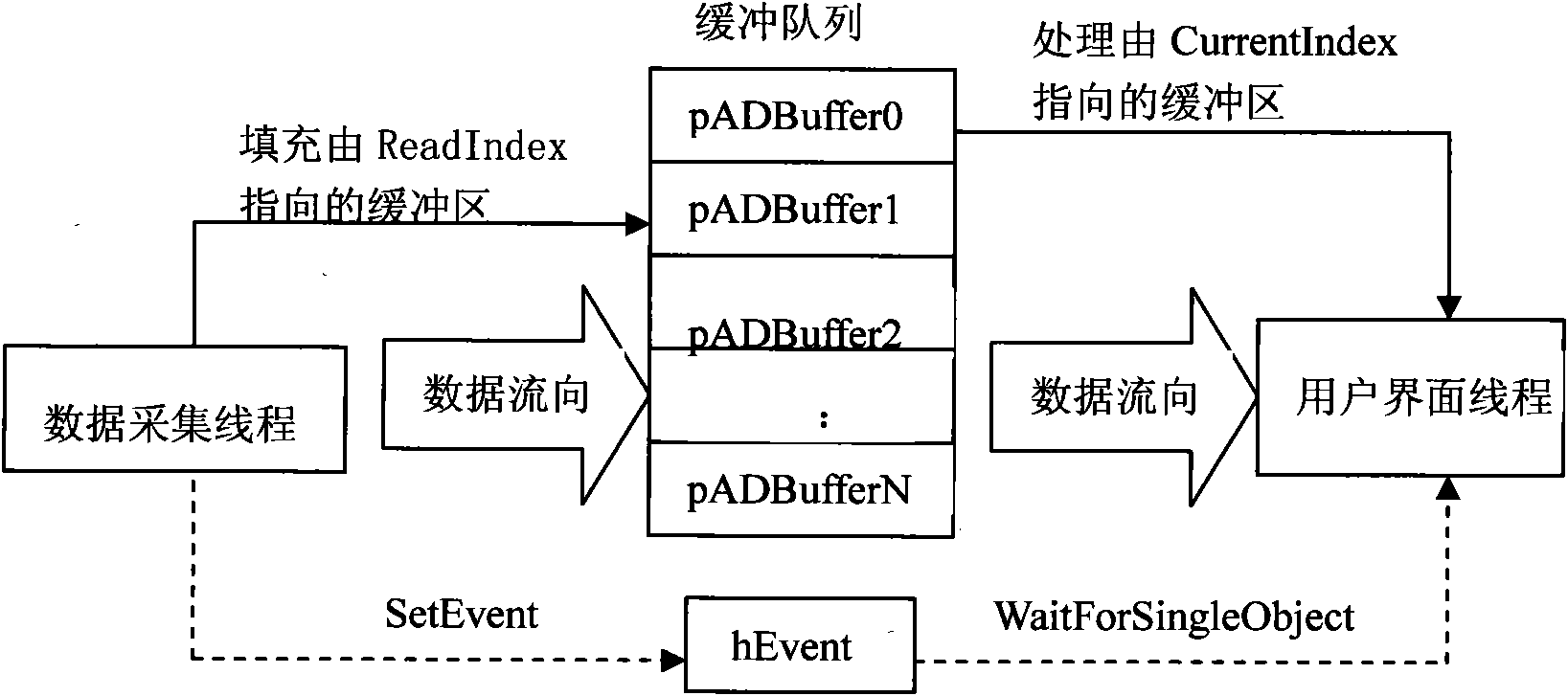

[0016] After the PC resets the acquisition board, first set the parameters such as the number of channels and acquisition frequency of the acquisition board, then release the reset, and start the data collector as required. After the acquisition board is started, the acquisition results are stored in the FIFO. When the collection board collects a certain amount of data, the data collection thread sends a signal (SetEvent) to the user interface thread, and the data collection thread continues to collect data at the same time. After the user interface thread receives the signal, it reads the collected data on the FIFO of the collection board and judges (if there is a defect, outputs a high lev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com